You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

do I rebuild or replace my b&s 24hp intek motor?

#1

alvinjohn62

alvinjohn62

I killed my motor on my Husqvarna YTH24v48, the oil filter loosened and the motor ran out of oil and it died. Now I got zero compression.

How do I figure the cost of replacing it vs rebuilding?

How do I figure the cost of replacing it vs rebuilding?

#2

B

bertsmobile1

B

bertsmobile1

Firstly stop cranking the engine as you could be doing a lot more damage .

You have no compression because of one or more of he following

1) can rod broken so pistons not moving . check with a pencil down the spark plug hole .

2) valve stuck open, check by removing the rocker covers and watching the valves moving

They are identical so should move the same amount and end up in the same place both valves, both sides

3) bore trashed / rings broken , pull heads off or look inside with a bore-o-scope.

Once you have looked & posted some photos ( no shakey out of focus videos with muffled sounds please )

we can give you a rough break down of what will be needed so you can cost the parts out .

You have no compression because of one or more of he following

1) can rod broken so pistons not moving . check with a pencil down the spark plug hole .

2) valve stuck open, check by removing the rocker covers and watching the valves moving

They are identical so should move the same amount and end up in the same place both valves, both sides

3) bore trashed / rings broken , pull heads off or look inside with a bore-o-scope.

Once you have looked & posted some photos ( no shakey out of focus videos with muffled sounds please )

we can give you a rough break down of what will be needed so you can cost the parts out .

#4

E

Elkins45

E

Elkins45

Just as an FYI in case it’s badly damaged and needs a lot of parts, Small Engine Warehouse has a 20hp on sale now for $499. I don’t know if you can live with four less HP but even with shipping the cost might not be much more than all the replacement parts likely ruined by oil starvation.

#6

sgkent

sgkent

I would suggest not starting a new thread on the same thing each time your question changes.

Other thread:

lawnmowerforum.com

lawnmowerforum.com

Other thread:

i blew an oil filter and now i can’t get it to run.

i have a husqvarna yth 24v48 mower with a 24 hp v twin briggs. While mowing the motor died and i found out that I blew an oil filter. Changed the filter, filled with oil and now it wont run. My question is: is there a low oil pressure switch that shuts off the ignition when oil pressure drops...

#7

alvinjohn62

alvinjohn62

suggestion taken seriously,

I really don't know why I did that.

Is there a way to merge the two threads that I started about the same problem?

I really don't know why I did that.

Is there a way to merge the two threads that I started about the same problem?

#8

alvinjohn62

alvinjohn62

Okay moving on forward I'll stay on this thread and stop any replies on the other.

Now I need some answers to questions and also some advice from the professionals/experienced people.

The right cylinder piston does not move.

I can rotate the crankshaft almost 360°

During that rotation I cant see any movement of the push rods of both cylinder.

I dont know which is cylinder 1 and which is cylinder 2.

What is the rotation of the motor viewed from the top?

Where in the flywheel is the TDC mark and where is the pointer on the crankcase?

What is my next step going forward?

Should I take the motor out of the mower or can work on it there?

I might be able to figure all this out myself but it will surely be easier and faster if you all good fellas can advice me.

And Thank You very much for all the help.

Alvin

Now I need some answers to questions and also some advice from the professionals/experienced people.

The right cylinder piston does not move.

I can rotate the crankshaft almost 360°

During that rotation I cant see any movement of the push rods of both cylinder.

I dont know which is cylinder 1 and which is cylinder 2.

What is the rotation of the motor viewed from the top?

Where in the flywheel is the TDC mark and where is the pointer on the crankcase?

What is my next step going forward?

Should I take the motor out of the mower or can work on it there?

I might be able to figure all this out myself but it will surely be easier and faster if you all good fellas can advice me.

And Thank You very much for all the help.

Alvin

Attachments

#10

sgkent

sgkent

normally those symptoms mean either a broken crankshaft, connecting rod or both. You would have to take it apart, document the disassembly for reference, and then price the defective parts. You'll need a service manual. You might be able to find good used parts to rebuild it. That said, it is probably less costly to find a replacement engine that is new, or a good core for parts/to rebuild. If the connecting rod broke and hit the cylinder wall then the case is likely not worth using. But if all you need is a crankshaft and rods you might be able to find good used parts. Myself, I would just replace the engine with a known good used or new one. There are salvage yards for mowers you can see if they have a good used engine. There are also engine wholesalers for new ones.

#11

E

Elkins45

E

Elkins45

The fact one piston isn’t moving suggests a broken connecting rod since the other one presumably still moves. The lack of valve movement suggests either the camshaft is broken or it somehow disengaged from the crank, since it is turned by direct engagement of gear teeth. Either way I suspect when you open the sump you’ll find very bad things. Honestly when an engine is that damaged I would be hesitant to put money into replacing parts because so much else could be wrong.

#12

alvinjohn62

alvinjohn62

Ok I'm considering buying a new motor or a used motor.

Any recommendations for a wholesaler and also a salvage yard?

Any recommendations for a wholesaler and also a salvage yard?

#13

sgkent

sgkent

add something that helps us know where you are. Also the manufacturers webpage lists two engines of the same power but different crankshafts for that model. You need to look to see what engine # you have in it. I don't know where the B&S model number will be but if it isn't obvious someone here can tell you where to look.Ok I'm considering buying a new motor or a used motor.

Any recommendations for a wholesaler and also a salvage yard?

#14

B

bertsmobile1

B

bertsmobile1

So ,if you like to pull things apart to see how they work then you have some thing to do during those long winter nights that will be beneficial to your brain cells rather than allowing the box to attrify them .

GO to Small Engine Warehouse or Small Engine Suppliers or Repower and read up on how to measure your engine.

AFAIK it looks like a std engine but it can have either a 1" or 1.125" diameter crankshaft .

The 20Hp engine listed on the other thread would be the way to go if the cranks are the same length & diameter .

Unless you have a lot of hills or tow or snow plough or like to cut your grass at 2' weather it needs it or not then you will not notice the 4 Hp

I regularly replace engines with lower power ones because I can get a particular size one cheap and not a single person has complained or even noticed any difference .

The only time we had grief was from a wife who did the mowing & she complained bitterly so we ( hubby & I ) polished the old engine blower housing , put a new sticker on it and wifey poo was then happy with the better performance .

Like cars mowers come out with the correct sized engine then each couple of seasons get a bigger engine to make it look like they are "upgrading" the model and FWIW the original engine is usually 25% bigger than what the mower actually needs to run .

Several different HP ratings are derrived rom each engine capacity and that is the first 2 digits of the engine number,'So if yours is a 44XXXX then you can swap out your alternator & carb & throttle controls with any new 44XXXX engine.

Cheaper engines usually have smaller alternators and a combined throttle-choke control .

GO to Small Engine Warehouse or Small Engine Suppliers or Repower and read up on how to measure your engine.

AFAIK it looks like a std engine but it can have either a 1" or 1.125" diameter crankshaft .

The 20Hp engine listed on the other thread would be the way to go if the cranks are the same length & diameter .

Unless you have a lot of hills or tow or snow plough or like to cut your grass at 2' weather it needs it or not then you will not notice the 4 Hp

I regularly replace engines with lower power ones because I can get a particular size one cheap and not a single person has complained or even noticed any difference .

The only time we had grief was from a wife who did the mowing & she complained bitterly so we ( hubby & I ) polished the old engine blower housing , put a new sticker on it and wifey poo was then happy with the better performance .

Like cars mowers come out with the correct sized engine then each couple of seasons get a bigger engine to make it look like they are "upgrading" the model and FWIW the original engine is usually 25% bigger than what the mower actually needs to run .

Several different HP ratings are derrived rom each engine capacity and that is the first 2 digits of the engine number,'So if yours is a 44XXXX then you can swap out your alternator & carb & throttle controls with any new 44XXXX engine.

Cheaper engines usually have smaller alternators and a combined throttle-choke control .

#15

alvinjohn62

alvinjohn62

Okay I am in Gainesville FL

As for liking to take things apart, that is just what i'm going to do. It's 5:25 am now and i'm heading out to the carport and shed to set up lights and start taking things apart.

I figured I need to take out the deck first or the belt that connects with the deck.

I also dont know how it connects to drive the mower so i will find out soon.

Thank You all!

As for liking to take things apart, that is just what i'm going to do. It's 5:25 am now and i'm heading out to the carport and shed to set up lights and start taking things apart.

I figured I need to take out the deck first or the belt that connects with the deck.

I also dont know how it connects to drive the mower so i will find out soon.

Thank You all!

#16

StarTech

StarTech

Personally I would not recommend dropping 4 hp. Usually it is best stick with the same hp or a little more as most mower are using engine at minimum hp needed.

PTO length convert to factional length is 3-5/32.

And threads is 7/16-20.

The direct replacement is 44S977-0032-G1 which is a Briggs promotional engine.

But 44N877-0007-G1 will also work or any engine with the same crankshaft specs and mounting bolt pattern.

PTO length convert to factional length is 3-5/32.

And threads is 7/16-20.

The direct replacement is 44S977-0032-G1 which is a Briggs promotional engine.

But 44N877-0007-G1 will also work or any engine with the same crankshaft specs and mounting bolt pattern.

#17

E

Elkins45

Since it appears your engine has a 1” PTO the 20hp I mentioned that’s on sale would work if you can live with 20hp. You might have to swap the alternator from your old engine if you have electric blade engagement. How big is your deck?

E

Elkins45

I did an engine swap on my Craftsman without removing the deck. I just dropped it all the way down and removed the belts. From the bottom all you have to do is remove the pulley and the four mounting bolts, at least in a mower with manual blade engagement. Does your blade engage electrically? If so you will have to deal with the electric blade clutch.Okay I am in Gainesville FL

As for liking to take things apart, that is just what i'm going to do. It's 5:25 am now and i'm heading out to the carport and shed to set up lights and start taking things apart.

I figured I need to take out the deck first or the belt that connects with the deck.

I also dont know how it connects to drive the mower so i will find out soon.

Thank You all!

Since it appears your engine has a 1” PTO the 20hp I mentioned that’s on sale would work if you can live with 20hp. You might have to swap the alternator from your old engine if you have electric blade engagement. How big is your deck?

#18

alvinjohn62

alvinjohn62

ok, again Thanks so much for all the help!!!!

i am done taking all the connections on the upper side. Now underneath i will take off the belt to the blades. What baffles me is what connects the motor to the rear wheels? I dont want to be surprised having to deal with that in the middle of lifting the motor.

i am done taking all the connections on the upper side. Now underneath i will take off the belt to the blades. What baffles me is what connects the motor to the rear wheels? I dont want to be surprised having to deal with that in the middle of lifting the motor.

#19

E

Elkins45

E

Elkins45

Most mowers have a dual pulley. The bottom groove is for the blade belt and the top one is for the drive belt. You should see it when you get under the mower.ok, again Thanks so much for all the help!!!!

i am done taking all the connections on the upper side. Now underneath i will take off the belt to the blades. What baffles me is what connects the motor to the rear wheels? I dont want to be surprised having to deal with that in the middle of lifting the motor.

#20

B

bertsmobile1

so once you have the belts and pulley off all hat holds the engine in place will be the muffler & the 4 mounting bolts.

If there is oil in the engine, remove it before you start lifting the engine out

The exhaust pipes are loose in the muffler but it rarely pulls out easily when lifting the engine up .

As for the engine

Back in 1997 Husqvarna put a 13 Hp Kohler single in the YTH150 which had a 42" deck

Followed in 2000 with the YTH 170 with a 31 series B & S rated at 15 Hp, again a 42" deck

2008 it became the YTH 180, same deck but an 18Hp Kohler single and by the ned of the model run an 18Hp Kohler twin

By 2015 tit had become the YTH 22V42 , same 42" deck but now fitted with a 44 series B &S rated at 22 HP

Then we have your YTH 2442 Same deck but now fitted with a 24HP B & S

So in the space of 13 years apparently the grass has become so much tougher that you need a mower with just about twice the Hp ,,,really ?

Nothing changed in this time other than the size of the engine and the spindle housing going from 3 lugs to 4 lugs

So the only thing you will notice about the 20 Hp engine is you will use less fuel as they all spin at the same speed .

B

bertsmobile1

Nothing other than the top beltok, again Thanks so much for all the help!!!!

i am done taking all the connections on the upper side. Now underneath i will take off the belt to the blades. What baffles me is what connects the motor to the rear wheels? I dont want to be surprised having to deal with that in the middle of lifting the motor.

so once you have the belts and pulley off all hat holds the engine in place will be the muffler & the 4 mounting bolts.

If there is oil in the engine, remove it before you start lifting the engine out

The exhaust pipes are loose in the muffler but it rarely pulls out easily when lifting the engine up .

As for the engine

Back in 1997 Husqvarna put a 13 Hp Kohler single in the YTH150 which had a 42" deck

Followed in 2000 with the YTH 170 with a 31 series B & S rated at 15 Hp, again a 42" deck

2008 it became the YTH 180, same deck but an 18Hp Kohler single and by the ned of the model run an 18Hp Kohler twin

By 2015 tit had become the YTH 22V42 , same 42" deck but now fitted with a 44 series B &S rated at 22 HP

Then we have your YTH 2442 Same deck but now fitted with a 24HP B & S

So in the space of 13 years apparently the grass has become so much tougher that you need a mower with just about twice the Hp ,,,really ?

Nothing changed in this time other than the size of the engine and the spindle housing going from 3 lugs to 4 lugs

So the only thing you will notice about the 20 Hp engine is you will use less fuel as they all spin at the same speed .

#21

StarTech

StarTech

YTH24v48

This mower usually has an electric PTO clutch so the deck will need to come off for two reasons. One just makes accessing things easier. Two it so you can access the drive belt path.

The electric PTO come off fairly most times just using an impact wrench with a 5/8 (16mm) socket. Once the electric clutch is off you will the drive pulley behind it next to the engine's sump. It needs to come off so the drive belt needs removing. Be careful during the removal of the clutch and drive pulley as sometime there spacer washers used. Need to close attention to the order of the parts including the orientation of the drive pulley.

When putting the electric PTO back on is when you use a torque wrench to tighten it. Also don't forget make the anti rotation device is properly located on the clutch. Some if PTO clutch has a double D adapter then a wrench is use to hold it while tightening the bolt to 55 ft/lbs. If not present which I doubt it is used on this particular clutch then you would need to remove the engine's shroud so the flywheel can held in place using a large flat blade screw up again one of the ignition coil's mounting posts. This where a helper is plus as it is hard to hold the screw driver in place and tighten the PTO retaining bolt at the same time. Not impossible to done but a lot harder when you are the only one doing it. Don't forget to use anti-seize compound on the crankshaft.

This mower usually has an electric PTO clutch so the deck will need to come off for two reasons. One just makes accessing things easier. Two it so you can access the drive belt path.

The electric PTO come off fairly most times just using an impact wrench with a 5/8 (16mm) socket. Once the electric clutch is off you will the drive pulley behind it next to the engine's sump. It needs to come off so the drive belt needs removing. Be careful during the removal of the clutch and drive pulley as sometime there spacer washers used. Need to close attention to the order of the parts including the orientation of the drive pulley.

When putting the electric PTO back on is when you use a torque wrench to tighten it. Also don't forget make the anti rotation device is properly located on the clutch. Some if PTO clutch has a double D adapter then a wrench is use to hold it while tightening the bolt to 55 ft/lbs. If not present which I doubt it is used on this particular clutch then you would need to remove the engine's shroud so the flywheel can held in place using a large flat blade screw up again one of the ignition coil's mounting posts. This where a helper is plus as it is hard to hold the screw driver in place and tighten the PTO retaining bolt at the same time. Not impossible to done but a lot harder when you are the only one doing it. Don't forget to use anti-seize compound on the crankshaft.

#22

alvinjohn62

alvinjohn62

Thanks You all!

I'm off to my day job now so I will continue working on the mower tomorrow.

Hopefully we will get to see the inside of it then.

I'm off to my day job now so I will continue working on the mower tomorrow.

Hopefully we will get to see the inside of it then.

#23

alvinjohn62

alvinjohn62

Oh, Do I need to take out the flywheel"

Also, just to be sure, all fasteners are SAE right?

Also, just to be sure, all fasteners are SAE right?

#24

StarTech

YTH24V48 and YTH24V54 mowers uses a three spindles and a very long deck belt. Even with a 24hp engine it is hard on the engine to start up these 48" and 54" decks. Plus when in operation the deck grass loads will need this hp just to clear it. The YTH2448 uses a different 2 deck belt setup but just as a big load as the single belt setup. Putting on a 20hp engine on either one these would just will not work very well at all.

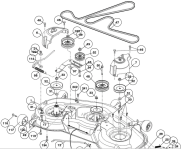

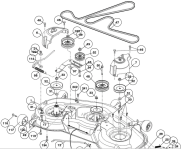

Here is the YTH24V48 deck setup.

I personally using a 42" MTD that came with a 16.5hp engine that was a gutless wonder. Now with a 21hp it came to life as an usable mower. Instead just cutting off a couple inches now it can 12" cut offs.

StarTech

Bert, The OP mower has a 48" deck per his model number posted as it need every bit of the 24 hp to operate the deck. Besides I believe the YTH2442 does not exist here. But a YTH2242 does as does the YTH24V42LS. Now YTH2448, YTH24V48 and YTH24V54 do exist.Nothing other than the top belt

so once you have the belts and pulley off all hat holds the engine in place will be the muffler & the 4 mounting bolts.

If there is oil in the engine, remove it before you start lifting the engine out

The exhaust pipes are loose in the muffler but it rarely pulls out easily when lifting the engine up .

As for the engine

Back in 1997 Husqvarna put a 13 Hp Kohler single in the YTH150 which had a 42" deck

Followed in 2000 with the YTH 170 with a 31 series B & S rated at 15 Hp, again a 42" deck

2008 it became the YTH 180, same deck but an 18Hp Kohler single and by the ned of the model run an 18Hp Kohler twin

By 2015 tit had become the YTH 22V42 , same 42" deck but now fitted with a 44 series B &S rated at 22 HP

Then we have your YTH 2442 Same deck but now fitted with a 24HP B & S

So in the space of 13 years apparently the grass has become so much tougher that you need a mower with just about twice the Hp ,,,really ?

Nothing changed in this time other than the size of the engine and the spindle housing going from 3 lugs to 4 lugs

So the only thing you will notice about the 20 Hp engine is you will use less fuel as they all spin at the same speed .

YTH24V48 and YTH24V54 mowers uses a three spindles and a very long deck belt. Even with a 24hp engine it is hard on the engine to start up these 48" and 54" decks. Plus when in operation the deck grass loads will need this hp just to clear it. The YTH2448 uses a different 2 deck belt setup but just as a big load as the single belt setup. Putting on a 20hp engine on either one these would just will not work very well at all.

Here is the YTH24V48 deck setup.

I personally using a 42" MTD that came with a 16.5hp engine that was a gutless wonder. Now with a 21hp it came to life as an usable mower. Instead just cutting off a couple inches now it can 12" cut offs.

#25

E

Elkins45

E

Elkins45

You don’t need to pull the flywheel. After you remove the engine you just need to flip it over and remove the sump bolts. You’ll also need to disconnect the governor.Oh, Do I need to take out the flywheel"

Also, just to be sure, all fasteners are SAE right?

#28

E

Elkins45

E

Elkins45

Ignore the foolishness and fast forward to 6:30by governor i assume it is the vane that is blown by airflow from the blower?

#29

B

bertsmobile1

B

bertsmobile1

Well Star, you & I will just have to dissagree on this one

I have a CZ 4815K in my run and that is a ZTR with the same 48" deck , and 2 hydros driven of a 15 Hp Kawasaki

Now this is the engine with the electronic ignition advance so it does have a few more testicales than your run of the mill 15 Hp B & S

and that is a 2000 model that got upgraded every year so they went from 15 , to 18 to 20 to 22 till the model was abandoned ,

And I have a 10/32 side valve that will happily chomp down 4' of grass & woody weeds along the 5 acres of verge that I have to mow with ease .

The YTH are what Husqvarna fobs off as a Yard Tractor so have substantially bigger engines in order to power the ground engaging attachments like rotary hoes

I have a CZ 4815K in my run and that is a ZTR with the same 48" deck , and 2 hydros driven of a 15 Hp Kawasaki

Now this is the engine with the electronic ignition advance so it does have a few more testicales than your run of the mill 15 Hp B & S

and that is a 2000 model that got upgraded every year so they went from 15 , to 18 to 20 to 22 till the model was abandoned ,

And I have a 10/32 side valve that will happily chomp down 4' of grass & woody weeds along the 5 acres of verge that I have to mow with ease .

The YTH are what Husqvarna fobs off as a Yard Tractor so have substantially bigger engines in order to power the ground engaging attachments like rotary hoes

#30

StarTech

StarTech

Yes some engines actually rated for their net hp and not the gross hp. I once had a 12.5hp Briggs side valve here on a 38" that reworked due governor failure and I miss timed the camshaft by one tooth and it hp (torque) was greatly increased. I also seen smaller hp side valves outperform larger OHV engines. It all matter where the peak torque curve is and the pulley system is designed.

#32

alvinjohn62

alvinjohn62

I'm up now and heading out to the carport, got my coffee and my vest on, I'll have pictures by tonight the latest or maybe in a few hours depending on life.

5:22 am

5:22 am

#33

alvinjohn62

alvinjohn62

Sorry for the delay everyone, life got in my way, and the weather too.

Might be Saturday I can proceed with my taking off the pulleys from underneath.

I think I can handle the 46° or wait for later in the day.

I got the deck out already, as well as wires, fuel hose and throttle cable.

Still thinking of putting back the blower housing as I will need to flip over the motor.

Or figuring out ways to set the motor upside down on blocks.

Might be Saturday I can proceed with my taking off the pulleys from underneath.

I think I can handle the 46° or wait for later in the day.

I got the deck out already, as well as wires, fuel hose and throttle cable.

Still thinking of putting back the blower housing as I will need to flip over the motor.

Or figuring out ways to set the motor upside down on blocks.

#34

E

Elkins45

Putting the screw that holds the dipstick tube just far enough under the flywheel you can’t access it was a really dumb design choice.

E

Elkins45

No need to replace the housing, it can set on the flywheel. Just watch out for the dipstick tube. I made a 2x4 frame so I could set mine up or down and not have to worry about the crankshaft or dipstick tube.Sorry for the delay everyone, life got in my way, and the weather too.

Might be Saturday I can proceed with my taking off the pulleys from underneath.

I think I can handle the 46° or wait for later in the day.

I got the deck out already, as well as wires, fuel hose and throttle cable.

Still thinking of putting back the blower housing as I will need to flip over the motor.

Or figuring out ways to set the motor upside down on blocks.

Putting the screw that holds the dipstick tube just far enough under the flywheel you can’t access it was a really dumb design choice.

#35

alvinjohn62

alvinjohn62

Ok Thanks for the info.

I will have my blocks ready.

Maybe my scooter repair blocks will work, it is a 7,9,11 block of wood that has a hallow center when set on 7 inch height.

Thanks again and I'm off to my day job now.

I will have my blocks ready.

Maybe my scooter repair blocks will work, it is a 7,9,11 block of wood that has a hallow center when set on 7 inch height.

Thanks again and I'm off to my day job now.

#36

E

Elkins45

E

Elkins45

When you get the sump cover off there are two locator pins. Be careful if one or both stick in the sump cover because it’s very easy to lose them. I know because I lost one when I was replacing my gasket and had to manufacture a replacement before I put it back together. I doubt it really matters in the case of your particular engine, but who knows?Ok Thanks for the info.

I will have my blocks ready.

Maybe my scooter repair blocks will work, it is a 7,9,11 block of wood that has a hallow center when set on 7 inch height.

Thanks again and I'm off to my day job now.

#38

alvinjohn62

alvinjohn62

i’m sorry for the delay, I promise to update soon as possible. Things are just not going in my favor. But it is also giving me more at home time so maybe in a week or two I can get back to it.

#39

alvinjohn62

alvinjohn62

I finally got to open the motor. So the connecting rod is broken and the piece that is still attached to the piston is wedged against the camshaft.

So now the hard decision is to buy a new motor or a new mower.

Got pictures but still figuring out how to reduce the file size as it is too large.

So now the hard decision is to buy a new motor or a new mower.

Got pictures but still figuring out how to reduce the file size as it is too large.

#40

E

Elkins45

E

Elkins45

If your deck and transmission are still in good shape it makes sense to replace the engine. Even if you only get a few more years out of them that gives you a newish engine to swap into a cheap used mower. There’s almost always a decent mower with a blown engine available for next to nothing on Craigslist or FB.

#41

B

bertsmobile1

Then was & check everything carefully for cracks , add up the price of new parts and compare it to the price of a superceeded engine from Small Engine Warehouse, Small Engine Suppliers, Surplus Centre , Repower Centre .

You can get some really cheap .

Unless you live in mountain goat country or think your mower is a Brush Hog anything from 18Hp up will be fine .

B

bertsmobile1

Firstly tap the piston back up the cylinder a little and pull the engine fully apart .I finally got to open the motor. So the connecting rod is broken and the piece that is still attached to the piston is wedged against the camshaft.

So now the hard decision is to buy a new motor or a new mower.

Got pictures but still figuring out how to reduce the file size as it is too large.

Then was & check everything carefully for cracks , add up the price of new parts and compare it to the price of a superceeded engine from Small Engine Warehouse, Small Engine Suppliers, Surplus Centre , Repower Centre .

You can get some really cheap .

Unless you live in mountain goat country or think your mower is a Brush Hog anything from 18Hp up will be fine .