I really appreciate all of the back and forth. You both are really helping me sort this out. Let's take a step back one second so I can get my head around this.

1. How was the Digital Speed Advance module originally wired in from the manufacturer? I ask because it was only attached from the mounting bolt of the coil to the black lead as a ground. The stator connected to the other dark wire and the yellow, and the Red went to the pigtail to supply power to the mower. The other wire to the coil came from the pigtail.

2. There was no other rectifier, so did the DSAI also provide rectification of the voltage? If not, how was the rectification taking place?

3. I hooked up the old coil to the mower and new rectifier and was able to start the mower. It was surging as it usually did, so I'm rebuilding the carb, but otherwise it started and ran.

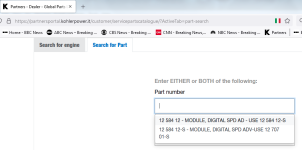

4. I do not know if the unit has the original fly wheel, but the 12 584 04-S definitely don't fit.

1.The Speed Advance Module has 5 wires. Red was key switched battery voltage. Black was ground. White was the kill lead. The other two wires, probably yellow and brown, went to the ignition coil. One spade terminal was slightly smaller than the other so you couldn't hook it up wrong.

2. The ignition system and charging system are not connected in anyway to each other. They operate completely independent of each other. The 12 584 12-S has nothing to do with the charging system.

If you engage the blades via a manual lever and not an electric clutch then there is probably no voltage regulator. If all the system needs to do is charge the battery and especially if this is a Sears unit, it is probably using a 3 amp unregulated charging system. The voltage gets rectified by a diode in the black wire. It's hard to see since it's in the stator. Typically there would be three wires coming off the stator under the flywheel. Black, White and green. The black wire if I am remembering correctly is the battery charging lead. The check the system that wire need to be disconnected so there is no load on it. Then running the engine at full speed you would check the DC voltage coming off that black wire. It should be a minimum of 20 volts dc. There is no maximum so it could be more than 20 and that is fine. All we care about is a minimum of 20 volts dc. The white wire is for headlights if the unit is so equipped and the green wire is the brake wire which if there, should stop the engine from rotating with 5 seconds of shutting off the mower.

3. Started and running is a good thing.

4. I don't know what brand of coils you got to replace the genuine Kohler 12 584 04-S but they are not correct as you know. The genuine Kohler 12 584 04-S will mount. Like I stated, it may not run correctly but it will mount trust me. If the brand you got says it replaces the Kohler 12 584 04-S they are wrong. Kohler didn't change the coil mounting bosses when they went to the CV16 with Smart Spark. Both the CV15 and CV16 use the exact same engine block.