I analyzed the situation of my deck a lot and came to some conclusions...

1 - It's a poorly made adaptation of a Husqvarna deck, on a Murray product. (obvious)

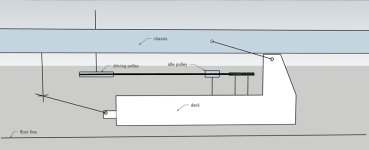

2 - The suspension arms must be the same size, which is why my deck twisted when going up or down.

3 - The distance from the deck towers (where the suspension arms connect) were too far apart, which is why it hit the bottom of the fender and still made it difficult to engage level 6 in height.

4 – I was wrong in imagining parallelism of the towers in relation to the end of the deck... yes, it is possible to do it, but the geometry and the distances interfere either in the front left tire with the deck (when turning to the left) or in the tensioner pulley with a right draglink (if you use the smaller arm that came with the suspension) or on the deflector (which, when open to place the tube, must be vertical) and also on the connection of the discharge tube in its complement to the collector's basket.

As I don't have any references with measurements, I attached the towers with two threaded bars with a distance slightly greater than the width of the chassis, so as not to hit the fender at the highest height of the deck.

I made two suspension bars of the same size as the larger one that came on the tractor.

I modified the arms that lift the deck (I didn't like the original design), fixed the arms on the towers and these to the arms and lift... I put the lever in position 6.

I placed the deck under the tractor and observed the best position (imagining it high and low) so as not to interfere with anything (tire, draglink, pulleys, deflector, discharge tube...), when I arrived at a position that seemed ideal to me , I lowered the lever to level 1, marked them on the deck and made punctual and temporary welds, as the left one did not even touch the deck and the right one only in two points (the geometry was very compromised, not following the curvature of the deck) .

I connected the front link, and the deck now goes up and down without interfering at all and also doesn't spin like before.

Now it's time to create a point to fix and adjust the hitch cable and buy a strap that meets the new distance, as the previous one was short.

I also redid pins and put bushings that were already worn out in some places… only later will I be able to assess whether the tension pulley trepidation continues or not.

Parts made or remade:

Marks on the floor so as not to lose the reference:

Marks on the deck:

Temporary welds:

Deck now lifts 8cm and has 1.8cm variance (front/rear).

But nothing is so good that it can't be improved...