I've learned "no more Husq's anything", through their chainsaw engine's "eating pistons & cylinders". Yes junk!I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head gasket

- Thread starter Oarhead

- Start date

More options

Export threadCheck the valve clearance, double check torque on head bolts.I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

Once again this is CAR technology being blindly applied to mowers where it does not necessarily hold.Wow generations of engineers have been wrong - what I suggested in the recommended procedure that's been taught since engines were invented. Heads only ever warp by a few thou and half an hour using glass and grinding paste will leave the surface perfectly flat. If half an hour is too long for you, pay a professional to do it properly rather than b' it up with a five minute bodge.

Not many car engines blow head gaskets on alloy block alloy head engines between the cylinder & pushrod tube .

In the case of these engines it is not head warp it is EROSION of the bridge which can be anything from 0.0005" to 0.030" ( worst one I have had in the shop ) .

Sorting this out with lapping paste will take a month of Sundays particularly as in many cases it will be in both the head & the barrel

In many case owners just put up with the leak till the mower will no longer start then they bring it to me & tell me "it has been making funny noises when I turn the blades on for the past 3 or 4 years but it sorts itself out after a few minutes"

Not sure who you're responding to but this is a lengthy process. I have stated in a couple of posts that I use well over 500 to 600 strokes to get one to where it looks pretty uniform and all the high spots are knocked down.Wow generations of engineers have been wrong - what I suggested in the recommended procedure that's been taught since engines were invented. Heads only ever warp by a few thou and half an hour using glass and grinding paste will leave the surface perfectly flat. If half an hour is too long for you, pay a professional to do it properly rather than b' it up with a five minute bodge.

My point and response to you was I don't think you'd ever get done just using valve compound and plus that stuff's very expensive. You claim that there were lots of wrong responses in this thread and that sandpaper was one of them and several good ways to ruin a perfectly good head which I completely disagree with.

There are several ways to end up with the same result desired which is a head that is flatter and what you begin with..

It certainly is very time consuming and the last time I counted I was between $500 and 600 strokes but I have no problem with going in straight lines as long as you're rotating the head frequently which I typically do quarter turn rotations after every 30 or 40 strokes..How are you lapping your surfaces?

I got hold of a good sized chunk of marble counter top. I spread out some valve lapping compound on the marble (med grit), along with a bit on the head or block (whatever I'm wanting to make flat) then start in using random orbital motion. Using no consistent pattern, go in an oval clockwise, then counter clockwise, then throw in a circular motion, a figure 8, whatever motion comes to mind EXCEPT FOR straight line back and forth. That's a big NO NO !

Every 5 - 7 minutes or so, stop and clean off your surface with Brakleen or whatever. If you have a low spot, it WILL show up. If so, go back at it.

It's time consuming, and it'll give you a work out, but it WILL be flat when you're done !

Once all is flat, give everything a thorough cleaning. Remember to get all of the lapping compound cleaned out as it IS a cutting agent. Follow all the other steps and that engine should run better than ever !!

I also do circles and diagonals and everything else because it gets pretty boring when you're doing it. It helps to have a good song going at a proper pace to keep up the tempo!

Make sure you alternate arms too because that way you get an equal workout. Lol

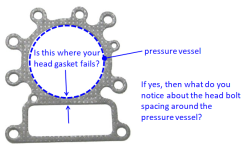

It's an obvious design flaw that's been known for decades but Briggs refused to fix it.

Some manufacturers even put a bolt in the middle there that would even go through and protrude into the intake runner which would be just fine.

All you have to do is have the right length bolt to where it comes out pretty much at the end and the turbulence etc is not going to be worth mentioning especially not compared to repeated blowing of gaskets because of too much distance between the two right bolt holes.

bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

Sand paper might mean some thing different in the USA

Down here is means just that, screened sand glued to paper used on plastics & wood

Wet & dry is what you use for lapping and by prefference on a flat but sloped surface with water feed to the top to lubricate the sheet & wash away the debris .

Automotive engines usually fail between cylinders so the engine will not start so it is not run in the damaged condition for very long

Or that fail between the cylinder & water jacket, same thing, boiled engine shut down before major damage is done

Mower engines are often run for years with a failed gasket till eventually they can not be made to start even with starter fluid .

Down here is means just that, screened sand glued to paper used on plastics & wood

Wet & dry is what you use for lapping and by prefference on a flat but sloped surface with water feed to the top to lubricate the sheet & wash away the debris .

Automotive engines usually fail between cylinders so the engine will not start so it is not run in the damaged condition for very long

Or that fail between the cylinder & water jacket, same thing, boiled engine shut down before major damage is done

Mower engines are often run for years with a failed gasket till eventually they can not be made to start even with starter fluid .

Funny you should mention that about putting the bolt in the middle. I finally got tired of replacing head gaskets and a flywheel that cracked off a piece at the keyway and replaced it with a JD labelled engine, just so I could sell it. A few weeks after it left for it's new home I went to visit a friend, who had just purchased the same model tractor. Within a few months he had similar issues. Being an even more stubborn person than myself, he drilled & tapped a hole in the block and a clearance hole in the head for either a .190 or .250 bolt (Inco718, of course). That actually fixed the problem for several years.It's an obvious design flaw that's been known for decades but Briggs refused to fix it.

Some manufacturers even put a bolt in the middle there that would even go through and protrude into the intake runner which would be just fine.

All you have to do is have the right length bolt to where it comes out pretty much at the end and the turbulence etc is not going to be worth mentioning especially not compared to repeated blowing of gaskets because of too much distance between the two right bolt holes.