Shear: In motor oil context, this refers to thinning of an oils in extreme circumstances, which cannot be explained by temperature differences alone.

Long chain Viscosity Modifiers may end up with their long chains chopped (sheared) , which leads to these VM-s losing some of their

efficiency permanently. This process is often described as "shearing down" to a lower viscosity over time. Note that various

synthetic base oils are naturally multi-viscous and are said to be "shear stabile" (depending on their type, such as PAO, Ester etc) .

This is one of principal advantages of using synthetic base oils, that they do not require VM-s, or much less.

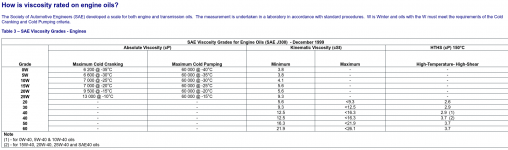

High pressure, high temperature applications e.g. a hydro, are often called HTHS ( High Temp, High Shear) environments.

Hydro manufacturers such as Hydrogear, and Zt mower manufacturers such as Gravely, Hustler, etc. explicitly call out the multi-viscosity grade of the

motor oils they recommend for their Hydro units. Typically, 15W50 or 20W50 multigrade oils, specifically.

The minimum Kinematic viscosity is given at a "non-standard", higher temperature such as 120 celsius to reflect the higher operating temperature

which is common for these units. I believe it would be a mistake to use this number as a basis to "re-think" the recommended hydro oil grade.

Keep in mind that ICE engines operate at a target temperature of around 100 celsius, which can be maintained given their higher oil volume and efficient cooling system

(water cooled, or high volume air cooled). Hydros tend to run hotter than this, because of their smaller oil volume and much less sophisticated/efficient cooling.

It seems like common sense to me, but, by all means draw your own conclusions. Perhaps I am totally wrong. If we are still around in 10 years, we can meet back up here.

and compare notes, how our respective maintenance approach worked out.

Cheers

Long chain Viscosity Modifiers may end up with their long chains chopped (sheared) , which leads to these VM-s losing some of their

efficiency permanently. This process is often described as "shearing down" to a lower viscosity over time. Note that various

synthetic base oils are naturally multi-viscous and are said to be "shear stabile" (depending on their type, such as PAO, Ester etc) .

This is one of principal advantages of using synthetic base oils, that they do not require VM-s, or much less.

High pressure, high temperature applications e.g. a hydro, are often called HTHS ( High Temp, High Shear) environments.

Hydro manufacturers such as Hydrogear, and Zt mower manufacturers such as Gravely, Hustler, etc. explicitly call out the multi-viscosity grade of the

motor oils they recommend for their Hydro units. Typically, 15W50 or 20W50 multigrade oils, specifically.

The minimum Kinematic viscosity is given at a "non-standard", higher temperature such as 120 celsius to reflect the higher operating temperature

which is common for these units. I believe it would be a mistake to use this number as a basis to "re-think" the recommended hydro oil grade.

Keep in mind that ICE engines operate at a target temperature of around 100 celsius, which can be maintained given their higher oil volume and efficient cooling system

(water cooled, or high volume air cooled). Hydros tend to run hotter than this, because of their smaller oil volume and much less sophisticated/efficient cooling.

It seems like common sense to me, but, by all means draw your own conclusions. Perhaps I am totally wrong. If we are still around in 10 years, we can meet back up here.

and compare notes, how our respective maintenance approach worked out.

Cheers