You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Problems with the cutting deck

#1

B

Bange

B

Bange

After completing 50 hours of use, I did the first preventive maintenance on my Murray 18.5 HP... (change of oil, filter, grease, valve gap readjustment, blade sharpening, inspection of several other items, etc.. .).

I spent some time analyzing my cutting deck, since I bought it (it's used, I'm the 3rd owner), it has three problems:

1 - difficulty adjusting the height.

2 - strong oscillation of the belt tension pulley.

3 - belt tension variation according to height level.

I have already identified other problems before and solved or alleviated them... this deck appears to be of a different age than the rest, as its condition is very good for the age of the tractor (2010) and also considering normal wear parts such as screws and holes in parts that move on the support (links, arms, etc...).

Another detail is the large amount of differences between the parts list manual and the reality of the deck... in short, it looks like an adapted deck... and poorly adapted... but it's what I have and I'll try to put it in the best possible way, with your help.

What has already been done for 1:

Regarding the height adjustment, I identified that the suspension arms, despite having the same number stamped (195186 - Husqvarna), have different lengths, which made the deck twist according to the selected level.

Solution: I created another support point on the deck and matched the arms to the smaller one, in addition to changing the connection point of the Link Lift Susp Mower Rear (91 in the diagram) to match the right side (only then were they aligned).

I cut the Link Asm Lift FXD (101), welded a long screw and made a piece similar to 91... getting the same height adjustment condition.

Now bring it down without twisting.

As for items 2 and 3, I have already tried several configurations and could not resolve them, as they are combined, that is, at level 1, the blades take a long time to turn and it is perceived that they do not have speed, but the tensioner pulley does not oscillate... As the deck level increases, the belt stretches, starts and increases oscillation.

I'm already thinking of a drastic solution, which is to put a coupling cable (which is fixed on my deck) like a bicycle brake adjustment...

I researched many decks on the internet and the one that comes closest is what appears in the following video... including the entry for the blade coupling cable... however the support arms are different...

I spent some time analyzing my cutting deck, since I bought it (it's used, I'm the 3rd owner), it has three problems:

1 - difficulty adjusting the height.

2 - strong oscillation of the belt tension pulley.

3 - belt tension variation according to height level.

I have already identified other problems before and solved or alleviated them... this deck appears to be of a different age than the rest, as its condition is very good for the age of the tractor (2010) and also considering normal wear parts such as screws and holes in parts that move on the support (links, arms, etc...).

Another detail is the large amount of differences between the parts list manual and the reality of the deck... in short, it looks like an adapted deck... and poorly adapted... but it's what I have and I'll try to put it in the best possible way, with your help.

What has already been done for 1:

Regarding the height adjustment, I identified that the suspension arms, despite having the same number stamped (195186 - Husqvarna), have different lengths, which made the deck twist according to the selected level.

Solution: I created another support point on the deck and matched the arms to the smaller one, in addition to changing the connection point of the Link Lift Susp Mower Rear (91 in the diagram) to match the right side (only then were they aligned).

I cut the Link Asm Lift FXD (101), welded a long screw and made a piece similar to 91... getting the same height adjustment condition.

Now bring it down without twisting.

As for items 2 and 3, I have already tried several configurations and could not resolve them, as they are combined, that is, at level 1, the blades take a long time to turn and it is perceived that they do not have speed, but the tensioner pulley does not oscillate... As the deck level increases, the belt stretches, starts and increases oscillation.

I'm already thinking of a drastic solution, which is to put a coupling cable (which is fixed on my deck) like a bicycle brake adjustment...

I researched many decks on the internet and the one that comes closest is what appears in the following video... including the entry for the blade coupling cable... however the support arms are different...

#2

B

bertsmobile1

B

bertsmobile1

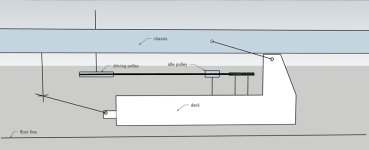

Stop and have a little think

The pulleys on the deck rise & fall with the deck

The engine pulley stays at the same height regardless of the deck position

So the belt run will be the hypotinuse of a triangle with the horizontal distance between the engine & deck pulley as the X base line and the difference in height being the Y value so it will change as you change the cutting height.

The last mower I saw that had a system to counter this was a Simplicity from around 1980 and it took well over an hour to change the belt .

Most mowers have the belt pulleys in line on the middle cutting height

As you have not provided model numbers or photos there is little more than we can do for you.

Pull the tesion arm off and check that the pivot hole is stll round & not egged out

Similar story with the pivot bolt bush they wear slots over time because people are too bone lazy to blow down decks and lube the pivots

The pulleys on the deck rise & fall with the deck

The engine pulley stays at the same height regardless of the deck position

So the belt run will be the hypotinuse of a triangle with the horizontal distance between the engine & deck pulley as the X base line and the difference in height being the Y value so it will change as you change the cutting height.

The last mower I saw that had a system to counter this was a Simplicity from around 1980 and it took well over an hour to change the belt .

Most mowers have the belt pulleys in line on the middle cutting height

As you have not provided model numbers or photos there is little more than we can do for you.

Pull the tesion arm off and check that the pivot hole is stll round & not egged out

Similar story with the pivot bolt bush they wear slots over time because people are too bone lazy to blow down decks and lube the pivots

#3

Tiger Small Engine

Tiger Small Engine

The reality on inexpensive mower decks is sometimes this: not ideal belt tension, sloppy action with tensioner pulley, and not able to hold up well to continuous abuse from getting hit, etc.Stop and have a little think

The pulleys on the deck rise & fall with the deck

The engine pulley stays at the same height regardless of the deck position

So the belt run will be the hypotinuse of a triangle with the horizontal distance between the engine & deck pulley as the X base line and the difference in height being the Y value so it will change as you change the cutting height.

The last mower I saw that had a system to counter this was a Simplicity from around 1980 and it took well over an hour to change the belt .

Most mowers have the belt pulleys in line on the middle cutting height

As you have not provided model numbers or photos there is little more than we can do for you.

Pull the tesion arm off and check that the pivot hole is stll round & not egged out

Similar story with the pivot bolt bush they wear slots over time because people are too bone lazy to blow down decks and lube the pivots

#4

B

Bange

If I make an adjustment for each of the 7 levels of the deck, the problem is solved... but it's not correct.

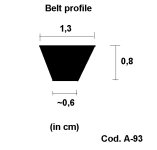

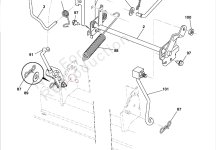

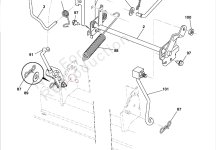

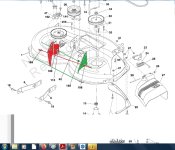

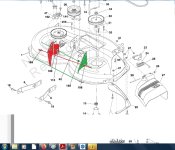

Pictures follow...

Only existing numbers on the suspension arms

Upper view

Tensioner support repairs

Part made for adjustment right side

Suspension arm connection replacement and lift link

Ops! My mower is Murray 42L18G60X8A

B

Bange

Yes, I understand that the movement of the deck makes an arc in relation to the driving pulley and this can affect the belt tension a little... but in my case this variation is very large and changes not only the belt tension but also the oscillation of the tensioner pulley.Stop and have a little think

The pulleys on the deck rise & fall with the deck

The engine pulley stays at the same height regardless of the deck position

So the belt run will be the hypotinuse of a triangle with the horizontal distance between the engine & deck pulley as the X base line and the difference in height being the Y value so it will change as you change the cutting height.

The last mower I saw that had a system to counter this was a Simplicity from around 1980 and it took well over an hour to change the belt .

Most mowers have the belt pulleys in line on the middle cutting height

As you have not provided model numbers or photos there is little more than we can do for you.

Pull the tesion arm off and check that the pivot hole is stll round & not egged out

Similar story with the pivot bolt bush they wear slots over time because people are too bone lazy to blow down decks and lube the pivots

If I make an adjustment for each of the 7 levels of the deck, the problem is solved... but it's not correct.

Pictures follow...

Only existing numbers on the suspension arms

Upper view

Tensioner support repairs

Part made for adjustment right side

Suspension arm connection replacement and lift link

Ops! My mower is Murray 42L18G60X8A

#6

B

bertsmobile1

B

bertsmobile1

That lift are was used by Murray from 2009 through to 2012 which is just after B & S took over Murray as they went bust .

They should be the same length and locate onto pegs in the frame that are directly opposite to each other .

I will guess that one broke so they drilled a new hole and moved the pin .

The deck engagement & pulleys appear to be from a Husqvarna LT or LTH, not a Murray one

Try moving the tension spring further forward

The belt ossillates because there is a not enough tension on it .

And of course if the deck is a lash up job the original belt is unlikley to be the correct length

They should be the same length and locate onto pegs in the frame that are directly opposite to each other .

I will guess that one broke so they drilled a new hole and moved the pin .

The deck engagement & pulleys appear to be from a Husqvarna LT or LTH, not a Murray one

Try moving the tension spring further forward

The belt ossillates because there is a not enough tension on it .

And of course if the deck is a lash up job the original belt is unlikley to be the correct length

#7

B

Bange

B

Bange

Really I conclude that there was a very poorly done adaptation.

When looking for new decks to buy, neither from the original importer (Trapp) does not exist.

Yes, it appears, but from Husqvrna... and I saw answers from the seller saying that people buy Husqvarna and adapt it to Murray.

But I disagree about the belt pressure, because:

Level 1 - Skate until you gain speed (low belt pressure)

Level 2 - Skates a little, but takes a while to gain speed.

Level 3 - Almost immediate departure

Level 4 - You don't notice skating, almost immediate speed (good belt pressure)

Level 5 - Immediate start and little pulley oscillation.

Level 6 - Immediate start and oscillation increases

Level 7 - Immediate starting and large pulley oscillation (too much belt pressure).

In my case there is no adjustment point for the belt tension cable...and if there was, the adjustment would be fine for the hitch, but wobble would occur anyway.

Interestingly, I removed the arms (19) and the operation improved a little, but without them there is lateral play of the deck, which I don't think is good or correct.

Another observation is that the distance from the points where the arms are fixed to the deck are too wide, because depending on the adjustment made (91), the deck hits the bottom (37).

Is this photo analysis correct?

When looking for new decks to buy, neither from the original importer (Trapp) does not exist.

Yes, it appears, but from Husqvrna... and I saw answers from the seller saying that people buy Husqvarna and adapt it to Murray.

But I disagree about the belt pressure, because:

Level 1 - Skate until you gain speed (low belt pressure)

Level 2 - Skates a little, but takes a while to gain speed.

Level 3 - Almost immediate departure

Level 4 - You don't notice skating, almost immediate speed (good belt pressure)

Level 5 - Immediate start and little pulley oscillation.

Level 6 - Immediate start and oscillation increases

Level 7 - Immediate starting and large pulley oscillation (too much belt pressure).

In my case there is no adjustment point for the belt tension cable...and if there was, the adjustment would be fine for the hitch, but wobble would occur anyway.

Interestingly, I removed the arms (19) and the operation improved a little, but without them there is lateral play of the deck, which I don't think is good or correct.

Another observation is that the distance from the points where the arms are fixed to the deck are too wide, because depending on the adjustment made (91), the deck hits the bottom (37).

Is this photo analysis correct?

#9

B

bertsmobile1

B

bertsmobile1

If you have come here for an arguement then you can do it with some one else.

You wanted a solution & you got one

If you are unwilling to accept what you have been told by a person who has probably rebuilt better that 100 decks ofer the past 11 years then I can nt be of any more assistance to you.

So good luck with yur fraken mower

I wish you well but there are others who actually want help.

Not another word from me .

You wanted a solution & you got one

If you are unwilling to accept what you have been told by a person who has probably rebuilt better that 100 decks ofer the past 11 years then I can nt be of any more assistance to you.

So good luck with yur fraken mower

I wish you well but there are others who actually want help.

Not another word from me .

#10

B

Bange

B

Bange

No... no discussion... it really helps...

My english is from google...

I just disagreed when you said that "The belt ossillates because there is a not enough tension on it".

I described to you the practice of my case, which is exactly the opposite, that is, greater tension, greater oscillation.

My english is from google...

I just disagreed when you said that "The belt ossillates because there is a not enough tension on it".

I described to you the practice of my case, which is exactly the opposite, that is, greater tension, greater oscillation.

#11

B

Bange

B

Bange

I removed the support on the left side (red) and repositioned it closer to the right, so as not to hit the bottom anymore, keeping the same height as the holes on the right (green).

However, as can be seen in the drawing, it was not parallel to the rear structure of the deck and, in addition, the tire scrapes the deck when turning to the left side.

I will have to change the structure of the left support (red) to position it parallel to the right support (green), keeping the holes the same height.

However, as can be seen in the drawing, it was not parallel to the rear structure of the deck and, in addition, the tire scrapes the deck when turning to the left side.

I will have to change the structure of the left support (red) to position it parallel to the right support (green), keeping the holes the same height.

#15

B

Bange

B

Bange

I analyzed the situation of my deck a lot and came to some conclusions...

1 - It's a poorly made adaptation of a Husqvarna deck, on a Murray product. (obvious)

2 - The suspension arms must be the same size, which is why my deck twisted when going up or down.

3 - The distance from the deck towers (where the suspension arms connect) were too far apart, which is why it hit the bottom of the fender and still made it difficult to engage level 6 in height.

4 – I was wrong in imagining parallelism of the towers in relation to the end of the deck... yes, it is possible to do it, but the geometry and the distances interfere either in the front left tire with the deck (when turning to the left) or in the tensioner pulley with a right draglink (if you use the smaller arm that came with the suspension) or on the deflector (which, when open to place the tube, must be vertical) and also on the connection of the discharge tube in its complement to the collector's basket.

As I don't have any references with measurements, I attached the towers with two threaded bars with a distance slightly greater than the width of the chassis, so as not to hit the fender at the highest height of the deck.

I made two suspension bars of the same size as the larger one that came on the tractor.

I modified the arms that lift the deck (I didn't like the original design), fixed the arms on the towers and these to the arms and lift... I put the lever in position 6.

I placed the deck under the tractor and observed the best position (imagining it high and low) so as not to interfere with anything (tire, draglink, pulleys, deflector, discharge tube...), when I arrived at a position that seemed ideal to me , I lowered the lever to level 1, marked them on the deck and made punctual and temporary welds, as the left one did not even touch the deck and the right one only in two points (the geometry was very compromised, not following the curvature of the deck) .

I connected the front link, and the deck now goes up and down without interfering at all and also doesn't spin like before.

Now it's time to create a point to fix and adjust the hitch cable and buy a strap that meets the new distance, as the previous one was short.

I also redid pins and put bushings that were already worn out in some places… only later will I be able to assess whether the tension pulley trepidation continues or not.

Parts made or remade:

Marks on the floor so as not to lose the reference:

Marks on the deck:

Temporary welds:

Deck now lifts 8cm and has 1.8cm variance (front/rear).

But nothing is so good that it can't be improved...

1 - It's a poorly made adaptation of a Husqvarna deck, on a Murray product. (obvious)

2 - The suspension arms must be the same size, which is why my deck twisted when going up or down.

3 - The distance from the deck towers (where the suspension arms connect) were too far apart, which is why it hit the bottom of the fender and still made it difficult to engage level 6 in height.

4 – I was wrong in imagining parallelism of the towers in relation to the end of the deck... yes, it is possible to do it, but the geometry and the distances interfere either in the front left tire with the deck (when turning to the left) or in the tensioner pulley with a right draglink (if you use the smaller arm that came with the suspension) or on the deflector (which, when open to place the tube, must be vertical) and also on the connection of the discharge tube in its complement to the collector's basket.

As I don't have any references with measurements, I attached the towers with two threaded bars with a distance slightly greater than the width of the chassis, so as not to hit the fender at the highest height of the deck.

I made two suspension bars of the same size as the larger one that came on the tractor.

I modified the arms that lift the deck (I didn't like the original design), fixed the arms on the towers and these to the arms and lift... I put the lever in position 6.

I placed the deck under the tractor and observed the best position (imagining it high and low) so as not to interfere with anything (tire, draglink, pulleys, deflector, discharge tube...), when I arrived at a position that seemed ideal to me , I lowered the lever to level 1, marked them on the deck and made punctual and temporary welds, as the left one did not even touch the deck and the right one only in two points (the geometry was very compromised, not following the curvature of the deck) .

I connected the front link, and the deck now goes up and down without interfering at all and also doesn't spin like before.

Now it's time to create a point to fix and adjust the hitch cable and buy a strap that meets the new distance, as the previous one was short.

I also redid pins and put bushings that were already worn out in some places… only later will I be able to assess whether the tension pulley trepidation continues or not.

Parts made or remade:

Marks on the floor so as not to lose the reference:

Marks on the deck:

Temporary welds:

Deck now lifts 8cm and has 1.8cm variance (front/rear).

But nothing is so good that it can't be improved...

#16

B

Bange

B

Bange

Do you think that a 3mm variation is good or is it still too big?

...at least on paper it worked...

...at least on paper it worked...

#18

B

Bange

B

Bange

Well friends,

Today I finished the adaptation project… it turned out really well.

The deck now rises and falls with virtually no forward or backward variation and no twisting.

I put a belt tension adjustment point (which I didn't have), replaced some coupling lever bushings... but the tensioner pulley still shakes a little, especially at low rpm.

I don't know if the lack of the keeper belt has anything to do with it, but now with the adjustment of the belt tension I could verify that with lower tension, the tensioner pulley vibrates less, but it is at a very critical point, because if it stays calm, I notice that the speed of the blades decreases, which means that the belt is slipping.

Today I finished the adaptation project… it turned out really well.

The deck now rises and falls with virtually no forward or backward variation and no twisting.

I put a belt tension adjustment point (which I didn't have), replaced some coupling lever bushings... but the tensioner pulley still shakes a little, especially at low rpm.

I don't know if the lack of the keeper belt has anything to do with it, but now with the adjustment of the belt tension I could verify that with lower tension, the tensioner pulley vibrates less, but it is at a very critical point, because if it stays calm, I notice that the speed of the blades decreases, which means that the belt is slipping.

#21

B

bertsmobile1

B

bertsmobile1

I would have put a stronger spring on the tension arm or just moved a bit further back to increase the tension a bit

This is of course assuming that the spindles spin freely , have good bearings and the blades are balanced .

This is of course assuming that the spindles spin freely , have good bearings and the blades are balanced .

#22

B

Bange

B

Bange

Well, now it's a refinement...

Today I'm on my micro farm and I'm going to do a test drive... here I still don't have a workshop structure like in my house where I live.

Here I still don't have internet or a computer... just my cell phone.

Free spindles, tensioner bearings and new passage... sharp and balanced blades still with the axis in the hole... but I noticed a difference in height at the ends of the blades, when ideally they should be leveled... there are approximately 3 or 4mm... would that be enough for the vibration?

If yes, how to correct this, as the cause must be an unevenness in the deck

Today I'm on my micro farm and I'm going to do a test drive... here I still don't have a workshop structure like in my house where I live.

Here I still don't have internet or a computer... just my cell phone.

Free spindles, tensioner bearings and new passage... sharp and balanced blades still with the axis in the hole... but I noticed a difference in height at the ends of the blades, when ideally they should be leveled... there are approximately 3 or 4mm... would that be enough for the vibration?

If yes, how to correct this, as the cause must be an unevenness in the deck

#24

B

Bange

B

Bange

Previously I had shown that I managed to hit the up/down movement of the deck, but I didn't show how.

I tried first not to shoot the water, and it turned out really well... here's the solution, simple and cheap.

I tried first not to shoot the water, and it turned out really well... here's the solution, simple and cheap.

#25

B

Bange

B

Bange

Well, back to the topic...

I did a re-evaluation of the balance, looking for something more dynamic, re-evaluating the axles for looseness or bending (everything perfect), I clamped the assembly on a piece of iron vertically and...

The pulley has little or no influence...a small gap in the shaft teeth, was the justification for the blade to always stop horizontally and with the same side down...

After the best possible corrections, the vibration improved well, but it's not over...

Do you think that the following gaps can have a significant influence on the vibration of the tensioning pulley?

I did a re-evaluation of the balance, looking for something more dynamic, re-evaluating the axles for looseness or bending (everything perfect), I clamped the assembly on a piece of iron vertically and...

The pulley has little or no influence...a small gap in the shaft teeth, was the justification for the blade to always stop horizontally and with the same side down...

After the best possible corrections, the vibration improved well, but it's not over...

Do you think that the following gaps can have a significant influence on the vibration of the tensioning pulley?

#26

B

bertsmobile1

B

bertsmobile1

The tension arm should swing around the bush freely with little to no up & down play

I regularly turn up new bushes , weld worn arms to build up cupped sections & fit substantially bigger flanges to give more support .

You seem to be handy with tools so it should not be a problem for you

I regularly turn up new bushes , weld worn arms to build up cupped sections & fit substantially bigger flanges to give more support .

You seem to be handy with tools so it should not be a problem for you

#27

B

Bange

B

Bange

Makes alot of sense...

I tried to eliminate the gaps by putting shims around the bushing and adding washers. all made of aluminum foil (from a beer can), the vibration has decreased significantly, but it's not gone and I don't know if the vibration that remained can be considered normal, as I haven't seen a reference yet.

But I'm thinking of putting a ball bearing... the problem is that if it doesn't work, the piece will be almost irreversible or at least very difficult to return.

Could you give me an idea of the traction force of the spring connected to the cable and the other one that returns the set when it is disengaged?

I tried to eliminate the gaps by putting shims around the bushing and adding washers. all made of aluminum foil (from a beer can), the vibration has decreased significantly, but it's not gone and I don't know if the vibration that remained can be considered normal, as I haven't seen a reference yet.

But I'm thinking of putting a ball bearing... the problem is that if it doesn't work, the piece will be almost irreversible or at least very difficult to return.

Could you give me an idea of the traction force of the spring connected to the cable and the other one that returns the set when it is disengaged?

#28

B

bertsmobile1

B

bertsmobile1

Way beyond my pay grade that oneMakes alot of sense...

I tried to eliminate the gaps by putting shims around the bushing and adding washers. all made of aluminum foil (from a beer can), the vibration has decreased significantly, but it's not gone and I don't know if the vibration that remained can be considered normal, as I haven't seen a reference yet.

But I'm thinking of putting a ball bearing... the problem is that if it doesn't work, the piece will be almost irreversible or at least very difficult to return.

Could you give me an idea of the traction force of the spring connected to the cable and the other one that returns the set when it is disengaged?

#29

B

Bange

B

Bange

Does anyone know how to inform the function of this coincident drilling?

youtube.com

youtube.com

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

#30

B

Bange

B

Bange

No answer???

I believe it has to do with the adjustment of the belt tension, because from this hole the brakes start releasing the spindles and the belt engages in the grooves of the pulleys, transmitting the movement of the engine.

One more question:

The pulley engagement lever describes an arc of just over 90° and this pulls the steel cable (only the cable), in my case the displacement is 8 centimeters... is this a standard value or does each manufacturer make their own?

I believe it has to do with the adjustment of the belt tension, because from this hole the brakes start releasing the spindles and the belt engages in the grooves of the pulleys, transmitting the movement of the engine.

One more question:

The pulley engagement lever describes an arc of just over 90° and this pulls the steel cable (only the cable), in my case the displacement is 8 centimeters... is this a standard value or does each manufacturer make their own?

#31

B

Bange

B

Bange

Evolution:

I placed an angle bracket with several holes that represent different angles of the steel cable to the axis of the tensioner pulley support... in relation to the initially chosen point, the vibration improved a lot in holes 2 and 3, getting very little at maximum rotation, but at low rotation, almost no improvement is noticed.

It could be that I'm too picky, but if it resolves low, the high will also be resolved satisfactorily.

I also replaced the original bearings on the brake arms with ball bearings... I haven't tested it yet, but it's already been noticed manually that it was very soft and this should reduce the noise a little.

As the diameter of the new bearings are larger, I had to readjust the grooves in the tensioner pulley support.

I placed an angle bracket with several holes that represent different angles of the steel cable to the axis of the tensioner pulley support... in relation to the initially chosen point, the vibration improved a lot in holes 2 and 3, getting very little at maximum rotation, but at low rotation, almost no improvement is noticed.

It could be that I'm too picky, but if it resolves low, the high will also be resolved satisfactorily.

I also replaced the original bearings on the brake arms with ball bearings... I haven't tested it yet, but it's already been noticed manually that it was very soft and this should reduce the noise a little.

As the diameter of the new bearings are larger, I had to readjust the grooves in the tensioner pulley support.

#32

B

Bange

B

Bange

I think I'm working with cold iron... everything I've been doing seems to have little or no effect on the vibration item... it's possible there are several causes and I'm eliminating each one, but the main one remains.

I don't have anything to turn the engine slowly, so I removed the spark plug, the belt and scratched the key to see the pulley turning and I didn't notice any play in its edges, but I noticed a variation in the groove that could be the root cause.

Removing this pulley must not be easy without the specific tool and I would like to remove it and analyze it on the lathe... does anyone have any tips to make the procedure easier? HELP!

I don't have anything to turn the engine slowly, so I removed the spark plug, the belt and scratched the key to see the pulley turning and I didn't notice any play in its edges, but I noticed a variation in the groove that could be the root cause.

Removing this pulley must not be easy without the specific tool and I would like to remove it and analyze it on the lathe... does anyone have any tips to make the procedure easier? HELP!

#33

B

bertsmobile1

B

bertsmobile1

You are solving a problem that does not exist as the deck should always be running at full speed

There is no such animal as a vibration free deck even more so when powered by a single cylinder engine that produces power pulses

Because the engine pulls forward on the left side , you get a twisting moment every times the engine fires ( 3500 rpm ) so you get a 3500Hz vibration for the engine alone.

Add to that the belt has a join so every time the join runs over the pulleys it will cause a vibration, a problem many lathe users have that can cause chatter , particulalry if the lathe has a flat belt drive

Next vibration causer is the actual shape of the deck itself as the blades are identical but the air space above them is not

When Victa made the Vortex push mower, they found that over 80% of the noise was generated by the blades so they made a weird blade carrier ( swing back blades ) and strange curved blades with no flutes to eliminate the under deck noise and they are quieter than a Honda in use which says a lot for a 2 stroke engine

Greenfield mowers ( local brand ) have a true parrallelogram lifting system that has bushes at every pivot point and that removes both noise & vibration

There is no such animal as a vibration free deck even more so when powered by a single cylinder engine that produces power pulses

Because the engine pulls forward on the left side , you get a twisting moment every times the engine fires ( 3500 rpm ) so you get a 3500Hz vibration for the engine alone.

Add to that the belt has a join so every time the join runs over the pulleys it will cause a vibration, a problem many lathe users have that can cause chatter , particulalry if the lathe has a flat belt drive

Next vibration causer is the actual shape of the deck itself as the blades are identical but the air space above them is not

When Victa made the Vortex push mower, they found that over 80% of the noise was generated by the blades so they made a weird blade carrier ( swing back blades ) and strange curved blades with no flutes to eliminate the under deck noise and they are quieter than a Honda in use which says a lot for a 2 stroke engine

Greenfield mowers ( local brand ) have a true parrallelogram lifting system that has bushes at every pivot point and that removes both noise & vibration

#34

B

Bange

B

Bange

I agree that the cutting speed is always maximum, but I use it a little lower for sites with only leaves, which don't need high RPM.

As I said before, it could be that I am very demanding and if the low is resolved, the high will be very smooth.

Without the weight of the cutting set, the vibration of the motor alone is practically non-existent and I would like it to remain the same with the deck, so analyzing the pulley on the lathe is what is missing, as the rest has already been settled... apart from that, just a Spartan solution, which is my plan "B".

As I said before, it could be that I am very demanding and if the low is resolved, the high will be very smooth.

Without the weight of the cutting set, the vibration of the motor alone is practically non-existent and I would like it to remain the same with the deck, so analyzing the pulley on the lathe is what is missing, as the rest has already been settled... apart from that, just a Spartan solution, which is my plan "B".

#35

B

Bange

B

Bange

Well, unable to turn the engine shaft very slowly, I tried to set the lowest possible speed by moving the carburetor and the problem is now evident, leaving no doubt (for me) that this is the root cause of the deck oscillation.

#39

B

Bange

B

Bange

An internet seller says this pulley is the same for Murray and Husqvarna LT 131 and LT 151.

Do you confirm this?

Do you confirm this?

#40

B

bertsmobile1

B

bertsmobile1

Find the part number

Use that to search on an after market site .

If you get a hit then click on the More info / specifications etc and yo will get a list of all of the mowers it fits

Use that to search on an after market site .

If you get a hit then click on the More info / specifications etc and yo will get a list of all of the mowers it fits

#42

B

bertsmobile1

B

bertsmobile1

before you go too far, remove the pulley, replace the bolt then run the engine to check it is in fact the pulley & not the crankshaft .

Fi the pulley is just warped then holding it upside down in your vice do some mechanical rectification with a block of hardwood & a big hammer

Fi the pulley is just warped then holding it upside down in your vice do some mechanical rectification with a block of hardwood & a big hammer

#43

B

Bange

B

Bange

It's already in my plans to remove and evaluate, I haven't done this yet because the tractor stayed in place... I had to return with the empty trailer for another activity.

I even have to take measurements, as some sellers are private importers and have never seen a lawnmower tractor in operation and buy cat for rabbit is complicated.

I only found 3 "suppliers":

The Official Importer - USD$250

A private seller in another state - USD$173 + shipping

And a repair shop in another state - USD$140 + shipping.

Speaking of an official importer, I know the reason why he no longer imports the brand... is that Briggs&Stratton bought the company Branco, which is now supplying 3 models with Briggs engines under the name Branco (traditional manufacturer of small machines for the garden and field), a zero turn 25HP, a 19HP and a 17.5HP.

I'm waiting for an answer from Branco if they also use this pulley (708363).

I even have to take measurements, as some sellers are private importers and have never seen a lawnmower tractor in operation and buy cat for rabbit is complicated.

I only found 3 "suppliers":

The Official Importer - USD$250

A private seller in another state - USD$173 + shipping

And a repair shop in another state - USD$140 + shipping.

Speaking of an official importer, I know the reason why he no longer imports the brand... is that Briggs&Stratton bought the company Branco, which is now supplying 3 models with Briggs engines under the name Branco (traditional manufacturer of small machines for the garden and field), a zero turn 25HP, a 19HP and a 17.5HP.

I'm waiting for an answer from Branco if they also use this pulley (708363).

#44

B

Bange

B

Bange

Well... I ended up buying a new pulley... but... it also shows the same symptom, less so, but it does.

See that the lathe bench even vibrates at high speed (700RPM).

I'm asking B&S to find out what the vibration specification is to condemn the new pulley.

See that the lathe bench even vibrates at high speed (700RPM).

I'm asking B&S to find out what the vibration specification is to condemn the new pulley.

#45

M

MParr

M

MParr

I don’t think that you are going to find any pulley that’s going to run perfectly true. Most are 2 piece of stamped steel that are either bolted or welded together. It awfully expensive to make a pulley out of solid stock and machine it down.

#46

B

Bange

B

Bange

This appears not to be made of two halves but rather hot formed and then welded to the shaft I believe in a standard form and welded by machine... even so, there is human interference in the operation, where the greatest probability of error lies... perhaps in the rush to produce.

#47

B

Bange

B

Bange

As consumers we are in a bad spot...

B&S USA referred me to technical assistance.

B&S Brasil, paid me a lot of attention, but couldn't say anything about the specification and couldn't even test another one from stock, as here they only sell it for the 17.5Hp engine, which according to them is different.

I'm going to return the new pulley, because not even the store that sold it to me can say anything...

I'm seeing if any company that works with industrial balancing can solve the problem with the original pulley.

B&S USA referred me to technical assistance.

B&S Brasil, paid me a lot of attention, but couldn't say anything about the specification and couldn't even test another one from stock, as here they only sell it for the 17.5Hp engine, which according to them is different.

I'm going to return the new pulley, because not even the store that sold it to me can say anything...

I'm seeing if any company that works with industrial balancing can solve the problem with the original pulley.

#48

B

Bange

B

Bange

No company returned positive information, always a “maybe” or “could be” and I will not pay for transportation and service that way.

I returned the purchased part and worked on the old one, achieving a good result... better than the new one, but only in the oscillation of the pulleys, as I have no way of checking the balance, but the improvement was noticeable both on the lathe and assembled.

But there is still a constant vibration of the motor assembly, which I believe is due to flexion of the tray where it is sitting, as it is 2.8mm and appears to be flexing.

What do you think?

I returned the purchased part and worked on the old one, achieving a good result... better than the new one, but only in the oscillation of the pulleys, as I have no way of checking the balance, but the improvement was noticeable both on the lathe and assembled.

But there is still a constant vibration of the motor assembly, which I believe is due to flexion of the tray where it is sitting, as it is 2.8mm and appears to be flexing.

What do you think?

#49

B

Bange

B

Bange

Well, I think I'm on the right path...

The base where the engine sits is actually flexing.

I made a support for the front part of the engine, just below the valve adjustment cover and the improvement was significant...

The deck vibration is now becoming acceptable...

But if the shaft is not bent and the pulley now has no more "play", I can only imagine something unbalanced inside the engine... what could it be???

The base where the engine sits is actually flexing.

I made a support for the front part of the engine, just below the valve adjustment cover and the improvement was significant...

The deck vibration is now becoming acceptable...

But if the shaft is not bent and the pulley now has no more "play", I can only imagine something unbalanced inside the engine... what could it be???