You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

WHAT BRAND OF OIL FOR THE HYDRO-GEARS IN AN "IS 700Z"

#1

S

stealurfish22

S

stealurfish22

Hi all, i just purchased a FERRIS IS 700Z ... WHAT VISCOSITY AND BRAND OF OIL DO YOU USE IN TH HYDRO GEARS? In addition, is it synthetic?

#4

BlazNT

BlazNT

This is what Hydro-Gear calls for:

"Typically, an engine oil with a minimum rating

of 9.0 cSt (55 SUS) at 230° F (110° C) and an

API classification of SL is recommended. A

20W50 engine oil has been selected for use

by the factory and is recommended for normal

operating procedures"

Hydro-gear also chooses Castrol as the brand they use.

What is in your mower has to do with what Ferris decided to put in it after they received the units.

"Typically, an engine oil with a minimum rating

of 9.0 cSt (55 SUS) at 230° F (110° C) and an

API classification of SL is recommended. A

20W50 engine oil has been selected for use

by the factory and is recommended for normal

operating procedures"

Hydro-gear also chooses Castrol as the brand they use.

What is in your mower has to do with what Ferris decided to put in it after they received the units.

#5

BlazNT

BlazNT

Service Manual

hydro-gear.com/83f663d662_sites/hydro-gear.com/files/zt-2800-3100-3200-3400.pdf

hydro-gear.com/83f663d662_sites/hydro-gear.com/files/zt-2800-3100-3200-3400.pdf

#6

S

stealurfish22

S

stealurfish22

Many thanks.

I reached out to 5 dealers in the New England area and received several answers. The most common response was "Mobil 1 synthetic 20w50".

Interestingly. I reached out to Ferris Corporate directly and was told the new Hydro's DO NOT RUN ON SYNTHETIC anymore. Therefore, a standard 20w50 wt oil is all you need.

I reached out to 5 dealers in the New England area and received several answers. The most common response was "Mobil 1 synthetic 20w50".

Interestingly. I reached out to Ferris Corporate directly and was told the new Hydro's DO NOT RUN ON SYNTHETIC anymore. Therefore, a standard 20w50 wt oil is all you need.

#8

C

coder

C

coder

I am surprised when a manufacturer recommends conventional oil vs synthetic.

E.g.: a Hyundai dealer told us that traditional oil was the new recommendation for the Sonatas in 2016.

Runs counter to anything i understand about dyno and synthetic oils. My reaction at the time was same as now: "color me lemming, I am all over that".

Is it unreasonable that I would like to hear some logical explanation backing up such controversial a guidance?

Given a long, possibly multi-year OCI and a hot running, high shear application, the traditional oil's friction modifiers will shear down over time,

and the oil will thin out as a consequence.

I think we can say that It is generally accepted / axiomatic today, that synthetic oils are superior to dyno oils in every possible way. (Except cost).

When I hear "use dyno oil" , I wonder if some info was misunderstood down the line of transmission.

Maybe they meant the _break in_ oil should be a dyno oil and someone took that out of context.

Can anybody offer some explanation?

E.g.: a Hyundai dealer told us that traditional oil was the new recommendation for the Sonatas in 2016.

Runs counter to anything i understand about dyno and synthetic oils. My reaction at the time was same as now: "color me lemming, I am all over that".

Is it unreasonable that I would like to hear some logical explanation backing up such controversial a guidance?

Given a long, possibly multi-year OCI and a hot running, high shear application, the traditional oil's friction modifiers will shear down over time,

and the oil will thin out as a consequence.

I think we can say that It is generally accepted / axiomatic today, that synthetic oils are superior to dyno oils in every possible way. (Except cost).

When I hear "use dyno oil" , I wonder if some info was misunderstood down the line of transmission.

Maybe they meant the _break in_ oil should be a dyno oil and someone took that out of context.

Can anybody offer some explanation?

#9

ILENGINE

ILENGINE

From Hydro-gears own internal factory testing found that Synthetic has no added benefit over dyno oil. But for what they want for their own branded oil you would think it was synthetic. Just for added content I have been to the factory watched them build the unit, talked to the engineers and have done a few factory teardowns.

#10

Hammermechanicman

Hammermechanicman

Funny how we call it dino oil wben it is not from dinosaurs but rather all the organic foliage the dinosaurs lived in.

Who all remembers the gas "Sinclair Dino Supreme"

Who all remembers the gas "Sinclair Dino Supreme"

#11

Mower King

Mower King

A high/good grade of 20-50 engine oil.....if you lift up the seat, there will be a sticker that says that.....if the sticker is still there!Hi all, i just purchased a FERRIS IS 700Z ... WHAT VISCOSITY AND BRAND OF OIL DO YOU USE IN TH HYDRO GEARS? In addition, is it synthetic?

#12

S

slomo

20w-50 oil has a viscosity rating of 19 cst at 100C or 212F.

Two completely different grades of oil. Please pass the pipe around. That's some awfully thick hydraulic fluid at 20w-50.

Must be typical American over thinking things. Manufacturer calls for vanilla ice cream. American public chooses a banana float.

slomo

S

slomo

A 9.0 cst oil is a SAE20 to SAE30 at 100C temp.This is what Hydro-Gear calls for:

"Typically, an engine oil with a minimum rating

of 9.0 cSt (55 SUS) at 230° F (110° C) and an

API classification of SL is recommended. A

20W50 engine oil has been selected for use

by the factory and is recommended for normal

operating procedures"

Hydro-gear also chooses Castrol as the brand they use.

What is in your mower has to do with what Ferris decided to put in it after they received the units.

20w-50 oil has a viscosity rating of 19 cst at 100C or 212F.

Two completely different grades of oil. Please pass the pipe around. That's some awfully thick hydraulic fluid at 20w-50.

Must be typical American over thinking things. Manufacturer calls for vanilla ice cream. American public chooses a banana float.

slomo

#13

C

coder

C

coder

Did they say with a straight face that the "traditional" oil does not sheer down to something less than the required minimum 120 celsius viscosity over the 400 hour service interval?

Or deteriorate in other ways? Does anybody here believe that the traditional oils are "just as good" as the high end synthetics?

I could do an UOA at the end of 400 hours with a traditional hydro oil to prove this, but that means I would have to take a risk on the longevity of my hydros to prove this point.

It is not worth it to me. If I only expected to get 5-10 years out of my Hydros, maybe it would not matter. I would like to get 20 years, if I live that long.

It makes more sense to me to err by being extra cautious and use the synthetic recommended by the makers of my mower .

It is relatively little extra money over the life of the hydros, for my peace of mind.

ILENGINE, let me ask you this: Do you follow your own advice? What fluid do You run in your Hydros?

Or deteriorate in other ways? Does anybody here believe that the traditional oils are "just as good" as the high end synthetics?

I could do an UOA at the end of 400 hours with a traditional hydro oil to prove this, but that means I would have to take a risk on the longevity of my hydros to prove this point.

It is not worth it to me. If I only expected to get 5-10 years out of my Hydros, maybe it would not matter. I would like to get 20 years, if I live that long.

It makes more sense to me to err by being extra cautious and use the synthetic recommended by the makers of my mower .

It is relatively little extra money over the life of the hydros, for my peace of mind.

ILENGINE, let me ask you this: Do you follow your own advice? What fluid do You run in your Hydros?

#14

C

coder

C

coder

Slomo, note that Hydrogear lists the cSt at 120 celsius. At 100, this would translate to a higher cSt, so

you cannot directly compare the @100 and @120 values. It is a high shear, high temperature application.

Hydros may run as high as 150 celsius, so the heavy, high viscosity 20w50 motor oil they call out is actually required.

Going to an even higher viscosity such as somethingw60 would sacrifice cooling efficiency.

They recommend motor oil instead of the even higher viscosity gear oil, because of the typically high temp environment.

(Gear oil could be something like 75w90)

you cannot directly compare the @100 and @120 values. It is a high shear, high temperature application.

Hydros may run as high as 150 celsius, so the heavy, high viscosity 20w50 motor oil they call out is actually required.

Going to an even higher viscosity such as somethingw60 would sacrifice cooling efficiency.

They recommend motor oil instead of the even higher viscosity gear oil, because of the typically high temp environment.

(Gear oil could be something like 75w90)

#15

ILENGINE

ILENGINE

Hydrogear units get the Hydrogear branded 20w50 oil unless the mower manufacturer recommends something else. Some call for 10w30, some 10w40, some 20w20 hydraulic oil. Tufft-torg get the recommended 5w50 tuff-torq branded synthetic oil. A few even use their own branded oil with no cross reference like the oil recommended in some IH cub cadet transmissions. JD get the hy-gard Low vis for the unit that use that oil.Did they say with a straight face that the "traditional" oil does not sheer down to something less than the required minimum 120 celsius viscosity over the 400 hour service interval?

Or deteriorate in other ways? Does anybody here believe that the traditional oils are "just as good" as the high end synthetics?

I could do an UOA at the end of 400 hours with a traditional hydro oil to prove this, but that means I would have to take a risk on the longevity of my hydros to prove this point.

It is not worth it to me. If I only expected to get 5-10 years out of my Hydros, maybe it would not matter. I would like to get 20 years, if I live that long.

It makes more sense to me to err by being extra cautious and use the synthetic recommended by the makers of my mower .

It is relatively little extra money over the life of the hydros, for my peace of mind.

ILENGINE, let me ask you this: Do you follow your own advice? What fluid do You run in your Hydros?

#16

S

slomo

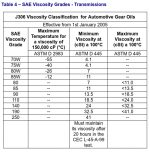

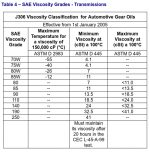

The original post said 110C and a 9.0 cst. Still an SAE20 to SAE30 oil.

So from what you said Hydrogear is saying, a 9.0 cst at 120C is perfect for an SAE30 oil.

An 80w-90 gear oil is roughly the same viscosity as SAE30 engine oil.

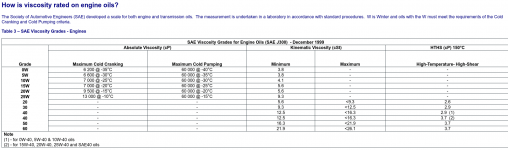

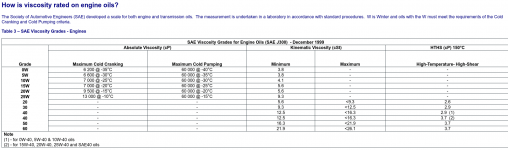

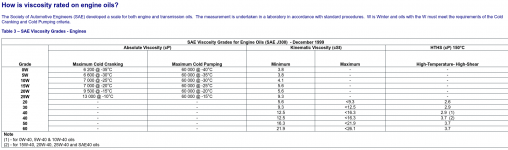

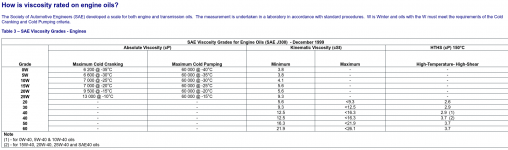

Engine oil cst ratings

GEAR or transmission oils

Notice they list cst at 100C.

slomo

S

slomo

Viscosity cst is rated at 100C or 212F. Hydrogear is confusing the situation by using some non-standard recommendation.Slomo, note that Hydrogear lists the cSt at 120 celsius. At 100, this would translate to a higher cSt, so

you cannot directly compare the @100 and @120 values. It is a high shear, high temperature application.

Hydros may run as high as 150 celsius, so the heavy, high viscosity 20w50 motor oil they call out is actually required.

Going to an even higher viscosity such as somethingw60 would sacrifice cooling efficiency.

They recommend motor oil instead of the even higher viscosity gear oil, because of the typically high temp environment.

(Gear oil could be something like 75w90)

The original post said 110C and a 9.0 cst. Still an SAE20 to SAE30 oil.

So from what you said Hydrogear is saying, a 9.0 cst at 120C is perfect for an SAE30 oil.

An 80w-90 gear oil is roughly the same viscosity as SAE30 engine oil.

Engine oil cst ratings

GEAR or transmission oils

Notice they list cst at 100C.

slomo

#17

S

slomo

You are correct about the 120C and slightly higher cst. Still not a standard comparison to real cst values. Don't know about high sheer at all. Nothing is sheering. Just a pump that builds pressure that creates heat while doing. Shearing is when two gears mesh together smashing oil molecules breaking the oil down.

150C is roughly 300F. Time for an oil cooler. A 0w-20 can handle 150C all day long. So your "thinking" you need some roofing tar because it's at high normal operating temps is off.

slomo

S

slomo

Hydrogear doesn't make the SAE classifications. Don't care what they list. Why can't they list some cst at 100C like the SAE rating?Slomo, note that Hydrogear lists the cSt at 120 celsius. At 100, this would translate to a higher cSt, so

you cannot directly compare the @100 and @120 values. It is a high shear, high temperature application.

Hydros may run as high as 150 celsius, so the heavy, high viscosity 20w50 motor oil they call out is actually required.

Going to an even higher viscosity such as somethingw60 would sacrifice cooling efficiency.

They recommend motor oil instead of the even higher viscosity gear oil, because of the typically high temp environment.

(Gear oil could be something like 75w90)

You are correct about the 120C and slightly higher cst. Still not a standard comparison to real cst values. Don't know about high sheer at all. Nothing is sheering. Just a pump that builds pressure that creates heat while doing. Shearing is when two gears mesh together smashing oil molecules breaking the oil down.

150C is roughly 300F. Time for an oil cooler. A 0w-20 can handle 150C all day long. So your "thinking" you need some roofing tar because it's at high normal operating temps is off.

slomo

#21

C

coder

C

coder

Shear: In motor oil context, this refers to thinning of an oils in extreme circumstances, which cannot be explained by temperature differences alone.

Long chain Viscosity Modifiers may end up with their long chains chopped (sheared) , which leads to these VM-s losing some of their

efficiency permanently. This process is often described as "shearing down" to a lower viscosity over time. Note that various

synthetic base oils are naturally multi-viscous and are said to be "shear stabile" (depending on their type, such as PAO, Ester etc) .

This is one of principal advantages of using synthetic base oils, that they do not require VM-s, or much less.

High pressure, high temperature applications e.g. a hydro, are often called HTHS ( High Temp, High Shear) environments.

Hydro manufacturers such as Hydrogear, and Zt mower manufacturers such as Gravely, Hustler, etc. explicitly call out the multi-viscosity grade of the

motor oils they recommend for their Hydro units. Typically, 15W50 or 20W50 multigrade oils, specifically.

The minimum Kinematic viscosity is given at a "non-standard", higher temperature such as 120 celsius to reflect the higher operating temperature

which is common for these units. I believe it would be a mistake to use this number as a basis to "re-think" the recommended hydro oil grade.

Keep in mind that ICE engines operate at a target temperature of around 100 celsius, which can be maintained given their higher oil volume and efficient cooling system

(water cooled, or high volume air cooled). Hydros tend to run hotter than this, because of their smaller oil volume and much less sophisticated/efficient cooling.

It seems like common sense to me, but, by all means draw your own conclusions. Perhaps I am totally wrong. If we are still around in 10 years, we can meet back up here.

and compare notes, how our respective maintenance approach worked out.

Cheers

Long chain Viscosity Modifiers may end up with their long chains chopped (sheared) , which leads to these VM-s losing some of their

efficiency permanently. This process is often described as "shearing down" to a lower viscosity over time. Note that various

synthetic base oils are naturally multi-viscous and are said to be "shear stabile" (depending on their type, such as PAO, Ester etc) .

This is one of principal advantages of using synthetic base oils, that they do not require VM-s, or much less.

High pressure, high temperature applications e.g. a hydro, are often called HTHS ( High Temp, High Shear) environments.

Hydro manufacturers such as Hydrogear, and Zt mower manufacturers such as Gravely, Hustler, etc. explicitly call out the multi-viscosity grade of the

motor oils they recommend for their Hydro units. Typically, 15W50 or 20W50 multigrade oils, specifically.

The minimum Kinematic viscosity is given at a "non-standard", higher temperature such as 120 celsius to reflect the higher operating temperature

which is common for these units. I believe it would be a mistake to use this number as a basis to "re-think" the recommended hydro oil grade.

Keep in mind that ICE engines operate at a target temperature of around 100 celsius, which can be maintained given their higher oil volume and efficient cooling system

(water cooled, or high volume air cooled). Hydros tend to run hotter than this, because of their smaller oil volume and much less sophisticated/efficient cooling.

It seems like common sense to me, but, by all means draw your own conclusions. Perhaps I am totally wrong. If we are still around in 10 years, we can meet back up here.

and compare notes, how our respective maintenance approach worked out.

Cheers

#22

S

slomo

S

slomo

Hydraulics does not require a super thick fluid, just to combat heat. That is what a cooler is for, remove the heat. Seems to me these manufactures KNOW the fluid gets to 150C and are not installing coolers. That is neglect and poor engineering. You can use water to pump anything in a hydro system. Will it corrode in time, sure. Will it work yes.

Again cst is rated at 100C. Some Chinese hydro company calling for some cst number at anything other than 100C is pointless.

slomo

Again cst is rated at 100C. Some Chinese hydro company calling for some cst number at anything other than 100C is pointless.

slomo

#23

L

loneryder

L

loneryder

Castrol just came out with a dino 20-50 with high zinc for classic cars. I would think that would work well in Hydrogear trannys. Think it's SM rated. Only at Walmart.

#24

Hammermechanicman

Hammermechanicman

Hey! Don't go hating on Motor Honey. Back in the early 70's i had a 352 Ford galaxie that burned oil like no other. 3 quarts of SAE50 wt and 2 quarts of Motor Honey and it didn't smoke a bit. Sold it like that.As long as you are using Motor Honey you are good LOL.

slomo

#25

Hammermechanicman

Hammermechanicman

Never fails. Just remember "My oil is better than your oil."?Let's have a great vicious "oil thread"!!!

#26

C

coder

C

coder

My point was, the Hydro manufacturer Hydrogear and multiple Zt manufacturers (those who use the Zt Hydros)

seem to all recommend 15W50 or 20W50 motor oil. This recommendation makes sense to me on multiple

levels, so I follow it.

Kinematic viscosity can be measured at any temperature the manufacturer choses.

100 celsius is merely one popular reference point often given, so is 40 celsius, so is 150 celsius.

AFAIK Listing it at 110 or 120 celsius is not forbidden.

Slomo, do you have an alternative recommendation? Let's hear it!

seem to all recommend 15W50 or 20W50 motor oil. This recommendation makes sense to me on multiple

levels, so I follow it.

Kinematic viscosity can be measured at any temperature the manufacturer choses.

100 celsius is merely one popular reference point often given, so is 40 celsius, so is 150 celsius.

AFAIK Listing it at 110 or 120 celsius is not forbidden.

Slomo, do you have an alternative recommendation? Let's hear it!

#27

S

slomo

I still stand by my deal of manufacturers knowing their fluid gets to 150C or roughly 300F, they should install an oil cooler.

slomo

S

slomo

Just saying the "standard" for kin viscos is 100C. End of message. Sure oil will thin a bit more if it gets hotter. We all know that. Use 200C if you like.My point was, the Hydro manufacturer Hydrogear and multiple Zt manufacturers (those who use the Zt Hydros)

seem to all recommend 15W50 or 20W50 motor oil. This recommendation makes sense to me on multiple

levels, so I follow it.

Kinematic viscosity can be measured at any temperature the manufacturer choses.

100 celsius is merely one popular reference point often given, so is 40 celsius, so is 150 celsius.

AFAIK Listing it at 110 or 120 celsius is not forbidden.

Slomo, do you have an alternative recommendation? Let's hear it!

I still stand by my deal of manufacturers knowing their fluid gets to 150C or roughly 300F, they should install an oil cooler.

slomo

#28

S

slomo

S

slomo

Why not use the HTHS (cP) rating instead? Look at the far right in the chart below. That is rated at 150C.

As we all can see, the viscosity at 150C is "slightly" thicker in the heavier single grade oils. Simple math comparing an SAE30 as I stated several threads ago, to a STRAIGHT grade SAE50 or SAE60 is only 0.8cP difference. Not a hill of beans at all. YES the heavier oils have slightly more viscosity at 150C. But 0.8 cP, not going to lose any sleep over it.

So trying to push that motor honey 20w-50 through a tiny hydro system, no wonder they are overheating at 150C. A hydraulic system should take a proper hydraulic fluid. Not,,,, motor oil.

As we all can see, the viscosity at 150C is "slightly" thicker in the heavier single grade oils. Simple math comparing an SAE30 as I stated several threads ago, to a STRAIGHT grade SAE50 or SAE60 is only 0.8cP difference. Not a hill of beans at all. YES the heavier oils have slightly more viscosity at 150C. But 0.8 cP, not going to lose any sleep over it.

So trying to push that motor honey 20w-50 through a tiny hydro system, no wonder they are overheating at 150C. A hydraulic system should take a proper hydraulic fluid. Not,,,, motor oil.

#29

C

coder

C

coder

HTHS? That may not be a bad idea. If the fluid is supposed to stand up to high heat and high (molecular) shear, car manufacturers tend to spec the required min HTHS.

If you will, it is a more "modern" oil spec. developed to quantify how the oil behaves in such environment.

Slomo, you could perhaps initiate a conversation with the manufacturer, and find out more about their reasoning, or induce them to change their ways, or at least explain

why they decided to spec what they did. https://www.hydro-gear.com/end-users ... I see no point in yelling at BITOG users, because of what Hydro-gear decides to publish.

You posted earlier " Don't know about high sheer at all. Nothing is sheering".

The sear here is molecular shear. When you push oil through tight spaces at high pressure, some of the friction modifier's long chains get chopped off

i.e. "sheared" resulting in undesirable viscosity changes. BITOG has an excellent article that explains the topic in some detail.

www.hydro-gear.com

www.hydro-gear.com

If you will, it is a more "modern" oil spec. developed to quantify how the oil behaves in such environment.

Slomo, you could perhaps initiate a conversation with the manufacturer, and find out more about their reasoning, or induce them to change their ways, or at least explain

why they decided to spec what they did. https://www.hydro-gear.com/end-users ... I see no point in yelling at BITOG users, because of what Hydro-gear decides to publish.

You posted earlier " Don't know about high sheer at all. Nothing is sheering".

The sear here is molecular shear. When you push oil through tight spaces at high pressure, some of the friction modifier's long chains get chopped off

i.e. "sheared" resulting in undesirable viscosity changes. BITOG has an excellent article that explains the topic in some detail.

Owners - Hydro-Gear

Our trained professionals can service or repair your Hydro-Gear product with original high-quality factory parts. Contact us today.

#30

S

slomo

All oils shear to some degree in all systems. Some shear more, some less.

HTHS is not a modern spec as you were hitting at. Simply details oil behavior at specific temps.

300F is getting pretty toasty for any oil with no cooler. Again if super tough whatever hydro company knows their hydro system is at 150C and lacks cooling of said oil, I would look elsewhere. They are waaay over spec'ing their recommended oil praying their system makes it past the 1-3 years of warranty. Some VP said, hey we can save 19 bucks making this system cheaper to manufacturer. Sell a lot more of these..... Not our problem after the warranty is over.

slomo

S

slomo

Shearing is simple. Oil molecules getting smaller from some process. Just leave it at that. Trust me, oil or let's call it a fluid in a hydro system has a leisure life compared to a fluid in a gearbox. Noted most mowers don't have gearboxes as we all know.HTHS? That may not be a bad idea. If the fluid is supposed to stand up to high heat and high (molecular) shear, car manufacturers tend to spec the required min HTHS.

If you will, it is a more "modern" oil spec. developed to quantify how the oil behaves in such environment.

Slomo, you could perhaps initiate a conversation with the manufacturer, and find out more about their reasoning, or induce them to change their ways, or at least explain

why they decided to spec what they did. https://www.hydro-gear.com/end-users ... I see no point in yelling at BITOG users, because of what Hydro-gear decides to publish.

You posted earlier " Don't know about high sheer at all. Nothing is sheering".

The sear here is molecular shear. When you push oil through tight spaces at high pressure, some of the friction modifier's long chains get chopped off

i.e. "sheared" resulting in undesirable viscosity changes. BITOG has an excellent article that explains the topic in some detail.

Owners - Hydro-Gear

Our trained professionals can service or repair your Hydro-Gear product with original high-quality factory parts. Contact us today.www.hydro-gear.com

All oils shear to some degree in all systems. Some shear more, some less.

HTHS is not a modern spec as you were hitting at. Simply details oil behavior at specific temps.

300F is getting pretty toasty for any oil with no cooler. Again if super tough whatever hydro company knows their hydro system is at 150C and lacks cooling of said oil, I would look elsewhere. They are waaay over spec'ing their recommended oil praying their system makes it past the 1-3 years of warranty. Some VP said, hey we can save 19 bucks making this system cheaper to manufacturer. Sell a lot more of these..... Not our problem after the warranty is over.

slomo

#31

B

bertsmobile1

B

bertsmobile1

oil shear is a funny subject

People invisage these :long chain: molecules as being like a hand full of straw passing through a set of gears & getting chopped up.

Firstly a very loooong molecule might be a couple of nanno meters

The space between gears is around 1000 times bigger than the length of the molecules.

Heat alone will cause the ends of the molecules to break off.

For decades we have been fighting the urban myth that gear pumps chop up multi grade oils while piston pumps don't

People invisage these :long chain: molecules as being like a hand full of straw passing through a set of gears & getting chopped up.

Firstly a very loooong molecule might be a couple of nanno meters

The space between gears is around 1000 times bigger than the length of the molecules.

Heat alone will cause the ends of the molecules to break off.

For decades we have been fighting the urban myth that gear pumps chop up multi grade oils while piston pumps don't

#32

L

loneryder

L

loneryder

I think they reccomend it because it is readily available. What about using 20-50 motorcycle oil which is high in zinc and phos.??Slomo, note that Hydrogear lists the cSt at 120 celsius. At 100, this would translate to a higher cSt, so

you cannot directly compare the @100 and @120 values. It is a high shear, high temperature application.

Hydros may run as high as 150 celsius, so the heavy, high viscosity 20w50 motor oil they call out is actually required.

Going to an even higher viscosity such as somethingw60 would sacrifice cooling efficiency.

They recommend motor oil instead of the even higher viscosity gear oil, because of the typically high temp environment.

(Gear oil could be something like 75w90)

#33

C

coder

C

coder

Motorcycle oil may be OK. I ended up not going for it, because I am worried about friction mods to work better with the

typical wet clutch. The gist seems to be to make the oil a bit less slippery, which is not particularly useful for the Hydros.

I felt that was a relevant difference, but maybe I worry about nothing there...

Maybe I give the manufacturer too much credit for brains and caring, but I thought if "20w50 motorcycle oil" was the best answer,

it would have been easy enough for them to mention it.

typical wet clutch. The gist seems to be to make the oil a bit less slippery, which is not particularly useful for the Hydros.

I felt that was a relevant difference, but maybe I worry about nothing there...

Maybe I give the manufacturer too much credit for brains and caring, but I thought if "20w50 motorcycle oil" was the best answer,

it would have been easy enough for them to mention it.

#34

S

slomo

S

slomo

Personally I would think a hydraulic fluid at an SAE30 is fine. It meets the cst viscosity value of 9.0 at 110C. Also meets it at 100C which cst is measured at. No need to reinvent the wheel with a super thick 20w-50 car oil.

"This is what Hydro-Gear calls for:

"Typically, an engine oil with a minimum rating

of 9.0 cSt (55 SUS) at 230° F (110° C) and an

API classification of SL is recommended"

slomo

"This is what Hydro-Gear calls for:

"Typically, an engine oil with a minimum rating

of 9.0 cSt (55 SUS) at 230° F (110° C) and an

API classification of SL is recommended"

slomo

#35

SirMowzalot

SirMowzalot

I prefer Amsoil products whenever possible. So being that I need to pick up some oil for the trans, I sent an email off to Hydro-Gear asking about any support or warranty implications if I use this. https://www.amsoil.com/p/20w-50-synthetic-hydrostatic-transmission-fluid-ahf/

When I get a response from them I'll reach out to Ferris to ensure they're both on the same page. Either way I'll follow up here.

When I get a response from them I'll reach out to Ferris to ensure they're both on the same page. Either way I'll follow up here.

#37

StarTech

StarTech

Actually it is good to know for us shop owners that prefer the synthetics over conventional oils as the synthetics have higher operating temperatures and low breakdown rates. But of every equipment OEM will use the cheapest oil they can get by with. Nearly every Tuff Torq here has 20W50 conventional oil in them until I go inside one then they get the Tuff Torq premium 15W50 Synthetic installed.

Plus with our Summer temps rising every year lately we need to adjust our type of oil usage.

Plus with our Summer temps rising every year lately we need to adjust our type of oil usage.

#38

SirMowzalot

YOU sound like you have a shop I'd love to send my equipment to, so I can do others things. Sure enough, all I see for you is "Torland". My guess and luck probably means that's Scotland, but I know for sure it's unfortunately nowhere near here. That's too bad. I'm never gonna get a weekend off, lol.

SirMowzalot

So I have yet to encounter a shop in my area that I would do business with. I guess it's the way I came up with respect to working on cars. I was taught by folks that one might call extremists from a very early age. I was putting cars on lifts at 8 years old, lol, which now that I think about it was a little insane but the guys teaching me knew where I was and when. I installed a car stereo in my mom's car at age 6 all because I watched someone do it that explained everything to me as they went. At age 7 my mom's car wouldn't start one winter morning, so she called my uncle down the block. She told him I was outside under the hood. He said "Give him a minute". I propped the choke flap open with a screwdriver and started it right up. I was also taught to wipe down my tools every day, and put them back in the box where they belong. Then wipe down any work areas because grease doesn't evaporate. I briefly worked in the field and realized there just wasn't enough money in it. So I moved on. But I still practice the same things I was taught, and unfortunately that created expectations from others that often just aren't there. So when I visited the local shops it was mostly walking in, looking around, and running like hell. Either I'd see a complete mess, low end consumables in the shop destined for customer machines, or just general disarray.Actually it is good to know for us shop owners that prefer the synthetics over conventional oils as the synthetics have higher operating temperatures and low breakdown rates. But of every equipment OEM will use the cheapest oil they can get by with. Nearly every Tuff Torq here has 20W50 conventional oil in them until I go inside one then they get the Tuff Torq premium 15W50 Synthetic installed.

Plus with our Summer temps rising every year lately we need to adjust our type of oil usage.

YOU sound like you have a shop I'd love to send my equipment to, so I can do others things. Sure enough, all I see for you is "Torland". My guess and luck probably means that's Scotland, but I know for sure it's unfortunately nowhere near here. That's too bad. I'm never gonna get a weekend off, lol.

#39

StarTech

StarTech

That means I prefer to just deal the locals when it comes to repairs and not have a lot folks just wasting my time. Here on Pluto I don't get much in the line of out of the area visitors. I do have one fellow tech out Huntsville that use to come by for technical help but I haven't seen him in a long time so I can assume doing fine on his own now.

Plus my shop is a mess in more than one way. I got young chickens staying in it until they are old enough to join the grown ones. I just don't know how the hen survived three week out in the open sitting on the eggs. She hid out on me. I just lost three chickens in the roost because of a raccoon breaking into the building. One of them was my biggest pet rooster which I had to finish killing the next morning. Not a task I wanted to do but it was necessary to prevent a horrible suffering death.

Plus nearly all my work is outdoors as I use my shop for tools and parts storage. I even got parts stored in my house right now due a failed storage room. Some idiot put the tin roof on it backwards and I didn't know it when I brought the place so it has ruin the whole area as the attic was insulated. A complete rebuild is in order but I be going back with blocks, concrete floor; but the same type roof, just this time I do it myself. Getting a little rough at 62 as I slowed down a little now.

Strange though that I have one customer from Florence coming to the shop. Apparently no good shop over there either. Now that is nearly 60+ miles away but he got farm work in my area so he just comes when he is in the area.

As for taking care of your tools it is important as if you make your living with them they be in good shape and you know where they are hiding. It not fun when you got to hunt down your tools especially the custom ones. The main thing is don't loan your tools out as it is usually the very ones you need for the next job and they have a bad habit of not coming back.

It not fun when you got to hunt down your tools especially the custom ones. The main thing is don't loan your tools out as it is usually the very ones you need for the next job and they have a bad habit of not coming back.

As for getting weekends off I don't get much off either that is why my yard looks like a hay field as I only got Sundays off and there is a lot to get done even when it is raining. I ended up having to soup up my mower so I can cut the tall grass. 42 cut with a 21 hp (was a 16.5 hp) and upgrade the deck belt from a 1/2 to 5/8 belt. Just keep burning up the 1/2 belts. But at least just goes through about anything I throw at it now.

Plus my shop is a mess in more than one way. I got young chickens staying in it until they are old enough to join the grown ones. I just don't know how the hen survived three week out in the open sitting on the eggs. She hid out on me. I just lost three chickens in the roost because of a raccoon breaking into the building. One of them was my biggest pet rooster which I had to finish killing the next morning. Not a task I wanted to do but it was necessary to prevent a horrible suffering death.

Plus nearly all my work is outdoors as I use my shop for tools and parts storage. I even got parts stored in my house right now due a failed storage room. Some idiot put the tin roof on it backwards and I didn't know it when I brought the place so it has ruin the whole area as the attic was insulated. A complete rebuild is in order but I be going back with blocks, concrete floor; but the same type roof, just this time I do it myself. Getting a little rough at 62 as I slowed down a little now.

Strange though that I have one customer from Florence coming to the shop. Apparently no good shop over there either. Now that is nearly 60+ miles away but he got farm work in my area so he just comes when he is in the area.

As for taking care of your tools it is important as if you make your living with them they be in good shape and you know where they are hiding.

As for getting weekends off I don't get much off either that is why my yard looks like a hay field as I only got Sundays off and there is a lot to get done even when it is raining. I ended up having to soup up my mower so I can cut the tall grass. 42 cut with a 21 hp (was a 16.5 hp) and upgrade the deck belt from a 1/2 to 5/8 belt. Just keep burning up the 1/2 belts. But at least just goes through about anything I throw at it now.

#40

SirMowzalot

SirMowzalot

Well, I tried to dress it up as best I could for an online forum. Because saying things like "Halfwit sixth grade dropouts with a drawer in their toolbox dedicated to various low-end narcotics" would have been a little impolite, and probably too spot on for most people's tastes. But hey, I never was all that great at keeping my observations to myself. Ya got me. I just don't have any respect for MOST people that do this work professionally. But the better folks are definitely the exception to one hell of a sad rule. Hell when I called the Ferris support department some weeks ago I ALMOST ASKED the guy that answered if his middle name was Gomer. But hey, it was either say "SHAZAM SHAZAM" and hang up, or keep the warranty going as long as possible. We all have difficult choices to make.That means I prefer to just deal the locals when it comes to repairs and not have a lot folks just wasting my time. Here on Pluto I don't get much in the line of out of the area visitors. I do have one fellow tech out Huntsville that use to come by for technical help but I haven't seen him in a long time so I can assume doing fine on his own now.

Plus my shop is a mess in more than one way. I got young chickens staying in it until they are old enough to join the grown ones. I just don't know how the hen survived three week out in the open sitting on the eggs. She hid out on me. I just lost three chickens in the roost because of a raccoon breaking into the building. One of them was my biggest pet rooster which I had to finish killing the next morning. Not a task I wanted to do but it was necessary to prevent a horrible suffering death.

Plus nearly all my work is outdoors as I use my shop for tools and parts storage. I even got parts stored in my house right now due a failed storage room. Some idiot put the tin roof on it backwards and I didn't know it when I brought the place so it has ruin the whole area as the attic was insulated. A complete rebuild is in order but I be going back with blocks, concrete floor; but the same type roof, just this time I do it myself. Getting a little rough at 62 as I slowed down a little now.

Strange though that I have one customer from Florence coming to the shop. Apparently no good shop over there either. Now that is nearly 60+ miles away but he got farm work in my area so he just comes when he is in the area.

As for taking care of your tools it is important as if you make your living with them they be in good shape and you know where they are hiding.It not fun when you got to hunt down your tools especially the custom ones. The main thing is don't loan your tools out as it is usually the very ones you need for the next job and they have a bad habit of not coming back.

As for getting weekends off I don't get much off either that is why my yard looks like a hay field as I only got Sundays off and there is a lot to get done even when it is raining. I ended up having to soup up my mower so I can cut the tall grass. 42 cut with a 21 hp (was a 16.5 hp) and upgrade the deck belt from a 1/2 to 5/8 belt. Just keep burning up the 1/2 belts. But at least just goes through about anything I throw at it now.

#41

StarTech

StarTech

I know you about the shops. In my area there are some pretty bad shop tech-wise. Some of the rig jobs I have straighten out just make me plain sick to be associate with him so avoid them myself. When JD tech can't even find a bad spark plug or tell the customer "Oh your engine doesn't have oil pump, just ignore the flashing oil pressure oil" when it is just a bad sending unit. It was plain as day that when you have an oil filter there must be a pump. Then when they couldn't find the reason for a Z925A that was randomly shutting down is just embarrassing to me as it was just a loose connector. But good came of it as the customer with ZTR which now has two only lets me service them even when one was under warranty by JD.

#42

B

bertsmobile1

Then I went to work in industry where you had to make a profit & I was expected to do around 15 an hour.

Scratches & facets mean nothing just so long as you can see & photograph what you need to.

A pristine workshop is nice eye candy but in reality some one has to pay for all that clean clear workspace and it is not the mechanic.

I am a mobile mechanic so breakdown work is done where the mower sits, in the middle of a lawn, in some ones shed , on their dirt driveway.

Friday I repaired a JD franken mower used as a tow motor in the middle of a pile wood chips .

Thursday it was the same story except it was being used to spread manure in the form of poultry shed scrapings .

Scheduled servicing is done at the workshop , again out in the open under a 2 ton yard crane .

There are some who can not abide leaving their mower in my "scrapyard" they are welcome to take them into town and pay $ 150 / hr to cover the costs of those big work bay and rolling tool boxes full of snap ons.

My work comes with an unconditional 12 month warranty, the big box gives 3 months .

I charge scheduled hours which of course are always less than the actual time taken to do a job

The "operating theatre " workshops charge actual hours and because it is computerised, every nut, bolt, washer, grease , cleaning solutions, shop rags & shop fuel and one even a used oil disposal fee .

However we are getting a long way off topic , as these threads often do .

When I was doing my 1 month evaluation before buying the run the vendor would wack me on the back of the head and ask "what time is NASSA coming for this job? "

It took a long time to come to grips with the fact that these are mowers and for the bulk of them they have been made as cheap as possible with the cheapest materials that might possibly do the job.

So getting ulcers about the brand of oil , spark plugs or filters is a waste of time & energy.

If the customer wants you to use some thing that is way over specked for their machine then just do it & charge them for it .

B

bertsmobile1

When I was in college we would spend an hour to mount & polish a near perfect microscope specimenSo I have yet to encounter a shop in my area that I would do business with. I guess it's the way I came up with respect to working on cars. I was taught by folks that one might call extremists from a very early age. I was putting cars on lifts at 8 years old, lol, which now that I think about it was a little insane but the guys teaching me knew where I was and when. I installed a car stereo in my mom's car at age 6 all because I watched someone do it that explained everything to me as they went. At age 7 my mom's car wouldn't start one winter morning, so she called my uncle down the block. She told him I was outside under the hood. He said "Give him a minute". I propped the choke flap open with a screwdriver and started it right up. I was also taught to wipe down my tools every day, and put them back in the box where they belong. Then wipe down any work areas because grease doesn't evaporate. I briefly worked in the field and realized there just wasn't enough money in it. So I moved on. But I still practice the same things I was taught, and unfortunately that created expectations from others that often just aren't there. So when I visited the local shops it was mostly walking in, looking around, and running like hell. Either I'd see a complete mess, low end consumables in the shop destined for customer machines, or just general disarray.

YOU sound like you have a shop I'd love to send my equipment to, so I can do others things. Sure enough, all I see for you is "Torland". My guess and luck probably means that's Scotland, but I know for sure it's unfortunately nowhere near here. That's too bad. I'm never gonna get a weekend off, lol.

Then I went to work in industry where you had to make a profit & I was expected to do around 15 an hour.

Scratches & facets mean nothing just so long as you can see & photograph what you need to.

A pristine workshop is nice eye candy but in reality some one has to pay for all that clean clear workspace and it is not the mechanic.

I am a mobile mechanic so breakdown work is done where the mower sits, in the middle of a lawn, in some ones shed , on their dirt driveway.

Friday I repaired a JD franken mower used as a tow motor in the middle of a pile wood chips .

Thursday it was the same story except it was being used to spread manure in the form of poultry shed scrapings .

Scheduled servicing is done at the workshop , again out in the open under a 2 ton yard crane .

There are some who can not abide leaving their mower in my "scrapyard" they are welcome to take them into town and pay $ 150 / hr to cover the costs of those big work bay and rolling tool boxes full of snap ons.

My work comes with an unconditional 12 month warranty, the big box gives 3 months .

I charge scheduled hours which of course are always less than the actual time taken to do a job

The "operating theatre " workshops charge actual hours and because it is computerised, every nut, bolt, washer, grease , cleaning solutions, shop rags & shop fuel and one even a used oil disposal fee .

However we are getting a long way off topic , as these threads often do .

When I was doing my 1 month evaluation before buying the run the vendor would wack me on the back of the head and ask "what time is NASSA coming for this job? "

It took a long time to come to grips with the fact that these are mowers and for the bulk of them they have been made as cheap as possible with the cheapest materials that might possibly do the job.

So getting ulcers about the brand of oil , spark plugs or filters is a waste of time & energy.

If the customer wants you to use some thing that is way over specked for their machine then just do it & charge them for it .