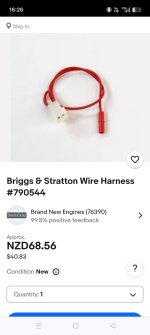

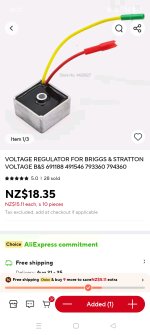

the manufacturer buys VR A from a company that makes VRs. They buy the alternator windings B from someone else. People in a factory assemble the parts onto an engine. The engineer looks at the pieces which have different connectors and decides it costs less to use a custom made jumper adapter along with lower cost VR A than to make a new custom VR. 15,000 jumpers are made and they are used to put part A together with part B. Next year the world changes again because someone comes out with a VR that costs a lot less than VR A but has different connectors to get around patents. Engineer orders a new connector to put this new VR C together with alternator B. Making matters worse, the VRs are potted so one cannot replace a simple blown diode. Now comes a DIY who wants to fix the parts using the NLA part after a mouse chews the wires and shorts out the VR A, People come along and make the NLA parts but they make 250 of them instead of 15,000, and it is 8 years later so the cost is higher. DIY complains the cost is too high.

Don't ever restore a car, airplane or boat and one will see what expensive is. Alternatively, they could get in their car and drive to the nearest mower bone yard, go thru old mowers until they find a used harness that works. Cost $5. Cost in time and gas $350. Cost to ***** and blame someone else $0.00.