You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Head gasket

#1

O

Oarhead

O

Oarhead

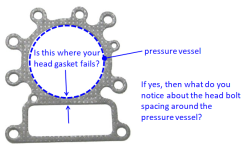

I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#2

S

slomo

S

slomo

1.Have you thought about lapping the head and block face where the gasket goes?

2.Torquing and retorquing the head bolts a few times after the job is done?

3.Cleaning the bolt holes out with a bottom tap?

4.Cleaning the bolt threads off with a die?

5.Spraying a little high tack sealant on the gasket prior to installing?

You know, doing the job proper?

2.Torquing and retorquing the head bolts a few times after the job is done?

3.Cleaning the bolt holes out with a bottom tap?

4.Cleaning the bolt threads off with a die?

5.Spraying a little high tack sealant on the gasket prior to installing?

You know, doing the job proper?

#3

O

Oarhead

O

Oarhead

I've actually done all of the above. Soooo....yea ....proper...along with an engine degrease and power wash. Same spot on ggasket.

#5

StarTech

StarTech

Now I am assume 18.5 single cylinder here.

Are you torquing in the sequence shown in the service manual use three step torque procedure to 21 ft/lbs. Service manual has it 220 in-lbs / 18.3 ft/lbs but Brigg increased it to 250 in-lbs / 20.8 (IE 21 ft-lbs) due head gasket failures.

Are you torquing in the sequence shown in the service manual use three step torque procedure to 21 ft/lbs. Service manual has it 220 in-lbs / 18.3 ft/lbs but Brigg increased it to 250 in-lbs / 20.8 (IE 21 ft-lbs) due head gasket failures.

#6

F

Forest#2

F

Forest#2

How long does a head gasket usually last on your engine? (average time, like one hour, one day, or a year???)

The head and or block is either warped or as startech indicates you are not torqueing the head bolts PROPERLY.

With patience you should be able to check the head and block for warpage.

Also if it has a small dip or groove in the aluminum where it is burning through is not a good thing.

That area you describe is a wimpy place for the single cylinder Briggs Intek engines, some last forever, some don't and proceed by the book (service manual) when replacing the head gasket on those type. Make sure all the cooling fins and flywheel plastic fins are in place. Do not test run the engine over few seconds with the cooling shroud removed.

If all else fails try two heads gaskets.

The head and or block is either warped or as startech indicates you are not torqueing the head bolts PROPERLY.

With patience you should be able to check the head and block for warpage.

Also if it has a small dip or groove in the aluminum where it is burning through is not a good thing.

That area you describe is a wimpy place for the single cylinder Briggs Intek engines, some last forever, some don't and proceed by the book (service manual) when replacing the head gasket on those type. Make sure all the cooling fins and flywheel plastic fins are in place. Do not test run the engine over few seconds with the cooling shroud removed.

If all else fails try two heads gaskets.

#7

S

slomo

S

slomo

He's already done all these items.How long does a head gasket usually last on your engine? (average time, like one hour, one day, or a year???)

The head and or block is either warped or as startech indicates you are not torqueing the head bolts PROPERLY.

With patience you should be able to check the head and block for warpage.

Also if it has a small dip or groove in the aluminum where it is burning through is not a good thing.

That area you describe is a wimpy place for the single cylinder Briggs Intek engines, some last forever, some don't and proceed by the book (service manual) when replacing the head gasket on those type. Make sure all the cooling fins and flywheel plastic fins are in place. Do not test run the engine over few seconds with the cooling shroud removed.

If all else fails try two heads gaskets.

#8

S

slomo

S

slomo

Every Briggs head I've removed is not flat. Not even close. Engine block face the same. Once a year I clean the cooling fins and change the oil. Check torque on the head bolts. Always find a couple or more that will turn a bit.

#9

F

Forest#2

F

Forest#2

He also asked:

Are these engines junk?

Post up the engine ID info for a more precise Yes or No.

Are these engines junk?

Post up the engine ID info for a more precise Yes or No.

#11

O

Ocean909

O

Ocean909

Are these OEM gaskets? I know its tempting to buy the aftermarket considering the price

#12

sgkent

sgkent

checking the head and block for straightness with a machinists straight edge should be done anytime there is a blown head gasket. If the old one was solid and the head and piston were just decarbonized, then there would not be a need for it, but with a blown head gasket there is often something warped.

#13

B

bertsmobile1

B

bertsmobile1

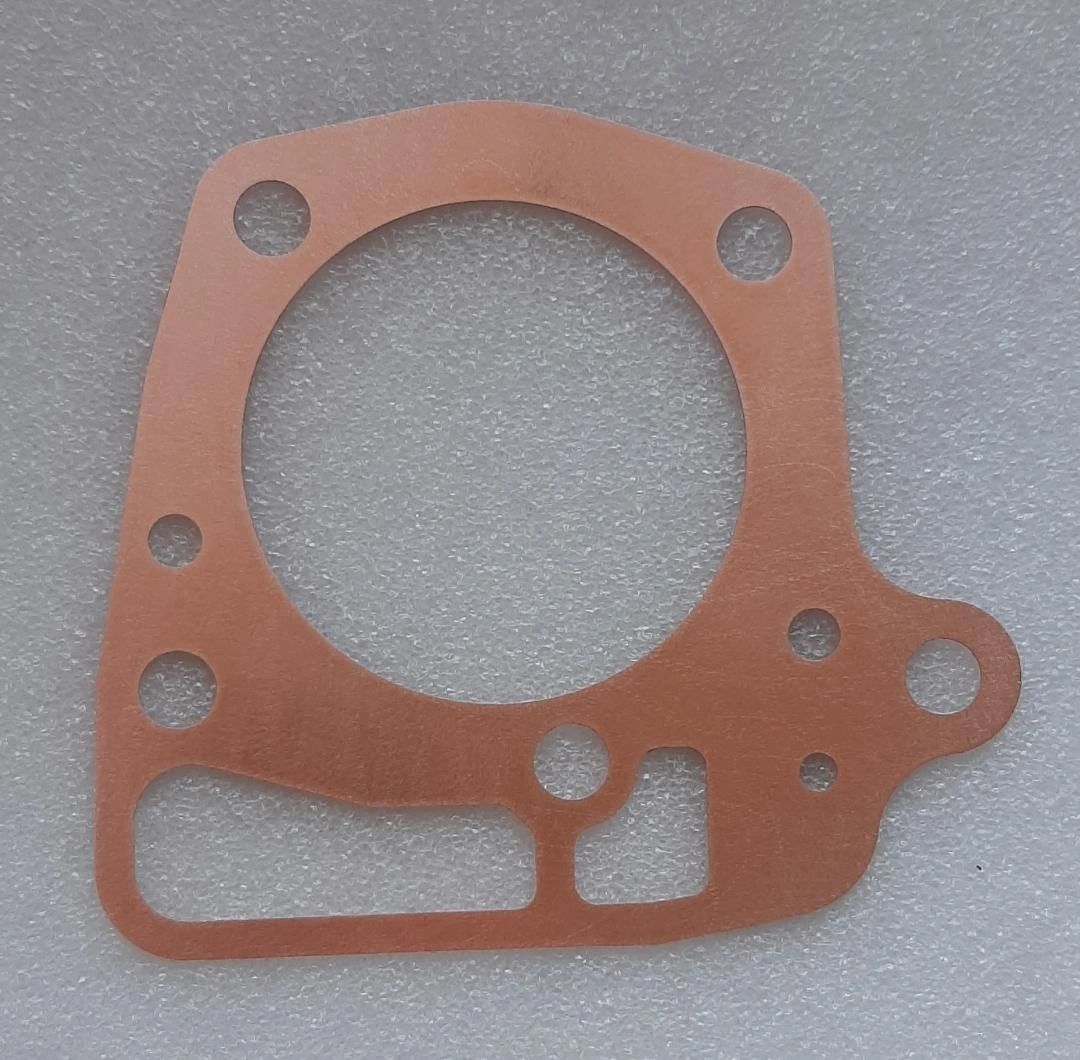

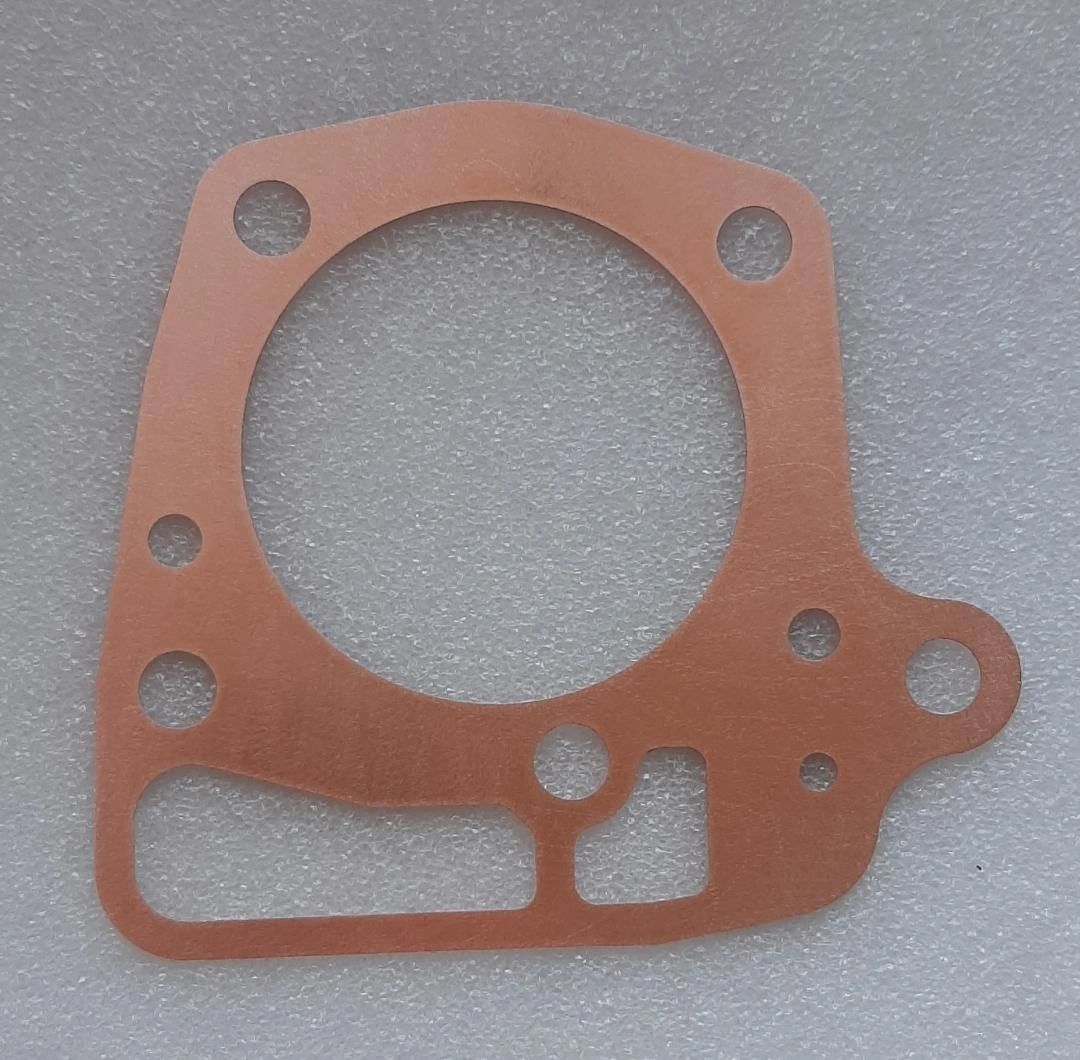

Go to CopperGasketsUS.

Speak to Lanni ( wonderful bloke )

Get one of his full copper head gaskets

Problem solved

Once fitted make sure you put an in line fuel tap and that you use it

The head gaskets are deliberately weak so that in the case of a hydro lock the gasket blows rather then bending a rod or cracking the head .

Fairly sure he does a stock line of various intek head gaskets .

Speak to Lanni ( wonderful bloke )

Get one of his full copper head gaskets

Problem solved

Once fitted make sure you put an in line fuel tap and that you use it

The head gaskets are deliberately weak so that in the case of a hydro lock the gasket blows rather then bending a rod or cracking the head .

Fairly sure he does a stock line of various intek head gaskets .

#17

O

Ocean909

O

Ocean909

Had no idea this existed. His gaskets are only a bit more than current OEM prices. Thanks for this.Go to CopperGasketsUS.

Speak to Lanni ( wonderful bloke )

Get one of his full copper head gaskets

Problem solved

Once fitted make sure you put an in line fuel tap and that you use it

The head gaskets are deliberately weak so that in the case of a hydro lock the gasket blows rather then bending a rod or cracking the head .

Fairly sure he does a stock line of various intek head gaskets .

#18

B

bertsmobile1

B

bertsmobile1

Told you Lanni was a nice guy

I get a lot of custom gaskets cut by him for antique motorcycles because it is actually cheaper than buying sheet copper & cutting them myself

They usually need to be annealed but some have arrived full soft

The rule of thumb is to roll your thumb nail over an edge pressing down hard

If it leaves a full crescent impression then the gasket is soft enough to use without annealing .

If it solves your problem please come back at the end of the season to let us know

I get a lot of custom gaskets cut by him for antique motorcycles because it is actually cheaper than buying sheet copper & cutting them myself

They usually need to be annealed but some have arrived full soft

The rule of thumb is to roll your thumb nail over an edge pressing down hard

If it leaves a full crescent impression then the gasket is soft enough to use without annealing .

If it solves your problem please come back at the end of the season to let us know

#19

M

melvin1942

M

melvin1942

Remove the head, take a straight edge Across both head and block. Use a feeler gauge and see if you and put it between the straight edge and the head and also between straight efce and block.I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#20

C

Curtisun

What I do is first take emery cloth and a flat block and emery the head and block clean of all discoloration, then I put on the new head with new bolts. I torque to specifications twice. This gives it max torque on the bolts. Torque bolts in the specified order. If this does not stop it from blowing head gaskets you will have to have the head and block resurfaced.

C

Curtisun

Replace the head bolts is one of the main things. Once a bolt has been torqued it changes the metal and can cause them to lessen the torque when the engine gets hot.I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

What I do is first take emery cloth and a flat block and emery the head and block clean of all discoloration, then I put on the new head with new bolts. I torque to specifications twice. This gives it max torque on the bolts. Torque bolts in the specified order. If this does not stop it from blowing head gaskets you will have to have the head and block resurfaced.

#21

C

Cajun power

C

Cajun power

if you have PROFESSIONALLY FACED the upper cylinder head and main block? (I'm skeptical...not saying you did not do it...but there is a world of difference between DIY truing and professional).

so if you removed to much material, it may be difficult to actually get valve clearance set...no matter what you must reset valve clearance. PER THE SERVICE MANUAL...Lot of bad information out on the interwebs., And check that valve seats have not stepped out...makes sure the exhaust and intake valve are not borked with soot or heat damage like warp ...also look at exhaust ports...something soot gets cooked and that can cause overheat.

the gaskets you bought may be the wrong type. (for instance...on some mower engines the OEM gaskets have been improved and superceded with better materials...usually a composite, metal/fiber type. you will need to research this...there is alot of junk resellers out there who send wrong parts and not the upgraded parts...recheck everything.

your engine might be running way too lean...this overheat cycle over and over is going to eventually blow out head gaskets. Try to look for any air leaks and adjust the carb spot on.

the mayb be serious internal damage to oil pressure pump...if yours has one. most of the cheaper have slingers...some have an actual oil pump. If oil is not getting where it needs to go, overheat...head gaskets blow out. (and hopefully, only that!)

the cylinder head may be cracked. Sometimes it a very small micro crack that only creates problems after hot cycle. If you suspect this, you can either do a penetrant dye and black light inspection...or shadetree: do a hot cycle, shut mower off and as soon as you can set up and perform a leak down check...the latter might be able to

other causes could be head gasket bolts that have stretched or bolt threads in the head are borked. It's one of those things that can happen from improper torque but also getting slammed by overheat cycles over and over.

if you've done all these things and everything checks out..AND THE LEAK DOWN CHECK IS GOOD AND GOOD COMPRESSION then consider buying COPPER GASKETS...They are superior in almost every way...better squish, and far superior heat transfer. Here is an reputable company that I have recently bought copper gaskets to fit a kawasaki mower engine I rebuilt..

coppergaskets.us

coppergaskets.us

so if you removed to much material, it may be difficult to actually get valve clearance set...no matter what you must reset valve clearance. PER THE SERVICE MANUAL...Lot of bad information out on the interwebs., And check that valve seats have not stepped out...makes sure the exhaust and intake valve are not borked with soot or heat damage like warp ...also look at exhaust ports...something soot gets cooked and that can cause overheat.

the gaskets you bought may be the wrong type. (for instance...on some mower engines the OEM gaskets have been improved and superceded with better materials...usually a composite, metal/fiber type. you will need to research this...there is alot of junk resellers out there who send wrong parts and not the upgraded parts...recheck everything.

your engine might be running way too lean...this overheat cycle over and over is going to eventually blow out head gaskets. Try to look for any air leaks and adjust the carb spot on.

the mayb be serious internal damage to oil pressure pump...if yours has one. most of the cheaper have slingers...some have an actual oil pump. If oil is not getting where it needs to go, overheat...head gaskets blow out. (and hopefully, only that!)

the cylinder head may be cracked. Sometimes it a very small micro crack that only creates problems after hot cycle. If you suspect this, you can either do a penetrant dye and black light inspection...or shadetree: do a hot cycle, shut mower off and as soon as you can set up and perform a leak down check...the latter might be able to

other causes could be head gasket bolts that have stretched or bolt threads in the head are borked. It's one of those things that can happen from improper torque but also getting slammed by overheat cycles over and over.

if you've done all these things and everything checks out..AND THE LEAK DOWN CHECK IS GOOD AND GOOD COMPRESSION then consider buying COPPER GASKETS...They are superior in almost every way...better squish, and far superior heat transfer. Here is an reputable company that I have recently bought copper gaskets to fit a kawasaki mower engine I rebuilt..

KAWASAKI 11004-7026,FS730V,FX651V, FX69V, FX730V,LAWNMOWERS,9C3

Made in USA Thickness .016" solid copper Bore 3.110" Reusable if not damaged SHIPS FOR FREE USA ONLY INTERNATIONAL SHIPPING $13

coppergaskets.us

coppergaskets.us

#22

O

Oarhead

O

Oarhead

33r777 for this one. Definetly headgasket. Gonna have head milled and do a close check on the block. I also have 33r877, changed everything,(springtime maintenence), fuel filters etc. Starts when choked but dies when throttle to fast run. Ugh...He also asked:

Are these engines junk?

Post up the engine ID info for a more precise Yes or No.

#23

O

Oarhead

O

Oarhead

Gonna pay closer attn to the surfaces. Thoughts on copper gaskets?How long does a head gasket usually last on your engine? (average time, like one hour, one day, or a year???)

The head and or block is either warped or as startech indicates you are not torqueing the head bolts PROPERLY.

With patience you should be able to check the head and block for warpage.

Also if it has a small dip or groove in the aluminum where it is burning through is not a good thing.

That area you describe is a wimpy place for the single cylinder Briggs Intek engines, some last forever, some don't and proceed by the book (service manual) when replacing the head gasket on those type. Make sure all the cooling fins and flywheel plastic fins are in place. Do not test run the engine over few seconds with the cooling shroud removed.

If all else fails try two heads gaskets.

#24

sgkent

sgkent

is the head worth milling cost wise? I use a machinists straight edge and check it I I I then three spots 90 degrees from that then an X. If it is good then milling it will only raise compression and make any overheating and compression worse. Compare the cost vs new. Best guess is that a machine shop will just lay it flat on a good quality band sander and surface it that way. One does a couple light X patterns with it to keep it even. I can't imagine trying to hold a mower head down on a real head and block milling machine. I used to run a Vulcan mill for that and no way would I trust a small mower head not to go flying if I tried to MILL it.

#25

G

grpascott

G

grpascott

I had trouble with my 18.5hp intek blowing head gasket too. The head bolts were lousy alloy and kept stretching, so I replaced them with grade 8 bolts. This required adding some additional thread length with a die as the bolts weren't threaded deep enough, but the extra work was worth it. It's been several years now...no blown head gaskets. (Torque to 22 ft lbs.)I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#26

S

slomo

S

slomo

These only have like 10-20ft lbs depending on engine.Replace the head bolts is one of the main things. Once a bolt has been torqued it changes the metal and can cause them to lessen the torque when the engine gets hot.

#27

S

slomo

S

slomo

It's not the space shuttle guys (Taryl). Little 220, 400 and 800 grit paper and a piece of plate glass for the block. Also use the side garage door window to lap the head. Cheap sanding block, what ever........ Get her done.

#28

G

GrumpyCat

G

GrumpyCat

That test will tell you if it is bad but will not be an assurance that it is good. Sure, it is straight from corner to corner but are the corners in the same plane square to the stroke?Remove the head, take a straight edge Across both head and block. Use a feeler gauge and see if you and put it between the straight edge and the head and also between straight efce and block.

#30

B

bertsmobile1

If you think 20 ftlbs into alloy is going to cause any structural change to a bolt, even a grade 3 bolt then you must have been asleep during your science classes at high school or gone to a school that teaches creationism and languages with no science at all .

When torquing down into alloy you damage the hole not the steel bolt which is why quality alloy engines use inserts , to protect the block.

On bolts

Higher tensile bolts have deeper cut threads so there is more surface area of metal to metal contact to create more friction between the bolt & the hole which is why the bolt stays in there and why using a grade 9 bolt seems to hold better, nothing to do with the tensile strength of the steel.

Please try not to conflate automative technology with mower technology where there is almost none .

B

bertsmobile1

This is only true for CAST IRON engine blocks where the head bolts are done up to 100 ftlbs of torque or there abouts .Replace the head bolts is one of the main things. Once a bolt has been torqued it changes the metal and can cause them to lessen the torque when the engine gets hot.

What I do is first take emery cloth and a flat block and emery the head and block clean of all discoloration, then I put on the new head with new bolts. I torque to specifications twice. This gives it max torque on the bolts. Torque bolts in the specified order. If this does not stop it from blowing head gaskets you will have to have the head and block resurfaced.

If you think 20 ftlbs into alloy is going to cause any structural change to a bolt, even a grade 3 bolt then you must have been asleep during your science classes at high school or gone to a school that teaches creationism and languages with no science at all .

When torquing down into alloy you damage the hole not the steel bolt which is why quality alloy engines use inserts , to protect the block.

On bolts

Higher tensile bolts have deeper cut threads so there is more surface area of metal to metal contact to create more friction between the bolt & the hole which is why the bolt stays in there and why using a grade 9 bolt seems to hold better, nothing to do with the tensile strength of the steel.

Please try not to conflate automative technology with mower technology where there is almost none .

#31

B

bertsmobile1

Warping is done corner to corner and is very rare on a mower head

Erosion is quite common because the gasket starts to leak and the movement of gas , particularly burning gas erodes the metal from both the head & the block, exactly the same way a river erodes a valley or canyon.

On Inteks the bridge region between the push rod tunnel & cylinder is where it usually erodes.

Then we come to thread pulling

Run a short strait edge across all of the holes in the block

Usually you fund the metal has raised slightly at the edge of the holes

This happens because there is a tiny annulus of the block that has no support when the pressure is applied because the head gaskets are not a tight fit on the engine bolts .

The head can do the same thing but usually the hole just collapses onto the bolt which is why some times the head bolts will not pull out easily.

Using a thick large diameter washer avoids this because it spreads the load over a larger area and thus only the shear plane is massively larger .

For those who have tried to flatten an intek head and block the first thing you will notice is while it is flat, it is not smooth and on the first couple of strokes you reveal the tooling swirls from the fly cutter used to machine them at the factory.

Do not try to remove them completely they are there to prevent the gasket from walking under pressure

Now we come to torque

People will argue to the ends of earth weather they should be 21 ft lbs or 22 ft lbs etc etc etc

It does not make a wrinkled rats rectum of difference

Anything from around 15 ft lbs to 30 ft lbs is fine

15 is where the clamping force is no longer enough to hold the surfaces tight enough to resist the gas pressure during combustion .

30 is approaching the yield strength of the alloy threads in that diameter bolt .

What is vital which all the Face Book experts fail to appreciate is that ALL THE TORQUES ARE IDENTICAL.

This is why B & S Started to use in lbs in place of the usual ft lbs

when they say 240 in lbs that is 240 +/- 0.5 in lbs so they expect you to do those bolts up to within 1 in lb of each other .

This implied accuracy is what every one fails to understand

a tension wrench marked in in lbs only will be a lot more accurate than one marked in ft lbs only and thus a lot more expensive

If they specified 20 ft lbs again that is +/- 0.5 ft lb with is 12 in lbs and no where near as accurate or in this case consistent and consistency is why you are shooting for for not absolute accuracy .

and when it come to accuracy, very few torque wrenches under $ 100 will be accurate and of those that are they only read true over a limited temperature range and micrometer adjusted ones go out of calibration very quickly even if you back them all off past zero every time you have finished using them because the internal coil spring collapses with use , same as your car suspension springs sag or valve springs shorten over time .

Next we come to the actual tightening

the more steps the better ( within reason ) so torquing them in 3 or 4 steps will always yield a better result then hand tight then final torque .

Finally a full copper head gasket has copper all the way from the cylinder to the outside world

a std B & S gasket has nothing more than the very thin fire ring ( if that ) to hold back the combustion gasses .

Once that is breached then you have a composite layered joining board and that does not have the structural integrity to stop leaking between the layers

So go with Lanni's full copper gasket & it will be a last time you have to do the job, if you do it properly

FWIW I use a1/2" drill bit hand held to cut a tiny champher around all the bolt holes

B

bertsmobile1

The head is tested for warping , erosion & thread pulling .Remove the head, take a straight edge Across both head and block. Use a feeler gauge and see if you and put it between the straight edge and the head and also between straight efce and block.

Warping is done corner to corner and is very rare on a mower head

Erosion is quite common because the gasket starts to leak and the movement of gas , particularly burning gas erodes the metal from both the head & the block, exactly the same way a river erodes a valley or canyon.

On Inteks the bridge region between the push rod tunnel & cylinder is where it usually erodes.

Then we come to thread pulling

Run a short strait edge across all of the holes in the block

Usually you fund the metal has raised slightly at the edge of the holes

This happens because there is a tiny annulus of the block that has no support when the pressure is applied because the head gaskets are not a tight fit on the engine bolts .

The head can do the same thing but usually the hole just collapses onto the bolt which is why some times the head bolts will not pull out easily.

Using a thick large diameter washer avoids this because it spreads the load over a larger area and thus only the shear plane is massively larger .

For those who have tried to flatten an intek head and block the first thing you will notice is while it is flat, it is not smooth and on the first couple of strokes you reveal the tooling swirls from the fly cutter used to machine them at the factory.

Do not try to remove them completely they are there to prevent the gasket from walking under pressure

Now we come to torque

People will argue to the ends of earth weather they should be 21 ft lbs or 22 ft lbs etc etc etc

It does not make a wrinkled rats rectum of difference

Anything from around 15 ft lbs to 30 ft lbs is fine

15 is where the clamping force is no longer enough to hold the surfaces tight enough to resist the gas pressure during combustion .

30 is approaching the yield strength of the alloy threads in that diameter bolt .

What is vital which all the Face Book experts fail to appreciate is that ALL THE TORQUES ARE IDENTICAL.

This is why B & S Started to use in lbs in place of the usual ft lbs

when they say 240 in lbs that is 240 +/- 0.5 in lbs so they expect you to do those bolts up to within 1 in lb of each other .

This implied accuracy is what every one fails to understand

a tension wrench marked in in lbs only will be a lot more accurate than one marked in ft lbs only and thus a lot more expensive

If they specified 20 ft lbs again that is +/- 0.5 ft lb with is 12 in lbs and no where near as accurate or in this case consistent and consistency is why you are shooting for for not absolute accuracy .

and when it come to accuracy, very few torque wrenches under $ 100 will be accurate and of those that are they only read true over a limited temperature range and micrometer adjusted ones go out of calibration very quickly even if you back them all off past zero every time you have finished using them because the internal coil spring collapses with use , same as your car suspension springs sag or valve springs shorten over time .

Next we come to the actual tightening

the more steps the better ( within reason ) so torquing them in 3 or 4 steps will always yield a better result then hand tight then final torque .

Finally a full copper head gasket has copper all the way from the cylinder to the outside world

a std B & S gasket has nothing more than the very thin fire ring ( if that ) to hold back the combustion gasses .

Once that is breached then you have a composite layered joining board and that does not have the structural integrity to stop leaking between the layers

So go with Lanni's full copper gasket & it will be a last time you have to do the job, if you do it properly

FWIW I use a1/2" drill bit hand held to cut a tiny champher around all the bolt holes

#32

H

Honest Abe

H

Honest Abe

how to check your head bolts to see if they've been over torqued. Take a regular nut the size of your bolt and try spinning it onto the bolt. If it goes on without and real resistance then go ahead and reuse it/them. If you have to use any amount of force to get it on then toss that bolt . . .

#33

S

slomo

S

slomo

What about any dirt, rust or any other contaminant on the threads? You must have a huge bucket of perfectly good bolts you toss out LOL.how to check your head bolts to see if they've been over torqued. Take a regular nut the size of your bolt and try spinning it onto the bolt. If it goes on without and real resistance then go ahead and reuse it/them. If you have to use any amount of force to get it on then toss that bolt . . .

#34

H

Honest Abe

H

Honest Abe

if the bolt has rust on the inside threads you've got more of a problem than just a head gasket. If you're sticking a head bolt with rust on it back into the head then I dang sure don't want you working on any of my stuff ( . ) . . . . . .What about any dirt, rust or any other contaminant on the threads? You must have a huge bucket of perfectly good bolts you toss out LOL.

#35

S

slomo

I agree, don't have me working on your mowers. No argument there.

S

slomo

For sure. I'm ordering all new bolts for all my mowers for every day of the week. Might get a snip of contamination on them while mowing.if the bolt has rust on the inside threads you've got more of a problem than just a head gasket. If you're sticking a head bolt with rust on it back into the head then I dang sure don't want you working on any of my stuff ( . ) . . . . . .

I agree, don't have me working on your mowers. No argument there.

#36

B

bertsmobile1

Abe is right, the thread can deform but they usually neck at the junction between the thread & the shank before the threads actually deform because the threads are constrained by the thread of what ever they are threaded into.

If you have a nut & bolt situation then over torquing will cause a deformation to the actual thread.

And this can be felt by running a CLOSE FITTING nut along the bolt

To a lesser extent this also works for through bolts like a B & S head bolt

But will not work for a bolt into a blind hole like most head bolts are .

In this case you measure the length of the bolt before & after .

Precision bolts are often ground at the end to be exactly the same length so you can detect a thou or two of elongation but B & S bolts are not precision they are standard roll forged domestic grade bolts and if you care to measure then you will find the lengths are all over the place and impossible to measure accurately because there is a rim around the end of the shank .

So again while technically correct this is something that does apply to automotive engines but is irrelevant to mower engines .

B

bertsmobile1

Keep it civil fellasFor sure. I'm ordering all new bolts for all my mowers for every day of the week. Might get a snip of contamination on them while mowing.

I agree, don't have me working on your mowers. No argument there.

Abe is right, the thread can deform but they usually neck at the junction between the thread & the shank before the threads actually deform because the threads are constrained by the thread of what ever they are threaded into.

If you have a nut & bolt situation then over torquing will cause a deformation to the actual thread.

And this can be felt by running a CLOSE FITTING nut along the bolt

To a lesser extent this also works for through bolts like a B & S head bolt

But will not work for a bolt into a blind hole like most head bolts are .

In this case you measure the length of the bolt before & after .

Precision bolts are often ground at the end to be exactly the same length so you can detect a thou or two of elongation but B & S bolts are not precision they are standard roll forged domestic grade bolts and if you care to measure then you will find the lengths are all over the place and impossible to measure accurately because there is a rim around the end of the shank .

So again while technically correct this is something that does apply to automotive engines but is irrelevant to mower engines .

#37

T

tank1949

T

tank1949

I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....Slomo is correct, but you should have first did a compression test after the rebuild. If the head or block is warped, u may have to discard it, since the machine shop expenses to flatten parts will not justify keeping it. .

#38

H

Honest Abe

I would respectfully disagree; because, if there's rust on the "threads" then there's no doubt rust on the threads in the hole. Unless you run a tap into the hole and clean off the hole threads and blow the debris out as well then you run the risk of not accurately tightening the bolt(s). This is just my take, not saying I've ever seen it more than a bunch of times . . . . . .

H

Honest Abe

".....this is something that does apply to automotive engines but is irrelevant to mower engines."Keep it civil fellas

Abe is right, the thread can deform but they usually neck at the junction between the thread & the shank before the threads actually deform because the threads are constrained by the thread of what ever they are threaded into.

If you have a nut & bolt situation then over torquing will cause a deformation to the actual thread.

And this can be felt by running a CLOSE FITTING nut along the bolt

To a lesser extent this also works for through bolts like a B & S head bolt

But will not work for a bolt into a blind hole like most head bolts are .

In this case you measure the length of the bolt before & after .

Precision bolts are often ground at the end to be exactly the same length so you can detect a thou or two of elongation but B & S bolts are not precision they are standard roll forged domestic grade bolts and if you care to measure then you will find the lengths are all over the place and impossible to measure accurately because there is a rim around the end of the shank .

So again while technically correct this is something that does apply to automotive engines but is irrelevant to mower engines .

I would respectfully disagree; because, if there's rust on the "threads" then there's no doubt rust on the threads in the hole. Unless you run a tap into the hole and clean off the hole threads and blow the debris out as well then you run the risk of not accurately tightening the bolt(s). This is just my take, not saying I've ever seen it more than a bunch of times . . . . . .

#39

B

bertsmobile1

B

bertsmobile1

Point is that there is zero chance of stretching a steel bolt in an aluminium casting, it just can not happen

Bolt stretch when tightening into a cast iron block can happen but not into an alloy block tensioned to 20 ft lbs

That sort of torque is not even in the elastic deformation range.

Nothing wrong with the nut test for thread deformation except it is not applicable to mower engines .

And yes threads should be clean and dry but that should be a given .

Bolt stretch when tightening into a cast iron block can happen but not into an alloy block tensioned to 20 ft lbs

That sort of torque is not even in the elastic deformation range.

Nothing wrong with the nut test for thread deformation except it is not applicable to mower engines .

And yes threads should be clean and dry but that should be a given .

#40

B

Big Al O

B

Big Al O

Make sure the muffler & exhaust are not restrictedI have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#41

K

kenv52

K

kenv52

I have a zero turn with a Briggs intek 18.5. I also have a friend that worked for a country clipper distributor for years. I’ve put two on mine so far. He said that engine is known for blowing head gaskets and that a lot of dealers would refuse shipment if it had that engine. It runs fine other than that. He even told me where it blows at and sure enough he was right. It did it two times. It then leaks compression into the block and blows oil out the vent/breather thing on the side of the motor. It’s important to re torque the head bolts after a mow or two after installation. I’ve been thinking about just buying another head gasket kit and having it on handI have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#42

G

Gord Baker

G

Gord Baker

Certain belt sanders have wide adhesive backed grit. Attach a long length to a FLAT piece of Steel and sand ead, rotating it often. Check with light and straight edge.

Ditto with flat piece of steel to Block. Are you using OEM gaskets. Torque and sequence are very important.

Perhaps try with copper anti-seize applied sparingly to both sides of gasket. Good luck. Check Crank for partially sheared key. Incorrect timing could cause excessive temps and pressure perhaps.

Ditto with flat piece of steel to Block. Are you using OEM gaskets. Torque and sequence are very important.

Perhaps try with copper anti-seize applied sparingly to both sides of gasket. Good luck. Check Crank for partially sheared key. Incorrect timing could cause excessive temps and pressure perhaps.

#43

Moparjoe499

Moparjoe499

Get a concrete block, lay the block down and take the head and rub it on the concrete block a couple times. Look at it and you will see where the low spot is. Keep rubbing it until the low spot disappears. I have done this before and it works.I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#44

Piros1

Piros1

Sounds as you are skilled at engine repair but I will throw something out I did not see mentioned. Did you clean both head and block surfaces and check with a good straight edge to be sure they are flat and not damaged or pitted?

#46

Roy405

Roy405

I'd have to think something is not flat.I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#47

C

Curtisun

I had a 4-wheeler with aluminum block, 650 cc that keep blowing head gaskets after a few hours of running. I made sure there was no cracks or warpage. Come to find out after I finally found a manual on it and after 5 head gasket replacements it stated, "Head bolts must be replaced when head is removed for any reason". It did not give a reason. I purchase all new head bolts and it has been running for about a year now with no problems.

C

Curtisun

Then I ask why it specifically says to replace head bolts in manuals for aluminum block and heads.This is only true for CAST IRON engine blocks where the head bolts are done up to 100 ftlbs of torque or there abouts .

If you think 20 ftlbs into alloy is going to cause any structural change to a bolt, even a grade 3 bolt then you must have been asleep during your science classes at high school or gone to a school that teaches creationism and languages with no science at all .

When torquing down into alloy you damage the hole not the steel bolt which is why quality alloy engines use inserts , to protect the block.

On bolts

Higher tensile bolts have deeper cut threads so there is more surface area of metal to metal contact to create more friction between the bolt & the hole which is why the bolt stays in there and why using a grade 9 bolt seems to hold better, nothing to do with the tensile strength of the steel.

Please try not to conflate automative technology with mower technology where there is almost none .

I had a 4-wheeler with aluminum block, 650 cc that keep blowing head gaskets after a few hours of running. I made sure there was no cracks or warpage. Come to find out after I finally found a manual on it and after 5 head gasket replacements it stated, "Head bolts must be replaced when head is removed for any reason". It did not give a reason. I purchase all new head bolts and it has been running for about a year now with no problems.

#48

J

Joed756

J

Joed756

If you have done all of this already, try using two head gaskets. Often that will make up for any head deformities.

#49

L

lofty66

L

lofty66

Almost certainly a warped head, but some of the methods being suggested here to flatten it are a good way to ruin a perfectly good head. Do not use sand paper or concrete both are far to coarse and inaccurate. The best way is to use fine valve grinding paste on a piece of glass, preferably 1/4" or thicker as that's flatter. Do not use a scrap double glazed panel as they're often slightly concave. oil the glass, then smear on some fine valve grinding paste. Place the head on it and move in a figure of eight motion, every dozen or so figures of eight stop, turn the head through 90 degrees and continue. Every so often lift up the head and check the lapped surface, low spots will be obvious. Continue, adding more grinding paste as necessary, until the whole surface is an even mat colour. Wash off, then refit using a new head gasket and torque down gradually, ie bring the bolts up together, do not torque down one fully then the next and so on. If the order is not known tightening diagonally is a good rule of thumb.

One other thing to check is to make sure the bolts (or one possibly) aren't bottoming out too early. Without the head try fitting them, and make sure when fully inserted the gaps between the block and the head of the bolt are all less than the thickness of the head. If they are bottoming out, even when torqued down they won't be squeezing the gasket correctly.

One other thing to check is to make sure the bolts (or one possibly) aren't bottoming out too early. Without the head try fitting them, and make sure when fully inserted the gaps between the block and the head of the bolt are all less than the thickness of the head. If they are bottoming out, even when torqued down they won't be squeezing the gasket correctly.

#50

G

G5200

G

G5200

Had this problem with a 21 HP B&S about 15 years ago. The key that positions the flywheel (and magneto) relative to the crank (times the spark) had partially sheared, causing the spark plug to fire too early. Preignition - overpressurized the cylinder and kept blowing out head gaskets. Check your TDC vs when the cams move the valves.

#51

B

barny57

B

barny57

Head can’t be flat , even 1 not torqued bolt wouldn’t cause thatI have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

#52

J

joea99

It happened when doing a head gasket replacement, doing the first bolt with a bad clicker torque wrench that had "worked last time". Since it was my first Subaru overhaul and I was following a script, it did not dawn on me, till too late, that I was WAY beyond where is should have clicked. Short story is that after redoing the torque sequence with a new wrench, I was not confident of a good job and pulled the head.

Yep, that bolt was clearly stretched very badly. I was concerned about having deformed or pulled the threads, but after checking the block and the bolt holes, got a new gasket and new bolts and finished the job. My own car, so not sorry at all, except for the expense.

J

joea99

I have personally stretched a brand new steel head bolt in an aluminum block. Granted, it was an automotive engine (a Subaru) and the ultimate torque was far over 20 ft lbs, but it IS an aluminum block.Point is that there is zero chance of stretching a steel bolt in an aluminium casting, it just can not happen

Bolt stretch when tightening into a cast iron block can happen but not into an alloy block tensioned to 20 ft lbs

That sort of torque is not even in the elastic deformation range.

Nothing wrong with the nut test for thread deformation except it is not applicable to mower engines .

And yes threads should be clean and dry but that should be a given .

It happened when doing a head gasket replacement, doing the first bolt with a bad clicker torque wrench that had "worked last time". Since it was my first Subaru overhaul and I was following a script, it did not dawn on me, till too late, that I was WAY beyond where is should have clicked. Short story is that after redoing the torque sequence with a new wrench, I was not confident of a good job and pulled the head.

Yep, that bolt was clearly stretched very badly. I was concerned about having deformed or pulled the threads, but after checking the block and the bolt holes, got a new gasket and new bolts and finished the job. My own car, so not sorry at all, except for the expense.

#53

T

TobyU

T

TobyU

Well, if you did all that then something wasn't done right or something is atypical and even though you're doing what you're supposed to be doing you're not getting the results and it's letting the procedure fail.

I have red posts over the past 10 years or so about people who have had more than one head gasket failure and it always astounds me because I have done a lot of these Briggs & Stratton 31xxxx and 33xxxx and I have literally never had a repeat failure!!

Maybe I'm just lucky but I don't think that's the case.

At bare minimum the head needs to be scraped clean with a razor blades scraper or putty knife or whatever and white clean with brake cleaner or carb cleaner or whatever and a rag and the same for the block surface. That's the bare minimum.

Then it is a must that you use the proper head bolt torquing sequence which has been revised and an accurate inch pound torque wrench.

Maybe you're rich is off one way or the other??

I want snapped a rod bolt on a 12-point headed Buick 455 engine because I borrowed a torque wrench when I was a teenager and didn't own one myself and it was calibrated way off! It must have been 25 to 30 lb minimum off because it snapped that off and I had to go to the junkyard to get another one..

So that's all I ever do and I never have failures but if I'm trying to prevent a failure I will go two extra steps..

I will place it on a flat piece of glass or very flat metal with some 60 or 80 grit sandpaper taped down..

Then I will send the heck out of it until the entire surface is even.

This of course isn't as good as actually milling one but you will quickly see the high spots and then as you keep going you're saying will start to hit the other spots so you know you have it much more flat than when you started.

It takes a long time and gets annoying. The last time I counted I had to do at least 500 strokes before I even got close to being smooth and acceptable.

Also, I do it in all different directions as I rotate it a quarter turn throughout the process multiple times.

Then the second thing I will do is spray the permatex copper spray gasket on both sides of the gasket.

Like I said I rarely do either of these and they still last for years after I put them together so I'm very surprised you're having repeated problems.

Are you using the Briggs & Stratton gaskets or the ones you get on eBay and amazon?

In this case the ones that are aftermarket could very well be better than the briggs one because it is junk from beginning and they sell you a same junk when to replace it.

I believe I saw a couple online that seemed to look like they had a fire ring around the combustion chamber which would be an improvement.

When Kohler had this problem back in the early 2000s they recalled all of their original head gaskets and replaced it with a head gasket kit, while expensive, it was a much improved head gasket much beefier and with a fire ring around it so the problem would not reoccur.

Briggs does nothing!

I have red posts over the past 10 years or so about people who have had more than one head gasket failure and it always astounds me because I have done a lot of these Briggs & Stratton 31xxxx and 33xxxx and I have literally never had a repeat failure!!

Maybe I'm just lucky but I don't think that's the case.

At bare minimum the head needs to be scraped clean with a razor blades scraper or putty knife or whatever and white clean with brake cleaner or carb cleaner or whatever and a rag and the same for the block surface. That's the bare minimum.

Then it is a must that you use the proper head bolt torquing sequence which has been revised and an accurate inch pound torque wrench.

Maybe you're rich is off one way or the other??

I want snapped a rod bolt on a 12-point headed Buick 455 engine because I borrowed a torque wrench when I was a teenager and didn't own one myself and it was calibrated way off! It must have been 25 to 30 lb minimum off because it snapped that off and I had to go to the junkyard to get another one..

So that's all I ever do and I never have failures but if I'm trying to prevent a failure I will go two extra steps..

I will place it on a flat piece of glass or very flat metal with some 60 or 80 grit sandpaper taped down..

Then I will send the heck out of it until the entire surface is even.

This of course isn't as good as actually milling one but you will quickly see the high spots and then as you keep going you're saying will start to hit the other spots so you know you have it much more flat than when you started.

It takes a long time and gets annoying. The last time I counted I had to do at least 500 strokes before I even got close to being smooth and acceptable.

Also, I do it in all different directions as I rotate it a quarter turn throughout the process multiple times.

Then the second thing I will do is spray the permatex copper spray gasket on both sides of the gasket.

Like I said I rarely do either of these and they still last for years after I put them together so I'm very surprised you're having repeated problems.

Are you using the Briggs & Stratton gaskets or the ones you get on eBay and amazon?

In this case the ones that are aftermarket could very well be better than the briggs one because it is junk from beginning and they sell you a same junk when to replace it.

I believe I saw a couple online that seemed to look like they had a fire ring around the combustion chamber which would be an improvement.

When Kohler had this problem back in the early 2000s they recalled all of their original head gaskets and replaced it with a head gasket kit, while expensive, it was a much improved head gasket much beefier and with a fire ring around it so the problem would not reoccur.

Briggs does nothing!

#54

C

charleneje

C

charleneje

If that is true about headbolts not stretching why do all automobile manufacturers in the workshop manual say to replace all headbolts on aluminum heads and even on some other uses where aluminum parts are used. I remember back in the 1960's that when taking the head of an all aluminum engine Hillman Imp you stood a good chance of breaking headbolts when taking the head of the engine to do a decoke something very few engines nowadays. I know that is about automotive but it proves the point about bolts stretching I believe.

#55

T

Tommy Mckeown

T

Tommy Mckeown

Well, the same spot would indicate that either the block, the head, or both are not true. I think you need to get a precision straight edge and check that area on both surfaces. A Starrett brand will be about $100 while an Amazon one will be $30. One is accurate to .0003". while the other is .001 You are just checking not machining so the $30 one should be just fine.

#56

reynoldston

reynoldston

I use a flat pace countertop and cover it with sandpaper. I start with 100 grit and work up to 600. I sand the head surface and engine. Then retorque head bolts to specs starting with a low setting and working up to the full setting. I have never had a gasket problem doing it this way. Also when removing the head you need to do that in the proper sequence also.

#57

C

charleneje

I did the repair thanks to advice from others on this forum Like you I was ready to just replace my few years old mower now my only problem is the rear automatic axle/gearbox makes noise and slips but I cant get it off with my equipment to check it out so I will wait for it to quit then replace the mower.

C

charleneje

I had the same problems on a 22hp Briggs engine I would replace the head gasket and it kept on blowing after just a short amount of use, I came on here and was suggested to make sure the head was flat by testing with a straight edge and using a piece of glass and sanding it I got some 240 grit sandpaper and spray glue and stuck the paper to a sheet of thick glass I have it took a long time but i used a figure eight sanding pattern and it finally got flat in every direction I checked also when sanding a head you can see all the highs and lows because of the sandpaper marks. I ordered a head gasket from CopperGasketsUS. having discussed my problem with Lanni and he sent me an already annealed head gasket, so I made sure everything was cleaned properly and sprayed Permatex copper spray gasket on both sides of the gasket and on the head and cylinder assembled and torqued the head according to manual I then left it for two days everything covered with a big rag and then retorqued the head bolts, put everything together and haven't had any problem's since I do have a fuel shut off on the mower because fuel will leak past the carb and fill the crankcase. I check my oil before each use and not long after I first got the mower the oil was right up the dipstick and it smelled of gas hence the fuel shutoff.I have a Husquvarna tractor. 18.5hp. Can anyone tell me why I have gone thru 4 head gaskets? This one being the 4th. Blows out right across from the plug. There is no way I screwed up 3 headgaskets. Getting a little tired of this crap. Are these engines junk? I can change a hot cylinder in a 2500hp EMD but can't keep this running. Should sell everything and buy a diesel....

I did the repair thanks to advice from others on this forum Like you I was ready to just replace my few years old mower now my only problem is the rear automatic axle/gearbox makes noise and slips but I cant get it off with my equipment to check it out so I will wait for it to quit then replace the mower.

#58

T

TobyU

T

TobyU

Well, if you did all that then something wasn't done right or something is atypical and even though you're doing what you're supposed to be doing you're not getting the results and it's letting the procedure fail.

I have red posts over the past 10 years or so about people who have had more than one head gasket failure and it always astounds me because I have done a lot of these Briggs & Stratton 31xxxx and 33xxxx and I have literally never had a repeat failure!!

Maybe I'm just lucky but I don't think that's the case.

At bare minimum the head needs to be scraped clean with a razor blades scraper or putty knife or whatever and white clean with brake cleaner or carb cleaner or whatever and a rag and the same for the block surface. That's the bare minimum.

Then it is a must that you use the proper head bolt torquing sequence which has been revised and an accurate inch pound torque wrench.

Maybe you're rich is off one way or the other??

I want snapped a rod bolt on a 12-point headed Buick 455 engine because I borrowed a torque wrench when I was a teenager and didn't own one myself and it was calibrated way off! It must have been 25 to 30 lb minimum off because it snapped that off and I had to go to the junkyard to get another one..

So that's all I ever do and I never have failures but if I'm trying to prevent a failure I will go two extra steps..

I will place it on a flat piece of glass or very flat metal with some 60 or 80 grit sandpaper taped down..

Then I will send the heck out of it until the entire surface is even.

This of course isn't as good as actually milling one but you will quickly see the high spots and then as you keep going you're saying will start to hit the other spots so you know you have it much more flat than when you started.

It takes a long time and gets annoying. The last time I counted I had to do at least 500 strokes before I even got close to being smooth and acceptable.

Also, I do it in all different directions as I rotate it a quarter turn throughout the process multiple times.

Then the second thing I will do is spray the permatex copper spray gasket on both sides of the gasket.

Like I said I rarely do either of these and they still last for years after I put them together so I'm very surprised you're having repeated problems.

Are you using the Briggs & Stratton gaskets or the ones you get on eBay and amazon?

In this case the ones that are aftermarket could very well be better than the brakes one because it is junk from beginning and they sell you a same junk when to replace it.

I believe I saw a couple online that seemed to look like they had a fire ring around the combustion chamber which would be an improvement.

When Kohler had this problem back in the early 2000s they recalled all of their original head gaskets and replaced it with a head gasket kit, while

Head bolts in the old days up until the late '80s were never TTY torque to yield.. then along came the ttys for a couple of reasons but I think mainly just they can sell more bolts.

There is a little more to it than that as they wanted to downsize everything including the holes in which these bolts resided because there wasn't as much meat in the heads and block and stuff like that around the holes so they didn't want to make the bolts as big and the bolts simply weren't as big with tons of Overkill where they can be used multiple, multiple times like many of the old head bolts on most of the engines I've built over the years were which did just fine.

They decide to use a smaller fastener and then tighten it to the point of starting to stretch so it was giving its most fascinating ability but we all know what happens then it's like a one-time use.

I don't believe these Briggs & Stratton head bolts are designed that way and I also don't believe they're very high quality either. There are some times where I can't quite get them to the new revised torque rating of 250 inch pounds without being afraid one will snap off or strip out the threads so often I don't know quite that high. It used to be 220 or 225 and now it's 250..

I think tightening in three steps which I forgot to mention in my other post, which I always do, and tightening them down evenly is more important than your final torque amount.

I have reused many of these old head bolts multiple times and I just keep them laying in a bowl somewhere they work just as well whether they've been used once or five times in my opinion.

You're not stretching them much if any and you're certainly not stretching them to yield in my opinion when you reinstall the head..

When you get good at the feel for it you can tell if one is out of whack by just using the torque wrench on it or even a 3/8 drive ratchet so maybe if one was messed up or I've been over Titan there could be an issue but other than that I think any old bolts work just as fine as buying brand new ones. Or if we could go buy some ARP head bowls I don't think it would make a bit of difference on these particular engines because it's a lousy design and a lousy gasket.

I have red posts over the past 10 years or so about people who have had more than one head gasket failure and it always astounds me because I have done a lot of these Briggs & Stratton 31xxxx and 33xxxx and I have literally never had a repeat failure!!

Maybe I'm just lucky but I don't think that's the case.

At bare minimum the head needs to be scraped clean with a razor blades scraper or putty knife or whatever and white clean with brake cleaner or carb cleaner or whatever and a rag and the same for the block surface. That's the bare minimum.

Then it is a must that you use the proper head bolt torquing sequence which has been revised and an accurate inch pound torque wrench.

Maybe you're rich is off one way or the other??

I want snapped a rod bolt on a 12-point headed Buick 455 engine because I borrowed a torque wrench when I was a teenager and didn't own one myself and it was calibrated way off! It must have been 25 to 30 lb minimum off because it snapped that off and I had to go to the junkyard to get another one..

So that's all I ever do and I never have failures but if I'm trying to prevent a failure I will go two extra steps..

I will place it on a flat piece of glass or very flat metal with some 60 or 80 grit sandpaper taped down..

Then I will send the heck out of it until the entire surface is even.

This of course isn't as good as actually milling one but you will quickly see the high spots and then as you keep going you're saying will start to hit the other spots so you know you have it much more flat than when you started.

It takes a long time and gets annoying. The last time I counted I had to do at least 500 strokes before I even got close to being smooth and acceptable.

Also, I do it in all different directions as I rotate it a quarter turn throughout the process multiple times.

Then the second thing I will do is spray the permatex copper spray gasket on both sides of the gasket.

Like I said I rarely do either of these and they still last for years after I put them together so I'm very surprised you're having repeated problems.

Are you using the Briggs & Stratton gaskets or the ones you get on eBay and amazon?

In this case the ones that are aftermarket could very well be better than the brakes one because it is junk from beginning and they sell you a same junk when to replace it.

I believe I saw a couple online that seemed to look like they had a fire ring around the combustion chamber which would be an improvement.

When Kohler had this problem back in the early 2000s they recalled all of their original head gaskets and replaced it with a head gasket kit, while

There is no point to prove about head bolts unless you know the design parameters and the materials used of the particular head bolts and we don't.If that is true about headbolts not stretching why do all automobile manufacturers in the workshop manual say to replace all headbolts on aluminum heads and even on some other uses where aluminum parts are used. I remember back in the 1960's that when taking the head of an all aluminum engine Hillman Imp you stood a good chance of breaking headbolts when taking the head of the engine to do a decoke something very few engines nowadays. I know that is about automotive but it proves the point about bolts stretching I believe.

Head bolts in the old days up until the late '80s were never TTY torque to yield.. then along came the ttys for a couple of reasons but I think mainly just they can sell more bolts.

There is a little more to it than that as they wanted to downsize everything including the holes in which these bolts resided because there wasn't as much meat in the heads and block and stuff like that around the holes so they didn't want to make the bolts as big and the bolts simply weren't as big with tons of Overkill where they can be used multiple, multiple times like many of the old head bolts on most of the engines I've built over the years were which did just fine.

They decide to use a smaller fastener and then tighten it to the point of starting to stretch so it was giving its most fascinating ability but we all know what happens then it's like a one-time use.

I don't believe these Briggs & Stratton head bolts are designed that way and I also don't believe they're very high quality either. There are some times where I can't quite get them to the new revised torque rating of 250 inch pounds without being afraid one will snap off or strip out the threads so often I don't know quite that high. It used to be 220 or 225 and now it's 250..

I think tightening in three steps which I forgot to mention in my other post, which I always do, and tightening them down evenly is more important than your final torque amount.

I have reused many of these old head bolts multiple times and I just keep them laying in a bowl somewhere they work just as well whether they've been used once or five times in my opinion.

You're not stretching them much if any and you're certainly not stretching them to yield in my opinion when you reinstall the head..

When you get good at the feel for it you can tell if one is out of whack by just using the torque wrench on it or even a 3/8 drive ratchet so maybe if one was messed up or I've been over Titan there could be an issue but other than that I think any old bolts work just as fine as buying brand new ones. Or if we could go buy some ARP head bowls I don't think it would make a bit of difference on these particular engines because it's a lousy design and a lousy gasket.

#59

H

Honest Abe

H

Honest Abe

if I had to "guess" I'd say that it's because these dang bolts are similar to trying to get nuts of aluminum rims. It seems to take infinitely more torque to break them free than to tighten them down. Just a wild guess though . . . . .Then I ask why it specifically says to replace head bolts in manuals for aluminum block and heads.

I had a 4-wheeler with aluminum block, 650 cc that keep blowing head gaskets after a few hours of running. I made sure there was no cracks or warpage. Come to find out after I finally found a manual on it and after 5 head gasket replacements it stated, "Head bolts must be replaced when head is removed for any reason". It did not give a reason. I purchase all new head bolts and it has been running for about a year now with no problems.

#60

H

Honest Abe

H

Honest Abe

you touched on something I meant to bring up earlier, i.e. "Torque wrench calibration". When was the last time folks had their calibrated? My son builds all kinds of engines for a living, and his are sent out every 6 months and recalibrated. When you're building $75k+ engines little things count, maybe not so much for some and a B&S . . . . . .Well, if you did all that then something wasn't done right or something is atypical and even though you're doing what you're supposed to be doing you're not getting the results and it's letting the procedure fail.

I have red posts over the past 10 years or so about people who have had more than one head gasket failure and it always astounds me because I have done a lot of these Briggs & Stratton 31xxxx and 33xxxx and I have literally never had a repeat failure!!

Maybe I'm just lucky but I don't think that's the case.

At bare minimum the head needs to be scraped clean with a razor blades scraper or putty knife or whatever and white clean with brake cleaner or carb cleaner or whatever and a rag and the same for the block surface. That's the bare minimum.

Then it is a must that you use the proper head bolt torquing sequence which has been revised and an accurate inch pound torque wrench.

Maybe you're rich is off one way or the other??

I want snapped a rod bolt on a 12-point headed Buick 455 engine because I borrowed a torque wrench when I was a teenager and didn't own one myself and it was calibrated way off! It must have been 25 to 30 lb minimum off because it snapped that off and I had to go to the junkyard to get another one..

So that's all I ever do and I never have failures but if I'm trying to prevent a failure I will go two extra steps..

I will place it on a flat piece of glass or very flat metal with some 60 or 80 grit sandpaper taped down..

Then I will send the heck out of it until the entire surface is even.

This of course isn't as good as actually milling one but you will quickly see the high spots and then as you keep going you're saying will start to hit the other spots so you know you have it much more flat than when you started.

It takes a long time and gets annoying. The last time I counted I had to do at least 500 strokes before I even got close to being smooth and acceptable.

Also, I do it in all different directions as I rotate it a quarter turn throughout the process multiple times.

Then the second thing I will do is spray the permatex copper spray gasket on both sides of the gasket.

Like I said I rarely do either of these and they still last for years after I put them together so I'm very surprised you're having repeated problems.

Are you using the Briggs & Stratton gaskets or the ones you get on eBay and amazon?

In this case the ones that are aftermarket could very well be better than the briggs one because it is junk from beginning and they sell you a same junk when to replace it.

I believe I saw a couple online that seemed to look like they had a fire ring around the combustion chamber which would be an improvement.

When Kohler had this problem back in the early 2000s they recalled all of their original head gaskets and replaced it with a head gasket kit, while expensive, it was a much improved head gasket much beefier and with a fire ring around it so the problem would not reoccur.

Briggs does nothing!

#61

K

kjonxx

K

kjonxx

Cheap bolts like kohler maybe ? Running to lean so it gets overly hot.? Just a thought.

#62

T

TobyU

Well, you would stop but in the end, it wouldn't be much different from just leaving alone and wiping it off with a rag after you scraped it in the first place.

These heads are so warped and have such large dips and valleys in them that you're never going to accomplish anything that way.

There is absolutely no problem with laying them on a fairly flat surface, with sandpaper on that surface and working them in all directions as you turn the head around a quarter turn multiple times so this way you're making up for any possible surface of regularities.

I prefer to start with 80 grit but I'm guessing you're going to say that's too course but it works great for me. Sometimes I'll go over it afterwards with something a little bit finer but nothing finer than 120 because this doesn't need to be polished to a smooth surface and you'd be amazed how pretty and smooth they look after doing 500 to 600 strokes with the 80 to 120 grit that I do.

Yes, it takes about 500 strokes doing it this way and I put a good deal of pressure down on the head to get it to where you have actually sanded the whole surface so there's no more high spots holding the rest of the head up off of the sandpaper.

They are that bad. And this is probably why so many people have repeat problems with head gasket failures despite the fact they claim their twerking them in the correct pattern and to the proper specs.

This is not rocket science and it's not very precise either. They are still very forgiving and it does not need any certain type of machine slash engine builders and finish on it to work perfectly.

These engines are actually junky little low performance turds that just luckily are pretty forgiving of most of the abuse, neglect, and design flaws, and low quality parts they're made with.

Sometimes though you have to take matters into your own hand to make a head relatively flat and smooth versus the abomination it was when you removed it.

So sandpaper away I say. It's worked well for me and I've done this more than most human beings alive.

The average person or the majority of people in this group probably haven't done over five in their life and maybe not even over three.

I really don't see that as a large enough sample to prove anything.

T

TobyU

You would literally never get done doing it this way..Almost certainly a warped head, but some of the methods being suggested here to flatten it are a good way to ruin a perfectly good head. Do not use sand paper or concrete both are far to coarse and inaccurate. The best way is to use fine valve grinding paste on a piece of glass, preferably 1/4" or thicker as that's flatter. Do not use a scrap double glazed panel as they're often slightly concave. oil the glass, then smear on some fine valve grinding paste. Place the head on it and move in a figure of eight motion, every dozen or so figures of eight stop, turn the head through 90 degrees and continue. Every so often lift up the head and check the lapped surface, low spots will be obvious. Continue, adding more grinding paste as necessary, until the whole surface is an even mat colour. Wash off, then refit using a new head gasket and torque down gradually, ie bring the bolts up together, do not torque down one fully then the next and so on. If the order is not known tightening diagonally is a good rule of thumb.

One other thing to check is to make sure the bolts (or one possibly) aren't bottoming out too early. Without the head try fitting them, and make sure when fully inserted the gaps between the block and the head of the bolt are all less than the thickness of the head. If they are bottoming out, even when torqued down they won't be squeezing the gasket correctly.

Well, you would stop but in the end, it wouldn't be much different from just leaving alone and wiping it off with a rag after you scraped it in the first place.

These heads are so warped and have such large dips and valleys in them that you're never going to accomplish anything that way.

There is absolutely no problem with laying them on a fairly flat surface, with sandpaper on that surface and working them in all directions as you turn the head around a quarter turn multiple times so this way you're making up for any possible surface of regularities.

I prefer to start with 80 grit but I'm guessing you're going to say that's too course but it works great for me. Sometimes I'll go over it afterwards with something a little bit finer but nothing finer than 120 because this doesn't need to be polished to a smooth surface and you'd be amazed how pretty and smooth they look after doing 500 to 600 strokes with the 80 to 120 grit that I do.

Yes, it takes about 500 strokes doing it this way and I put a good deal of pressure down on the head to get it to where you have actually sanded the whole surface so there's no more high spots holding the rest of the head up off of the sandpaper.

They are that bad. And this is probably why so many people have repeat problems with head gasket failures despite the fact they claim their twerking them in the correct pattern and to the proper specs.

This is not rocket science and it's not very precise either. They are still very forgiving and it does not need any certain type of machine slash engine builders and finish on it to work perfectly.

These engines are actually junky little low performance turds that just luckily are pretty forgiving of most of the abuse, neglect, and design flaws, and low quality parts they're made with.

Sometimes though you have to take matters into your own hand to make a head relatively flat and smooth versus the abomination it was when you removed it.

So sandpaper away I say. It's worked well for me and I've done this more than most human beings alive.

The average person or the majority of people in this group probably haven't done over five in their life and maybe not even over three.

I really don't see that as a large enough sample to prove anything.

#63

T

TobyU

T

TobyU