- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,863

My shop was already outgrown before I moved into it. About half of my parts are stored in my home. I want to build another building too but as you costs are prohibitive even me doing all the building.

Here I am a $55/hr plus tax. Parts are sold per OEM price files except outside the distributors. Even then most are only mark-up 35% max with parts from JD usually at 20% which allows me to be 10% above parts cost [not counting shc] when I sell to seniors. Most understand that I must pay shipping to get the parts. Sometimes the parts actually sold at a loss if shc is high. I do tend buy extra when I get a deal on parts or use a different OEM part when they are the same part but at a lower cost. Procuring parts can be a challenge that pays off in the long run.

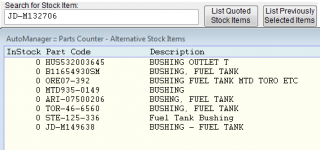

Its that way when I can buy Husqvarna parts for a newer Snapper mower instead going through Briggs and paying them their markup. That one thing about my accounting system inventory setup that helps keeps me profitable and competitive. I could be making more profit using the OEM part numbers but I am little more honest than that give the customer better price while I make a decent profit.

Here is an example of one item that JD actually (acquired) cheaper on than the other OEMs. Now of course Oregon was .02 more each but I had other JD parts I needed so I order a dozen of them and save the separate shipping charges. JD was $1.30 vs the Briggs price of $5.21 for the same part.

BTW if I had brought the Briggs part at $5.21 which I am supposed to sell them at $5.79 so I would lose money if order is below the minimum free shipping order size. The last time I order Briggs parts below the minimum free ship the order was $192 but that came in with a $45 shipping charge. OUCH!!! I didn't even break even on that order.

Here I am a $55/hr plus tax. Parts are sold per OEM price files except outside the distributors. Even then most are only mark-up 35% max with parts from JD usually at 20% which allows me to be 10% above parts cost [not counting shc] when I sell to seniors. Most understand that I must pay shipping to get the parts. Sometimes the parts actually sold at a loss if shc is high. I do tend buy extra when I get a deal on parts or use a different OEM part when they are the same part but at a lower cost. Procuring parts can be a challenge that pays off in the long run.

Its that way when I can buy Husqvarna parts for a newer Snapper mower instead going through Briggs and paying them their markup. That one thing about my accounting system inventory setup that helps keeps me profitable and competitive. I could be making more profit using the OEM part numbers but I am little more honest than that give the customer better price while I make a decent profit.

Here is an example of one item that JD actually (acquired) cheaper on than the other OEMs. Now of course Oregon was .02 more each but I had other JD parts I needed so I order a dozen of them and save the separate shipping charges. JD was $1.30 vs the Briggs price of $5.21 for the same part.

BTW if I had brought the Briggs part at $5.21 which I am supposed to sell them at $5.79 so I would lose money if order is below the minimum free shipping order size. The last time I order Briggs parts below the minimum free ship the order was $192 but that came in with a $45 shipping charge. OUCH!!! I didn't even break even on that order.