You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Model YTH 18542 Mandrel Assembly

#1

P

platefire

P

platefire

I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

#2

ILENGINE

ILENGINE

The mandrels use sealed bearings. And the truth is your greasable mandrels also had sealed bearings, and the grease fitting is a feel good attempt for people that want to grease their bearing even though for the most part the grease never enters the bearing.

#3

P

platefire

P

platefire

Thanks! Guess there is no use force feeding grease to a sealed bearing

when he don't want it:>)

when he don't want it:>)

#4

P

platefire

P

platefire

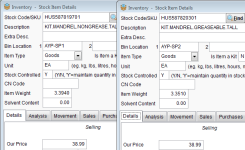

Unless I fooled myself, this looks like a true Husqvarna Replacement # 587819701 as per link:

https://www.ebay.com/itm/4048174656...NtZRj5Xqd1GtZgR6V8YBLJ1Bh/M=|tkp:BFBMkq_2uvBj

May as well replace drive belt while I have deck removed. The Mandrels are not ready to be changed yet but I know

it won't be too long. So now I got jump up on it

https://www.ebay.com/itm/4048174656...NtZRj5Xqd1GtZgR6V8YBLJ1Bh/M=|tkp:BFBMkq_2uvBj

May as well replace drive belt while I have deck removed. The Mandrels are not ready to be changed yet but I know

it won't be too long. So now I got jump up on it

#5

Tiger Small Engine

Tiger Small Engine

Some people on internet claim the grease still gets into bearings despite being sealed. I know in some cases it takes up to 150 pumps on these spindles before grease comes out to let you know it is full. Others claim at a minimum it helps keep moisture out. It has bothered me for a long time, and wish I could get a definitive answer.Thanks! Guess there is no use force feeding grease to a sealed bearing

when he don't want it:>)

#6

StarTech

StarTech

What happens when you try to force grease into the sealed bearing is a lot of the time the inner seals are pushed into the bearing and the outer seal can actually get pushed out. The bearings has to be change to ZZ bearings from the the 2RS bearings as the ZZ will allow grease to enter and exit the bearings while still retaining most of the grease.

Also both the greaseable and non-grease spindle are the same retail price and cost.

I also see no reason to change the spindle housing when just the bearing are needing replacing; unless, you try removing the spindles to change out the bearing which leads to broken mounting screws.

Also both the greaseable and non-grease spindle are the same retail price and cost.

I also see no reason to change the spindle housing when just the bearing are needing replacing; unless, you try removing the spindles to change out the bearing which leads to broken mounting screws.

#8

tgzzzz

tgzzzz

Couple of thoughts: Somewhere in Timken literature, the term used was "shield." This makes more sense than "seal" when grease/water/dirt can get around whatever is covering the bearing retainer.

I read Bert's post #7, just above, as the ZZ actually is a sealed bearing, as in nothing gets in or out ... ergo sealed.

However, we all just read Star Tech, post #6: "The bearings has to be change to ZZ bearings from the the 2RS bearings as the ZZ will allow grease to enter and exit the bearings while still retaining most of the grease." I read that as not "sealed."

123Bearing Co. calls the ZZs: "... 2 sheet metal deflectors, for dust-tightness. ..."

Are there no actually grease and water tight bearings available? ZZs cost more but is the difference meaningful?

I read Bert's post #7, just above, as the ZZ actually is a sealed bearing, as in nothing gets in or out ... ergo sealed.

However, we all just read Star Tech, post #6: "The bearings has to be change to ZZ bearings from the the 2RS bearings as the ZZ will allow grease to enter and exit the bearings while still retaining most of the grease." I read that as not "sealed."

123Bearing Co. calls the ZZs: "... 2 sheet metal deflectors, for dust-tightness. ..."

Are there no actually grease and water tight bearings available? ZZs cost more but is the difference meaningful?

#9

P

platefire

P

platefire

It appears that this subject is really subjective. I got started on these off brand Mandrels with grease fittings when my old Sears 2000 42" cut when the originals went out. The replacements had a vertical grease fitting in the top of

the shaft and was vertical that made them almost impossible to access with a grease gun, so I had to buy

some 90 degree L fittings and they worked fine. I really don't know it the replacement mandrels had sealed or grease-able bearings? All I know is the Mandrels worked fine for the rest of the life of the mower until the deck

completely disintegrated after several welded patches.

So you all are causing me to think about it a lot more. I guess I always thought the bearing were all grease-able and never could understand why then didn't install grease fittings--thinking they wanted them to wear out faster so you would have to replace them quicker:>) I have to admit, plugging them with grease did give a warm and fuzzy thinking I was being wise. I've really been surprised that these in the Husqvarna has held up this long because

I have a lot of tree-roots above ground that causes me to lift and lower the deck constantly and sometimes I'm

not fast enough and really nail them. So for no grease in 5 years and still ticking isn't bad. So I'm going to see how

long they hold out. Thanks for the information, so now I know I have a choice and can refer back to this info you've

provided when it comes time.

the shaft and was vertical that made them almost impossible to access with a grease gun, so I had to buy

some 90 degree L fittings and they worked fine. I really don't know it the replacement mandrels had sealed or grease-able bearings? All I know is the Mandrels worked fine for the rest of the life of the mower until the deck

completely disintegrated after several welded patches.

So you all are causing me to think about it a lot more. I guess I always thought the bearing were all grease-able and never could understand why then didn't install grease fittings--thinking they wanted them to wear out faster so you would have to replace them quicker:>) I have to admit, plugging them with grease did give a warm and fuzzy thinking I was being wise. I've really been surprised that these in the Husqvarna has held up this long because

I have a lot of tree-roots above ground that causes me to lift and lower the deck constantly and sometimes I'm

not fast enough and really nail them. So for no grease in 5 years and still ticking isn't bad. So I'm going to see how

long they hold out. Thanks for the information, so now I know I have a choice and can refer back to this info you've

provided when it comes time.

#10

S

SeniorCitizen

S

SeniorCitizen

No grease fitting for a sealed bearing doesn't concern me , but I am concerned if at least 1 of the 2 bearings is not a push ( with my finger ) fit .

#11

P

platefire

P

platefire

YELP! When you get to changing the bearings out separately, that's beyond my pay grade>>>>>may need to

go off on a week long bearing seminar to do that

go off on a week long bearing seminar to do that

#12

S

SeniorCitizen

S

SeniorCitizen

If you can tie boot laces ya can replace the bearings . There's only 3 pieces inside the assembly and all will go in either end first .YELP! When you get to changing the bearings out separately, that's beyond my pay grade>>>>>may need to

go off on a week long bearing seminar to do that

#13

B

bertsmobile1

B

bertsmobile1

OK,

Let's clear things up for ones & for all

There is no such thing as a water tight bearing they simply do not exist without external seals .

A rubber seal bearing has a rubber seal, with the LIP POINTING IN to prevent the grease getting out not to prevent anything else other than dirt getting in

Pop one off and old bearing and look at the lip

Nest there are various types of seals

Grease seals like you have on your front wheel bearings and water ( or liquid seals ) like you have on a pump and in between them are oil seals like the ones on the engine crank shaft designed to prevent oil leaving the engine .

They all have different constructions and different fits , or tightness on the spinning bit if you like .

If a 2 RS bearing was water tight then you would not be able to jamb your finger in the middle & turn the outer race, there would be too much resistance .

Now we get to metal shields

They are designed to prevent debris getting INTO the bearing from the outside but they do not prevent the grease getting out from the inside

SO if you pump a spindle with a ZZ or Z bearing fitted with grease then eventually it will ooze out through the shield

This tends to make them water tight as the grease repels water.

If you fit a 2 RS bearing into a spindle then pump it full of grease then usually the bearing will pop out because the grease can get from the spindle into the bearing past the rubber seal but it can not get out of the other side of the bearing and in fact is a recognised method of no damage bearing removal if you have a fast high volume grease gun

The other big difference is the metal shield is held tightly in place so the pressure of the grease acting on it will not cause it to to shift inwards or deform to touch the cage where as a RS will .

So take awys is if you want to fil the spindle with grease ( which I do ) then at least 1 bearing has to be either open or a metal shield and because of gravity it is best to have it on the top because the air will accumulate on the top so can be expelled the next time you grease the spindle along with any water degraded grease around the bearing.

Z or ZZ bearings will usually substantially outlast a RS bearing if the spindle is kept greased .

My commercial customers have been trained to give each spindle 1 stroke of the grease gun to all spindles every week and those who follow this rule have never experienced a spindle bearing collapse and in most cases their spindle bearings last for a very long time

I have several Z masters in the run and they are supposed to run open bearings with grease seals but the seals cost more than the bearings so I now fit ZZ bearings to the spindles and most of them have gone from 2 sets of bearings / year to one set every 2 to 3 years .

Nad remember commercial mowing contractors have to mow in the rain in many cases and their mowers live on their trailers, most of which are parked on the street overnight or in a drive so they cop a lot of weather .

Let's clear things up for ones & for all

There is no such thing as a water tight bearing they simply do not exist without external seals .

A rubber seal bearing has a rubber seal, with the LIP POINTING IN to prevent the grease getting out not to prevent anything else other than dirt getting in

Pop one off and old bearing and look at the lip

Nest there are various types of seals

Grease seals like you have on your front wheel bearings and water ( or liquid seals ) like you have on a pump and in between them are oil seals like the ones on the engine crank shaft designed to prevent oil leaving the engine .

They all have different constructions and different fits , or tightness on the spinning bit if you like .

If a 2 RS bearing was water tight then you would not be able to jamb your finger in the middle & turn the outer race, there would be too much resistance .

Now we get to metal shields

They are designed to prevent debris getting INTO the bearing from the outside but they do not prevent the grease getting out from the inside

SO if you pump a spindle with a ZZ or Z bearing fitted with grease then eventually it will ooze out through the shield

This tends to make them water tight as the grease repels water.

If you fit a 2 RS bearing into a spindle then pump it full of grease then usually the bearing will pop out because the grease can get from the spindle into the bearing past the rubber seal but it can not get out of the other side of the bearing and in fact is a recognised method of no damage bearing removal if you have a fast high volume grease gun

The other big difference is the metal shield is held tightly in place so the pressure of the grease acting on it will not cause it to to shift inwards or deform to touch the cage where as a RS will .

So take awys is if you want to fil the spindle with grease ( which I do ) then at least 1 bearing has to be either open or a metal shield and because of gravity it is best to have it on the top because the air will accumulate on the top so can be expelled the next time you grease the spindle along with any water degraded grease around the bearing.

Z or ZZ bearings will usually substantially outlast a RS bearing if the spindle is kept greased .

My commercial customers have been trained to give each spindle 1 stroke of the grease gun to all spindles every week and those who follow this rule have never experienced a spindle bearing collapse and in most cases their spindle bearings last for a very long time

I have several Z masters in the run and they are supposed to run open bearings with grease seals but the seals cost more than the bearings so I now fit ZZ bearings to the spindles and most of them have gone from 2 sets of bearings / year to one set every 2 to 3 years .

Nad remember commercial mowing contractors have to mow in the rain in many cases and their mowers live on their trailers, most of which are parked on the street overnight or in a drive so they cop a lot of weather .

#14

P

platefire

P

platefire

Thanks, I've read through your explanation several times trying to absorb all the info. Haven't had any experience

with different types of bearing seals and how they work. I'm assuming "RS" is rubber sealed and not sure about ZZ or Z type(metal sealed?). Seems like what experience I have had is like in a housing like a spindle Mandrel

is getting the old bearings out that sometimes requires a puller tool. Then if you start beating to pull old or install new you end up tearing something up. When you change these kind of things out on a regular basis it's easy but

if you never have, its a big old bear:>)

with different types of bearing seals and how they work. I'm assuming "RS" is rubber sealed and not sure about ZZ or Z type(metal sealed?). Seems like what experience I have had is like in a housing like a spindle Mandrel

is getting the old bearings out that sometimes requires a puller tool. Then if you start beating to pull old or install new you end up tearing something up. When you change these kind of things out on a regular basis it's easy but

if you never have, its a big old bear:>)

#15

B

bertsmobile1

B

bertsmobile1

leave the blade on remove the pulley nut & pulley, they usually come off easy

Slip the nut back on 2/3 of the way so it is not flush with the end of the spindle

Put a drift onto the end of the spindle and give it a good whack

The shaft will drop out a bit. loosen the nut a bit more & repeat

Just before you get to the last turn of the thread the spindle will fall out taking the bottom bearing with it

Poke a long drift in from the bottom & tap the top bearing out.

Support the bottom bearing some how & remove it from the shaft

Fits

The bottom bearing is a light press fit on the shaft and a hand press into the housing so you use a piece of water pipe to tap the CENTRE of the bearing home before returning it to the spindle

The upper bearing is a sliding fit on the shaft and a light press fit into the housing so it goes into the housing first then the spindle gets passed through it .

Usually I chill the spindle then warm ( in the sun light ) the lower bearing and it will usually push on by hand

I chill the top bearing and it falls into the spindle housing and it is allowed to warm up while I chill the spindle with the lower bearing on it.

And again they will usually slide in. occasionally needing a little tap

Slip the nut back on 2/3 of the way so it is not flush with the end of the spindle

Put a drift onto the end of the spindle and give it a good whack

The shaft will drop out a bit. loosen the nut a bit more & repeat

Just before you get to the last turn of the thread the spindle will fall out taking the bottom bearing with it

Poke a long drift in from the bottom & tap the top bearing out.

Support the bottom bearing some how & remove it from the shaft

Fits

The bottom bearing is a light press fit on the shaft and a hand press into the housing so you use a piece of water pipe to tap the CENTRE of the bearing home before returning it to the spindle

The upper bearing is a sliding fit on the shaft and a light press fit into the housing so it goes into the housing first then the spindle gets passed through it .

Usually I chill the spindle then warm ( in the sun light ) the lower bearing and it will usually push on by hand

I chill the top bearing and it falls into the spindle housing and it is allowed to warm up while I chill the spindle with the lower bearing on it.

And again they will usually slide in. occasionally needing a little tap

#16

P

platefire

P

platefire

OK Thanks, I might just try doing the bearing change out when the time comes and use this thread as a

reference. Other question I have is from past experience in removing the mounting bolts that hold the Mandrel

assembly in place usually break off when you try to remove them! For the normal hack mechanic

like me, that pretty much renderers the housings un-useable

I guess pre-treating the treads with penetrating oil might help that

reference. Other question I have is from past experience in removing the mounting bolts that hold the Mandrel

assembly in place usually break off when you try to remove them! For the normal hack mechanic

like me, that pretty much renderers the housings un-useable

I guess pre-treating the treads with penetrating oil might help that

#17

K

kjonxx

K

kjonxx

Put your own grease fittings in before installing, I so this on alot of greaseless ones. Also notice that ones with grease fittings have rubber sealed bearings so whats the point? I usually cut a small slit in rubber seal so grease can get in on the inside. Been working for years.I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

#18

J

jd345lx188

RS is the designation for radial seal, which is a rubber seal and seals water/grease/dirt out (up to the point where pressure, vacuum, wear, or some other force causes the seal to fail). 2RS designates that there is one on both sides of the bearing. ZZ metal shields are not necessarily water/grease/fine dirt tight, but do keep the bigger stuff out.

I work in manufacturing, we also do some assembly. One of those assemblies calls for a 1RS bearing. The seal gets assembled on the environment (water/dirt) side, the 'no seal' side towards the grease fitting. The 1RS bearing is a special, the 2RS is readily available. We buy the 2RS bearing, pop 1 of the rubber seals out with a screwdriver or pick, and we're good to go. The 'no seal' side allows the grease to enter from the grease fitting, the seal keeps the environment stuff out and allows pressurized grease out.

I don't work in the mower world and am curious, do those of you who do work on them daily see more spindle bearing failures on the decks that have those garden hose ports built into them and used all the time?

J

jd345lx188

Couple of thoughts: Somewhere in Timken literature, the term used was "shield." This makes more sense than "seal" when grease/water/dirt can get around whatever is covering the bearing retainer.

I read Bert's post #7, just above, as the ZZ actually is a sealed bearing, as in nothing gets in or out ... ergo sealed.

However, we all just read Star Tech, post #6: "The bearings has to be change to ZZ bearings from the the 2RS bearings as the ZZ will allow grease to enter and exit the bearings while still retaining most of the grease." I read that as not "sealed."

123Bearing Co. calls the ZZs: "... 2 sheet metal deflectors, for dust-tightness. ..."

Are there no actually grease and water tight bearings available? ZZs cost more but is the difference meaningful?

RS is the designation for radial seal, which is a rubber seal and seals water/grease/dirt out (up to the point where pressure, vacuum, wear, or some other force causes the seal to fail). 2RS designates that there is one on both sides of the bearing. ZZ metal shields are not necessarily water/grease/fine dirt tight, but do keep the bigger stuff out.

I work in manufacturing, we also do some assembly. One of those assemblies calls for a 1RS bearing. The seal gets assembled on the environment (water/dirt) side, the 'no seal' side towards the grease fitting. The 1RS bearing is a special, the 2RS is readily available. We buy the 2RS bearing, pop 1 of the rubber seals out with a screwdriver or pick, and we're good to go. The 'no seal' side allows the grease to enter from the grease fitting, the seal keeps the environment stuff out and allows pressurized grease out.

I don't work in the mower world and am curious, do those of you who do work on them daily see more spindle bearing failures on the decks that have those garden hose ports built into them and used all the time?

#19

C

closecut

The inner shield or seal can be removed by simply prying it out from the outer edge carefully with a small screwdriver.The main reason for bearing failure,according to Fafnir,the bearing company,is OVER GREASING.The grease must have room to get out of the ball path,or it will churn the grease and heat up and eventually carbonize the grease causing failure.

If you manually grease a bearing, leave some room for the grease to move out of the ball channel.I have had success drilling out the rivets of the mandrels and taking it apart,and getting access to the bearings,Replaced the rivets with cap screws and locktite. Popped out the inner seals,and left them out.Cleaned and re greased the bearings. Put Permatex#3 on mating faces of the mandrels to keep out trash.I have mandrels on an old 1986 Cub(sold by JC Penny before cub put out their own brand.)Original mandrels still working.I disassemble and put new grease in about every 5 years or so.I use a high temp grease like for wheel bearings on cars and trucks.

C

closecut

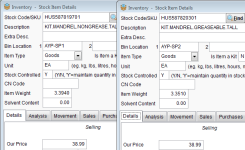

A "RS" or "2RS" suffix is a rubber sealed bearing.The "2RS" is sealed on both sides.A "RS" is sealed on one side only..A shielded bearing,like with a "KD",or"KDD" bearing is a shielded bearing,It is designed to keep dirt out,but not keep grease in.A Sealed bearing does both.What happens when you try to force grease into the sealed bearing is a lot of the time the inner seals are pushed into the bearing and the outer seal can actually get pushed out. The bearings has to be change to ZZ bearings from the the 2RS bearings as the ZZ will allow grease to enter and exit the bearings while still retaining most of the grease.

Also both the greaseable and non-grease spindle are the same retail price and cost.

View attachment 68671

I also see no reason to change the spindle housing when just the bearing are needing replacing; unless, you try removing the spindles to change out the bearing which leads to broken mounting screws.

The inner shield or seal can be removed by simply prying it out from the outer edge carefully with a small screwdriver.The main reason for bearing failure,according to Fafnir,the bearing company,is OVER GREASING.The grease must have room to get out of the ball path,or it will churn the grease and heat up and eventually carbonize the grease causing failure.

If you manually grease a bearing, leave some room for the grease to move out of the ball channel.I have had success drilling out the rivets of the mandrels and taking it apart,and getting access to the bearings,Replaced the rivets with cap screws and locktite. Popped out the inner seals,and left them out.Cleaned and re greased the bearings. Put Permatex#3 on mating faces of the mandrels to keep out trash.I have mandrels on an old 1986 Cub(sold by JC Penny before cub put out their own brand.)Original mandrels still working.I disassemble and put new grease in about every 5 years or so.I use a high temp grease like for wheel bearings on cars and trucks.

#20

S

STEVES

S

STEVES

You are removing deck, change the bearings without removing spindles the from deck. If you put on a bench it's an easy job.OK Thanks, I might just try doing the bearing change out when the time comes and use this thread as a

reference. Other question I have is from past experience in removing the mounting bolts that hold the Mandrel

assembly in place usually break off when you try to remove them! For the normal hack mechanic

like me, that pretty much renderers the housings un-useable

I guess pre-treating the treads with penetrating oil might help that

#21

O

oldntired55

O

oldntired55

i disassemble the mandrels, wash out any dirt grease etc, then i drill and tap for 1/4 x 28 grease fitting. clean the chips out... THEN, remove the seals from bearings that face toward inside of mandrel. rinse the bearings out, then re-assemble. i also drill a 1/16 weep hole at the top of mandrel, just below upper brg. this lets you know when the grease is up there, BEFORE you blow the remaining seals out . when you're finished greasing, put a #8 self drilling screw in the hole. that will keep the water out and grease in. before anyone doubts my process...i did this to my 30 yr old Craftsman mower 12 yrs ago... SAME spindles today.i grease mine twice a season. sealed bearings are a joke in this application, you will see what i mean when you pop those seals. if the bearings spin free after you remove the old dried out grease.. re use them!!I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

#22

R

RevB

Rant done. Get a set of grease needles off Amazon. In most cases you won't need to remove the spindle to slip the needle under the seal edge, or straight through if desired, and give the bearing a couple of shots.... don't over grease as too much will cause balls to skid, not roll as they should

R

RevB

I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

This damn forum software sucks....what damn site DOESN'T take jpeg files. And for mobile devices....halt, stop, freeze, tries to correct your spelling.......y'all should ***** hard at this site's owners.....but good luck finding them.I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

Rant done. Get a set of grease needles off Amazon. In most cases you won't need to remove the spindle to slip the needle under the seal edge, or straight through if desired, and give the bearing a couple of shots.... don't over grease as too much will cause balls to skid, not roll as they should

#23

StarTech

StarTech

Well you can also blame your mobile devices for saving in the largest file they can. And forum site only has has so much storage capacity.

I recently was given a Smart phone that every image takes up a lot memory with unnecessary reduntant data. Personally I still use the old VGA pixel format of 640 x 480 for images. And for this site I use a 1000 x 1000 max format.

I recently was given a Smart phone that every image takes up a lot memory with unnecessary reduntant data. Personally I still use the old VGA pixel format of 640 x 480 for images. And for this site I use a 1000 x 1000 max format.

#24

tgzzzz

tgzzzz

So, bearings don't come with much grease ..........and that's OK. Kinda hard thing to relearn. I have back up spindles without Zerks. Think I'll jsut leave them as is.

#25

StarTech

StarTech

And after market bearings comes packed with lousy grease too. This is why I repack them here before I install them with EP2 wheel bearing grease.

#26

T

TobyU

T

TobyU

People say a lot of inaccurate crap on the internet. I have taken these bearings out myself and have yet to find one that was open on the inside. They are the most common and cheapest bearings out there with the little rubber press and seal on each side which is designed to keep everything out so no grease is getting in there.Some people on internet claim the grease still gets into bearings despite being sealed. I know in some cases it takes up to 150 pumps on these spindles before grease comes out to let you know it is full. Others claim at a minimum it helps keep moisture out. It has bothered me for a long time, and wish I could get a definitive answer.

#27

T

TobyU

The last ones I ordered we're between 9 and 12 dollars a piece shipped to my house. I do always buy the ones that come with the screws too so I don't have to go to the hardware store because you almost always snap off some of the bolts. At these prices if you get over 3 years out of them it's well worth doing again.

Also, if you're not doing that long out of them, keep water away from machine and never use that deck Port wash clean out.

T

TobyU

It's not worth messing within all the news pretty low quality bearings today. Just don't buy the brand name spindles and buy them online where you can get them super cheaply.I've had this riding mower since 2019 and after this much use I'm anticipating replacing them even

though at this point they seem to be doing ok. From past experiences I never get more than five years

out of a Mandrel assembly. So on my last sears mower I replaced those mandrels with ones that had

grease fittings which worked real well. But---now I see from doing internet searches, all the mandrel

assemblies available for my mower are grease-less?

Could somebody please explain how these new mandrels work without grease? and is it a waste to

look for an assembly with grease fittings these days? Thanks Bob

The last ones I ordered we're between 9 and 12 dollars a piece shipped to my house. I do always buy the ones that come with the screws too so I don't have to go to the hardware store because you almost always snap off some of the bolts. At these prices if you get over 3 years out of them it's well worth doing again.

Also, if you're not doing that long out of them, keep water away from machine and never use that deck Port wash clean out.

#28

B

bertsmobile1

Pull a seal out and have a good look at the direction of the lip

It keeps the grease in not water out

And yes the water sits on top of the hot bearing then gets sucked in as it cools

Replaced so many of them it is not funny and for some reason Cubs seem to be the worst .

Never let water near then deck, use air, grass responds better to air than water .

B

bertsmobile1

You have that backwardsRS is the designation for radial seal, which is a rubber seal and seals water/grease/dirt out (up to the point where pressure, vacuum, wear, or some other force causes the seal to fail). 2RS designates that there is one on both sides of the bearing. ZZ metal shields are not necessarily water/grease/fine dirt tight, but do keep the bigger stuff out.

I work in manufacturing, we also do some assembly. One of those assemblies calls for a 1RS bearing. The seal gets assembled on the environment (water/dirt) side, the 'no seal' side towards the grease fitting. The 1RS bearing is a special, the 2RS is readily available. We buy the 2RS bearing, pop 1 of the rubber seals out with a screwdriver or pick, and we're good to go. The 'no seal' side allows the grease to enter from the grease fitting, the seal keeps the environment stuff out and allows pressurized grease out.

I don't work in the mower world and am curious, do those of you who do work on them daily see more spindle bearing failures on the decks that have those garden hose ports built into them and used all the time?

Pull a seal out and have a good look at the direction of the lip

It keeps the grease in not water out

And yes the water sits on top of the hot bearing then gets sucked in as it cools

Replaced so many of them it is not funny and for some reason Cubs seem to be the worst .

Never let water near then deck, use air, grass responds better to air than water .

#29

B

bertsmobile1

The self tapping threads have very sharp edges that raise stresses so initiate a failure

They are also induction hardened and that makes them even more prone to cracking .

The bolt is steel the mandrel is aluminium so you get galvanic corrosion if the two metals are in intimate contact and the whole thing gets damp and for that just dew is enough.

THe aluminium oxide Al203 is about 4 times the volume of the aluminium before it corroded so it locks the thread in really tight

The mechanical shape of the self tapping thread means it is very strong when being screwed in but a lot weaker when being undone so usually ay least 1 of the bolts will break or a lug snap off completely so never touch the mandrel bolts unless you are going to replace the whole shooting match .

This is why I suggested precutting the thread and applying anti seize ( not grease ) to the bolts .

B

bertsmobile1

penetrating oil is of little useOK Thanks, I might just try doing the bearing change out when the time comes and use this thread as a

reference. Other question I have is from past experience in removing the mounting bolts that hold the Mandrel

assembly in place usually break off when you try to remove them! For the normal hack mechanic

like me, that pretty much renderers the housings un-useable

I guess pre-treating the treads with penetrating oil might help that

The self tapping threads have very sharp edges that raise stresses so initiate a failure

They are also induction hardened and that makes them even more prone to cracking .

The bolt is steel the mandrel is aluminium so you get galvanic corrosion if the two metals are in intimate contact and the whole thing gets damp and for that just dew is enough.

THe aluminium oxide Al203 is about 4 times the volume of the aluminium before it corroded so it locks the thread in really tight

The mechanical shape of the self tapping thread means it is very strong when being screwed in but a lot weaker when being undone so usually ay least 1 of the bolts will break or a lug snap off completely so never touch the mandrel bolts unless you are going to replace the whole shooting match .

This is why I suggested precutting the thread and applying anti seize ( not grease ) to the bolts .

#30

P

platefire

P

platefire

So that is why it's being recommended just to pull the deck and change the

bearings in place-------saves dealing with a broken Mandrel bolt or having to

replace the whole Mandrel assmebly?

bearings in place-------saves dealing with a broken Mandrel bolt or having to

replace the whole Mandrel assmebly?

#31

ILENGINE

ILENGINE

Correct, because if the bolt breaks off trying to remove it, you will have to replace the mandrel because the chances of removing the broken bolt are very very low.So that is why it's being recommended just to pull the deck and change the

bearings in place-------saves dealing with a broken Mandrel bolt or having to

replace the whole Mandrel assmebly?

#33

T

TobyU

I just did a quick search in it does irritate me greatly that they're going for about 32 to $38 for a two pack because I was getting them for 18 to 24.

However there are rebuild kits available that's called a deck rebuild kit that comes with blades and everything and this one came up for $26.

T

TobyU

This is an okay method also but for most of these residential grade riding mowers, the bearings individually will cost you more than just buying the commonly available spindle assembly on eBay or amazon..So that is why it's being recommended just to pull the deck and change the

bearings in place-------saves dealing with a broken Mandrel bolt or having to

replace the whole Mandrel assmebly?

I just did a quick search in it does irritate me greatly that they're going for about 32 to $38 for a two pack because I was getting them for 18 to 24.

However there are rebuild kits available that's called a deck rebuild kit that comes with blades and everything and this one came up for $26.

Attachments

#34

T

TobyU

T

TobyU

I keep looking and it keeps getting worse. I just checked Amazon of course I always tell people Amazon is a terrible place to buy lawn mower parts 90% of the time. This is because you can get a better price and almost always a better selection if you scroll down eBay but there are a couple of things out there Amazon will give you a two pack deal on cheaper but spindles are not one of them.

Silly me, being spoiled for over 20 years with cheap Chinese stuff coming in but at great prices, just doesn't want to have to pay 18 to $25 for one spindle assembly.

Even though back in 2010 the prices started at $49.99 at Lowe's for an MTD brand one and the local shops were charging 62 to 70 for some of them and I don't even want to think about what John Deere dealers were getting for some of theirs.

Regardless, I'm spoiled and I don't do change.

I have some still here wrapped in Saran wrap that came as a multi-pack unit that I purchased probably around 2015 to 2017 and I was getting two packs and three packs and these things were literally under $9 shipped to my door.

This is the way it should be!!

Silly me, being spoiled for over 20 years with cheap Chinese stuff coming in but at great prices, just doesn't want to have to pay 18 to $25 for one spindle assembly.

Even though back in 2010 the prices started at $49.99 at Lowe's for an MTD brand one and the local shops were charging 62 to 70 for some of them and I don't even want to think about what John Deere dealers were getting for some of theirs.

Regardless, I'm spoiled and I don't do change.

I have some still here wrapped in Saran wrap that came as a multi-pack unit that I purchased probably around 2015 to 2017 and I was getting two packs and three packs and these things were literally under $9 shipped to my door.

This is the way it should be!!

#35

B

bertsmobile1

B

bertsmobile1

The 4 bolt spindles are now available from China for almost nothing and yes they are cheaper than just buying quality bearings

But the bearings in them are junk made for the Husqvarna clones and designed to fall apart 3 seconds after warranty

I buy them for the spindles & housings as of course those items bought separately are quite expensive and the spline at the top always fails because the star on the bottom prevents blade slip.

I usually fit NTN bearings from Japan which are a reasonable price from my wholesaler .

But the bearings in them are junk made for the Husqvarna clones and designed to fall apart 3 seconds after warranty

I buy them for the spindles & housings as of course those items bought separately are quite expensive and the spline at the top always fails because the star on the bottom prevents blade slip.

I usually fit NTN bearings from Japan which are a reasonable price from my wholesaler .

#36

StarTech

StarTech

Well as long as people buy by price alone and don't consider quality they will always be disappointed in the end. Yes things are cheaper but so the lack of quality. So I ask the customers do they want cheap spindles or good quality ones if I need to replace them. Yes I buy at lower cost too but I do try to compare apples to apples not apples to lemons.

The after market bearings I have tried were failing do to poor grease. It was drying up becoming hard causing the sealed bearing to fail. Once I started cleaning out this grease before installation of the bearings and replacing it with good EP2 wheel bearing grease the problem went away. Just takes a little more time than simply slapping in a set of bearings. Now I get my bearing from a bearing supplier and I still repack the ones with rubber seals as they are Chinese bearings with lousy grease.

As for the double hex end failing most times it it is it was never properly torqued. I get in spindles with stripped pulleys, repair things by replacing the pulleys and spindles, torque them to specs, and next time the mower comes with problems the blades are bent.

My current problem mowers are Gravely ZTRs where the blade retaining screws are so tight that I can't even break them free with a 900 ft/lb impact here or using a 3/4 breaker with a six foot cheater bar. I'm sending the mower to a heavy equipment shop where they have stronger impacts. These just round blades that tightening screws way past what I can get loose. I know it more of static bond then super torque due the rusting that is involved but getting pass that initial bond is a pain. I got to upgrade my equipment if I keep seeing these. Normally the 1/2 dr AirCat can get about anything loose but I am now considering adding a 1400 ft/lb 3/4 1778-VXL to my tool line up.

The after market bearings I have tried were failing do to poor grease. It was drying up becoming hard causing the sealed bearing to fail. Once I started cleaning out this grease before installation of the bearings and replacing it with good EP2 wheel bearing grease the problem went away. Just takes a little more time than simply slapping in a set of bearings. Now I get my bearing from a bearing supplier and I still repack the ones with rubber seals as they are Chinese bearings with lousy grease.

As for the double hex end failing most times it it is it was never properly torqued. I get in spindles with stripped pulleys, repair things by replacing the pulleys and spindles, torque them to specs, and next time the mower comes with problems the blades are bent.

My current problem mowers are Gravely ZTRs where the blade retaining screws are so tight that I can't even break them free with a 900 ft/lb impact here or using a 3/4 breaker with a six foot cheater bar. I'm sending the mower to a heavy equipment shop where they have stronger impacts. These just round blades that tightening screws way past what I can get loose. I know it more of static bond then super torque due the rusting that is involved but getting pass that initial bond is a pain. I got to upgrade my equipment if I keep seeing these. Normally the 1/2 dr AirCat can get about anything loose but I am now considering adding a 1400 ft/lb 3/4 1778-VXL to my tool line up.

#37

T

TobyU

I would venture to say that 95 plus percent of the people do not end up with quality bearings because the average bearing you buy today is also cheap junk.

Even though this is the case, I find they still last long enough to be quite respectable.

Frankly, the fact that these old mowers went 15 and 20 years plus with the same bearings in them was wonderful but a little absurd if you consider it.

Something spinning that quickly and for that many hours and especially in the lousy conditions with a lot of them getting damp or literally sprayed on with water hoses or pressure washers, which I strictly forbid, and the various blade impacts over these decades...

Anybody should be happy to get 6 to 8 years out of a bearing in these conditions but yet we did so much better.

So if anything it's pretty fair now but when I can get a spindle for $11, and if I get over 5 years out of it, I'm more than getting my money's worth.

I understand that there are some people that would gladly pay three times as much to get something to the last three times as long because it is the exact same amount of money.

I only consider this for things that can cause catastrophic additional failures when they fail or things that are very hard to replace.

I don't consider lawn mower spindles to be either of these.

T

TobyU

That's fine but only IF a person uses quality bearings..The 4 bolt spindles are now available from China for almost nothing and yes they are cheaper than just buying quality bearings

But the bearings in them are junk made for the Husqvarna clones and designed to fall apart 3 seconds after warranty

I buy them for the spindles & housings as of course those items bought separately are quite expensive and the spline at the top always fails because the star on the bottom prevents blade slip.

I usually fit NTN bearings from Japan which are a reasonable price from my wholesaler .

I would venture to say that 95 plus percent of the people do not end up with quality bearings because the average bearing you buy today is also cheap junk.

Even though this is the case, I find they still last long enough to be quite respectable.

Frankly, the fact that these old mowers went 15 and 20 years plus with the same bearings in them was wonderful but a little absurd if you consider it.

Something spinning that quickly and for that many hours and especially in the lousy conditions with a lot of them getting damp or literally sprayed on with water hoses or pressure washers, which I strictly forbid, and the various blade impacts over these decades...

Anybody should be happy to get 6 to 8 years out of a bearing in these conditions but yet we did so much better.

So if anything it's pretty fair now but when I can get a spindle for $11, and if I get over 5 years out of it, I'm more than getting my money's worth.

I understand that there are some people that would gladly pay three times as much to get something to the last three times as long because it is the exact same amount of money.

I only consider this for things that can cause catastrophic additional failures when they fail or things that are very hard to replace.

I don't consider lawn mower spindles to be either of these.

#38

T

TobyU

I have had no problems with these cheap spindles. They last far longer than they should for the money I've paid for them.

Now there are other things I will not buy again.

I replace two window regulator assemblies in two different cars a few years ago that I purchased on eBay for $36 and 42.

Neither of them lasted 40 days and probably hadn't gone up and down 20 times.

When they failed I went to O'Reilly Auto Parts and bought the doorman lifetime warranty one for $79.99. it is still working fine..

It ever does fail I will simply have to remove it and spend the 20 minutes it takes to take it out drive two blocks to the store warranty it come back and stick it back in.

But I will never again risk one of the cheap ones online.

Until I start having problems with spindles I will do the same with these.

I will also recommend not buying aftermarket camshafts for Briggs & Stratton engines for the ACR problem.

The OEM are lousy enough in quality and I had one of the cheap ones fail and under 5 months and not even 15 mows..

I put the factory OEM one back in and it's been almost 2 years now.

T

TobyU

I don't find this to always be true.Well as long as people buy by price alone and don't consider quality they will always be disappointed in the end. Yes things are cheaper but so the lack of quality. So I ask the customers do they want cheap spindles or good quality ones if I need to replace them. Yes I buy at lower cost too but I do try to compare apples to apples not apples to lemons.

The after market bearings I have tried were failing do to poor grease. It was drying up becoming hard causing the sealed bearing to fail. Once I started cleaning out this grease before installation of the bearings and replacing it with good EP2 wheel bearing grease the problem went away. Just takes a little more time than simply slapping in a set of bearings. Now I get my bearing from a bearing supplier and I still repack the ones with rubber seals as they are Chinese bearings with lousy grease.

As for the double hex end failing most times it it is it was never properly torqued. I get in spindles with stripped pulleys, repair things by replacing the pulleys and spindles, torque them to specs, and next time the mower comes with problems the blades are bent.

My current problem mowers are Gravely ZTRs where the blade retaining screws are so tight that I can't even break them free with a 900 ft/lb impact here or using a 3/4 breaker with a six foot cheater bar. I'm sending the mower to a heavy equipment shop where they have stronger impacts. These just round blades that tightening screws way past what I can get loose. I know it more of static bond then super torque due the rusting that is involved but getting pass that initial bond is a pain. I got to upgrade my equipment if I keep seeing these. Normally the 1/2 dr AirCat can get about anything loose but I am now considering adding a 1400 ft/lb 3/4 1778-VXL to my tool line up.

I have had no problems with these cheap spindles. They last far longer than they should for the money I've paid for them.

Now there are other things I will not buy again.

I replace two window regulator assemblies in two different cars a few years ago that I purchased on eBay for $36 and 42.

Neither of them lasted 40 days and probably hadn't gone up and down 20 times.

When they failed I went to O'Reilly Auto Parts and bought the doorman lifetime warranty one for $79.99. it is still working fine..

It ever does fail I will simply have to remove it and spend the 20 minutes it takes to take it out drive two blocks to the store warranty it come back and stick it back in.

But I will never again risk one of the cheap ones online.

Until I start having problems with spindles I will do the same with these.

I will also recommend not buying aftermarket camshafts for Briggs & Stratton engines for the ACR problem.

The OEM are lousy enough in quality and I had one of the cheap ones fail and under 5 months and not even 15 mows..

I put the factory OEM one back in and it's been almost 2 years now.

#39

ILENGINE

ILENGINE

I am curious of what the repair failure of the OEM Briggs camshafts are . Has anybody experienced repeat failures with the same customers mower. Or is it more of a "one and done". It seems like a lot of the ACR fail and lots of camshafts get replaced but in the large scheme of things I wonder what the overall failure rate is.I will also recommend not buying aftermarket camshafts for Briggs & Stratton engines for the ACR problem.

The OEM are lousy enough in quality and I had one of the cheap ones fail and under 5 months and not even 15 mows..

I put the factory OEM one back in and it's been almost 2 years now.

#40

StarTech

StarTech

Considering the shear number of the 21, 28, 31, and 33 the failure rate is quite low. And for it is mainly the 31 series with a few 33 series. Kinda strange that I don't the same failure in the 21 and 28 that uses the same camshaft. THe only repeat failure I had was the cheap Chinese knock off I tried.

I noticed on the latest 793880 camshafts that an engineering change has been made. They have hour glassed the ACR pin so that the lifters are now contacting it less.

I noticed on the latest 793880 camshafts that an engineering change has been made. They have hour glassed the ACR pin so that the lifters are now contacting it less.

#41

ILENGINE

ILENGINE

You are right about the 21 and 28 series engines. Those engine have been around since the early 1990's and a lot are still running the original cams and several that have never had the valves adjusted outside of the occasional head gasket. When the 31 series came out in the early 2000's is when the valve adjustment issues, and the blown head gaskets, and the camshaft ACR issues really intensified.Considering the shear number of the 21, 28, 31, and 33 the failure rate is quite low. And for it is mainly the 31 series with a few 33 series. Kinda strange that I don't the same failure in the 21 and 28 that uses the same camshaft. THe only repeat failure I had was the cheap Chinese knock off I tried.

I noticed on the latest 793880 camshafts that an engineering change has been made. They have hour glassed the ACR pin so that the lifters are now contacting it less.

#42

T

TobyU

In fact, anything over one or two is too high because they didn't have this problem before and then they started having the problem SO should have fixed it.

They didn't -at least not for a long time and maybe they still haven't.

It's hard to trust Briggs, thinking a new part may have improved the design because they have a history of changing their part numbers all the time even though it's the exact same item and not improved.

I don't have a lot of faith in their replacement parts because I've seen too many almost brand new Factory ones fail.

It doesn't seem to matter how young or old the thing is.

I've seen them fail under 10 hours and seen them fail anywhere up to 100 hours without any rhyme or reason.

Then I've seen some be closer to 200 hours when they fail.

Most mowers in my area don't get over 230 to 260 hours on them because the people end up replacing the entire mower by then because going from the dates of manufacture and the hour meters on the mini mowers I serviced over the decades, they tend to put under 25 hours per year on their mower with only a few getting close to 35.

I routinely did the math and it ended up being under 25 hours per year. So somewhere in that 12 to 14 year range with still quite low hours on it, they would end up upgrading to a new mower.

When I purchased the last camshaft I did notice Briggs had changed this particular one from there standard six digit part number to a part number much longer with a lot of nines in it from what I remember.

I thought I would give them the benefit of the doubt and hope they had changed this part along with a numbering system so I made sure I got one of those and not one of the other replacements with the six digit number that were readily available.

Don't know if that helped or not and I didn't actually notice any difference on this particular part versus the old one when I installed it like you mentioned on the redesign.

I will maintain it's a crap design though and way too delicate.

Mostly I will blame the little plastic bushing because they don't believe plastic has any place inside of any engine.

I can't think of an application where I would rather or just have to put plastic inside of an engine because there should always be another material that can be used and I feel that in almost every application the other material would be superior.

The pin of the spring are delicate enough but I think they would manage if it weren't for the plastic bushing but I know for a fact we could redesign and improve this system without a whole lot of effort.

Fact that they haven't done this ticks me off.

So there are way too many because even one is way too many.

T

TobyU

Yes, percentage-wise it's quite low and probably quite acceptable to their company decision makers. But numerically, it's still too high!Considering the shear number of the 21, 28, 31, and 33 the failure rate is quite low. And for it is mainly the 31 series with a few 33 series. Kinda strange that I don't the same failure in the 21 and 28 that uses the same camshaft. THe only repeat failure I had was the cheap Chinese knock off I tried.

I noticed on the latest 793880 camshafts that an engineering change has been made. They have hour glassed the ACR pin so that the lifters are now contacting it less.

In fact, anything over one or two is too high because they didn't have this problem before and then they started having the problem SO should have fixed it.

They didn't -at least not for a long time and maybe they still haven't.

It's hard to trust Briggs, thinking a new part may have improved the design because they have a history of changing their part numbers all the time even though it's the exact same item and not improved.

I don't have a lot of faith in their replacement parts because I've seen too many almost brand new Factory ones fail.

It doesn't seem to matter how young or old the thing is.

I've seen them fail under 10 hours and seen them fail anywhere up to 100 hours without any rhyme or reason.

Then I've seen some be closer to 200 hours when they fail.

Most mowers in my area don't get over 230 to 260 hours on them because the people end up replacing the entire mower by then because going from the dates of manufacture and the hour meters on the mini mowers I serviced over the decades, they tend to put under 25 hours per year on their mower with only a few getting close to 35.

I routinely did the math and it ended up being under 25 hours per year. So somewhere in that 12 to 14 year range with still quite low hours on it, they would end up upgrading to a new mower.

When I purchased the last camshaft I did notice Briggs had changed this particular one from there standard six digit part number to a part number much longer with a lot of nines in it from what I remember.

I thought I would give them the benefit of the doubt and hope they had changed this part along with a numbering system so I made sure I got one of those and not one of the other replacements with the six digit number that were readily available.

Don't know if that helped or not and I didn't actually notice any difference on this particular part versus the old one when I installed it like you mentioned on the redesign.

I will maintain it's a crap design though and way too delicate.

Mostly I will blame the little plastic bushing because they don't believe plastic has any place inside of any engine.

I can't think of an application where I would rather or just have to put plastic inside of an engine because there should always be another material that can be used and I feel that in almost every application the other material would be superior.

The pin of the spring are delicate enough but I think they would manage if it weren't for the plastic bushing but I know for a fact we could redesign and improve this system without a whole lot of effort.

Fact that they haven't done this ticks me off.

So there are way too many because even one is way too many.

#43

T

TobyU

If I had to estimate, I would say it's well under 2% of all these similar Briggs engines and likely closer to a half of a percent.

That is quite acceptable by most company standards of quality control etc but still this leaves hundreds and hundreds of them in any large market and I feel that's unacceptable.

I mean, I could literally fix one of these camshafts myself to wear it would be much more durable than the factory design and likely never fail.

I saw a thread one time where somebody was doing just this I believe.

Simply welding the pin into the hole in the camshaft I believe would solve the problem.

I don't have one in front of me to play with now but I don't believe the pin itself has to move and if after it was assembled, the pim was welded into place, it wouldn't need the plastic bushing and there wouldn't be the potential for the slop that allows things to get a place and then come apart and get broken.

But of course even if you fix this problem you have the other smaller problem of the camshaft lobes becoming loose or spending or whatever like I've seen a few times.

Another lousy, low quality design so they can save some money in the assembly process.

If they're going to press lobes onto a camshaft, which shouldn't be done in the first place, they could at least take some other precautions with standard machine shop procedures like drilling pinning it so it can't turn.

T

TobyU

It's certainly low percentage wise on the failures but numerically it's way too many as I mentioned in another post.I am curious of what the repair failure of the OEM Briggs camshafts are . Has anybody experienced repeat failures with the same customers mower. Or is it more of a "one and done". It seems like a lot of the ACR fail and lots of camshafts get replaced but in the large scheme of things I wonder what the overall failure rate is.

If I had to estimate, I would say it's well under 2% of all these similar Briggs engines and likely closer to a half of a percent.

That is quite acceptable by most company standards of quality control etc but still this leaves hundreds and hundreds of them in any large market and I feel that's unacceptable.

I mean, I could literally fix one of these camshafts myself to wear it would be much more durable than the factory design and likely never fail.

I saw a thread one time where somebody was doing just this I believe.

Simply welding the pin into the hole in the camshaft I believe would solve the problem.

I don't have one in front of me to play with now but I don't believe the pin itself has to move and if after it was assembled, the pim was welded into place, it wouldn't need the plastic bushing and there wouldn't be the potential for the slop that allows things to get a place and then come apart and get broken.

But of course even if you fix this problem you have the other smaller problem of the camshaft lobes becoming loose or spending or whatever like I've seen a few times.

Another lousy, low quality design so they can save some money in the assembly process.

If they're going to press lobes onto a camshaft, which shouldn't be done in the first place, they could at least take some other precautions with standard machine shop procedures like drilling pinning it so it can't turn.

#44

ILENGINE

ILENGINE

The basic acceptable failure rate is around 1% for all industries, which includes appliances, tractors, automobiles, computers, etc.It's certainly low percentage wise on the failures but numerically it's way too many as I mentioned in another post.

If I had to estimate, I would say it's well under 2% of all these similar Briggs engines and likely closer to a half of a percent.

That is quite acceptable by most company standards of quality control etc but still this leaves hundreds and hundreds of them in any large market and I feel that's unacceptable.

#45

T

TobyU

Different companies do it in different ways. Sometimes if they had a failure rate of over a certain number in a whole run of production, they would pull that entire batch out and go back in and check the actual problem areas or replace a board etc.

It doesn't matter what the numbers are in this because that's not what I was discussing but rather that because there are so many made, the percentage, even being small makes for a very large number of them.

This number is completely unacceptable in my opinion.

The fact that they didn't change it close to immediately is also unacceptable.

My opinion and comments on this are further supported by the fact that other manufacturers and other engines have not had similar problems repeatedly and for decades. Lol

You never hear of a Kohler camshaft ACR failure even though anything is possible.

So for me, even if it's only half of that 1% of industry acceptance (which I believe I used in one of my estimations) even being twice as good as the industry accepted standard in most things... It's still completely UNACCEPTABLE to me.

They're also is the extra consideration in my determination of these things whether it's something that's just annoying but quick and easy to fix versus something that's internal engine and requires extensive time, effort, labor to fix.

Completely unacceptable!

1% be damned...

T

TobyU

Yes, and often even slightly higher than that is acceptable. Even three to four has still gotten a pass for an entire batch in many situations.The basic acceptable failure rate is around 1% for all industries, which includes appliances, tractors, automobiles, computers, etc.

Different companies do it in different ways. Sometimes if they had a failure rate of over a certain number in a whole run of production, they would pull that entire batch out and go back in and check the actual problem areas or replace a board etc.

It doesn't matter what the numbers are in this because that's not what I was discussing but rather that because there are so many made, the percentage, even being small makes for a very large number of them.

This number is completely unacceptable in my opinion.

The fact that they didn't change it close to immediately is also unacceptable.

My opinion and comments on this are further supported by the fact that other manufacturers and other engines have not had similar problems repeatedly and for decades. Lol

You never hear of a Kohler camshaft ACR failure even though anything is possible.

So for me, even if it's only half of that 1% of industry acceptance (which I believe I used in one of my estimations) even being twice as good as the industry accepted standard in most things... It's still completely UNACCEPTABLE to me.

They're also is the extra consideration in my determination of these things whether it's something that's just annoying but quick and easy to fix versus something that's internal engine and requires extensive time, effort, labor to fix.

Completely unacceptable!

1% be damned...

#46

B

bertsmobile1

B

bertsmobile1

Goes like this

Some mental giant with 15 university degrees decided that B & S could make more money if they old off all of their manufacturing plants and just assembled engines from bought in parts where they could screw down the price with each new delivery

Once having done they they lost the ability to make the small but significant changes that failures point out need to be done .

Having gone back to the "core business" they are now stuck and will vanish from the face of the earth in the near future .

I buy my cams direct from the factory in China that makes them and have never had a problem other than having to buy them in larger quantities than needed

Back in the good old days B & S had the capacity to check parts orders for quality.

Now like every other business the "check" is done by the customer and B & S gets discounts if the number of reported failures exceeds a specified value .

I no longer fit B & S engines as there is no point in doing so as B & S Australia are pathetic when it comes to stocks of spare parts so I fit either Kawasaki or Loncin .

Both are substantially better built engines and both have a more reliable parts supply .

Some mental giant with 15 university degrees decided that B & S could make more money if they old off all of their manufacturing plants and just assembled engines from bought in parts where they could screw down the price with each new delivery

Once having done they they lost the ability to make the small but significant changes that failures point out need to be done .

Having gone back to the "core business" they are now stuck and will vanish from the face of the earth in the near future .

I buy my cams direct from the factory in China that makes them and have never had a problem other than having to buy them in larger quantities than needed

Back in the good old days B & S had the capacity to check parts orders for quality.

Now like every other business the "check" is done by the customer and B & S gets discounts if the number of reported failures exceeds a specified value .

I no longer fit B & S engines as there is no point in doing so as B & S Australia are pathetic when it comes to stocks of spare parts so I fit either Kawasaki or Loncin .

Both are substantially better built engines and both have a more reliable parts supply .

#47

chunkypigs72

chunkypigs72

It’s difficult to trust Briggs, as they often change part numbers without actually improving the design. Despite the new number, the part is frequently the same as the previous one, leaving little assurance that any upgrades have been made.It's certainly low percentage wise on the failures but numerically it's way too many as I mentioned in another post.

If I had to estimate, I would say it's well under 2% of all these similar Briggs engines and likely closer to a half of a percent.

That is quite acceptable by most company standards of quality control etc but still this leaves hundreds and hundreds of them in any large market and I feel that's unacceptable.

I mean, I could literally fix one of these camshafts myself to wear it would be much more durable than the factory design and likely never fail.

I saw a thread one time where somebody was doing just this I believe.

Simply welding the pin into the hole in the camshaft I believe would solve the problem.

I don't have one in front of me to play with now but I don't believe the pin itself has to move and if after it was assembled, the pim was welded into place, it wouldn't need the plastic bushing and there wouldn't be the potential for the slop that allows things to get a place and then come apart and get broken.

But of course even if you fix this problem you have the other smaller problem of the camshaft lobes becoming loose or spending or whatever like I've seen a few times.

Another lousy, low quality design so they can save some money in the assembly process.

If they're going to press lobes onto a camshaft About Us, which shouldn't be done in the first place, they could at least take some other precautions with standard machine shop procedures like drilling pinning it so it can't turn.

#48

A

Auto Doc's

A

Auto Doc's

Modern spindles come with sealed roller ball bearings. The ones with fittings still (usually) have only the lower bearing that will accept grease, but I have disassembled a few lately to find out that both bearings were indeed sealed.

If they have no fitting. Drive the center mandrel shaft out, drill the housing and tap in a new grease fitting (in a strategic area). Then remove retainer clips and the bearings and take only 1 side inner plastic seal out of them and reinstall so the one sealed side is to the outside of the housing. Pump them with about 10 shots of good high temp grease and never worry about them again unless you hit something and break one.

If they have no fitting. Drive the center mandrel shaft out, drill the housing and tap in a new grease fitting (in a strategic area). Then remove retainer clips and the bearings and take only 1 side inner plastic seal out of them and reinstall so the one sealed side is to the outside of the housing. Pump them with about 10 shots of good high temp grease and never worry about them again unless you hit something and break one.

#49

P

platefire

P

platefire

I finally installed one Husqvarna OEM($70) Mandrel Assembly last week. My intentions were to take the old original

Mandrel ***'y and try installing new sealed bearings in it but two of the old bolts broke off in the old ***'y. I really don't

have any tools to extract the old broke bolts, so guess I'll just get another OEM for the other side when it goes out.

BTW-The new Man ***'y had a built in spacer for under the pulley, so didn't have to install the old spacer

Mandrel ***'y and try installing new sealed bearings in it but two of the old bolts broke off in the old ***'y. I really don't

have any tools to extract the old broke bolts, so guess I'll just get another OEM for the other side when it goes out.

BTW-The new Man ***'y had a built in spacer for under the pulley, so didn't have to install the old spacer

#50

A

Auto Doc's

A

Auto Doc's

Hi platefire,

Many of the new OEM mandrels come with one time use self-tapping bolts (On purpose). These bolts are common to break off on purpose, so the mandrel cannot be reused. Creative engineering at its best.

I prefer the aftermarket mandrels with regular threaded holes, bolts and washers. "Oem" mandrels are overpriced in my opinion. Most OEM are made by the aftermarket anyway.

I have refurbished several decks over the past couple of years with full deck rebuild kits by a company called 8-ten on Ebay. Comes with mandrels, pullies, blades and deck belt.... Some even come with mounting hardware for the mandrels.

Many of the new OEM mandrels come with one time use self-tapping bolts (On purpose). These bolts are common to break off on purpose, so the mandrel cannot be reused. Creative engineering at its best.

I prefer the aftermarket mandrels with regular threaded holes, bolts and washers. "Oem" mandrels are overpriced in my opinion. Most OEM are made by the aftermarket anyway.

I have refurbished several decks over the past couple of years with full deck rebuild kits by a company called 8-ten on Ebay. Comes with mandrels, pullies, blades and deck belt.... Some even come with mounting hardware for the mandrels.

#51

P

platefire

P

platefire

Hay Doc

Well I had a debate between me and myself regarding OEM and aftermarket. Because the Husq one lasted since 2019, I thought I would go with

it again. The 8-ten sounds pretty tempting. I'll checkum out

Well I had a debate between me and myself regarding OEM and aftermarket. Because the Husq one lasted since 2019, I thought I would go with

it again. The 8-ten sounds pretty tempting. I'll checkum out

#52

A

Auto Doc's

A

Auto Doc's

Hi platefire,

Many of the new OEM mandrels come installed with one time use self-tapping bolts (On purpose). These bolts are common to break off on purpose, so the mandrel cannot be reused. Creative engineering at its best.

I prefer the aftermarket mandrels with regular threaded holes, bolts and washers. "Oem" mandrels are overpriced anyway, in my opinion. Most OEM mandrels are made by the aftermarket supply chains under strict design guidelines. (Bolts that break)