I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

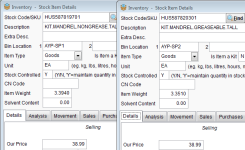

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob