You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Let's talk about blade sharpening?

#1

B

Bange

B

Bange

I don't know the correct way to sharpen a blade, but I'll describe mine... what's yours?

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

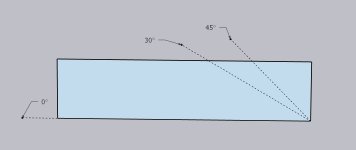

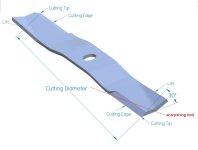

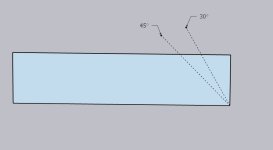

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.

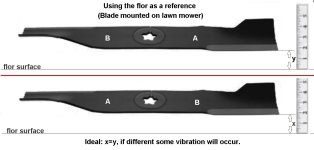

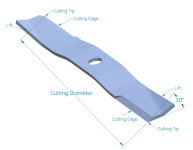

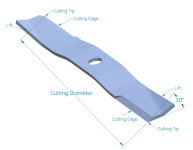

After satisfactory sharpening, I move on to the balancing stage, an important procedure to keep the deck serene, without unnecessary vibrations that can cause loosening of screws, premature wear of pulley bearings, noise, etc.

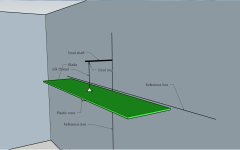

To do this, just fix a rod with a rounded profile in a vise or workbench and hang the blade through its hole... the photos speak for themselves...

Cleaning the blade

Cleaning up will make balancing easier at the end.

Sharpening...

Balancing

Blade one...

Very good...

Bade two...

Oops! Necessary adjustment...

Mark the side and remove material to make it lighter... preferably not on the sharp part.

Until equilibrium is achieved, several attempts can be made...

The end of the blade must be given special care, as it is the first to attack the grass... in any case, the edge is lost along the entire stretch due to stones, stumps, sand, sidewalks, hard fruit seeds and other objects. ..

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.

After satisfactory sharpening, I move on to the balancing stage, an important procedure to keep the deck serene, without unnecessary vibrations that can cause loosening of screws, premature wear of pulley bearings, noise, etc.

To do this, just fix a rod with a rounded profile in a vise or workbench and hang the blade through its hole... the photos speak for themselves...

Cleaning the blade

Cleaning up will make balancing easier at the end.

Sharpening...

Balancing

Blade one...

Very good...

Bade two...

Oops! Necessary adjustment...

Mark the side and remove material to make it lighter... preferably not on the sharp part.

Until equilibrium is achieved, several attempts can be made...

The end of the blade must be given special care, as it is the first to attack the grass... in any case, the edge is lost along the entire stretch due to stones, stumps, sand, sidewalks, hard fruit seeds and other objects. ..

Attachments

#2

sgkent

sgkent

I glass bead the blade to clean everything off it. Then file the edge, then balance it with the proper tool, which was not inexpensive. Far better than a screwdriver. I check the length of the blade from center the first time I sharpen one. Then I lightly paint it with a fast drying spray paint and when dry check the balance again. There is a limit to how far a blade can be sharpened, and yours below looks pretty worn. I also inspect for cracks after cleaning it. Blades can break when they are old, tired and have been used too many hours. I would not want to get hit by a piece. A neighbor hit a brass sprinkler head many years ago and his mower tossed the head about 80', thru my glass window, thru blinds shattering them, put a dent in some drywall down the hall. and ended up another 25' into the house. Imagine what a broken blade could do - and the instant imbalance that the system would suffer.

#3

A

AutoMechanic

A

AutoMechanic

I always just use a file. The only blades I’ve ever sharpened are on my grandmas mower. It’s easier to just wear them out and replace them in my opinion.

#4

StarTech

StarTech

I recently got one those commercially made blade balancers and I surprised by how much new blades can be out blade before they ever touch grass. Considering what I charge for sharpening sometimes new blades are a better deal for my customers; especially when it comes to the 1/4" thick ones. Besides stones do get expensive to wear out.

Taking some time getting use to the new balancer but I am getting better fast.

Taking some time getting use to the new balancer but I am getting better fast.

#5

B

Bange

Danger of breaking or throwing something out of the deck will occur even with a new blade, but with an old one the breakage is indeed greater...

I think manufacturers should indicate a TWI for blades...

I liked the paint procedure for inspecting cracks...

B

Bange

I don't know what the technical limit is for replacing the blade... probably the manufacturer doesn't even recommend sharpening, but it ends up being up to each person's feelings.I glass bead the blade to clean everything off it. Then file the edge, then balance it with the proper tool, which was not inexpensive. Far better than a screwdriver. I check the length of the blade from center the first time I sharpen one. Then I lightly paint it with a fast drying spray paint and when dry check the balance again. There is a limit to how far a blade can be sharpened, and yours below looks pretty worn. I also inspect for cracks after cleaning it. Blades can break when they are old, tired and have been used too many hours. I would not want to get hit by a piece. A neighbor hit a brass sprinkler head many years ago and his mower tossed the head about 80', thru my glass window, thru blinds shattering them, put a dent in some drywall down the hall. and ended up another 25' into the house. Imagine what a broken blade could do - and the instant imbalance that the system would suffer.

Danger of breaking or throwing something out of the deck will occur even with a new blade, but with an old one the breakage is indeed greater...

I think manufacturers should indicate a TWI for blades...

I liked the paint procedure for inspecting cracks...

#6

B

Bange

The cost of the blade around here is quite high and sharpening is the first option.

I see no problem in sharpening any cutting element, but I would like to know the technical limit.

B

Bange

You are absolutely right to change the blade, but send the old and sharp ones to the mother-in-law, right? kkkk....I always just use a file. The only blades I’ve ever sharpened are on my grandmas mower. It’s easier to just wear them out and replace them in my opinion.

The cost of the blade around here is quite high and sharpening is the first option.

I see no problem in sharpening any cutting element, but I would like to know the technical limit.

#7

B

Bange

Do you know the limit for sharpening?

What better angle?

Is it very wrong to balance as I described?

This is the second sharpening I've done... the previous one has been sharpening for 50 hours with some stones, small coconuts, roots, stumps, etc...

I added blade inspection and sharpening (if necessary) to my preventative maintenance program. Do you think this range is good or should I shorten it?

B

Bange

Good... you're a sharpener and with a dynamic balancer it's a show!I recently got one those commercially made blade balancers and I surprised by how much new blades can be out blade before they ever touch grass. Considering what I charge for sharpening sometimes new blades are a better deal for my customers; especially when it comes to the 1/4" thick ones. Besides stones do get expensive to wear out.

Taking some time getting use to the new balancer but I am getting better fast.

Do you know the limit for sharpening?

What better angle?

Is it very wrong to balance as I described?

This is the second sharpening I've done... the previous one has been sharpening for 50 hours with some stones, small coconuts, roots, stumps, etc...

I added blade inspection and sharpening (if necessary) to my preventative maintenance program. Do you think this range is good or should I shorten it?

#9

StarTech

And I have used the way you describe but had limited results as some blades have weird center holes. Even some of them can't be easily blade using either system. Especially those rectangle holes where you got the center and then balance by placing flat on the edge of edge edged metal piece.

StarTech

Yes the limits.Good... you're a sharpener and with a dynamic balancer it's a show!

Do you know the limit for sharpening?

What better angle?

Is it very wrong to balance as I described?

This is the second sharpening I've done... the previous one has been sharpening for 50 hours with some stones, small coconuts, roots, stumps, etc...

I added blade inspection and sharpening (if necessary) to my preventative maintenance program. Do you think this range is good or should I shorten it?

And I have used the way you describe but had limited results as some blades have weird center holes. Even some of them can't be easily blade using either system. Especially those rectangle holes where you got the center and then balance by placing flat on the edge of edge edged metal piece.

#10

B

Bange

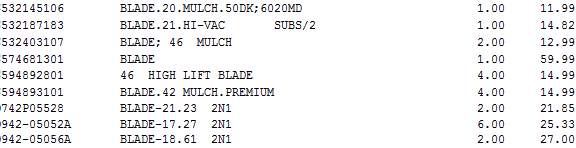

What do the numbers in columns 3 and 4 mean?

B

Bange

If you have more than two types around here, I'm already satisfied... the market here is almost exclusive to two importers.

What do the numbers in columns 3 and 4 mean?

#11

B

Bange

B

Bange

Well, for lack of experience with other machines and blades, I'm just talking about mine, but if it's not easy to discover the center of balance, the thing is impossible in my view.

In the past I had a small traction mower with a Teconseh engine (6HP), but I sold it in a short time and never sharpened its blade.

In the past I had a small traction mower with a Teconseh engine (6HP), but I sold it in a short time and never sharpened its blade.

#12

sgkent

sgkent

the thing that concerned me is that blade was probably straight when new. If so a lot of steel has already been worn away. I would replace it and start over. Also the before photo shows a really blunt blade. Mine gets sharpened 2 - 4 times a year. When maintaining a blade it doesn't take much to keep it sharp, only a pass or two with the mill file. When it gets to be blunt then a lot of material must come off to sharpen it. That blade screams to me that it is time to replace it, but maybe y'all who work on these mowers all the time just see that as par for the course.

#13

ILENGINE

ILENGINE

I use an Oregon belt blade grinder aka Burrking 760 and a magnetic balancer. The Oregon blade sharpening recommendation is what is called the 30-30 rule which means sharpen at a 30 degree angle and leave a .030 blunt edge. All blades are wire brushed to remove all buildup and debris and for inspection. Worn or cracked air lifts get tossed and replaced with new blades.

#14

B

Bange

Lower the deck less than 5cm... not a chance.

My space and mini tractor are old but I am new user without experience.

B

Bange

I believe that the use and quality of the grass and the ground determine the frequency of sharpening, as I said before, the previous sharpening was 50 hours of use (max 3 months passed)... in my space the lawn is still bad treated and the land is full of fruit trees such as coconut, mango, avocado, cashew... often the blade picks up something, in addition to the earth which is a real sandpaper.the thing that concerned me is that blade was probably straight when new. If so a lot of steel has already been worn away. I would replace it and start over. Also the before photo shows a really blunt blade. Mine gets sharpened 2 - 4 times a year. When maintaining a blade it doesn't take much to keep it sharp, only a pass or two with the mill file. When it gets to be blunt then a lot of material must come off to sharpen it. That blade screams to me that it is time to replace it, but maybe y'all who work on these mowers all the time just see that as par for the course.

Lower the deck less than 5cm... not a chance.

My space and mini tractor are old but I am new user without experience.

#15

Hammermechanicman

Totally jealous. I just have the All American sharpener with an angle grinder with 36 grit flap disks. I built a wire brush blade cleaner from a table saw motor but it makes such a mess I don't use it much. If my shop was bigger I would get something better but I am so crowded now no room for anything new.

Hammermechanicman

Dang! You got a $3k Burrking.I use an Oregon belt blade grinder aka Burrking 760 and a magnetic balancer. The Oregon blade sharpening recommendation is what is called the 30-30 rule which means sharpen at a 30 degree angle and leave a .030 blunt edge. All blades are wire brushed to remove all buildup and debris and for inspection. Worn or cracked air lifts get tossed and replaced with new blades.

Totally jealous. I just have the All American sharpener with an angle grinder with 36 grit flap disks. I built a wire brush blade cleaner from a table saw motor but it makes such a mess I don't use it much. If my shop was bigger I would get something better but I am so crowded now no room for anything new.

#16

B

Bange

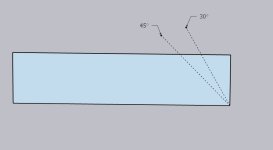

For mowing the grass itself, I see no difference between 45 and 30°, other than less material removal...

Of course, different damages that can't be resolved with sharpening, blade for the trash.

But what does "leave a .030 blunt edge" mean?

B

Bange

Another sharpener... very good...I use an Oregon belt blade grinder aka Burrking 760 and a magnetic balancer. The Oregon blade sharpening recommendation is what is called the 30-30 rule which means sharpen at a 30 degree angle and leave a .030 blunt edge. All blades are wire brushed to remove all buildup and debris and for inspection. Worn or cracked air lifts get tossed and replaced with new blades.

For mowing the grass itself, I see no difference between 45 and 30°, other than less material removal...

Of course, different damages that can't be resolved with sharpening, blade for the trash.

But what does "leave a .030 blunt edge" mean?

#17

M

MParr

M

MParr

I freehand sharpen with a 4” angle grinder with a 40 grit flapper wheel. I have a cheap 2 piece Oregon balancer. It gets the job done. I have to put sharp blades on around every 12 hours. I cut 3 acres once a week.

By the way, the OP needs new blades.

By the way, the OP needs new blades.

#18

Hammermechanicman

Hammermechanicman

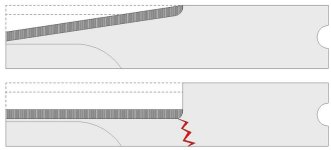

You can sharpen to a razor edge but after just a few minutes of mowing the edge will round over to around ,030 so no need to sharpen to a razor edge. Look at the edge of most any new blade and it is not sharp like a knife.

There are some commercial guys that change blades every day and sharpen to knife edge so that when they cut rich people's yards the grass cuts ends stay green. Dull blades rip the grass and the ends turn greyish..

There are some commercial guys that change blades every day and sharpen to knife edge so that when they cut rich people's yards the grass cuts ends stay green. Dull blades rip the grass and the ends turn greyish..

#19

StarTech

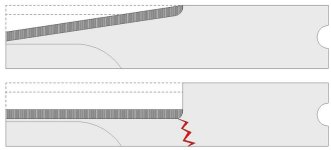

Now the angle as shown below is a lot closer to factory edge. And of course you don't need a razor sharp edge as it dulls rather quickly anyway.

StarTech

Well you are on the wrong train of thought here as the 30 degrees is right the opposite of your drawing. In your drawing the edge is too blunt and basically doesn't sharp very long.Another sharpener... very good...

For mowing the grass itself, I see no difference between 45 and 30°, other than less material removal...

Of course, different damages that can't be resolved with sharpening, blade for the trash.

But what does "leave a .030 blunt edge" mean?

View attachment 64049

Now the angle as shown below is a lot closer to factory edge. And of course you don't need a razor sharp edge as it dulls rather quickly anyway.

#21

Glades Cat

Glades Cat

Retired blades make good knives. Cut to rough shape, flatten, grind to shape, sharpen, drill and make handle.

#23

M

MParr

M

MParr

I don’t follow a set angle. I follow the original blade angle. After a while, you just know.

#25

7394

7394

For cleaning blades, I simply put them in a old drain pan, & add some tap water to barely submerge them, & let soak 1/2 hour,

remove & simply wipe clean. The water does the work & makes cleaning so simple.. No grinding debris dust to breathe.

Sharpening, I use a mill file & finish with a flap wheel... The OE blades I have are Marbain Steel ( heat treated ) so they hold an edge very well..(30* x .030") I also use a set of Oregon blades, & really like them. I pivot balance, & works for my private use.

remove & simply wipe clean. The water does the work & makes cleaning so simple.. No grinding debris dust to breathe.

Sharpening, I use a mill file & finish with a flap wheel... The OE blades I have are Marbain Steel ( heat treated ) so they hold an edge very well..(30* x .030") I also use a set of Oregon blades, & really like them. I pivot balance, & works for my private use.

#26

B

Bange

B

Bange

Very ecological... but water does not remove the rust crust and in these cases you must use something more aggressive...

#28

7394

7394

Mine don't have rust on them..Very ecological... but water does not remove the rust crust and in these cases you must use something more aggressive...

#29

Hammermechanicman

Hammermechanicman

I match the angle of whatever is on the blade. If the blade is so bad I can't tell I use 30 degrees. In the shop I see dozens of different bladesMParr and Hammermechanicman.

What is your sharpening angle?

#30

ILENGINE

ILENGINE

Actually in my case I split the cost with my nephew who runs a stump removal business, and the same grinder uses the diamond belts so he can sharpen his carbide stump grinder teeth. Those belts are $134 each. but my 1-1/2x60 36 grit ceramic sharpening belts are $10.99 and will do about 80 blades before replacement.Dang! You got a $3k Burrking.

Totally jealous. I just have the All American sharpener with an angle grinder with 36 grit flap disks. I built a wire brush blade cleaner from a table saw motor but it makes such a mess I don't use it much. If my shop was bigger I would get something better but I am so crowded now no room for anything new.

#31

ILENGINE

ILENGINE

The 45 degree angle will be more resistance to damage and wear but will also be duller and be prone to tearing not cutting of the grass.Star tech

I understand your point now...

But which angle offers the greatest resistance of blade material to the material being cut, or something else?

I am convinced that the 45° is stronger and will suffer less damage...

View attachment 64051

#32

B

Bange

B

Bange

I would like to see a trial of a lawnmower with 3 blades... one at 30°, one at 40° and one at 45° and see the result of the cut immediately and after days of use.

#33

Hammermechanicman

Hammermechanicman

You won't see much difference. A rotary mower doesn't really cut grass but rips it using Inertia. Talk to a pro golf course senior groundskeeper sometime if you want to know about reel vs rotary mowers and how they cut grass.

When a rotary mower blade is very sharp it will give a cut nearly equaling a reel mower but that will last a short time depending on factors like type of grass and moisture in the grass. Lush green grass is less abrasive than dry grass. Once the edge rounds over the angle doesn't matter. They will cut the same. There is a reason golf courses use gang reel mowers. As one guy put it. You "cut" the fairways and "chop" the rough. I have had customers bring in mowers with the blade on upside down and they didn't realize it. The biggest difference in the grass you will see is dull blades leave the ends of the grass ragged and those ragged ends turn yellowish or grayish a couple days after mowing. Especially if the grass is dry and needs water. A sharp or dull blade moving at 250mph will rip the grass in half and it will look the same that day but not in a couple days.

When a rotary mower blade is very sharp it will give a cut nearly equaling a reel mower but that will last a short time depending on factors like type of grass and moisture in the grass. Lush green grass is less abrasive than dry grass. Once the edge rounds over the angle doesn't matter. They will cut the same. There is a reason golf courses use gang reel mowers. As one guy put it. You "cut" the fairways and "chop" the rough. I have had customers bring in mowers with the blade on upside down and they didn't realize it. The biggest difference in the grass you will see is dull blades leave the ends of the grass ragged and those ragged ends turn yellowish or grayish a couple days after mowing. Especially if the grass is dry and needs water. A sharp or dull blade moving at 250mph will rip the grass in half and it will look the same that day but not in a couple days.

#34

sgkent

sgkent

I am confused by the concept of harsh landscapes mean duller blades. In my world, harsh landscapes would mean sharpening more often. It is like saying if I cook a lot more the kitchen gets dirtier quicker. That means more effort goes into cleaning it, not we allow it to get dirtier because we cook more often.

#35

B

Bange

B

Bange

As in a short time of use the blades lose their good edge, why not change them for nylon or steel wire?

Is there any experience with this?

What is your opinion?

Is there any experience with this?

What is your opinion?

#36

Hammermechanicman

Hammermechanicman

I am pretty amazed at the gator blades with the fusion edge. Put a set on my ferris 3100 a couple years ago and haven't needed to sharpen them yet. I mow 4 acres. The original marbain blades would go a whole season between sharpenings.

#37

S

slomo

I would say used truck leaf springs would be a better choice.

S

slomo

I would disagree with that one. Usually mower blades, well, OEM mower blades are made of inferior steel. From what I've used Oregon has the best steel.Retired blades make good knives. Cut to rough shape, flatten, grind to shape, sharpen, drill and make handle.

I would say used truck leaf springs would be a better choice.

#38

S

slomo

Use the factory bevel angle and you will be fine.

S

slomo

More acute the angle, the sharper the blade CAN be. So at 30 and 45 degrees, both can be sharp. The 30 will be sharper but the 45 has more steel at the cutting edge and will last longer till the edge fades/disappears. Hatchets have say 30 degree bevels. Japanese straight razors can be in the low teens or less. Sharper but dulls faster.I would like to see a trial of a lawnmower with 3 blades... one at 30°, one at 40° and one at 45° and see the result of the cut immediately and after days of use.

Use the factory bevel angle and you will be fine.

#39

S

slomo

S

slomo

My 4 cents on sharpening.

I use a hand file myself. Takes a few minutes to get a blade back to fighting weight. New files obviously work faster than older dull ones. I can pull a file from the tool box, few slaps on both sides and I'm done. Not looking for shaving sharp blades here. Just a good bevel clean up.

No reason to fire up some super expensive electric grinder. These are lawn mowers, not the space shuttle (Taryl). I can have a blade sharpened roughly in the same time as pulling a grinder out and plugging it in. Look at the bevel, set your sharpening angle and finally remve TOO MUCH material. Now you are into balancing for quite a while...... And your blades all have smiles to them now compared to simple hand files. More grinding to correct the smiles. Now you've just removed a bunch of life from that blade.

Summation, you burn through blades a lot faster with grinders than with hand files. Most people don't even check for sharpness when done. They see a shiny new bevel and think the blade is sharp.

I use a hand file myself. Takes a few minutes to get a blade back to fighting weight. New files obviously work faster than older dull ones. I can pull a file from the tool box, few slaps on both sides and I'm done. Not looking for shaving sharp blades here. Just a good bevel clean up.

No reason to fire up some super expensive electric grinder. These are lawn mowers, not the space shuttle (Taryl). I can have a blade sharpened roughly in the same time as pulling a grinder out and plugging it in. Look at the bevel, set your sharpening angle and finally remve TOO MUCH material. Now you are into balancing for quite a while...... And your blades all have smiles to them now compared to simple hand files. More grinding to correct the smiles. Now you've just removed a bunch of life from that blade.

Summation, you burn through blades a lot faster with grinders than with hand files. Most people don't even check for sharpness when done. They see a shiny new bevel and think the blade is sharp.

#40

Hammermechanicman

Most folks on this forum fall into two categories. Homeowners and shop owners. Each will have their own way to do things. Sharpening 150 or so blades with most of them beat to hell with a file wouldn't be profitable. I need to be able to sharpen a 3 blade mower in 10 minutes or less.

Hammermechanicman

Do you run a mower shop?My 4 cents on sharpening.

I use a hand file myself. Takes a few minutes to get a blade back to fighting weight. New files obviously work faster than older dull ones. I can pull a file from the tool box, few slaps on both sides and I'm done. Not looking for shaving sharp blades here. Just a good bevel clean up.

No reason to fire up some super expensive electric grinder. These are lawn mowers, not the space shuttle (Taryl). I can have a blade sharpened roughly in the same time as pulling a grinder out and plugging it in. Look at the bevel, set your sharpening angle and finally remve TOO MUCH material. Now you are into balancing for quite a while...... And your blades all have smiles to them now compared to simple hand files. More grinding to correct the smiles. Now you've just removed a bunch of life from that blade.

Summation, you burn through blades a lot faster with grinders than with hand files. Most people don't even check for sharpness when done. They see a shiny new bevel and think the blade is sharp.

Most folks on this forum fall into two categories. Homeowners and shop owners. Each will have their own way to do things. Sharpening 150 or so blades with most of them beat to hell with a file wouldn't be profitable. I need to be able to sharpen a 3 blade mower in 10 minutes or less.

#41

B

Bange

B

Bange

LOL... the subject is controversial, but the 30° seem pacified...

At least you could see how the profile of the sharpening is, which depends on the damage.

At least you could see how the profile of the sharpening is, which depends on the damage.

#42

S

slomo

S

slomo

My 4 cents on sharpening.

I use a hand file myself. Takes a few minutes to get a blade back to fighting weight. New files obviously work faster than older dull ones. I can pull a file from the tool box, few slaps on both sides and I'm done. Not looking for shaving sharp blades here. Just a good bevel clean up.

No reason to fire up some super expensive electric grinder. These are lawn mowers, not the space shuttle (Taryl). I can have a blade sharpened roughly in the same time as pulling a grinder out and plugging it in. Look at the bevel, set your sharpening angle and finally remve TOO MUCH material. Now you are into balancing for quite a while...... And your blades all have smiles to them now compared to simple hand files. More grinding to correct the smiles. Now you've just removed a bunch of life from that blade.

Summation, you burn through blades a lot faster with grinders than with hand files. Most people don't even check for sharpness when done. T

No I do not have a mower shop.

Best was to sharpen a blade is install a new one.

I use a hand file myself. Takes a few minutes to get a blade back to fighting weight. New files obviously work faster than older dull ones. I can pull a file from the tool box, few slaps on both sides and I'm done. Not looking for shaving sharp blades here. Just a good bevel clean up.

No reason to fire up some super expensive electric grinder. These are lawn mowers, not the space shuttle (Taryl). I can have a blade sharpened roughly in the same time as pulling a grinder out and plugging it in. Look at the bevel, set your sharpening angle and finally remve TOO MUCH material. Now you are into balancing for quite a while...... And your blades all have smiles to them now compared to simple hand files. More grinding to correct the smiles. Now you've just removed a bunch of life from that blade.

Summation, you burn through blades a lot faster with grinders than with hand files. Most people don't even check for sharpness when done. T

So why even waste the 10 minutes sharpening with your grinder? Just throw on new blades. Much faster than grinding and balancing. If it's all about speed....Do you run a mower shop?

Most folks on this forum fall into two categories. Homeowners and shop owners. Each will have their own way to do things. Sharpening 150 or so blades with most of them beat to hell with a file wouldn't be profitable. I need to be able to sharpen a 3 blade mower in 10 minutes or less.

No I do not have a mower shop.

Best was to sharpen a blade is install a new one.

#43

B

BTBO

B

BTBO

I too clean the blades as best I can with wire wheel / brush, then use a 4.5" grinder w/a 60 grit flapwheel. I THINK the correct cutting angle is 30`. I use my $150 MAGNA-MATIC to balance. It is unbelievably sensitive, which explains my frustration having to keep checking balance so often. Sure, paying that much to balance blades is arguably overkill, but the cost of replacing spindles is something I hope to not have to do any time soon.I don't know the correct way to sharpen a blade, but I'll describe mine... what's yours?

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.

After satisfactory sharpening, I move on to the balancing stage, an important procedure to keep the deck serene, without unnecessary vibrations that can cause loosening of screws, premature wear of pulley bearings, noise, etc.

To do this, just fix a rod with a rounded profile in a vise or workbench and hang the blade through its hole... the photos speak for themselves...

Cleaning the blade

View attachment 64029View attachment 64030

Cleaning up will make balancing easier at the end.

Sharpening...

View attachment 64031

Balancing

Blade one...

View attachment 64032

Very good...

View attachment 64033

Bade two...

Oops! Necessary adjustment...

Mark the side and remove material to make it lighter... preferably not on the sharp part.

View attachment 64036

View attachment 64036

View attachment 64038

View attachment 64039

Until equilibrium is achieved, several attempts can be made...

The end of the blade must be given special care, as it is the first to attack the grass... in any case, the edge is lost along the entire stretch due to stones, stumps, sand, sidewalks, hard fruit seeds and other objects. ..

#44

F

Freddie21

F

Freddie21

Time to clean that work area, Dude. Safety first.I don't know the correct way to sharpen a blade, but I'll describe mine... what's yours?

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.

After satisfactory sharpening, I move on to the balancing stage, an important procedure to keep the deck serene, without unnecessary vibrations that can cause loosening of screws, premature wear of pulley bearings, noise, etc.

To do this, just fix a rod with a rounded profile in a vise or workbench and hang the blade through its hole... the photos speak for themselves...

Cleaning the blade

View attachment 64029View attachment 64030

Cleaning up will make balancing easier at the end.

Sharpening...

View attachment 64031

Balancing

Blade one...

View attachment 64032

Very good...

View attachment 64033

Bade two...

Oops! Necessary adjustment...

Mark the side and remove material to make it lighter... preferably not on the sharp part.

View attachment 64036

View attachment 64036

View attachment 64038

View attachment 64039

Until equilibrium is achieved, several attempts can be made...

The end of the blade must be given special care, as it is the first to attack the grass... in any case, the edge is lost along the entire stretch due to stones, stumps, sand, sidewalks, hard fruit seeds and other objects. ..

#45

C

*CPB*

C

*CPB*

The goal when using a Magna-Matic balancer isn't to get the blade to be motionless, it's only to get it to move very slowly. If you get motionless then that's just a bonus. Their balancer is the equivalent of a calculator that goes out 100 decimal places, whereas a nail is like a calculator that does whole numbers only.

#46

F

Freddie21

F

Freddie21

Penny saved is a penny earned, especially if machine is at a shop.My 4 cents on sharpening.

I use a hand file myself. Takes a few minutes to get a blade back to fighting weight. New files obviously work faster than older dull ones. I can pull a file from the tool box, few slaps on both sides and I'm done. Not looking for shaving sharp blades here. Just a good bevel clean up.

No reason to fire up some super expensive electric grinder. These are lawn mowers, not the space shuttle (Taryl). I can have a blade sharpened roughly in the same time as pulling a grinder out and plugging it in. Look at the bevel, set your sharpening angle and finally remve TOO MUCH material. Now you are into balancing for quite a while...... And your blades all have smiles to them now compared to simple hand files. More grinding to correct the smiles. Now you've just removed a bunch of life from that blade.

Summation, you burn through blades a lot faster with grinders than with hand files. Most people don't even check for sharpness when done. T

So why even waste the 10 minutes sharpening with your grinder? Just throw on new blades. Much faster than grinding and balancing. If it's all about speed....

No I do not have a mower shop.

Best was to sharpen a blade is install a new one.

#47

StarTech

StarTech

I agree it is very sensitive but with experience you can or at least I can get the blade near perfect balance fairly quickly. It is strange to new be so far out of balance which explains some of the problems I have encountered over the years. Just started using it this season after 13 yrs of using one of those cone balancers. Even the cone was better than the nail method.The goal when using a Magna-Matic balancer isn't to get the blade to be motionless, it's only to get it to move very slowly. If you get motionless then that's just a bonus. Their balancer is the equivalent of a calculator that goes out 100 decimal places, whereas a nail is like a calculator that does whole numbers only.

#48

J

Johner

J

Johner

Have seen new blades without the fine sharp edge, which does not last long at all. Maybe so the new owner does not cut hands when putting them on. Would you know the reason?I don't know the correct way to sharpen a blade, but I'll describe mine... what's yours?

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.

After satisfactory sharpening, I move on to the balancing stage, an important procedure to keep the deck serene, without unnecessary vibrations that can cause loosening of screws, premature wear of pulley bearings, noise, etc.

To do this, just fix a rod with a rounded profile in a vise or workbench and hang the blade through its hole... the photos speak for themselves...

Cleaning the blade

View attachment 64029View attachment 64030

Cleaning up will make balancing easier at the end.

Sharpening...

View attachment 64031

Balancing

Blade one...

View attachment 64032

Very good...

View attachment 64033

Bade two...

Oops! Necessary adjustment...

Mark the side and remove material to make it lighter... preferably not on the sharp part.

View attachment 64036

View attachment 64036

View attachment 64038

View attachment 64039

Until equilibrium is achieved, several attempts can be made...

The end of the blade must be given special care, as it is the first to attack the grass... in any case, the edge is lost along the entire stretch due to stones, stumps, sand, sidewalks, hard fruit seeds and other objects. ..

#49

J

Johner

J

Johner

30deg edge will last longer, a 45deg. will slice better. Take an axe and try each angle see how each cuts. New blades come with a blunt edge I think for safety reasons.

#50

G

garyoldfart

G

garyoldfart

I invented and patented a sharpening jig for mower blades in the 1990's.

Your Wife can sit down and sharpen one handed with this device.

Perfect blade every time.

I could not get the price down enough for everybody to afford one. Quit making them

but I have parts and know how if anyone cares to take over

Mini-Miller is what I called it...A Mini Milling Machine.

You want sharp blades...This is it!

Pic is of a yard I mowed with sharp blades and My 1951 Farmall Cub 14hp tractor.

regards gary

Your Wife can sit down and sharpen one handed with this device.

Perfect blade every time.

I could not get the price down enough for everybody to afford one. Quit making them

but I have parts and know how if anyone cares to take over

Mini-Miller is what I called it...A Mini Milling Machine.

You want sharp blades...This is it!

Pic is of a yard I mowed with sharp blades and My 1951 Farmall Cub 14hp tractor.

regards gary

Attachments

#51

G

garyoldfart

G

garyoldfart

Here is the way to sharpen:LOL... the subject is controversial, but the 30° seem pacified...

At least you could see how the profile of the sharpening is, which depends on the damage.

Attachments

#53

ILENGINE

ILENGINE

Oregon blades which also make a lot of OEM blades sharpens them to a 30 degree angle leaving the recommended .030 blunt edge and then they are painted which makes them appear even duller.Have seen new blades without the fine sharp edge, which does not last long at all. Maybe so the new owner does not cut hands when putting them on. Would you know the reason?

#54

clarkoh

clarkoh

Good Point. Leaf springs are great source of tough, hard steel. We have made slap hammers for body work and they are very resistant to deformation and hold their shape.I would disagree with that one. Usually mower blades, well, OEM mower blades are made of inferior steel. From what I've used Oregon has the best steel.

I would say used truck leaf springs would be a better choice.

#55

G

Grum

G

Grum

I sharpen mine on a bench grinder and spray them with water from a squeeze bottle to keep them from over heating. I used to balance them on a nail but lately I’ve used one of those aluminum cones. Works for me.

#56

E

Earthquake Landscaping

E

Earthquake Landscaping

Oh hell yeah!! The right combination of tensile strength, and metal composition.. They make a great bushwacker! For real fun, try a large file..Retired blades make good knives. Cut to rough shape, flatten, grind to shape, sharpen, drill and make handle.

#57

woodstover

woodstover

Really good post. I think the 45° is a little steep. I personally sharpen mine to 30°ish. All the new blades I've ever bought have an initial grind of about 30° so that's what I've stuck with, they seem to stay sharp quite long.

#58

T

TobyU

T

TobyU

Before I even read the replies I'm going... Let's not! Let's don't even bother to talk about it because no one is ever going to agree on it and there no real consensus since brand new blade manufacturers will sell you a brand new blade in different types of sharpness, coated/dipped and paint, or not extremely sharp to begin with.

If there was one right or wrong way you would assume that by now the manufacturers would have all gotten on the same page and that's how they would come when you buy a replacement blade but it's not the case so everything else is simply going to be personal preference and then reality it makes little difference.

So much so that I get multiple mowers in every single year with the blades on upside down and the customers had no idea!

Now, I'm a lot more repair guy and not a landscaper so I fixed them but I don't use them but even I in my total disregard or care for lawns and grass can usually spot grass that's been ripped apart or roughly jaggedly chopped as opposed to cut with a somewhat sharper blade but the fact is most people can't tell the difference.

That thin piece of metal is spinning so quickly that whether you want to argue about 45, 33, flat spot on the very edge, or sharp as a razor, it's going to make very little difference and anyone who thinks they can tell the difference I could set up a demonstration and I guarantee I could fool you among 20 mowers.

So as I said, I guess it's fun for conversation but let's not worry too much about it.

If there was one right or wrong way you would assume that by now the manufacturers would have all gotten on the same page and that's how they would come when you buy a replacement blade but it's not the case so everything else is simply going to be personal preference and then reality it makes little difference.

So much so that I get multiple mowers in every single year with the blades on upside down and the customers had no idea!

Now, I'm a lot more repair guy and not a landscaper so I fixed them but I don't use them but even I in my total disregard or care for lawns and grass can usually spot grass that's been ripped apart or roughly jaggedly chopped as opposed to cut with a somewhat sharper blade but the fact is most people can't tell the difference.

That thin piece of metal is spinning so quickly that whether you want to argue about 45, 33, flat spot on the very edge, or sharp as a razor, it's going to make very little difference and anyone who thinks they can tell the difference I could set up a demonstration and I guarantee I could fool you among 20 mowers.

So as I said, I guess it's fun for conversation but let's not worry too much about it.

#59

T

TobyU

T

TobyU

Now after reading most of the replies I'm going to say I'm glad that most people realize it's not that big of a deal.

Those of you who are going to insist that some commercial blade bouncer is really necessary and it makes a real difference or any other thing like cleaning off the blades and bead blasting them painting them etc... I just want to know exactly how much time do you guys have??

Are you doing this professionally or just as a hobby and don't even do two or three a week?

It's pointless to clean up the blade because typically it has about the same amount of buildup on each side so the balance rains the same and it's just going to build up again.

I mean, you can knock the most of it off with one little push of a scraper putty knife or something on each side but going beyond anything past that it's just a waste of time.

It might make you feel better, or superior, but it's still a waste of time.

This is why I said my other post let's just not because it's just a contentious opinionated argument and we're never going to solve anything.

Now the more important thing is how many times you can sharpen a blade or when you need to replace one.

Generally you can sharpen a blade at least three or four times if not four or five times plus before you have to worry about it but that is entirely relative to how much knowing it's done between sharpening and how much each sharpening takes off.

These commercial shops with the high end grinders are kind of like production and they don't worry about whether the blade is pretty sharp to begin with OR beat the heck. They just swoop it across one to three times and eat off a lot of metal. The same reason lots of people don't want those shop shopping their chainsaw chains.

Anyways, eventually the blade will get cut back from its straight edge like in one of the pictures and while that is not the worst thing in the world it still can affect the quality of cut and the power in inertia some so when it gets cut back to where it's pretty noticeable like coming up on 3/8 to a half of an inch it's probably time to replace but fortunately it usually works out pretty well because the most important thing is when the back of the blade gets thin or it starts to crack on the little airfoil

bend.

The back non cutting Edge the blade is typically the thing that makes you have to replace the blade before the cutting edge! I know it makes no sense but that's just the way it is.

It will get razor blade thin and start to wear off the back edge and often crack with a little bend is which can allow pieces of metal to blow around which means the blade needs to be replaced.

There has been a general rule of thumb about the 30° versus 45 as in one gives a better quality of cut but doesn't stay sharp as long and the other one vice versa. I think the Honda twin cut system kind of goes for this effect. I just continue to sharpen the blades at the angle they come from the factory but I believe the Honda has one sharper angle and one lesser angle so they're trying to get the best of both worlds with their two blades.

However, oddly enough, I don't find that Honda's have the best quality of cut! They often leave stragglers and the overall quality isn't as good as some other mowers with simply one blade.

I think deck design has far more to do with it than blade and and blade design has more to do with it than sharpness.

Those of you who are going to insist that some commercial blade bouncer is really necessary and it makes a real difference or any other thing like cleaning off the blades and bead blasting them painting them etc... I just want to know exactly how much time do you guys have??

Are you doing this professionally or just as a hobby and don't even do two or three a week?

It's pointless to clean up the blade because typically it has about the same amount of buildup on each side so the balance rains the same and it's just going to build up again.

I mean, you can knock the most of it off with one little push of a scraper putty knife or something on each side but going beyond anything past that it's just a waste of time.

It might make you feel better, or superior, but it's still a waste of time.

This is why I said my other post let's just not because it's just a contentious opinionated argument and we're never going to solve anything.

Now the more important thing is how many times you can sharpen a blade or when you need to replace one.

Generally you can sharpen a blade at least three or four times if not four or five times plus before you have to worry about it but that is entirely relative to how much knowing it's done between sharpening and how much each sharpening takes off.

These commercial shops with the high end grinders are kind of like production and they don't worry about whether the blade is pretty sharp to begin with OR beat the heck. They just swoop it across one to three times and eat off a lot of metal. The same reason lots of people don't want those shop shopping their chainsaw chains.

Anyways, eventually the blade will get cut back from its straight edge like in one of the pictures and while that is not the worst thing in the world it still can affect the quality of cut and the power in inertia some so when it gets cut back to where it's pretty noticeable like coming up on 3/8 to a half of an inch it's probably time to replace but fortunately it usually works out pretty well because the most important thing is when the back of the blade gets thin or it starts to crack on the little airfoil

bend.

The back non cutting Edge the blade is typically the thing that makes you have to replace the blade before the cutting edge! I know it makes no sense but that's just the way it is.

It will get razor blade thin and start to wear off the back edge and often crack with a little bend is which can allow pieces of metal to blow around which means the blade needs to be replaced.

There has been a general rule of thumb about the 30° versus 45 as in one gives a better quality of cut but doesn't stay sharp as long and the other one vice versa. I think the Honda twin cut system kind of goes for this effect. I just continue to sharpen the blades at the angle they come from the factory but I believe the Honda has one sharper angle and one lesser angle so they're trying to get the best of both worlds with their two blades.

However, oddly enough, I don't find that Honda's have the best quality of cut! They often leave stragglers and the overall quality isn't as good as some other mowers with simply one blade.

I think deck design has far more to do with it than blade and and blade design has more to do with it than sharpness.

#60

R

Ray52

R

Ray52

I've been clamping my blades and using a side grinder and large file for years. I'll grind or file the cutting edge flat with the bottom of the blade, and grind an approximate angle of cut, close to the original angle.

This general method has allowed me to get a clean, smooth cut every time. IMO the slightly flat edge on the cutting tip allows for force dispersion on the blade allowing the

This general method has allowed me to get a clean, smooth cut every time. IMO the slightly flat edge on the cutting tip allows for force dispersion on the blade allowing the

#61

Tiger Small Engine

Tiger Small Engine

I sharpen a lot of mower blades, mostly on tune ups for customer mowers. Most of the time, these blades are beat to hell, nicks, very dull, and needed to be sharpened a long time ago. Often an edge needs to be reestablished and they have been sharpened incorrectly, or are bent. It takes a while to get a blade back in shape (just like a chainsaw chain), when it has been neglected. I personally run nothing but Gator G5 blades. I use a 4” angle grinder with a metal abrasive wheel to sharpen. The difference styles of blades dictate being able to effectively freehand and maintain the correct angle with a grinder by hand an eye.I've been clamping my blades and using a side grinder and large file for years. I'll grind or file the cutting edge flat with the bottom of the blade, and grind an approximate angle of cut, close to the original angle.

This general method has allowed me to get a clean, smooth cut every time. IMO the slightly flat edge on the cutting tip allows for force dispersion on the blade allowing the

#62

B

bertsmobile1

B

bertsmobile1

FWIW I sand blast the blades to remove the build up of dirt & clippings

How I sharpen depnds upon the mower that the blades are going onto

Mowers with good overlap just get the edge touched up& nicks removed

Blade with little to no overlap are different as a tiny amount of rounding to the outer edge will leave a mowhalk between the blades

for them it is grind the strait line from he inner edge of the cutting edge to the outer edge of the blade just past where the rounding is

Then restore the edge & angle

I have been trying to justify the cost of an Oregan sharpening tool but in reality I usually replace worn blades .

The ood ones go into a bin and get sent to the local TAFE for students to practice on then go into the "poverty bin" of used but servicable parts used to repair pensioners mowers

How I sharpen depnds upon the mower that the blades are going onto

Mowers with good overlap just get the edge touched up& nicks removed

Blade with little to no overlap are different as a tiny amount of rounding to the outer edge will leave a mowhalk between the blades

for them it is grind the strait line from he inner edge of the cutting edge to the outer edge of the blade just past where the rounding is

Then restore the edge & angle

I have been trying to justify the cost of an Oregan sharpening tool but in reality I usually replace worn blades .

The ood ones go into a bin and get sent to the local TAFE for students to practice on then go into the "poverty bin" of used but servicable parts used to repair pensioners mowers

#63

B

bertsmobile1

Age old story for inventors

Convincing customers it is worth the money and finding the time to make them yourselves.

or

Finding the money to have them made in mass then then marketing them yourself

I have dozens of special tools made for repairing motorcycles that are in this situation .

People never seem to understand that distribution , wholesale & retail profits is at least 75% of the price you pay for anything .

B

bertsmobile1

Nice idea for strait blades.I invented and patented a sharpening jig for mower blades in the 1990's.

Your Wife can sit down and sharpen one handed with this device.

Perfect blade every time.

I could not get the price down enough for everybody to afford one. Quit making them

but I have parts and know how if anyone cares to take over

Mini-Miller is what I called it...A Mini Milling Machine.

You want sharp blades...This is it!

Pic is of a yard I mowed with sharp blades and My 1951 Farmall Cub 14hp tractor.

regards gary

Age old story for inventors

Convincing customers it is worth the money and finding the time to make them yourselves.

or

Finding the money to have them made in mass then then marketing them yourself

I have dozens of special tools made for repairing motorcycles that are in this situation .

People never seem to understand that distribution , wholesale & retail profits is at least 75% of the price you pay for anything .

#64

G

Gord Baker

G

Gord Baker

I clean off obvious dirt and make 2 or 3 passes against my coarse Grinding Wheel. Same # for other end and blades. It's not the Space Shuttle as Tarryl would say. A gram or 2 out of balance is no big deal.

Tighten carefully after engaging any drive teeth, sharp side Down. Done. Skip OCD.

Tighten carefully after engaging any drive teeth, sharp side Down. Done. Skip OCD.

#65

T

TobyU

I get a lot of mowers in every year the blades are on upside down and I often tell people that since they usually understand that lawn mower blades are only sharpened on one side, to put the sharpened edge up towards the sky.

T

TobyU

I'm a little confused by your statement sharp side down..I clean off obvious dirt and make 2 or 3 passes against my coarse Grinding Wheel. Same # for other end and blades. It's not the Space Shuttle as Tarryl would say. A gram or 2 out of balance is no big deal.

Tighten carefully after engaging any drive teeth, sharp side Down. Done. Skip OCD.

I get a lot of mowers in every year the blades are on upside down and I often tell people that since they usually understand that lawn mower blades are only sharpened on one side, to put the sharpened edge up towards the sky.

#66

A

aussielawny

A

aussielawny

l bought a Magna-matic many years ago when l was starting out, its been gathering dust for 10 yrs or more......l buy Sten blades in bulk & swap em as needed, l'm right on the beach so all of my lawns are sandy and blades wear very quickly

#67

B

Bange

B

Bange

Well, let’s summarize here…

End of blades:

So far there is no technical definition for the sharpening limit (apart from cracks, warping or significant material loss), they can be sharpened up to a very subjective evaluation limit.

I would like to see something like this: blades can be sharpen up to the limit of X% of their width and/or Y% of their radius, as they are also insecure or inefficient.

Pre-cleaning:

I think this activity is important, although I agree that dirt occurs equally on both sides of the blade… but in the case of stationary parts where uneven oxidation occurs… does it affect the balance?

I prefer to do the procedure regardless of the case, as I am not a sharpener, I am an enthusiast and time is not an issue for me.

I understand that anyone who works with sharpening should look for a procedure that takes as little time as possible, but without jeopardizing the final result.

Goals:

1 – just lower the height of the lawn (sharpening doesn’t matter)

2 – lower the height of the lawn and leave it healthy and always green (sharpening is important)

Those aiming for #1 can skip this topic, but those aiming for #2 want to know everything about how it's done in the best possible way at their fingertips. Not everyone is going to buy a specific machine to sharpen (for example, me), but knowing how the final result should be, they can do the same (or near) with some expense of time.

Balancing:

I cannot agree with those who ignore balancing, as a piece rotating at more than 3000 RPM, without balancing, contributes to noise and harmful vibrations to the set of pulleys, bearings, increased clearances and previous fatigue.

End of blades:

So far there is no technical definition for the sharpening limit (apart from cracks, warping or significant material loss), they can be sharpened up to a very subjective evaluation limit.

I would like to see something like this: blades can be sharpen up to the limit of X% of their width and/or Y% of their radius, as they are also insecure or inefficient.

Pre-cleaning:

I think this activity is important, although I agree that dirt occurs equally on both sides of the blade… but in the case of stationary parts where uneven oxidation occurs… does it affect the balance?

I prefer to do the procedure regardless of the case, as I am not a sharpener, I am an enthusiast and time is not an issue for me.

I understand that anyone who works with sharpening should look for a procedure that takes as little time as possible, but without jeopardizing the final result.

Goals:

1 – just lower the height of the lawn (sharpening doesn’t matter)

2 – lower the height of the lawn and leave it healthy and always green (sharpening is important)

Those aiming for #1 can skip this topic, but those aiming for #2 want to know everything about how it's done in the best possible way at their fingertips. Not everyone is going to buy a specific machine to sharpen (for example, me), but knowing how the final result should be, they can do the same (or near) with some expense of time.

Balancing:

I cannot agree with those who ignore balancing, as a piece rotating at more than 3000 RPM, without balancing, contributes to noise and harmful vibrations to the set of pulleys, bearings, increased clearances and previous fatigue.

#68

B

Bange

No answers!?!?!

B

Bange

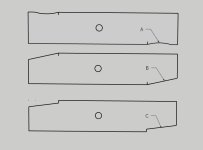

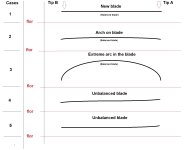

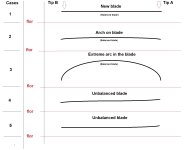

Attention sharpeners...One question...

A = dull blade that needs sharpening.

B = Use of an appropriate power tool for sharpening

C= Another form of sharpening with a specific tool.

Consider B and C after many sharpenings...

What is trend B or C?

View attachment 64064

No answers!?!?!

#69

W

woody70

W

woody70

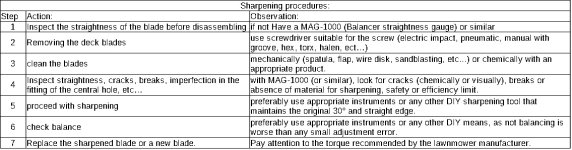

Saw this post in a daily email and intrigued me. Not a professional sharpener by any means, but I did invest in Magna Matic sharpener and balancer several years ago. If anyone desires to take a deep dive into the scholarly side of blade sharpening, take a look at the video below (be warned its almost an hour long, but very informative). Synopsis of video is keep a 30 degree angle and square end for best cutting.

I mow in rough conditions at industrial sites. Rocks, random pieces of metal that weren't there last time you mowed, and of course fields of bahia grass (which can be difficult to cut with new blades lol). I change blades everyday and keep around 8-10 sets of blades in a rotation for the season. Mow for a day, take them off and replace with newly sharpened set and sharpen the ones I took off. I can attest that keeping a square edge and balanced blade makes a lot of difference. Maybe I've just become in tune with my mower (turf tiger 2 61"), but I can tell by vibration/resonance if a blade is out of whack while I'm cutting. I'll enlist help occasionally when a site is overgrown or I'm running behind and they will ask almost immediately why my mower is cutting faster and better than their is (same mower). I'll look at there blades and they are essentially cutting with butter knives lol. It doesn't show up when they are cutting easy grass like centipede, but when asked to cut fields of bahia/weeds its a different story. Swap blades for them with extras I keep on hand and nothing but smiles lol. Yes, this is kind of an extreme example. Average Joe homeowner with average small/medium lot can probably get away with sharpening/buying new blades once a season depending on conditions. If you do it for a living or side hustle, need to keep those blades at 30 degrees, square end and balanced (your spindles will thank you). You don't have to invest in a expensive system as long as whatever method you use results in 30, square, and balanced.

My setup is below. Ignore the junk around it lol. Once I sharpen a blade, I also blunt it along the cutting edge. Razor sharp blades will dull in about 27 seconds in my opinion. I don't bother cleaning blades unless I can tell they have an uneven buildup on one side. Anyway here is my setup and a short video of me checking balance of a blade. On Magna balancer, once you put blade on horizontally (9/3 o'clock) and let go, if you can count four to eight seconds before it gets to 12/6 o'clock, it's considered balanced. If it barely even moves your really good, because that balancer is VERY sensitive. And no, I normally don't get the blades that balanced lol.

I mow in rough conditions at industrial sites. Rocks, random pieces of metal that weren't there last time you mowed, and of course fields of bahia grass (which can be difficult to cut with new blades lol). I change blades everyday and keep around 8-10 sets of blades in a rotation for the season. Mow for a day, take them off and replace with newly sharpened set and sharpen the ones I took off. I can attest that keeping a square edge and balanced blade makes a lot of difference. Maybe I've just become in tune with my mower (turf tiger 2 61"), but I can tell by vibration/resonance if a blade is out of whack while I'm cutting. I'll enlist help occasionally when a site is overgrown or I'm running behind and they will ask almost immediately why my mower is cutting faster and better than their is (same mower). I'll look at there blades and they are essentially cutting with butter knives lol. It doesn't show up when they are cutting easy grass like centipede, but when asked to cut fields of bahia/weeds its a different story. Swap blades for them with extras I keep on hand and nothing but smiles lol. Yes, this is kind of an extreme example. Average Joe homeowner with average small/medium lot can probably get away with sharpening/buying new blades once a season depending on conditions. If you do it for a living or side hustle, need to keep those blades at 30 degrees, square end and balanced (your spindles will thank you). You don't have to invest in a expensive system as long as whatever method you use results in 30, square, and balanced.

My setup is below. Ignore the junk around it lol. Once I sharpen a blade, I also blunt it along the cutting edge. Razor sharp blades will dull in about 27 seconds in my opinion. I don't bother cleaning blades unless I can tell they have an uneven buildup on one side. Anyway here is my setup and a short video of me checking balance of a blade. On Magna balancer, once you put blade on horizontally (9/3 o'clock) and let go, if you can count four to eight seconds before it gets to 12/6 o'clock, it's considered balanced. If it barely even moves your really good, because that balancer is VERY sensitive. And no, I normally don't get the blades that balanced lol.

#70

W

woody70

W

woody70

Eh, as I rarely post, I have no idea how to upload my own video. So, sorry about not having balancing video in there, but it does show several balancing methods in the original hour long sharpening video.

#71

C

*CPB*

If you don't have sandy soil and are only cutting grass and not hitting a bunch of foreign objects then your blades should last years with regular sharpening, IMO. I have blades I've sharpened dozens of times and there's still plenty of life left in them. The pic below is taken from the Magna-Matic sharpener manual, and shows their opinion on the right and wrong way to sharpen a blade over the course of its life. I sharpened a blade last year that was getting close to looking like the bottom one. I showed the guy the picture and told him to get another set of blades. Although they don't explicitly say it, I believe Magna-Matic believes that you can sharpen the edge of a blade almost back to where the sail of the blade starts to curve upward. You can see that in the pic below as well. That seems to make sense to me.

C

*CPB*

If you live in an area where the soil is sandy then to me that's a whole 'nother animal. Over the years I've seen pics of the effects sand has on blades and it's just crazy the way the metal gets eaten away. If that's your situation then I would just sharpen regularly and then recycle them long before they look anything like the ones in these pics....Attention sharpeners...

No answers!?!?!

If you don't have sandy soil and are only cutting grass and not hitting a bunch of foreign objects then your blades should last years with regular sharpening, IMO. I have blades I've sharpened dozens of times and there's still plenty of life left in them. The pic below is taken from the Magna-Matic sharpener manual, and shows their opinion on the right and wrong way to sharpen a blade over the course of its life. I sharpened a blade last year that was getting close to looking like the bottom one. I showed the guy the picture and told him to get another set of blades. Although they don't explicitly say it, I believe Magna-Matic believes that you can sharpen the edge of a blade almost back to where the sail of the blade starts to curve upward. You can see that in the pic below as well. That seems to make sense to me.

#72

ILENGINE

ILENGINE

Had a customer years ago that lived on a river bluff area and over time the sandblasting cut the bottom inch of deck off his JD.If you live in an area where the soil is sandy then to me that's a whole 'nother animal. Over the years I've seen pics of the effects sand has on blades and it's just crazy the way the metal gets eaten away. If that's your situation then I would just sharpen regularly and then recycle them long before they look anything like the ones in these pics....

View attachment 64171View attachment 64172

If you don't have sandy soil and are only cutting grass and not hitting a bunch of foreign objects then your blades should last years with regular sharpening, IMO. I have blades I've sharpened dozens of times and there's still plenty of life left in them. The pic below is taken from the Magna-Matic sharpener manual, and shows their opinion on the right and wrong way to sharpen a blade over the course of its life. I sharpened a blade last year that was getting close to looking like the bottom one. I showed the guy the picture and told him to get another set of blades. Although they don't explicitly say it, I believe Magna-Matic believes that you can sharpen the edge of a blade almost back to where the sail of the blade starts to curve upward. You can see that in the pic below as well. That seems to make sense to me.

View attachment 64176

#73

C

*CPB*

C

*CPB*

Yep. I've seen pics of decks with no rust, but had areas where the sand had worn them so thin you could see holes forming.Had a customer years ago that lived on a river bluff area and over time the sandblasting cut the bottom inch of deck off his JD.

#74

Roy405

Roy405

What mower is that fromI don't know the correct way to sharpen a blade, but I'll describe mine... what's yours?

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.

After satisfactory sharpening, I move on to the balancing stage, an important procedure to keep the deck serene, without unnecessary vibrations that can cause loosening of screws, premature wear of pulley bearings, noise, etc.

To do this, just fix a rod with a rounded profile in a vise or workbench and hang the blade through its hole... the photos speak for themselves...

Cleaning the blade

View attachment 64029View attachment 64030

Cleaning up will make balancing easier at the end.

Sharpening...

View attachment 64031

Balancing

Blade one...

View attachment 64032

Very good...

View attachment 64033

Bade two...

Oops! Necessary adjustment...

Mark the side and remove material to make it lighter... preferably not on the sharp part.

View attachment 64036

View attachment 64036

View attachment 64038

View attachment 64039

Until equilibrium is achieved, several attempts can be made...

The end of the blade must be given special care, as it is the first to attack the grass... in any case, the edge is lost along the entire stretch due to stones, stumps, sand, sidewalks, hard fruit seeds and other objects. ..

#75

P

Petriw

P

Petriw

Blade sharpening. What I do.

- Clean the blade

- Restore the edge with an axe file

- Course first

- Fine Next

- Sharpening stone - Coarse

- Sharpening stone - fine.

- Neighbors like the way I do this!

- Anyone want a shave?

#76

T

TobyU

Obviously a very dull blade is going to take long and one that's not nicked or chewed up or even that dull won't take long at all but how long does the average blade take you?

T

TobyU

But exactly how long does it take you to sharpen the average blade like this?Blade sharpening. What I do.

- Clean the blade

- Restore the edge with an axe file

- Course first

- Fine Next

- Sharpening stone - Coarse

- Sharpening stone - fine.

- Neighbors like the way I do this!

- Anyone want a shave?

Obviously a very dull blade is going to take long and one that's not nicked or chewed up or even that dull won't take long at all but how long does the average blade take you?

#77

T

TobyU

T

TobyU

It is worth noting how much certain conditions will chew up the blades.

Living near creeks I think is the worst and then woods is the second worst but I learned a long time ago how amazingly rough simply sticks and or pine cones were on a blade.

It makes sense that blades get chewed up if people have landscaping rocks etc and stones around that they will occasionally hit but you would not think small sticks the size of your pinky finger or pine cones would take big nicks out of blades but they do.

Living near creeks I think is the worst and then woods is the second worst but I learned a long time ago how amazingly rough simply sticks and or pine cones were on a blade.

It makes sense that blades get chewed up if people have landscaping rocks etc and stones around that they will occasionally hit but you would not think small sticks the size of your pinky finger or pine cones would take big nicks out of blades but they do.

#78

S

Steve Smith

S

Steve Smith

I agree with everything said here except I use a cone type balancer. I clean my blades by soaking them in warm water to loosen the material then take a wire wheel to them. It seems easer.I don't know the correct way to sharpen a blade, but I'll describe mine... what's yours?

In fact, sharpening is not a very important item for many users, because even if the blade is not sharp, the cutter will shred the grass or any tree leaf... but the result is not satisfactory, in addition to causing greater consumption with more passes and even damage to the deck as a whole.

To those who don't sharpen, but change it after noticing an inefficiency, congratulations... it's the most correct way... but expensive.

Let's go...

With the blade off the deck, clamp it with a clamp on the workbench and clean (rust, glued and dry grass, animal manure, etc...), on all surfaces, using a grinder with flap disc, wire disc, etc.

After cleaning, I change the disk for an iron grinding disk (carburundum, diamond, aggressive flap, etc...) and grind at approximately 45° until I get a good edge.