You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Impact driver vs impact wrench

- Thread starter rigoletto

- Start date

More options

Export threadYes, they can be rebuilt.

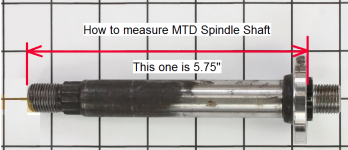

The point myself and others are trying to make is that one part may not be exactly like the original part. For instance, the shaft length or overall length may be slightly different that the original part. Say that you have two or three blades and you replace one spindle that is not exactly the same length as the originals. The results can be a stepped cut of your yard.

The point myself and others are trying to make is that one part may not be exactly like the original part. For instance, the shaft length or overall length may be slightly different that the original part. Say that you have two or three blades and you replace one spindle that is not exactly the same length as the originals. The results can be a stepped cut of your yard.

Got the new shaft, and it fits nicely. Now, when I dry fit the new blade onto the bottom sprocket, then thread the old nut on it the nut bottoms out before masking a snug contact to the bottom of the blade. I dont ever remember there being a washer between nut and blade to take up the void space of about 1/16" or so. Maybe Im remembering wrong(?). Opinions?

Thanks.

Thanks.

StarTech

Lawn Royalty

- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,817

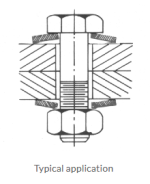

I supposed like the Gravely that I am working on this last week and the coming where they have Bellevue washers with the screw (bolt) being torqued anywhere from 115 to 125 lbf-ft (156 to 169 N•m).I said good mowers, not cheap mowers.

Pre-stressed disc springs are used to maintain load or tension in bolted assemblies. Pressure begins at the outer radius and flattens gradually toward the bolt as deflection progresses. Disc springs exert a uniform pressure that remains constant despite tension losses caused by thermal expansion and contraction, compression set or wear of parts. Because pressures are predictable, disc springs provide a simple and effective means of determining bolt tension that is far more accurate than "torque" readings.

Wow, 95 lbs, never knew that. I always just tightened it up as best I could. I doubt it was 95 lbs. That is like the lug nut on my GM car!MTD uses a 5/8-18 Flange Nut with has a built in recess. Torqued to 95 ft/lbs.

View attachment 61222View attachment 61223

No need for an additional washer.

StarTech

Lawn Royalty

- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,817

MTD actually specs these as being torqued to 70-90 ft/lbs per their service manual but I always tighten them to 95 ft/lbs as I had them to come loose at 90 ft/lbs.Wow, 95 lbs, never knew that. I always just tightened it up as best I could. I doubt it was 95 lbs. That is like the lug nut on my GM car!

Hammermechanicman

Lawn Addict

- Joined

- Jan 10, 2020

- Threads

- 69

- Messages

- 3,927

The big question is how many ugga duggas on the impact is 90 ft/lbs?