Wait a moment... I wasn't talking about sharpening, I was talking about vibration or (axial) imbalance.

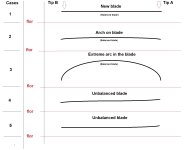

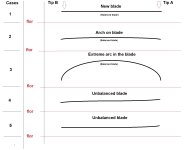

For me cases 1, 2 and 3 are perfect for use... cases 4 and 5 are unusable.

How do you fix cases 4 and 5?

Why do you determine that four and five are unusable?

I don't really care what goes on between the middle of the blade and the tip of the blade as long as the tip and most of the cutting surface is relatively flat and parallel to the ground and ends up being at the same height above the ground which is what I check when I see where each tip of the blade touches a spot in relation to the deck as I rotated around.

I don't care if there's a way or whatever in there and it very well may cause some imbalance well, let's just say it will cost some imbalance and some vibration but you already have a lot of vibration and harmonics going on in a mower anyways so it's just a matter of how much or how much extra or what is okay or what is tolerable or what is noticeable.

As I mentioned, I have tweaked many blades bending them etc and even twisting them back that had become twisted. It takes advice and a pretty sturdy work bench and a pipe wrench with a pretty long cheater bar on it so you can twist the end of the blade that has been twisted upward or downward because it hit something.

Then I have been plenty of them so the tip and the majority of the length of the blade from the center hole will be at the same height as the other side when you rotate it around.

Now here's the kicker on balance vibrations and all that.

If you have a mower that is hit something enough to bend the blade putting a new blade on or even putting a new blade on that's perfectly balanced, because not all are, isn't necessarily the fix.

Crankshafts really don't get bent as much as they get twisted even though we call it a bent crankshaft.

However, when you look at one and spend it or use a dial indicator mounted on a magnet etc and you see that it is wobbling in other words moving somewhere out of its small circle that it should rotate in then you know you have some damage to it.

Sometimes an old blade or an imbalanced blade can make up for vibrations like that and make a more smoother!

I know, we're talking Frankenstein at this point and it's probably nuts to even worry about that and I rarely do.

It's not like I keep old bent blades around just to try this however just because the crankshaft is bent or twisted does not mean the mower is unusable.

Let's don't even talk about trying to straighten the crank out but you should all know that at one time this was standard operating procedure and allowed an authorized by Major engine manufacturers like Briggs & stratton..

They made a machine specifically for it and other people have built their own. You were supposed to stamp an s on the crank in a certain spot once this has been done because it was never supposed to be done a second time.

Others have just used a huge hammer and a towel or a block of wood and beat the heck out of it trying to get it a little bit closer to spending in a solid circle instead of wobbly but the same people have also destroy the number of engines cracked mounting ears off the bottom of them and other things from doing this.

But the point is an engine can have only a very minor noticeable bend or twist or wobble in the crankshaft and can vibrate like MAD with any blade and be totally unusable whereas another engine can have a very good deal of bend and wobble to the crank and amazingly be so smooth you can't tell there's a problem!

This is why I always tell people you don't know it until you try it and you can't just make generalized comments about the way things are always going to be because there is a lot more going on in that blade spinning down there and that crankshaft at those RPMs then we can ever comprehend in real time.

So therefore sometimes just spinning a blade over 180° around makes a world of difference!!

What I started doing this in high numbers and found this out for myself I couldn't believe what a difference it made and I showed a bunch of people I work with.

I started up The Mower and have them put their hands on the handle and feel for it and they said yeah feels fine.

Then I let them watch me clock the blade around 180 and fire it back up and you could barely hold on to the handle and they were amazed too.

Then you have lights with five different ways to clock them on the star pattern so you have to try all of them.

Then with the Honda with the two blades you have four different ways you can install the blades so you have to try all of them too.

Anytime a mower has some vibration in it I will always try to find the smoothest sweet spot where it's it's absolute smoothest because often it makes the mower unnoticeable with any problem and makes it quite okay and safe to use whereas other installations might make it vibrate enough to make it annoying and buzzing your hands and excessive vibration of course can be dangerous.

So I would think the average person would say that any of the scenarios with event blade is unusable unless it's fixed whereas I don't see any reason for four and five to be any more unusable than the other ones..

I would tweak any of them and get them where they match up at the same point on the deck and look relatively straight and symmetrical and check for vibration and be totally happy with them.