- Joined

- Feb 19, 2020

- Threads

- 122

- Messages

- 12,902

YTH24v48

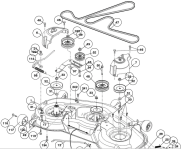

This mower usually has an electric PTO clutch so the deck will need to come off for two reasons. One just makes accessing things easier. Two it so you can access the drive belt path.

The electric PTO come off fairly most times just using an impact wrench with a 5/8 (16mm) socket. Once the electric clutch is off you will the drive pulley behind it next to the engine's sump. It needs to come off so the drive belt needs removing. Be careful during the removal of the clutch and drive pulley as sometime there spacer washers used. Need to close attention to the order of the parts including the orientation of the drive pulley.

When putting the electric PTO back on is when you use a torque wrench to tighten it. Also don't forget make the anti rotation device is properly located on the clutch. Some if PTO clutch has a double D adapter then a wrench is use to hold it while tightening the bolt to 55 ft/lbs. If not present which I doubt it is used on this particular clutch then you would need to remove the engine's shroud so the flywheel can held in place using a large flat blade screw up again one of the ignition coil's mounting posts. This where a helper is plus as it is hard to hold the screw driver in place and tighten the PTO retaining bolt at the same time. Not impossible to done but a lot harder when you are the only one doing it. Don't forget to use anti-seize compound on the crankshaft.

This mower usually has an electric PTO clutch so the deck will need to come off for two reasons. One just makes accessing things easier. Two it so you can access the drive belt path.

The electric PTO come off fairly most times just using an impact wrench with a 5/8 (16mm) socket. Once the electric clutch is off you will the drive pulley behind it next to the engine's sump. It needs to come off so the drive belt needs removing. Be careful during the removal of the clutch and drive pulley as sometime there spacer washers used. Need to close attention to the order of the parts including the orientation of the drive pulley.

When putting the electric PTO back on is when you use a torque wrench to tighten it. Also don't forget make the anti rotation device is properly located on the clutch. Some if PTO clutch has a double D adapter then a wrench is use to hold it while tightening the bolt to 55 ft/lbs. If not present which I doubt it is used on this particular clutch then you would need to remove the engine's shroud so the flywheel can held in place using a large flat blade screw up again one of the ignition coil's mounting posts. This where a helper is plus as it is hard to hold the screw driver in place and tighten the PTO retaining bolt at the same time. Not impossible to done but a lot harder when you are the only one doing it. Don't forget to use anti-seize compound on the crankshaft.