You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

post proof of bad ethanol problems

#1

exotion

exotion

So I am not the only one getting annoyed at every problem getting blamed on ethanol.

I want proof. Actual with sources proof posted here.

If you can find some hard evidence and facts let me know.

I want proof. Actual with sources proof posted here.

If you can find some hard evidence and facts let me know.

#2

Carscw

Carscw

All your going to hear is. I saw it happen to fuel lines. I have asked the same thing because I have never had a problem because of it.

(( cowboy up and get over it ))

(( cowboy up and get over it ))

#3

exotion

exotion

That's why I asked for proof " I saw" does not count as proof. Show me pics, internet sites that state proof

#4

B

Brucebotti

B

Brucebotti

That's all we have here in CT is 10% ethanol, and I have never encountered a problem with it.

Bruce

Bruce

#5

chobbs1957

Maybe I'm gullible and naive! I grew up around cars, and spent some years working in a service station as teenager back in the mid-70's, when you bought gas, got oil changes, and got minor repairs at the local service station. I've been running lawn mowers since I was about 8 years old.

Those were the days before electronic fuel injection, even before electronic ignition cars. We had much different blends of gasoline then. Engines were designed to run a much richer fuel to air mix. It was common to have to rebuild carburetors after about 3-5 years or 60-80K miles. They were challenging to keep adjusted properly.

I understand

The problems we see with poor quality fuel on smaller power equipment today are very similar to what we saw on cars back in the heyday of carburetors, only worse. Avoiding ethanol based gasoline is part of total preventive management plan, but it is not a single solution to guaranteeing no fuel system problems.

While I may fail to exercise the discipline necessary to keep it up, my plan includes:

I work as an agronomist with commercial farming operations. Much of what we deal with in maximizing crop production inputs to increase profits in our fields involves a "total management strategy" approach. It makes no difference, for example, to buy the best hybrid of corn that has the genetics for a top yield if you do a poor job of fertilizing, tillage, weed control, or insect control. Some things we know to manage with a mindset to prevent problems, others we manage once the problem manifests itself. I guess I am applying some of the same logic with power equipment maintenance. The old saying that "an ounce of prevention is worth a pound of cure" applies, and may not have ever been more applicable with outdoor power equipment than it is with today's mix of fuel and common equipment.

I am sure I will still have problems sooner or later, even fuel system troubles. Over the decades, my number one problem with 4 cycle equipment has been burning oil and carburetors second. My number one problem with handheld equipment is carburetors. I plan to reduce the chances of carburetor failure with this program, while increasing the the chances of keeping things easy to crank.

chobbs1957

That's why I asked for proof " I saw" does not count as proof. Show me pics, internet sites that state proof

Maybe I'm gullible and naive! I grew up around cars, and spent some years working in a service station as teenager back in the mid-70's, when you bought gas, got oil changes, and got minor repairs at the local service station. I've been running lawn mowers since I was about 8 years old.

Those were the days before electronic fuel injection, even before electronic ignition cars. We had much different blends of gasoline then. Engines were designed to run a much richer fuel to air mix. It was common to have to rebuild carburetors after about 3-5 years or 60-80K miles. They were challenging to keep adjusted properly.

I understand

- E10 gas is 10% ethanol, a close cousin, if you will, to alchohol. Alcohol did not use to be in gasolines back in the day when carburetors were being developed.

- Ethanol blends of gasoline, I am told and believe, tend to attract more moisture and condensation where stored.

- Outdoor power equipment units have small carburetors, and thus more sensitive to operating under adverse conditions of fuel or air.

- Lines, o-rings, seals, etc. are materials that will deteriorate and lose their texture, negatively affecting their ability to seal against fuel and air leaks. Alcohol in the gasoline, even at low levels of 10%, after lengthy use or long term storage may understandably have a negative effect on the lines, o-rings, seals, and gaskets that were not designed for it.

- I have read that nearly all internal combustion engines are now designed to run a lean fuel-air ratio, trying to make them burn cleaner. This makes it that much harder to get the power from the fuel-air mix, as the engine power demand will be wanting more from the carburetor.

- To compete, many manufacturers look at any way they can to keep manufacturing margins up, as competition, both foreign and domestic, will force them to squeeze every dollar they can.

The problems we see with poor quality fuel on smaller power equipment today are very similar to what we saw on cars back in the heyday of carburetors, only worse. Avoiding ethanol based gasoline is part of total preventive management plan, but it is not a single solution to guaranteeing no fuel system problems.

While I may fail to exercise the discipline necessary to keep it up, my plan includes:

- Using ethanol free gasoline. I drive to a convenience store twenty miles away about once a month and fill 2-5 cans of 5 gallons each. I have other business in that town, and a couple of places there that sell no-ethanol gas.

- I add Sta-Bil fuel stabilizer to the can.

- if a piece of equipment is going to go more than three weeds without being cranked, shut off the fuel and run it until it is dry and shuts down.

- I use high quality Stihl synthetic 2-cycle mix for my handheld stuff. I bought a six pack each time I bought a new piece, as they offered a 1 year warranty extension if I bought and agreed to use it.

- I am using a Mr. Funnel system to transfer fuel. It filters out impurities in gas, including water.

I work as an agronomist with commercial farming operations. Much of what we deal with in maximizing crop production inputs to increase profits in our fields involves a "total management strategy" approach. It makes no difference, for example, to buy the best hybrid of corn that has the genetics for a top yield if you do a poor job of fertilizing, tillage, weed control, or insect control. Some things we know to manage with a mindset to prevent problems, others we manage once the problem manifests itself. I guess I am applying some of the same logic with power equipment maintenance. The old saying that "an ounce of prevention is worth a pound of cure" applies, and may not have ever been more applicable with outdoor power equipment than it is with today's mix of fuel and common equipment.

I am sure I will still have problems sooner or later, even fuel system troubles. Over the decades, my number one problem with 4 cycle equipment has been burning oil and carburetors second. My number one problem with handheld equipment is carburetors. I plan to reduce the chances of carburetor failure with this program, while increasing the the chances of keeping things easy to crank.

#6

djdicetn

You can prove it yourself. Here's how:

1)Take one(any) of your mowers out of service in regard to your business.

2)Fill it up at the beginning of the season with fresh regular/unleaded/ethanol gasoline.

3)Start it and run the engine for 30 minutes and turn it off.

4)Store the mower until the end of the season.

5)Get the mower out at the end of the season and start it up, running it for 30 minutes and turn it off.

6)Store the mower for the winter.

7)Next beginning of the season start the mower(if it will). Top up with more ethanol gas and repeat Steps 2-6.

If this mower isn't "ruined" in 2 seasons....at most 3 seasons of this regiment of ethanol gas, you've proved it isn't harmful......otherwise you have your proof.

It's more the moisture/water that the ethanol additive attracts(no combustion engine is designed to run on a high percentage content of water) as well as the ethanol itself(in regards to long periods of storage in regular gas lines).

Personally, I don't need proof as I've only got one lawn mower, cannot afford to take it out of service to prove that ethanol is bad for it and am just not willing to gamble.

Again, I reiterate....if a Kawasaki manual specifically states that using gasoline with ethanol in excess of 10% "voids the engine warranty" why doe they say that??? My interpretation of that is why would 11% be harmful(your position on ethanol)???? If 11% is that bad, IMHO 1% can't be "good".

P.S.

I can honestly say that I have "performed the steps above" years ago with "regular/unleaded/non-ethanol" gasoline in a lawn tractor I purchased in 1993. I did this for better than 19 years(never draining the gas tank or shutting off the fuel supply at the end of the season). I actually NEVER had any fuel-related problems with that mower that was retired in 2012(19 years of running non-ethanol gas). I sure wouldn't try that with ethanol gasoline!!!! I put ethanol gas in a front-tine tiller and the next season it wouldn't start. Sea-Foam got it going again, but it still has to have the choke partially on to keep it from dying. That's enough proof for me:0)

djdicetn

So I am not the only one getting annoyed at every problem getting blamed on ethanol.

I want proof. Actual with sources proof posted here.

If you can find some hard evidence and facts let me know.

You can prove it yourself. Here's how:

1)Take one(any) of your mowers out of service in regard to your business.

2)Fill it up at the beginning of the season with fresh regular/unleaded/ethanol gasoline.

3)Start it and run the engine for 30 minutes and turn it off.

4)Store the mower until the end of the season.

5)Get the mower out at the end of the season and start it up, running it for 30 minutes and turn it off.

6)Store the mower for the winter.

7)Next beginning of the season start the mower(if it will). Top up with more ethanol gas and repeat Steps 2-6.

If this mower isn't "ruined" in 2 seasons....at most 3 seasons of this regiment of ethanol gas, you've proved it isn't harmful......otherwise you have your proof.

It's more the moisture/water that the ethanol additive attracts(no combustion engine is designed to run on a high percentage content of water) as well as the ethanol itself(in regards to long periods of storage in regular gas lines).

Personally, I don't need proof as I've only got one lawn mower, cannot afford to take it out of service to prove that ethanol is bad for it and am just not willing to gamble.

Again, I reiterate....if a Kawasaki manual specifically states that using gasoline with ethanol in excess of 10% "voids the engine warranty" why doe they say that??? My interpretation of that is why would 11% be harmful(your position on ethanol)???? If 11% is that bad, IMHO 1% can't be "good".

P.S.

I can honestly say that I have "performed the steps above" years ago with "regular/unleaded/non-ethanol" gasoline in a lawn tractor I purchased in 1993. I did this for better than 19 years(never draining the gas tank or shutting off the fuel supply at the end of the season). I actually NEVER had any fuel-related problems with that mower that was retired in 2012(19 years of running non-ethanol gas). I sure wouldn't try that with ethanol gasoline!!!! I put ethanol gas in a front-tine tiller and the next season it wouldn't start. Sea-Foam got it going again, but it still has to have the choke partially on to keep it from dying. That's enough proof for me:0)

#7

Carscw

Nice story but you can not do a test like this with just one mower it would not prove anything.

You would need two mowers same make and model both brand new one with ethanol and one without. I bet they both end up the same.

Ok a man brings his blower to a pawn shop starts it to show it runs. They put it in the back room with gas still in it. 120 days later after he does not come back for it they put it on the floor to sell 5 people start it in the next month still on the old gas. Now you go in and buy it and add more has and it runs just fine for the next year. How can this be? I will tell how.

Because this is all made up bull**** from the mower builders to explain why the bellow grade cheap **** the use to build their mowers falls apart in a year.

I have mowers out back that sit for months I can go start any of them and cut the grass with no problems.

For many years we would go buy stuff to add to our gas well guess what it all has ethanol in it.

So still no one can prove that ethanol does any harm.

(( cowboy up and get over it ))

Carscw

You can prove it yourself. Here's how:

1)Take one(any) of your mowers out of service in regard to your business.

2)Fill it up at the beginning of the season with fresh regular/unleaded/ethanol gasoline.

3)Start it and run the engine for 30 minutes and turn it off.

4)Store the mower until the end of the season.

5)Get the mower out at the end of the season and start it up, running it for 30 minutes and turn it off.

6)Store the mower for the winter.

7)Next beginning of the season start the mower(if it will). Top up with more ethanol gas and repeat Steps 2-6.

If this mower isn't "ruined" in 2 seasons....at most 3 seasons of this regiment of ethanol gas, you've proved it isn't harmful......otherwise you have your proof.

It's more the moisture/water that the ethanol additive attracts(no combustion engine is designed to run on a high percentage content of water) as well as the ethanol itself(in regards to long periods of storage in regular gas lines).

Personally, I don't need proof as I've only got one lawn mower, cannot afford to take it out of service to prove that ethanol is bad for it and am just not willing to gamble.

Again, I reiterate....if a Kawasaki manual specifically states that using gasoline with ethanol in excess of 10% "voids the engine warranty" why doe they say that??? My interpretation of that is why would 11% be harmful(your position on ethanol)???? If 11% is that bad, IMHO 1% can't be "good".

P.S.

I can honestly say that I have "performed the steps above" years ago with "regular/unleaded/non-ethanol" gasoline in a lawn tractor I purchased in 1993. I did this for better than 19 years(never draining the gas tank or shutting off the fuel supply at the end of the season). I actually NEVER had any fuel-related problems with that mower that was retired in 2012(19 years of running non-ethanol gas). I sure wouldn't try that with ethanol gasoline!!!! I put ethanol gas in a front-tine tiller and the next season it wouldn't start. Sea-Foam got it going again, but it still has to have the choke partially on to keep it from dying. That's enough proof for me:0)

Nice story but you can not do a test like this with just one mower it would not prove anything.

You would need two mowers same make and model both brand new one with ethanol and one without. I bet they both end up the same.

Ok a man brings his blower to a pawn shop starts it to show it runs. They put it in the back room with gas still in it. 120 days later after he does not come back for it they put it on the floor to sell 5 people start it in the next month still on the old gas. Now you go in and buy it and add more has and it runs just fine for the next year. How can this be? I will tell how.

Because this is all made up bull**** from the mower builders to explain why the bellow grade cheap **** the use to build their mowers falls apart in a year.

I have mowers out back that sit for months I can go start any of them and cut the grass with no problems.

For many years we would go buy stuff to add to our gas well guess what it all has ethanol in it.

So still no one can prove that ethanol does any harm.

(( cowboy up and get over it ))

#8

A

afoulk

A

afoulk

No one, not even the car manufacturers, unless the fuel system is specifically rated to run on E85, recommends running anything more than E10 because of the corrosive properties of the ethanol and the damage it can do to hoses and orings. Other than that, and the decrease in fuel economy (many reported seeing as much as 2mpg less when gas stations began switching to the e10), I see no disadvantage to using e10. Straight gas might run better, but I've been using e10 in all mystuff, and all I do is treat it with some stabil over the winter and havn't had any issues.

#9

exotion

I believe your test would prove more human error and failure to properly use and maintain your equipment that's not proof.

exotion

You can prove it yourself. Here's how:

1)Take one(any) of your mowers out of service in regard to your business.

2)Fill it up at the beginning of the season with fresh regular/unleaded/ethanol gasoline.

3)Start it and run the engine for 30 minutes and turn it off.

4)Store the mower until the end of the season.

5)Get the mower out at the end of the season and start it up, running it for 30 minutes and turn it off.

6)Store the mower for the winter.

7)Next beginning of the season start the mower(if it will). Top up with more ethanol gas and repeat Steps 2-6.

If this mower isn't "ruined" in 2 seasons....at most 3 seasons of this regiment of ethanol gas, you've proved it isn't harmful......otherwise you have your proof.

It's more the moisture/water that the ethanol additive attracts(no combustion engine is designed to run on a high percentage content of water) as well as the ethanol itself(in regards to long periods of storage in regular gas lines).

Personally, I don't need proof as I've only got one lawn mower, cannot afford to take it out of service to prove that ethanol is bad for it and am just not willing to gamble.

Again, I reiterate....if a Kawasaki manual specifically states that using gasoline with ethanol in excess of 10% "voids the engine warranty" why doe they say that??? My interpretation of that is why would 11% be harmful(your position on ethanol)???? If 11% is that bad, IMHO 1% can't be "good".

P.S.

I can honestly say that I have "performed the steps above" years ago with "regular/unleaded/non-ethanol" gasoline in a lawn tractor I purchased in 1993. I did this for better than 19 years(never draining the gas tank or shutting off the fuel supply at the end of the season). I actually NEVER had any fuel-related problems with that mower that was retired in 2012(19 years of running non-ethanol gas). I sure wouldn't try that with ethanol gasoline!!!! I put ethanol gas in a front-tine tiller and the next season it wouldn't start. Sea-Foam got it going again, but it still has to have the choke partially on to keep it from dying. That's enough proof for me:0)

I believe your test would prove more human error and failure to properly use and maintain your equipment that's not proof.

#10

J

jtk

J

jtk

I have worked with small engines all my life. My Dad owned an outdoor power equipment dealership and this topic came up quite often. Ethanol is not bad for a small engine. What is bad is when you allow ethanol blended fuel to sit in the tank or the carb for extended periods of time. The earlier post was on the money. Ethanol attracts condensation. Over time this can damage carburetors and internal engine parts. If you use your equipment everyday and run all he fuel out everyday you will not have any issues. Years ago, fuel lines could not hold up to ethanol blended fuels. This is not the case today.

If you are homeowner who only runs a few tanks a year through your equipment I would say you should buy fuel with no ethanol. If you use your equipment everyday it won't matter as long as you don't leave the fuel in while you store it over the winter. I myself am a typical homeowner now. I work on small engines for fun and to relax. I never drain my fuel over the winter, I only use the highest octane fuel I can find at the gas station and I never, ever have an issue starting my equipment come springtime. I made plenty of money each spring (and winter with snowblowers) from people who did not do this. I also worked with plenty of Lawn cutting services who only bought 87 octane blended fuel that never had an issue. This is a topic that will be debated for quite some time to come, I'm sure.

If you are homeowner who only runs a few tanks a year through your equipment I would say you should buy fuel with no ethanol. If you use your equipment everyday it won't matter as long as you don't leave the fuel in while you store it over the winter. I myself am a typical homeowner now. I work on small engines for fun and to relax. I never drain my fuel over the winter, I only use the highest octane fuel I can find at the gas station and I never, ever have an issue starting my equipment come springtime. I made plenty of money each spring (and winter with snowblowers) from people who did not do this. I also worked with plenty of Lawn cutting services who only bought 87 octane blended fuel that never had an issue. This is a topic that will be debated for quite some time to come, I'm sure.

#11

Ric

I agree exotion it's more human error and failure to properly use and maintain your equipment that's way people have the problems they have, they just have to have something to blame. This ethanol thing is nothing more than a myth that was created by the oil company's. Ethanol is a bio-fuel which is a gas substitute and using it cuts the oil company's profits and they want you to think and believe it's the worst stuff in the world when in reality it doesn't hurt a thing. It doesn't hurt plastic, rubber fuel lines, seals or metal fuel tanks. All those thing have been approved to run 10% ethanol and have been for god knows how many years.

Ric

I believe your test would prove more human error and failure to properly use and maintain your equipment that's not proof.

I agree exotion it's more human error and failure to properly use and maintain your equipment that's way people have the problems they have, they just have to have something to blame. This ethanol thing is nothing more than a myth that was created by the oil company's. Ethanol is a bio-fuel which is a gas substitute and using it cuts the oil company's profits and they want you to think and believe it's the worst stuff in the world when in reality it doesn't hurt a thing. It doesn't hurt plastic, rubber fuel lines, seals or metal fuel tanks. All those thing have been approved to run 10% ethanol and have been for god knows how many years.

#12

R

Rivets

R

Rivets

Boy I'm glad that the lawn care specialists are such experts on the problems with todays fuels. You probably won't accept my proof, but it might help the average uneducated lawn specialists. About 4 years ago we started seeing equipment coming back four to five months after it has be in for routine tune-ups and complete check overs. Problems we were seeing, but confined to, surging, lean running engines, fuel line problems in two-cycle equipment. What we were finding was, gel in fuel bowls, corrosion of aluminum carb bodies, fuel lines and filters softening and breaking down in four cycle, hradening and breaking in two cycle. If you are in the repair business this is not how to keep customers. We tried everything that we knew to find what we were missing, doing wrong, or what is causing our problems. We had heard about people suggesting ethanol causing the problem and decided to change the fuel we used in the shop to non ethanol fuel and had a sticker made up to educate our customers which is put on every piece of equipment that leaves the shop. Since doing so we have cut our comebacks by over 90% and have also seen our business increase as more new customers are returning with different equipment which other dealers have not been able to repair. Most of them now use the non ethanol fuel in all of their small engine equipment and have told us that they are please with the way they running and now only see us for routine service.

Also, one of the small engine trade magazines just had an article by a VP at Briggs, who talked about the problems which engine manufacturers are having with the different fuels out there and what they are doing to find a solution.

Is this the proof you want, probably not, but for the average guy who reads this, it is a way which we have helped our customers and it only costs about $10.00 a year. (That's figuring 40 cents more per gallon for the customer who uses 25 gallons a year in their small engine equipment). To me that's cheap insurance.

For those that question whether we really have experience in our shop, there are four mechanics who have over 125 years in the service industry, with the lowest guy with only about 20. Certificates on our wall include those for working on 8 small engine manufacturers, 6 equipment manufactures ranging for saws to 140 HP tractors, so we are not a bunch of dumbos.

Is there a problem with ethanol in the small engine industry? It all depends on what you believe. I say yes and right now the solution for us is paying 40 cents more per gallon of gas.

Please. Remember to read my signature.

Also, one of the small engine trade magazines just had an article by a VP at Briggs, who talked about the problems which engine manufacturers are having with the different fuels out there and what they are doing to find a solution.

Is this the proof you want, probably not, but for the average guy who reads this, it is a way which we have helped our customers and it only costs about $10.00 a year. (That's figuring 40 cents more per gallon for the customer who uses 25 gallons a year in their small engine equipment). To me that's cheap insurance.

For those that question whether we really have experience in our shop, there are four mechanics who have over 125 years in the service industry, with the lowest guy with only about 20. Certificates on our wall include those for working on 8 small engine manufacturers, 6 equipment manufactures ranging for saws to 140 HP tractors, so we are not a bunch of dumbos.

Is there a problem with ethanol in the small engine industry? It all depends on what you believe. I say yes and right now the solution for us is paying 40 cents more per gallon of gas.

Please. Remember to read my signature.

#13

exotion

exotion

I am not doubting anyones experience... I would like to consider myself decent at repair rebuild small engines and equipment. And I read every post on this forum and I see a lot of blame on ethanol when I use it daily my family uses maybe 5 gallons a year with no winter draining that's a lot of sitting and they and I and so many others don't have any problems

#14

chobbs1957

Thanks for your opinion, Rivets. I like your blunt honesty. It's believable. :thumbsup:

chobbs1957

Boy I'm glad that the lawn care specialists are such experts on the problems with todays fuels. You probably won't accept my proof, but it might help the average uneducated lawn specialists. About 4 years ago we started seeing equipment coming back four to five months after it has be in for routine tune-ups and complete check overs. Problems we were seeing, but confined to, surging, lean running engines, fuel line problems in two-cycle equipment. What we were finding was, gel in fuel bowls, corrosion of aluminum carb bodies, fuel lines and filters softening and breaking down in four cycle, hradening and breaking in two cycle. If you are in the repair business this is not how to keep customers. We tried everything that we knew to find what we were missing, doing wrong, or what is causing our problems. We had heard about people suggesting ethanol causing the problem and decided to change the fuel we used in the shop to non ethanol fuel and had a sticker made up to educate our customers which is put on every piece of equipment that leaves the shop. Since doing so we have cut our comebacks by over 90% and have also seen our business increase as more new customers are returning with different equipment which other dealers have not been able to repair. Most of them now use the non ethanol fuel in all of their small engine equipment and have told us that they are please with the way they running and now only see us for routine service.

Also, one of the small engine trade magazines just had an article by a VP at Briggs, who talked about the problems which engine manufacturers are having with the different fuels out there and what they are doing to find a solution.

Is this the proof you want, probably not, but for the average guy who reads this, it is a way which we have helped our customers and it only costs about $10.00 a year. (That's figuring 40 cents more per gallon for the customer who uses 25 gallons a year in their small engine equipment). To me that's cheap insurance.

For those that question whether we really have experience in our shop, there are four mechanics who have over 125 years in the service industry, with the lowest guy with only about 20. Certificates on our wall include those for working on 8 small engine manufacturers, 6 equipment manufactures ranging for saws to 140 HP tractors, so we are not a bunch of dumbos.

Is there a problem with ethanol in the small engine industry? It all depends on what you believe. I say yes and right now the solution for us is paying 40 cents more per gallon of gas.

Please. Remember to read my signature.

Thanks for your opinion, Rivets. I like your blunt honesty. It's believable. :thumbsup:

#15

Ric

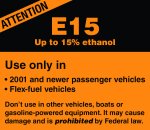

Well cheer up if you think your having problems now, wait until the E15 gets here. There already using it in cars in the midwest and they have been making FFVs since the 1980s and there dozens of models currently available, there running E85 and there are 10 Gas stations currently in the state of Florida that sell E 85 for FFvs so it's here.

From personal experience I've been running the ethanol gas in all my Stihl equipment, Honda, Briggs, Kohler and Kawasaki engines for the last six or seven years and I've never had an ethanol related issue.

Ric

Boy I'm glad that the lawn care specialists are such experts on the problems with todays fuels. You probably won't accept my proof, but it might help the average uneducated lawn specialists. About 4 years ago we started seeing equipment coming back four to five months after it has be in for routine tune-ups and complete check overs. Problems we were seeing, but confined to, surging, lean running engines, fuel line problems in two-cycle equipment. What we were finding was, gel in fuel bowls, corrosion of aluminum carb bodies, fuel lines and filters softening and breaking down in four cycle, hradening and breaking in two cycle. If you are in the repair business this is not how to keep customers. We tried everything that we knew to find what we were missing, doing wrong, or what is causing our problems. We had heard about people suggesting ethanol causing the problem and decided to change the fuel we used in the shop to non ethanol fuel and had a sticker made up to educate our customers which is put on every piece of equipment that leaves the shop. Since doing so we have cut our comebacks by over 90% and have also seen our business increase as more new customers are returning with different equipment which other dealers have not been able to repair. Most of them now use the non ethanol fuel in all of their small engine equipment and have told us that they are please with the way they running and now only see us for routine service.

Also, one of the small engine trade magazines just had an article by a VP at Briggs, who talked about the problems which engine manufacturers are having with the different fuels out there and what they are doing to find a solution.

Is this the proof you want, probably not, but for the average guy who reads this, it is a way which we have helped our customers and it only costs about $10.00 a year. (That's figuring 40 cents more per gallon for the customer who uses 25 gallons a year in their small engine equipment). To me that's cheap insurance.

For those that question whether we really have experience in our shop, there are four mechanics who have over 125 years in the service industry, with the lowest guy with only about 20. Certificates on our wall include those for working on 8 small engine manufacturers, 6 equipment manufactures ranging for saws to 140 HP tractors, so we are not a bunch of dumbos.

Is there a problem with ethanol in the small engine industry? It all depends on what you believe. I say yes and right now the solution for us is paying 40 cents more per gallon of gas.

Please. Remember to read my signature.

Well cheer up if you think your having problems now, wait until the E15 gets here. There already using it in cars in the midwest and they have been making FFVs since the 1980s and there dozens of models currently available, there running E85 and there are 10 Gas stations currently in the state of Florida that sell E 85 for FFvs so it's here.

From personal experience I've been running the ethanol gas in all my Stihl equipment, Honda, Briggs, Kohler and Kawasaki engines for the last six or seven years and I've never had an ethanol related issue.

#16

exotion

exotion

Also rivets I would like a link to that article you were talking about please I am interested in reading it

#17

Carscw

What make a lawn specialists uneducated?

When we talk about cutting grass we don't call you the uneducated service techs.

125 years in the service industry would make you very old. Just because there are 6 guys there with 20 years experience each does not mean you have 120 years experience.

I believe what you just said but you can not put the whole blame on ethanol. Many of us have been running e10 for years and have never had any problems from it. Just a guess but I would say around 70% of problems blamed on ethanol is more from lack of maintenance and not reading the manual.

This is one of them topics that will never have a ending just like what oil to use and how to sharping blades.

Ps if I insulted you in any way I did not mean to or try to.

(( cowboy up and get over it ))

Carscw

Boy I'm glad that the lawn care specialists are such experts on the problems with todays fuels. You probably won't accept my proof, but it might help the average uneducated lawn specialists. About 4 years ago we started seeing equipment coming back four to five months after it has be in for routine tune-ups and complete check overs. Problems we were seeing, but confined to, surging, lean running engines, fuel line problems in two-cycle equipment. What we were finding was, gel in fuel bowls, corrosion of aluminum carb bodies, fuel lines and filters softening and breaking down in four cycle, hradening and breaking in two cycle. If you are in the repair business this is not how to keep customers. We tried everything that we knew to find what we were missing, doing wrong, or what is causing our problems. We had heard about people suggesting ethanol causing the problem and decided to change the fuel we used in the shop to non ethanol fuel and had a sticker made up to educate our customers which is put on every piece of equipment that leaves the shop. Since doing so we have cut our comebacks by over 90% and have also seen our business increase as more new customers are returning with different equipment which other dealers have not been able to repair. Most of them now use the non ethanol fuel in all of their small engine equipment and have told us that they are please with the way they running and now only see us for routine service.

Also, one of the small engine trade magazines just had an article by a VP at Briggs, who talked about the problems which engine manufacturers are having with the different fuels out there and what they are doing to find a solution.

Is this the proof you want, probably not, but for the average guy who reads this, it is a way which we have helped our customers and it only costs about $10.00 a year. (That's figuring 40 cents more per gallon for the customer who uses 25 gallons a year in their small engine equipment). To me that's cheap insurance.

For those that question whether we really have experience in our shop, there are four mechanics who have over 125 years in the service industry, with the lowest guy with only about 20. Certificates on our wall include those for working on 8 small engine manufacturers, 6 equipment manufactures ranging for saws to 140 HP tractors, so we are not a bunch of dumbos.

Is there a problem with ethanol in the small engine industry? It all depends on what you believe. I say yes and right now the solution for us is paying 40 cents more per gallon of gas.

Please. Remember to read my signature.

What make a lawn specialists uneducated?

When we talk about cutting grass we don't call you the uneducated service techs.

125 years in the service industry would make you very old. Just because there are 6 guys there with 20 years experience each does not mean you have 120 years experience.

I believe what you just said but you can not put the whole blame on ethanol. Many of us have been running e10 for years and have never had any problems from it. Just a guess but I would say around 70% of problems blamed on ethanol is more from lack of maintenance and not reading the manual.

This is one of them topics that will never have a ending just like what oil to use and how to sharping blades.

Ps if I insulted you in any way I did not mean to or try to.

(( cowboy up and get over it ))

#18

R

Rivets

R

Rivets

First, I never talk about cutting lawns, edging, raking, etc. as you imply I do. I stick to what I know, engines and equipment. I stay away from those discussions and leave that to those in that business. Second, if you read my post, I said 4 mechanics, between the owner and me we have over 80 years. Those mechanics who have been around will tell you the the engine manufacturers have been talking about fuel and ethanol problems at update schools for the last 15 years.

Lawn care guys probably have not had the problem, because they go through more fuel in a week than the average guy does in a year. The fuel is not sitting around, but being used, just like in your vehicles. There are hundreds of people who come to this forum looking for answers, and you know that when I see info posted that could hurt them or their equipment, I am going to call out the poster. Insulted, no. Call me what you want, it will stick like water to a oily floor, which you'll slip on in the future if you don't clean it up. I stand by what I post and have hundreds of customers who have thanked us for preaching "non ethanol fuel".

To read about what I related to, just google "Briggs VP talks ethanol" and you will find plenty of articles. Even Consumer Reports say "ethanol can destroy small engines"

Lawn care guys probably have not had the problem, because they go through more fuel in a week than the average guy does in a year. The fuel is not sitting around, but being used, just like in your vehicles. There are hundreds of people who come to this forum looking for answers, and you know that when I see info posted that could hurt them or their equipment, I am going to call out the poster. Insulted, no. Call me what you want, it will stick like water to a oily floor, which you'll slip on in the future if you don't clean it up. I stand by what I post and have hundreds of customers who have thanked us for preaching "non ethanol fuel".

To read about what I related to, just google "Briggs VP talks ethanol" and you will find plenty of articles. Even Consumer Reports say "ethanol can destroy small engines"

#19

ILENGINE

ILENGINE

Ethanol does not cause small engine problems. There I said it. Ethanol is actually a solvent, which in other words is a cleaner. The problem with ethanol is its love for water. Ethanol can absorb up to 1% water before it separates out of the gas. which also lowers the octane of the fuel about 2 octane. The water contains desolved minerals that interact with the water and the ethanol and form a mild acid, similar to vinegar. The vinegar slime, water mix causes corrosion to aluminum and steel parts of engines, and with todays fine tuned, microscopic passage carbs, it takes very little corrosion to cause blockages of those passages.

The people that run large amounts of fuel through there equipment will not see problems with there engines. There is enough fuel exchanged to prevent phase separation, and the cleaning properties of the ethanol actually help remove any deposits that have accumulated. The problem is more pronounced in equipment that sets for periods of time, and I am not even sure that draining the fuel, which will leave a small amount of fuel in the carb, doesn't accelerate the problem in some cases, because of the added oxygen in the fuel due to the ethanol.

Twenty years ago techs such as myself were dealing with adjustable carbs, very little ethanol fuel available. but would see water in carbs, and fuel tanks, which if was allowed to set for a period of time would cause rust of metal parts. what we are seeing now is carbs are white internally, with aluminum oxide corrosion, and they look like the have been setting in an acid bath. The main thing that has changed with fuel over the period of time is the additional availablity of ethanol enriched fuel.

The fuel lines that are being used on most equipment are not designed for continuious exposure to solvents. Try putting a piece of fuel line in carb cleaner for a period of time and see what happens. it will either soften, swell if rubber, or harden and shrink if made from a plastic material.

The people that run large amounts of fuel through there equipment will not see problems with there engines. There is enough fuel exchanged to prevent phase separation, and the cleaning properties of the ethanol actually help remove any deposits that have accumulated. The problem is more pronounced in equipment that sets for periods of time, and I am not even sure that draining the fuel, which will leave a small amount of fuel in the carb, doesn't accelerate the problem in some cases, because of the added oxygen in the fuel due to the ethanol.

Twenty years ago techs such as myself were dealing with adjustable carbs, very little ethanol fuel available. but would see water in carbs, and fuel tanks, which if was allowed to set for a period of time would cause rust of metal parts. what we are seeing now is carbs are white internally, with aluminum oxide corrosion, and they look like the have been setting in an acid bath. The main thing that has changed with fuel over the period of time is the additional availablity of ethanol enriched fuel.

The fuel lines that are being used on most equipment are not designed for continuious exposure to solvents. Try putting a piece of fuel line in carb cleaner for a period of time and see what happens. it will either soften, swell if rubber, or harden and shrink if made from a plastic material.

#20

djdicetn

Between the experience in this and user ILENGINE's post, I am VERY comfortable with my position in this "debate" which is IMHO a personal choice with no right or wrong. As I see it the statement(s) that make the most sense is if you are in the lawn maintenance business and seldom have ethanol gasoline sit in a machine very long by all means use it. If you are a homeowner, like myself, you can take your chances with ethanol e10 gasoline or as aptly put burn non-ethanol as "an insurance policy". Actually, Rivet's first post is (1)posted on the Internet; (2)shows evidence of the adverse effects(necessary repairs and/or evidence of damages) before(using ethanol) and after(using non-ethanol) and (3)is what I would consider a reputable source of information. To me.....even without my less-than accurate test suggestion, that's proof enough based upon the OP's requirements.

djdicetn

First, I never talk about cutting lawns, edging, raking, etc. as you imply I do. I stick to what I know, engines and equipment. I stay away from those discussions and leave that to those in that business. Second, if you read my post, I said 4 mechanics, between the owner and me we have over 80 years. Those mechanics who have been around will tell you the the engine manufacturers have been talking about fuel and ethanol problems at update schools for the last 15 years.

Lawn care guys probably have not had the problem, because they go through more fuel in a week than the average guy does in a year. The fuel is not sitting around, but being used, just like in your vehicles. There are hundreds of people who come to this forum looking for answers, and you know that when I see info posted that could hurt them or their equipment, I am going to call out the poster. Insulted, no. Call me what you want, it will stick like water to a oily floor, which you'll slip on in the future if you don't clean it up. I stand by what I post and have hundreds of customers who have thanked us for preaching "non ethanol fuel".

To read about what I related to, just google "Briggs VP talks ethanol" and you will find plenty of articles. Even Consumer Reports say "ethanol can destroy small engines"

Between the experience in this and user ILENGINE's post, I am VERY comfortable with my position in this "debate" which is IMHO a personal choice with no right or wrong. As I see it the statement(s) that make the most sense is if you are in the lawn maintenance business and seldom have ethanol gasoline sit in a machine very long by all means use it. If you are a homeowner, like myself, you can take your chances with ethanol e10 gasoline or as aptly put burn non-ethanol as "an insurance policy". Actually, Rivet's first post is (1)posted on the Internet; (2)shows evidence of the adverse effects(necessary repairs and/or evidence of damages) before(using ethanol) and after(using non-ethanol) and (3)is what I would consider a reputable source of information. To me.....even without my less-than accurate test suggestion, that's proof enough based upon the OP's requirements.

#21

Carscw

Thank you sir.

I think now we can put this to rest as you have gave us the facts we have asked for.

You post was easy to read and understand.

Thank you for taking your time and putting this in away we can all understand.

(( cowboy up and get over it ))

Carscw

Ethanol does not cause small engine problems. There I said it. Ethanol is actually a solvent, which in other words is a cleaner. The problem with ethanol is its love for water. Ethanol can absorb up to 1% water before it separates out of the gas. which also lowers the octane of the fuel about 2 octane. The water contains desolved minerals that interact with the water and the ethanol and form a mild acid, similar to vinegar. The vinegar slime, water mix causes corrosion to aluminum and steel parts of engines, and with todays fine tuned, microscopic passage carbs, it takes very little corrosion to cause blockages of those passages.

The people that run large amounts of fuel through there equipment will not see problems with there engines. There is enough fuel exchanged to prevent phase separation, and the cleaning properties of the ethanol actually help remove any deposits that have accumulated. The problem is more pronounced in equipment that sets for periods of time, and I am not even sure that draining the fuel, which will leave a small amount of fuel in the carb, doesn't accelerate the problem in some cases, because of the added oxygen in the fuel due to the ethanol.

Twenty years ago techs such as myself were dealing with adjustable carbs, very little ethanol fuel available. but would see water in carbs, and fuel tanks, which if was allowed to set for a period of time would cause rust of metal parts. what we are seeing now is carbs are white internally, with aluminum oxide corrosion, and they look like the have been setting in an acid bath. The main thing that has changed with fuel over the period of time is the additional availablity of ethanol enriched fuel.

The fuel lines that are being used on most equipment are not designed for continuious exposure to solvents. Try putting a piece of fuel line in carb cleaner for a period of time and see what happens. it will either soften, swell if rubber, or harden and shrink if made from a plastic material.

Thank you sir.

I think now we can put this to rest as you have gave us the facts we have asked for.

You post was easy to read and understand.

Thank you for taking your time and putting this in away we can all understand.

(( cowboy up and get over it ))

#22

djdicetn

May not be the same article mentioned by Rivets, but here's an interesing read about the ethanol treatment Briggs developed(and why):

Briggs & Stratton develops ethanol additive

djdicetn

Also rivets I would like a link to that article you were talking about please I am interested in reading it

May not be the same article mentioned by Rivets, but here's an interesing read about the ethanol treatment Briggs developed(and why):

Briggs & Stratton develops ethanol additive

#23

exotion

This is a good post and definately calls for what I am asking for thank you.

exotion

Ethanol does not cause small engine problems. There I said it. Ethanol is actually a solvent, which in other words is a cleaner. The problem with ethanol is its love for water. Ethanol can absorb up to 1% water before it separates out of the gas. which also lowers the octane of the fuel about 2 octane. The water contains desolved minerals that interact with the water and the ethanol and form a mild acid, similar to vinegar. The vinegar slime, water mix causes corrosion to aluminum and steel parts of engines, and with todays fine tuned, microscopic passage carbs, it takes very little corrosion to cause blockages of those passages.

The people that run large amounts of fuel through there equipment will not see problems with there engines. There is enough fuel exchanged to prevent phase separation, and the cleaning properties of the ethanol actually help remove any deposits that have accumulated. The problem is more pronounced in equipment that sets for periods of time, and I am not even sure that draining the fuel, which will leave a small amount of fuel in the carb, doesn't accelerate the problem in some cases, because of the added oxygen in the fuel due to the ethanol.

Twenty years ago techs such as myself were dealing with adjustable carbs, very little ethanol fuel available. but would see water in carbs, and fuel tanks, which if was allowed to set for a period of time would cause rust of metal parts. what we are seeing now is carbs are white internally, with aluminum oxide corrosion, and they look like the have been setting in an acid bath. The main thing that has changed with fuel over the period of time is the additional availablity of ethanol enriched fuel.

The fuel lines that are being used on most equipment are not designed for continuious exposure to solvents. Try putting a piece of fuel line in carb cleaner for a period of time and see what happens. it will either soften, swell if rubber, or harden and shrink if made from a plastic material.

This is a good post and definately calls for what I am asking for thank you.

#24

Ric

Good article, I love the part Is Briggs exaggerating? I think like she says it's a house keeping issue :thumbsup:

Ric

May not be the same article mentioned by Rivets, but here's an interesting read about the ethanol treatment Briggs developed(and why):

Briggs & Stratton develops ethanol additive

Good article, I love the part Is Briggs exaggerating? I think like she says it's a house keeping issue :thumbsup:

#25

djdicetn

Yeah.....but "she" is vice president of technical services for the Renewable Fuels Association(and may be a little "biased towards ethanol" ya think:0). "She" also goes on to say...."failing to use a fuel stabilizer when outdoor power equipment is put in storage for months" is one of the causes of problems....just why would you need that???? You don't need it for non-ethanol.

No homeowner can feasibly protect any stored ethanol fuel from obtaining moisture over time, no matter how good their "housekeeping" is.

djdicetn

Good article, I love the part Is Briggs exaggerating? I think like she says it's a house keeping issue :thumbsup:

Yeah.....but "she" is vice president of technical services for the Renewable Fuels Association(and may be a little "biased towards ethanol" ya think:0). "She" also goes on to say...."failing to use a fuel stabilizer when outdoor power equipment is put in storage for months" is one of the causes of problems....just why would you need that???? You don't need it for non-ethanol.

No homeowner can feasibly protect any stored ethanol fuel from obtaining moisture over time, no matter how good their "housekeeping" is.

#27

B

Brucebotti

B

Brucebotti

I just wanted to make an observation about this post. I was amazed at how civil everyone was, especially since this is a controversial topic. That's why I value all the info I get from you guys (and gals). Keep up the great work..:thumbsup:

Bruce

Bruce

#28

djdicetn

djdicetn

Another ethanol-bashing comment......have you noticed the increase in the price of meat & dairy products since the proliferation of ethanol gasoline. Information I have gotten from Tennessee farmers that I know is that the competitive pricing for maintaining "corn-fed" stock with the biofuel producers scooping up huge corn crops have filtered down to the price they have to charge to market their products because of increased feed costs. That......2-4mpg less fuel mileage economy, "debatable" adverse affects on fuel systems.....can someone please tell what is GOOD about ethanol???? And don't tell me "environmental benefits"....my 1995 Chevy truck passed emissions testing before ethanol and actually, the only time it failed was with a post-ethanol annual MARTA test to renew the tags(good ole SeaFoam cured that failed test). Also......have you noticed how many "gas treatment products" have come to market over the last few years(since ethanol became widespread) with the intention of helping your vehicle pass the emission tests(what's up with that:0)

#29

chobbs1957

The price pressure that ethanol has put on corn is but one factor in food prices.

I see some blaming ethanol for global warming, too. Ethanol is what they are using as an alternative to MTBE as an oxygenate in the refining of gasoline. I don't pretend to understand all that that means, but they have to add something like to the gas. MTBE is equally effective, but is somehow not as "environmentally friendly" as ethanol.

chobbs1957

Another ethanol-bashing comment......have you noticed the increase in the price of meat & dairy products since the proliferation of ethanol gasoline. Information I have gotten from Tennessee farmers that I know is that the competitive pricing for maintaining "corn-fed" stock with the biofuel producers scooping up huge corn crops have filtered down to the price they have to charge to market their products because of increased feed costs.... that:0)

The price pressure that ethanol has put on corn is but one factor in food prices.

- There have been some major crop failures in grains, for example, here last year and abroad sporadically the last few years.

- Increases in the standard of living and growing populations in countries like India and China have increased demand for higher protein foods, specifically meat products.

- Freight costs have gone up over the last 6-8 years as fuel prices have jumped.

I see some blaming ethanol for global warming, too. Ethanol is what they are using as an alternative to MTBE as an oxygenate in the refining of gasoline. I don't pretend to understand all that that means, but they have to add something like to the gas. MTBE is equally effective, but is somehow not as "environmentally friendly" as ethanol.

#30

G

ghper

I live 4 miles from on of those "awful" ethanol plants. I know that more than 50 semi loads of distillers grains come out of that plant daily and go right to the feedlots within 100 miles of the plant. Highly concentrated feed that replaces corn. Ethanol can not be blamed

for everything. My great aunt developed a limp due to ethanol, she tried to kick a gas can that had 10% in it!!!!! I have used nothing but ethanol in my JD 180 with a Kawasaki engine in it that's 30 years old, never drain the tank over winter, and have never had the engine worked on. Same thing with my 2 cycle 25 year old string trimmer. I even had the courage to run it through my rebuilt 72 Nova, NO PROBLEM!!!!

G

ghper

Another ethanol-bashing comment......have you noticed the increase in the price of meat & dairy products since the proliferation of ethanol gasoline. Information I have gotten from Tennessee farmers that I know is that the competitive pricing for maintaining "corn-fed" stock with the biofuel producers scooping up huge corn crops have filtered down to the price they have to charge to market their products because of increased feed costs. That......2-4mpg less fuel mileage economy, "debatable" adverse affects on fuel systems.....can someone please tell what is GOOD about ethanol???? And don't tell me "environmental benefits"....my 1995 Chevy truck passed emissions testing before ethanol and actually, the only time it failed was with a post-ethanol annual MARTA test to renew the tags(good ole SeaFoam cured that failed test). Also......have you noticed how many "gas treatment products" have come to market over the last few years(since ethanol became widespread) with the intention of helping your vehicle pass the emission tests(what's up with that:0)

I live 4 miles from on of those "awful" ethanol plants. I know that more than 50 semi loads of distillers grains come out of that plant daily and go right to the feedlots within 100 miles of the plant. Highly concentrated feed that replaces corn. Ethanol can not be blamed

for everything. My great aunt developed a limp due to ethanol, she tried to kick a gas can that had 10% in it!!!!! I have used nothing but ethanol in my JD 180 with a Kawasaki engine in it that's 30 years old, never drain the tank over winter, and have never had the engine worked on. Same thing with my 2 cycle 25 year old string trimmer. I even had the courage to run it through my rebuilt 72 Nova, NO PROBLEM!!!!

#31

G

GregGA

I haven't had any ethanol problems either. However I found an E0 90 octane station close to me. Since some of my OPE specifies 89 octane, I am switching to E0. It's something like 25 cents a gallon more, so no big deal. Nothing to lose.

G

GregGA

No ethanol problems here i only buy 90 octane ethanol free gasoline

I haven't had any ethanol problems either. However I found an E0 90 octane station close to me. Since some of my OPE specifies 89 octane, I am switching to E0. It's something like 25 cents a gallon more, so no big deal. Nothing to lose.

#32

P

possum

P

possum

Humidity can play a large part in ethanol problems. My dealer like to show off the ruined carbs. I looked a string trimmer yesterday at a neighbors. The fuel he drained from the tank was about two thirds fuel mix and one third water. It had been filled from an almost empty five gallon fuel container that still looked brand new but had fuel in it from the year before. The amazing thing was the trimmer started and ran for a minute or so. The carb is white pitted metal with rust scattered through it. Some portions of the metal is just gone.

#33

Ric

Question what and why does Humidity have to do with ethanol problems.

Ric

Humidity can play a large part in ethanol problems. My dealer like to show off the ruined carbs. I looked a string trimmer yesterday at a neighbors. The fuel he drained from the tank was about two thirds fuel mix and one third water. It had been filled from an almost empty five gallon fuel container that still looked brand new but had fuel in it from the year before. The amazing thing was the trimmer started and ran for a minute or so. The carb is white pitted metal with rust scattered through it. Some portions of the metal is just gone.

Question what and why does Humidity have to do with ethanol problems.

#34

exotion

I agree I don't see the connection.

So far what I have seen here is ethanol has the potential to be a problem if the person using ethanol gas is unaware of how to use it. You cannot leave it sitting to long without use. That being said you cannot leave oil to long either so why would you leave gas? comes down to maintenance.

If you cannot maintain or pay to have your machine maintained you should own said machine you need to hire out.

exotion

Question what and why does Humidity have to do with ethanol problems.

I agree I don't see the connection.

So far what I have seen here is ethanol has the potential to be a problem if the person using ethanol gas is unaware of how to use it. You cannot leave it sitting to long without use. That being said you cannot leave oil to long either so why would you leave gas? comes down to maintenance.

If you cannot maintain or pay to have your machine maintained you should own said machine you need to hire out.

#35

chobbs1957

:confused2: My head is spinning with some of these pretty wise comments, comments from posters with lots of obvious common sense and lots of experience.

Anyhoos, as for the relationship between humidity and ethanol, my logic:

Ethanol "attracts" moisture THEREFORE high humidity = high probability of condensation (like fog and dew) THEREFORE condensation + oxygen = high probability of problems like rust

chobbs1957

Question what and why does Humidity have to do with ethanol problems.

:confused2: My head is spinning with some of these pretty wise comments, comments from posters with lots of obvious common sense and lots of experience.

Anyhoos, as for the relationship between humidity and ethanol, my logic:

Ethanol "attracts" moisture THEREFORE high humidity = high probability of condensation (like fog and dew) THEREFORE condensation + oxygen = high probability of problems like rust

#36

Ric

Well if your logic holds true than me of all people should have more problems than anyone. Considering where I live is seldom below about 96% to 100% humidity at night and most times during the day is in the 75 to 80% range. IT's 7:00am now, Brandon 100% humidity, Orlando =91%, Sarasota =96%, Brooksville 100%, Winter Haven =93% just to name a few. So due to the fact that I've been running all types of Lawn equipment for years without any issue with ethanol what conclusion should I draw?

Ric

:confused2: My head is spinning with some of these pretty wise comments, comments from posters with lots of obvious common sense and lots of experience.

Anyhoos, as for the relationship between humidity and ethanol, my logic:

Ethanol "attracts" moisture THEREFORE high humidity = high probability of condensation (like fog and dew) THEREFORE condensation + oxygen = high probability of problems like rust

Well if your logic holds true than me of all people should have more problems than anyone. Considering where I live is seldom below about 96% to 100% humidity at night and most times during the day is in the 75 to 80% range. IT's 7:00am now, Brandon 100% humidity, Orlando =91%, Sarasota =96%, Brooksville 100%, Winter Haven =93% just to name a few. So due to the fact that I've been running all types of Lawn equipment for years without any issue with ethanol what conclusion should I draw?

#37

ILENGINE

I think there may be some sense to this, but I think it may be more related to temperature variations. Large swings in temperature variation, due to expansion and contraction may play a part due to air exchange in unsealed containers.

Years ago there was a problem with water condensing in fuel containers, and I always asked how the water got in there. And was always told condensation. And I always asked how the condensation got inside of a seal container. And they could never answer that questions.

ILENGINE

:confused2: My head is spinning with some of these pretty wise comments, comments from posters with lots of obvious common sense and lots of experience.

Anyhoos, as for the relationship between humidity and ethanol, my logic:

Ethanol "attracts" moisture THEREFORE high humidity = high probability of condensation (like fog and dew) THEREFORE condensation + oxygen = high probability of problems like rust

I think there may be some sense to this, but I think it may be more related to temperature variations. Large swings in temperature variation, due to expansion and contraction may play a part due to air exchange in unsealed containers.

Years ago there was a problem with water condensing in fuel containers, and I always asked how the water got in there. And was always told condensation. And I always asked how the condensation got inside of a seal container. And they could never answer that questions.

#38

Ric

ILENGINE Your right, temperature variations, due to expansion and contraction cause condensation. We've had problems with water in gas long before Ethanol or Bio-fuels were ever thought of so to blame Ethanol for the problem I think is a little strange to say the least.

Ric

I think there may be some sense to this, but I think it may be more related to temperature variations. Large swings in temperature variation, due to expansion and contraction may play a part due to air exchange in unsealed containers.

Years ago there was a problem with water condensing in fuel containers, and I always asked how the water got in there. And was always told condensation. And I always asked how the condensation got inside of a seal container. And they could never answer that questions.

ILENGINE Your right, temperature variations, due to expansion and contraction cause condensation. We've had problems with water in gas long before Ethanol or Bio-fuels were ever thought of so to blame Ethanol for the problem I think is a little strange to say the least.

#39

djdicetn

Question(s).......when, not if, the EPA forces E15 ethanol sales on the masses will you burn that readily available fuel in your existing equipment without hesitation........OR.......will you seek out E10 that you have been using without problems "if" it is still avaialble???? If you answer that you will seek out E10, what's the difference in that and those of us now seeking out ethanol-free???

djdicetn

ILENGINE Your right, temperature variations, due to expansion and contraction cause condensation. We've had problems with water in gas long before Ethanol or Bio-fuels were ever thought of so to blame Ethanol for the problem I think is a little strange to say the least.

Question(s).......when, not if, the EPA forces E15 ethanol sales on the masses will you burn that readily available fuel in your existing equipment without hesitation........OR.......will you seek out E10 that you have been using without problems "if" it is still avaialble???? If you answer that you will seek out E10, what's the difference in that and those of us now seeking out ethanol-free???

#40

Ric

If the EPA has there way and if they decide on E15 instead of just jumping to the E85, What I'll use will be decided by the equipment I'm using. When and if E15 hits the market I would guess that they would already have the equipment for it's use already for sale so I would be replacing what I have with new if the old couldn't be converted. As far as me seeking out the E10.... No...I wouldn't look for it or go out of my way to find it anymore than I have for ethanol free gas, In my opinion seeking out Ethanol free gas to run when I have equipment that is very capable of running E10 is ridiculous and a waste of time and money and not away to show a larger profit for the business, say nothing about trying to explain it to an auditor why I'm doing that when I get deductions on gas use.

The thing I think that bothers me is the E85 that's already available and being sold at stations for FFV's. As I said there are 10 stations in Florida now that have and sell E85 and almost 3000 stations throughout the country. Ford, GM and Dodge have had FFV's on the market since the early 1980's that would run and use E85 and are using it now, so tell me why the EPA should even consider using E15, people may be in for a rude awakening.

Ric

Question(s).......when, not if, the EPA forces E15 ethanol sales on the masses will you burn that readily available fuel in your existing equipment without hesitation........OR.......will you seek out E10 that you have been using without problems "if" it is still avaialble???? If you answer that you will seek out E10, what's the difference in that and those of us now seeking out ethanol-free???

If the EPA has there way and if they decide on E15 instead of just jumping to the E85, What I'll use will be decided by the equipment I'm using. When and if E15 hits the market I would guess that they would already have the equipment for it's use already for sale so I would be replacing what I have with new if the old couldn't be converted. As far as me seeking out the E10.... No...I wouldn't look for it or go out of my way to find it anymore than I have for ethanol free gas, In my opinion seeking out Ethanol free gas to run when I have equipment that is very capable of running E10 is ridiculous and a waste of time and money and not away to show a larger profit for the business, say nothing about trying to explain it to an auditor why I'm doing that when I get deductions on gas use.

The thing I think that bothers me is the E85 that's already available and being sold at stations for FFV's. As I said there are 10 stations in Florida now that have and sell E85 and almost 3000 stations throughout the country. Ford, GM and Dodge have had FFV's on the market since the early 1980's that would run and use E85 and are using it now, so tell me why the EPA should even consider using E15, people may be in for a rude awakening.

#41

djdicetn

I am thoroughly convinced that it makes absolutely no sense for someone(like you) that mows commercially to use non-ethanol gas for the many logical reasons you have given(and the fact that you go through gas so quickly the chances of having fuel system problems is slim or none). I still contend that for homeowners that mow weekly at best there is still a strong argument towards burning the non-ethanol. You may be right about E85 becoming the norm before E15 is even considered. And most likely E10 would continue to be marketed for "pre-FFV" equipment. If they completely do away with non-ethanol(also a very good possibility) I guess I'll use E10 with Stabil and once-a-season SeaFoam treatment:0(

P.S.

of course, they will probably "gouge the consumer price-wise" for E10 after E85 dominates just like they are doing now with non-ethanol:0(

djdicetn

If the EPA has there way and if they decide on E15 instead of just jumping to the E85, What I'll use will be decided by the equipment I'm using. When and if E15 hits the market I would guess that they would already have the equipment for it's use already for sale so I would be replacing what I have with new if the old couldn't be converted. As far as me seeking out the E10.... No...I wouldn't look for it or go out of my way to find it anymore than I have for ethanol free gas, In my opinion seeking out Ethanol free gas to run when I have equipment that is very capable of running E10 is ridiculous and a waste of time and money and not away to show a larger profit for the business, say nothing about trying to explain it to an auditor why I'm doing that when I get deductions on gas use.

The thing I think that bothers me is the E85 that's already available and being sold at stations for FFV's. As I said there are 10 stations in Florida now that have and sell E85 and almost 3000 stations throughout the country. Ford, GM and Dodge have had FFV's on the market since the early 1980's that would run and use E85 and are using it now, so tell me why the EPA should even consider using E15, people may be in for a rude awakening.

I am thoroughly convinced that it makes absolutely no sense for someone(like you) that mows commercially to use non-ethanol gas for the many logical reasons you have given(and the fact that you go through gas so quickly the chances of having fuel system problems is slim or none). I still contend that for homeowners that mow weekly at best there is still a strong argument towards burning the non-ethanol. You may be right about E85 becoming the norm before E15 is even considered. And most likely E10 would continue to be marketed for "pre-FFV" equipment. If they completely do away with non-ethanol(also a very good possibility) I guess I'll use E10 with Stabil and once-a-season SeaFoam treatment:0(

P.S.

of course, they will probably "gouge the consumer price-wise" for E10 after E85 dominates just like they are doing now with non-ethanol:0(

#42

jekjr

jekjr

All I low is the techs at both local dealers who sell Stihl tell us that Stihl warns against using it. One tech told me that not to even use a can that had previously had 10% in it. I run 93 octane non ethanol in every thing I have that is gas but my Kubota 222. It has over 200 hours on it and has had no problems so far. The reason I do not run the non ethanol in it is the availability. The places we normally fuel that have off road diesel which I run in my 326 don't have non ethanol. We use a covered trailer and have to unload to fuel. The book says no more than 10% and we fill it often so I go with the flow.

I did run my hand held equipment on it when we started up last summer. I had some carb problems on my cub cadet trimmer early this spring. We used it basically all winter too because it was a split pole and we used th pole saw and other attachments on it basically all winter.

I did run my hand held equipment on it when we started up last summer. I had some carb problems on my cub cadet trimmer early this spring. We used it basically all winter too because it was a split pole and we used th pole saw and other attachments on it basically all winter.

#43

M

marvinlee

M

marvinlee

The best single source of information that I know of is the Coordinating Research Council, Inc. (CRC) of 3650 Mansell Road, Suite 140, Alpharetta, GA 30022. Their best known report is CRC Project CM-136-09-1B, titled,all in capital letters, INTERMEDIATE-LEVEL ETHANOL BLENDS ENGINE DURABILITY STUDY, April 2012. This 97 page report, of which I have two copies, tests ethanol blends in several different engines. Some operated with few problems, others suffered premature engine wear reflected, for some, in valve leakage and high pressure testing leakdown rates. I refer you to the full report for more details.

The report was followed by criticism from both the US Energy Department and various ethanol-advocate groups. Their criticism focused on 1) the fact that one of the several engines tested failed, also, on ordinary gasoline and 2) that the engines were subjected to unusual testing stringency that is not normal to ordinary real-life engine use. The criticism was followed by a strong rebuttal from the CRC.

My best interpretation is that ethanol performs adequately in most engines, most of the time, but that certain operating conditions that are not yet well defined can result in engine problems for some engines. That is pretty vague, and probably has to be considering the hundreds of millions of engines of all ages and accumulated hours in operation and the vast variations in how they are used, stored, fueled, and maintained.

I don't attach much broad importance to personal experience. For what little it is worth, I've used Oregon's 10% ethanol blend in, among others, a 40-year old garden tractor with a cast-iron Briggs and Stratton 32-cubic inch engine which is normally operated at full throttle and RPM; seven different chainsaws of varied age and engine time, an old Cadillac with the cast-iron V8 engine designed back in the 1950's, a late model Subaru with the naturally aspirated six cylinder engine, a four-cycle Honda and a four-cycle Dolmar water pump, both of which operate at full RPM when used. They are stored most of the time without draining fuel beforehand. In past years, we have used ethanol fuel in a Suzuki six cylinder car with Alusil cylinders, where the cylinders are the base aluminum alloy etched to reveal silicon crystals which provide the wearing surface. In all these engines, and several that I've forgotten, we had no observable problems with Oregon's ethanol fuel. A friend who does considerable chainsawing refuses to use any ethanol fuel in his chainsaws and pays a high price for specialty ethanol-free, high octane fuel, which is legal for some uses in Oregon. I hope that all of the above helps shed some light on the real complexity of the ethanol fuel issue.