You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Daily Yardman Thread

- Thread starter Roger B

- Start date

More options

Export threadBoobala

Lawn Pro

- Joined

- Feb 15, 2015

- Threads

- 200

- Messages

- 7,000

Re: MTD Yardman Transaxle Rebuild

GOOOOOOOD Mornin Chuck, .... N U 2 Goomba !!

Giddy-up all the rest of my brethren, .... (actually means Good Morn ! )

(actually means Good Morn ! )

Thought 4 2day : ( 2 4 1 - SPECIAL 2day !! ) ... Special for Ron, ...

And for the rest of the world !! .... ... BUT it COULD apply to Ron with his .. "Door=Dilemma"

... BUT it COULD apply to Ron with his .. "Door=Dilemma"

GOOOOOOOD Mornin Chuck, .... N U 2 Goomba !!

Giddy-up all the rest of my brethren, ....

(actually means Good Morn ! )

(actually means Good Morn ! )Thought 4 2day : ( 2 4 1 - SPECIAL 2day !! ) ... Special for Ron, ...

And for the rest of the world !! ....

... BUT it COULD apply to Ron with his .. "Door=Dilemma"

... BUT it COULD apply to Ron with his .. "Door=Dilemma"Ronno6

Lawn Addict

- Joined

- Apr 8, 2016

- Threads

- 24

- Messages

- 1,933

Re: Garage Doors

Hey, Rog,

Well. door #1 is partially completed: tracks shortened and installed, 4ea 19" panels installed, torsion spring installed and tensioned.

The door goes up and down just fine, leaving a 7" gap at the top.

Spring tension is a bit high, but that should work itself out after the weight of the remaining panel comes into play.

I am going to obtain a 1 x 8 board for testing purposes.

If it looks like the door will be operable with the short panel at the top, I'll trim the panel out to not look so patchwork

and install there. I may actually be able to affix it to the top of the existing metal door panel and it may clear everything as it swings inward.

If not, I'll hinge and roller it.

Then I have to determine where to attach the opener...

I'm sure it would work fine in the middle or at the bottom, but the bottom metal panel has the seal affixed with numerous spot welds, so removal is not a viable option.

The steel door is a typical unit made to look like is comprised of raised panel, style and rail construction which is embossed into the thin steel skin.

like this: https://www.lowes.com/pd/Pella-Traditional-108-in-x-84-in-White-Single-Garage-Door/50259747

Putting the short panel in the middle would work, just look funky.

As there will be 2 doors side by side, symmetry is an issue.

Pics may follow later.........

So, Ron..

How has the garage door installation gone so far? In my minds eye I see a possible problem with having panel strips of differing widths, but maybe that doesn't matter. Are the door-width panel strips made up of individual panels? Or are they just made to 'look' like they are? You mentioned aluminum, maybe the panel strips are flat pieces?

I'm still working out how you can reduce the height of one panel strip, but not knowing what they look like, makes my mind puzzle over the numerous styles of garage doors I've seen in my lifetime and that gives me too many possibilities to work with.

I wonder if the radius of the 90 degree turn at the top of the track has some bearing on the height of each panel strip as each one has a guide wheel and again, if the space between guide wheels is too close together, I wonder of they might jamb trying to negotiate that turn in the track. I tried drawing it out, it 'looks' like it will work alright, smaller panels would actually allow for a tighter turn, like a tambor door.

How about some pictures, you know the rules here on the site, you must provide detailed pictures and model numbers if you expect to get any usable feedback. (Other than being told to raise your ceiling, or jack up your garage.)

Roger

Hey, Rog,

Well. door #1 is partially completed: tracks shortened and installed, 4ea 19" panels installed, torsion spring installed and tensioned.

The door goes up and down just fine, leaving a 7" gap at the top.

Spring tension is a bit high, but that should work itself out after the weight of the remaining panel comes into play.

I am going to obtain a 1 x 8 board for testing purposes.

If it looks like the door will be operable with the short panel at the top, I'll trim the panel out to not look so patchwork

and install there. I may actually be able to affix it to the top of the existing metal door panel and it may clear everything as it swings inward.

If not, I'll hinge and roller it.

Then I have to determine where to attach the opener...

I'm sure it would work fine in the middle or at the bottom, but the bottom metal panel has the seal affixed with numerous spot welds, so removal is not a viable option.

The steel door is a typical unit made to look like is comprised of raised panel, style and rail construction which is embossed into the thin steel skin.

like this: https://www.lowes.com/pd/Pella-Traditional-108-in-x-84-in-White-Single-Garage-Door/50259747

Putting the short panel in the middle would work, just look funky.

As there will be 2 doors side by side, symmetry is an issue.

Pics may follow later.........

Ronno6

Lawn Addict

- Joined

- Apr 8, 2016

- Threads

- 24

- Messages

- 1,933

Re: MTD Yardman Transaxle Rebuild

More door stuff............

One door has a pretty badly injured panel, as the torsion spring broke and use of the opener without spring assist

cause the door to buckle and fracture in the middle.

Had this not happened and I had 4 good panels other than the bottom with the seal on it, I would install the

short panel at the bottom. That would probably be the best design.

I could still pit it in the center, but I dunno how that will look. Less noticeable at top or bottom.

I'm beginning to understand the black magic of door torsion springs.

If a spring is too strong, the door will not remain closed when down.

Relieving a turn of tension may allow the door st remain closed, but the spring will unwind before the door

gets to the top of the opening, which means it will not stay up, or the cable will go slack if an opener pulls the door

past that point. Cable slack is not a good thing........

Too low a spring rate and it will not provide adequate lift assist to the door, overstressing the opener and top panel where the opener attaches.

I think the existing spring will work OK when I get the additional weight of the short panel in play.

Lengthening the track would reduce the headroom necessary for the opener.

Of course, I could just reduce the opening size to fit the door but my truck may be too tall to get thru a 6'3" opening..........

More door stuff............

One door has a pretty badly injured panel, as the torsion spring broke and use of the opener without spring assist

cause the door to buckle and fracture in the middle.

Had this not happened and I had 4 good panels other than the bottom with the seal on it, I would install the

short panel at the bottom. That would probably be the best design.

I could still pit it in the center, but I dunno how that will look. Less noticeable at top or bottom.

I'm beginning to understand the black magic of door torsion springs.

If a spring is too strong, the door will not remain closed when down.

Relieving a turn of tension may allow the door st remain closed, but the spring will unwind before the door

gets to the top of the opening, which means it will not stay up, or the cable will go slack if an opener pulls the door

past that point. Cable slack is not a good thing........

Too low a spring rate and it will not provide adequate lift assist to the door, overstressing the opener and top panel where the opener attaches.

I think the existing spring will work OK when I get the additional weight of the short panel in play.

Lengthening the track would reduce the headroom necessary for the opener.

Of course, I could just reduce the opening size to fit the door but my truck may be too tall to get thru a 6'3" opening..........

Ronno6

Lawn Addict

- Joined

- Apr 8, 2016

- Threads

- 24

- Messages

- 1,933

Re: MTD Yardman Transaxle Rebuild

It may, but it slides into a track which is spot welded to the door panel.

Rubber on bottom should slide in from side. Check and see if you can pull it out.

It may, but it slides into a track which is spot welded to the door panel.

Boobala

Lawn Pro

- Joined

- Feb 15, 2015

- Threads

- 200

- Messages

- 7,000

Re: MTD Yardman Transaxle Rebuild

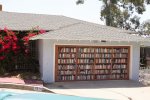

No matter how bad it looks, ..you can hide it all with a door mural !! ( LOL )

View attachment 36079...View attachment 36080...View attachment 36081...View attachment 36082...

No matter how bad it looks, ..you can hide it all with a door mural !! ( LOL )

View attachment 36079...View attachment 36080...View attachment 36081...View attachment 36082...

Ronno6

Lawn Addict

- Joined

- Apr 8, 2016

- Threads

- 24

- Messages

- 1,933

Re: MTD Yardman Transaxle Rebuild

Can't open any but the book case......................

No matter how bad it looks, ..you can hide it all with a door mural !! ( LOL )

View attachment 36079...View attachment 36080...View attachment 36081...View attachment 36082...View attachment 36086

Can't open any but the book case......................

Ronno6

Lawn Addict

- Joined

- Apr 8, 2016

- Threads

- 24

- Messages

- 1,933

Re: More Dor N ews

I have test fitted a short piece of 1 x 8 to one side, attaching with the hinge and installing a top guide roller.

It appears that this approach will work.

The door panels have a tongue and groove configuration that I can easily machine into the wood.

I will use a 1 x 8full width, frame inside with 1 x 2 and 1 x 4, then outside with something 1/2" thick w, beveled edges

to give the 3-D effect and bring the panel to the required 2" thickness.

I didn't know how things would track with 2 rollers so close together, but apparently, just fine.

Then, it'll be on to the opener.........

Keep yer fin'ers crossed.............

Eyes,too in yer case,Boo....

I have test fitted a short piece of 1 x 8 to one side, attaching with the hinge and installing a top guide roller.

It appears that this approach will work.

The door panels have a tongue and groove configuration that I can easily machine into the wood.

I will use a 1 x 8full width, frame inside with 1 x 2 and 1 x 4, then outside with something 1/2" thick w, beveled edges

to give the 3-D effect and bring the panel to the required 2" thickness.

I didn't know how things would track with 2 rollers so close together, but apparently, just fine.

Then, it'll be on to the opener.........

Keep yer fin'ers crossed.............

Eyes,too in yer case,Boo....

Ronno6

Lawn Addict

- Joined

- Apr 8, 2016

- Threads

- 24

- Messages

- 1,933

Re: More Door News

Prior to acquiring these doors I had thought of slicing the top panel to the correct dimension, then fastening a 2 x 1 x 1/8 piece of aluminum channel to the raw edge.

That seemed like too much work and expense.

I guess I could dig a trench for the door to go down into, but............

It is the top panel that is too long.......not the bottom one!

Prior to acquiring these doors I had thought of slicing the top panel to the correct dimension, then fastening a 2 x 1 x 1/8 piece of aluminum channel to the raw edge.

That seemed like too much work and expense.

I guess I could dig a trench for the door to go down into, but............

It is the top panel that is too long.......not the bottom one!