You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Ignition Coil Gapping

#1

W

Whalensdad

W

Whalensdad

I have a CV-15 with a 12 584 04-S ignition coil. I've purchased 3 replacements but none of them mount so I can set a gapping of the width of a business card. All of the replacements end up with a gap of about 2 to 3 tenths of an inch (I didn't measure, just a guestimate). Is this something I should be concerned with or should I just give it a go and try with what I'm sent?

#2

StarTech

StarTech

First need verify you are ordering the correct so what is the engine's spec number.

Normally the coils will go to zero clearance when mounted loose which is a hint that you have the wrong coils.

Normally the coils will go to zero clearance when mounted loose which is a hint that you have the wrong coils.

#3

W

Whalensdad

W

Whalensdad

Unfortunately I don't know the specs. There is no label plate on the engine. The best Kohler could tell me is that it is either a CV13 or CV15 based on the carburetor.

#4

W

Whalensdad

W

Whalensdad

So here is something interesting. I got the numbers off of the coil that was in it: 1A138-52-12. This appears to be an ignition coil for a Tecumsah and not a kohler. Now I'm scratching my head. I know the engine is a Kohler in a Craftsman LT1000 that replaced a B&S 17.5 HP Intec engine. Should I get another Tecumsah Ignition Coil or try the Kohler?

#6

W

Whalensdad

W

Whalensdad

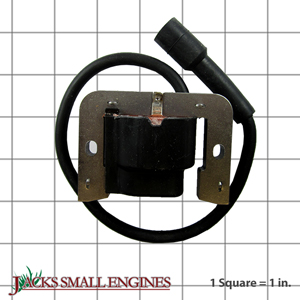

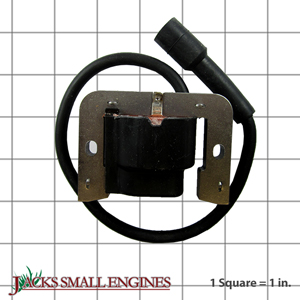

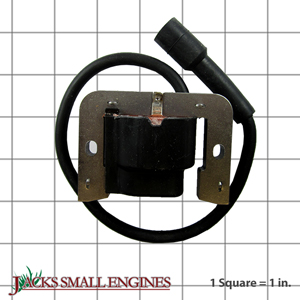

It's the one on the left. I guess the question is, should I just buy another Tecumsah coil or drill out the holes on a Kohler to make it fit?Compare these to the old coil.

Tecumseh 34443D on the left Kohler 12 584 04-S on the right

View attachment 62606View attachment 62605

#7

R

Rivets

R

Rivets

Just drilling out the holes on the Kohler coil doesn’t mean the the curvature of the legs will match the curvature of the flywheel. Can you post a few pictures of the engine and the old coil, as we will have a better idea of what you are dealing with? Make sure we can see the entire engine.

#9

R

Rivets

R

Rivets

After rereading this thread I’ve got more questions than answers. You’ve never told us why you want to replace the coil and what did you do to get to that point? The videos and info you are getting are not helping your cause, so you need to back up. First, the two coils are not interchangeable, the curvature on the legs and won’t work. Second, are you sure you mounted the old Kohler coil properly? If my brain still works, which is debatable at my age, I thought I remember that the spark plug wire should be next to the block, not away. If I’m wrong someone will correct me. Third, time to stop trying to save a nickel and go to your local repair shop, with the old coil in hand, and have them get you the correct coil. If you’ve been using a repair shop, find a new one.

#10

W

Whalensdad

W

Whalensdad

1. The coil that came out was a Tecumsah.

2. I'm replacing the coil because it is leaking spark from the wire.

3. I only mounted to show the gap. Yes it was mounted upside down.

4. There is nothing a shop will do differently. They will either use the Tecumsah, or modify a Kohler. I'm just trying to find out which I should do.

2. I'm replacing the coil because it is leaking spark from the wire.

3. I only mounted to show the gap. Yes it was mounted upside down.

4. There is nothing a shop will do differently. They will either use the Tecumsah, or modify a Kohler. I'm just trying to find out which I should do.

#13

StarTech

StarTech

I think I see the problem. I thinking it is one of the CV16-FHP engines which uses the 12 584 17-S coil which looks very much like the Tecumseh coil in my previous post. Notice the distance in where the mounting holes are when compare to the one you currently have on the engine.

Also here is an image of CV460 that uses the 12 584 04-S coil.Notice the flywheel magnets are mounted differently than the one you have. It is right inline the ring gear teeth tips. Your flywheel has it recessed.

One other problem is that is a DSAI coil that requires 12V lead along with the normal grounding kill lead. So it looks someone did a make shift conversion to the Tecumseh coil.

Also here is an image of CV460 that uses the 12 584 04-S coil.Notice the flywheel magnets are mounted differently than the one you have. It is right inline the ring gear teeth tips. Your flywheel has it recessed.

One other problem is that is a DSAI coil that requires 12V lead along with the normal grounding kill lead. So it looks someone did a make shift conversion to the Tecumseh coil.

#14

StarTech

StarTech

Also with patience the high tension lead can be replaced completely but with the after market version being only $27 from Amazon it is just a lot easier to replace it.

But I thinking the 32 584 06-S CDI coil might work as its width matches the Tecumseh coil width and mounting holes seem to be in the right places. Note this is just a guess as it from the newer engines so timing will probably be off.

But I thinking the 32 584 06-S CDI coil might work as its width matches the Tecumseh coil width and mounting holes seem to be in the right places. Note this is just a guess as it from the newer engines so timing will probably be off.

#15

W

Whalensdad

Should I:

1. Get another Tecumsah coil

2. Try the coil you suggested, not knowing whether it will work

3. Redrill the Kohler coil so it fits

Also, I noticed the parts lists talk about DSAI. My engine had what was listed as #23 in the following diagram(https://www.jackssmallengines.com/j...hp-16-hp-11-9-kw/ignition-electrical-5-27-174) but didn't have #9. I assumed that #23 was the rectifier, which I just swapped out with #9. When I say I had part #23, it was the square thing in the drawing (not the part shown for 23)

W

Whalensdad

Very interesting as that was not what Kohler listed as an engine option. They could have been very wrong. I don't remember the exhaust looking the way the parts diagrams show (I can't look right now). I see what you mean by the flywheel teeth and the magnet mounting. The coil that came out though was a Tecumsah based on the part number on it. I'm thinking that somewhere in the past, someone couldn't figure out what coil to use since they didn't know what engine they had and found the Tecumsah the closest in appearance. Which brings me to this question:I think I see the problem. I thinking it is one of the CV16-FHP engines which uses the 12 584 17-S coil which looks very much like the Tecumseh coil in my previous post. Notice the distance in where the mounting holes are when compare to the one you currently have on the engine.

Also here is an image of CV460 that uses the 12 584 04-S coil.Notice the flywheel magnets are mounted differently than the one you have. It is right inline the ring gear teeth tips. Your flywheel has it recessed.

View attachment 62624

Should I:

1. Get another Tecumsah coil

2. Try the coil you suggested, not knowing whether it will work

3. Redrill the Kohler coil so it fits

Also, I noticed the parts lists talk about DSAI. My engine had what was listed as #23 in the following diagram(https://www.jackssmallengines.com/j...hp-16-hp-11-9-kw/ignition-electrical-5-27-174) but didn't have #9. I assumed that #23 was the rectifier, which I just swapped out with #9. When I say I had part #23, it was the square thing in the drawing (not the part shown for 23)

#16

StarTech

StarTech

Hmmm. Apparently someone did a rig job on the engine. You might need to get a local Kohler tech involved on straightening out the mess.

#17

W

Whalensdad

W

Whalensdad

The places I called wouldn't touch it since they couldn't identify the engine. So I'm on my own here. I think I'll drill out the Kohler coil I have to see if I can make it work. If not I'll just get another Tecumsah coil, since it was working with it. This whole process started when I found that my battery wasn't charging, which uncovered a mouse nest under the blower cover. From there I found chewed through wires (including damage to the coil wire). Thanks for the suggestions, and any other insight you may have.Hmmm. Apparently someone did a rig job on the engine. You might need to get a local Kohler tech involved on straightening out the mess.

#18

V

VegetiveSteam

V

VegetiveSteam

The 12 584 04-S is the correct module for CV11 thru CV15 and there is no other. Kohler has used that module for 20 plus years. Are your incorrect replacements genuine Kohler parts? It is possible to mount the module wrong side out but it still fits the same and you can set the proper gap but it won't fire. If it does fire it fires very weak. What ever you are trying to put on is obviously not correct. With the screws loose that module should be able to go right against the magnets.

#19

W

Whalensdad

W

Whalensdad

My engine is missing the label plate. When I contacted Kohler, they guessed what I had based on the part numbers I could find on some of the components. I think StarTech was correct in that he thinks I have a CV-16. This is based on that the coil most resembles the techumsah coil that was previously installed, that the parts diagram shows item #23 (https://www.jackssmallengines.com/j...hp-16-hp-11-9-kw/ignition-electrical-5-27-174) which my unit had, but the CV13 thru 15 did not. The unit wasn't wired with the extra 12v going to the coil, which is probably why they used the Tecumsah coil.The 12 584 04-S is the correct module for CV11 thru CV15 and there is no other. Kohler has used that module for 20 plus years. Are your incorrect replacements genuine Kohler parts? It is possible to mount the module wrong side out but it still fits the same and you can set the proper gap but it won't fire. If it does fire it fires very weak. What ever you are trying to put on is obviously not correct. With the screws loose that module should be able to go right against the magnets.

#20

V

VegetiveSteam

V

VegetiveSteam

Doesn't matter. CV15 or CV16 the blocks are the same so the 12 584 04-S will mount regardless. It might not run right but the coil will still mount, it would just be out of time. It would probably seem to run fine until you got it under a load. It would then be low on power. The CV16 was just a CV15 with a variable timed ignition module and the keyway cut in a different spot on the flywheel. Are you using genuine Kohler parts?

#21

W

Whalensdad

W

Whalensdad

It didn't have genuine Kohler parts, hence the Tecumsah coil. Since I don't know what model this engine really is and what was changed, it is hard to determine what genuine parts I should get. It ran fine using the Tecumsah coil. The engine had the stator going to part 12 584 12 (see images). I assumed this was the rectifier. I swapped this with the new type rectifier because I was only getting 12 or so volts out and it wasn't charging my battery.Doesn't matter. CV15 or CV16 the blocks are the same so the 12 584 04-S will mount regardless. It might not run right but the coil will still mount, it would just be out of time. It would probably seem to run fine until you got it under a load. It would then be low on power. The CV16 was just a CV15 with a variable timed ignition module and the keyway cut in a different spot on the flywheel. Are you using genuine Kohler parts?

#23

V

VegetiveSteam

V

VegetiveSteam

The 12 584 12-S isn't a voltage regulator but is called a Speed Advance Module, sometimes a Spark Advance Module which says you have a CV16. This still doesn't explain why your replacement coils won't mount other than they aren't the correct replacement for a 12 584 04-S.

If your engine still has the original flywheel the correct Kohler part you need is 12 707 01-S. This is a DSAI conversion kit that eliminates the original no longer available Speed Advance Module and ignition module and replaces them with one ignition coil that has the advance built into it and it no longer needs any battery voltage which actually never went to the ignition coil but to the Speed Advance Module and in turn that module sent a lower voltage signal to the coil to trigger it. This kit will only need the white wire connected to it to kill the ignition.

If your engine still has the original flywheel the correct Kohler part you need is 12 707 01-S. This is a DSAI conversion kit that eliminates the original no longer available Speed Advance Module and ignition module and replaces them with one ignition coil that has the advance built into it and it no longer needs any battery voltage which actually never went to the ignition coil but to the Speed Advance Module and in turn that module sent a lower voltage signal to the coil to trigger it. This kit will only need the white wire connected to it to kill the ignition.

#24

W

Whalensdad

1. How was the Digital Speed Advance module originally wired in from the manufacturer? I ask because it was only attached from the mounting bolt of the coil to the black lead as a ground. The stator connected to the other dark wire and the yellow, and the Red went to the pigtail to supply power to the mower. The other wire to the coil came from the pigtail.

2. There was no other rectifier, so did the DSAI also provide rectification of the voltage? If not, how was the rectification taking place?

3. I hooked up the old coil to the mower and new rectifier and was able to start the mower. It was surging as it usually did, so I'm rebuilding the carb, but otherwise it started and ran.

4. I do not know if the unit has the original fly wheel, but the 12 584 04-S definitely don't fit.

W

Whalensdad

That isn't a voltage regular but is a Digital Speed Advance module for the ignition system. It currently superseded to the DSAI kit PN 12 707 01-S.

View attachment 62634

So if you installed a voltage regulator in its place it will not work.

I really appreciate all of the back and forth. You both are really helping me sort this out. Let's take a step back one second so I can get my head around this.The 12 584 12-S isn't a voltage regulator but is called a Speed Advance Module, sometimes a Spark Advance Module which says you have a CV16. This still doesn't explain why your replacement coils won't mount other than they aren't the correct replacement for a 12 584 04-S.

If your engine still has the original flywheel the correct Kohler part you need is 12 707 01-S. This is a DSAI conversion kit that eliminates the original no longer available Speed Advance Module and ignition module and replaces them with one ignition coil that has the advance built into it and it no longer needs any battery voltage which actually never went to the ignition coil but to the Speed Advance Module and in turn that module sent a lower voltage signal to the coil to trigger it. This kit will only need the white wire connected to it to kill the ignition.

1. How was the Digital Speed Advance module originally wired in from the manufacturer? I ask because it was only attached from the mounting bolt of the coil to the black lead as a ground. The stator connected to the other dark wire and the yellow, and the Red went to the pigtail to supply power to the mower. The other wire to the coil came from the pigtail.

2. There was no other rectifier, so did the DSAI also provide rectification of the voltage? If not, how was the rectification taking place?

3. I hooked up the old coil to the mower and new rectifier and was able to start the mower. It was surging as it usually did, so I'm rebuilding the carb, but otherwise it started and ran.

4. I do not know if the unit has the original fly wheel, but the 12 584 04-S definitely don't fit.

#25

V

VegetiveSteam

2. The ignition system and charging system are not connected in anyway to each other. They operate completely independent of each other. The 12 584 12-S has nothing to do with the charging system.

If you engage the blades via a manual lever and not an electric clutch then there is probably no voltage regulator. If all the system needs to do is charge the battery and especially if this is a Sears unit, it is probably using a 3 amp unregulated charging system. The voltage gets rectified by a diode in the black wire. It's hard to see since it's in the stator. Typically there would be three wires coming off the stator under the flywheel. Black, White and green. The black wire if I am remembering correctly is the battery charging lead. The check the system that wire need to be disconnected so there is no load on it. Then running the engine at full speed you would check the DC voltage coming off that black wire. It should be a minimum of 20 volts dc. There is no maximum so it could be more than 20 and that is fine. All we care about is a minimum of 20 volts dc. The white wire is for headlights if the unit is so equipped and the green wire is the brake wire which if there, should stop the engine from rotating with 5 seconds of shutting off the mower.

3. Started and running is a good thing.

4. I don't know what brand of coils you got to replace the genuine Kohler 12 584 04-S but they are not correct as you know. The genuine Kohler 12 584 04-S will mount. Like I stated, it may not run correctly but it will mount trust me. If the brand you got says it replaces the Kohler 12 584 04-S they are wrong. Kohler didn't change the coil mounting bosses when they went to the CV16 with Smart Spark. Both the CV15 and CV16 use the exact same engine block.

V

VegetiveSteam

1.The Speed Advance Module has 5 wires. Red was key switched battery voltage. Black was ground. White was the kill lead. The other two wires, probably yellow and brown, went to the ignition coil. One spade terminal was slightly smaller than the other so you couldn't hook it up wrong.I really appreciate all of the back and forth. You both are really helping me sort this out. Let's take a step back one second so I can get my head around this.

1. How was the Digital Speed Advance module originally wired in from the manufacturer? I ask because it was only attached from the mounting bolt of the coil to the black lead as a ground. The stator connected to the other dark wire and the yellow, and the Red went to the pigtail to supply power to the mower. The other wire to the coil came from the pigtail.

2. There was no other rectifier, so did the DSAI also provide rectification of the voltage? If not, how was the rectification taking place?

3. I hooked up the old coil to the mower and new rectifier and was able to start the mower. It was surging as it usually did, so I'm rebuilding the carb, but otherwise it started and ran.

4. I do not know if the unit has the original fly wheel, but the 12 584 04-S definitely don't fit.

2. The ignition system and charging system are not connected in anyway to each other. They operate completely independent of each other. The 12 584 12-S has nothing to do with the charging system.

If you engage the blades via a manual lever and not an electric clutch then there is probably no voltage regulator. If all the system needs to do is charge the battery and especially if this is a Sears unit, it is probably using a 3 amp unregulated charging system. The voltage gets rectified by a diode in the black wire. It's hard to see since it's in the stator. Typically there would be three wires coming off the stator under the flywheel. Black, White and green. The black wire if I am remembering correctly is the battery charging lead. The check the system that wire need to be disconnected so there is no load on it. Then running the engine at full speed you would check the DC voltage coming off that black wire. It should be a minimum of 20 volts dc. There is no maximum so it could be more than 20 and that is fine. All we care about is a minimum of 20 volts dc. The white wire is for headlights if the unit is so equipped and the green wire is the brake wire which if there, should stop the engine from rotating with 5 seconds of shutting off the mower.

3. Started and running is a good thing.

4. I don't know what brand of coils you got to replace the genuine Kohler 12 584 04-S but they are not correct as you know. The genuine Kohler 12 584 04-S will mount. Like I stated, it may not run correctly but it will mount trust me. If the brand you got says it replaces the Kohler 12 584 04-S they are wrong. Kohler didn't change the coil mounting bosses when they went to the CV16 with Smart Spark. Both the CV15 and CV16 use the exact same engine block.

#26

W

Whalensdad

1. The Speed advance module was never hooked to the coil. I don't know why.

2. I know. That was why I was wondering why they hooked the speed advance module to the stator (charging system). The unit had headlights, but they weren't connected with the Kohler engine. That was something I wanted to do. With the speed advance module, there was no up deflection of the amp meter when running. When I took it out and put the rectifier in its place, the amp meter went up. There is a separate wire coming from the pigtail to the coil to stop it when shutting off (also a wire going to the fuel shut off solenoid).

3. Started and ran, except for the surging which I hope to correct when I get this all sorted out.

4. I must have a bastardized engine. The carburetor serial number matches a CV13 and 15 and not what is on a CV16. The fly wheel doesn't appear to be the correct one for a CV13/15 based on what you say. I don't know.

I think I'm going to get the Tecumsah coil (1A138-52-12) and see if I can get it running again. I don't know what else to do without spending a fortune.

W

Whalensdad

Not sure if you read thru from the start of the thread, but the LT1000 started life with a B&S 17.5 HP Intec. Somewhere along the line it was swapped with the Kohler.1.The Speed Advance Module has 5 wires. Red was key switched battery voltage. Black was ground. White was the kill lead. The other two wires, probably yellow and brown, went to the ignition coil. One spade terminal was slightly smaller than the other so you couldn't hook it up wrong.

2. The ignition system and charging system are not connected in anyway to each other. They operate completely independent of each other. The 12 584 12-S has nothing to do with the charging system.

If you engage the blades via a manual lever and not an electric clutch then there is probably no voltage regulator. If all the system needs to do is charge the battery and especially if this is a Sears unit, it is probably using a 3 amp unregulated charging system. Typically there would be three wires coming off the stator under the flywheel. Black, White and green. The black wire if I am remembering correctly is the battery charging lead. The check the system that wire need to be disconnected so there is no load on it. Then running the engine at full speed you would check the DC voltage coming off that black wire. It should be a minimum of 20 volts dc. There is no maximum so it could be more than 20 and that is fine. All we care about is a minimum of 20 volts dc. The white wire is for headlights if the unit is so equipped and the green wire is the brake wire which if there, should stop the engine from rotating with 5 seconds of shutting off the mower.

3. Started and running is a good thing.

4. I don't know what brand of coils you got to replace the genuine Kohler 12 584 04-S but they are not correct as you know. The genuine Kohler 12 584 04-S will mount. Like I stated, it may not run correctly but it will mount trust me. If the brand you got says it replaces the Kohler 12 584 04-S they are wrong. Kohler didn't change the coil mounting bosses when they went to the CV16 with Smart Spark. Both the CV15 and CV16 use the exact same engine block.

1. The Speed advance module was never hooked to the coil. I don't know why.

2. I know. That was why I was wondering why they hooked the speed advance module to the stator (charging system). The unit had headlights, but they weren't connected with the Kohler engine. That was something I wanted to do. With the speed advance module, there was no up deflection of the amp meter when running. When I took it out and put the rectifier in its place, the amp meter went up. There is a separate wire coming from the pigtail to the coil to stop it when shutting off (also a wire going to the fuel shut off solenoid).

3. Started and ran, except for the surging which I hope to correct when I get this all sorted out.

4. I must have a bastardized engine. The carburetor serial number matches a CV13 and 15 and not what is on a CV16. The fly wheel doesn't appear to be the correct one for a CV13/15 based on what you say. I don't know.

I think I'm going to get the Tecumsah coil (1A138-52-12) and see if I can get it running again. I don't know what else to do without spending a fortune.

#27

sgkent

sgkent

do not drill it. That said, best to post lots of photos of the engine here. Don't assume because the shroud says kohler that it is. We just saw one the other day where someone swapped shrouds on an engine before they sold it.

#28

V

VegetiveSteam

V

VegetiveSteam

There should never be any direct battery voltage going to any magneto type ignition coil so I don't quite follow what you have going on there. I actually taught Kohler technicians for 27 years and you definitely have something cobbled together there. And from you pictures you do for sure have a Kohler CV engine. What was the regulator part number and what wires did you connect to it? The fuel solenoid and Speed Advance Module shouldn't have any connection to the stator. Those two components should be powered through the key switch.Not sure if you read thru from the start of the thread, but the LT1000 started life with a B&S 17.5 HP Intec. Somewhere along the line it was swapped with the Kohler.

1. The Speed advance module was never hooked to the coil. I don't know why.

2. I know. That was why I was wondering why they hooked the speed advance module to the stator (charging system). The unit had headlights, but they weren't connected with the Kohler engine. That was something I wanted to do. With the speed advance module, there was no up deflection of the amp meter when running. When I took it out and put the rectifier in its place, the amp meter went up. There is a separate wire coming from the pigtail to the coil to stop it when shutting off (also a wire going to the fuel shut off solenoid).

3. Started and ran, except for the surging which I hope to correct when I get this all sorted out.

4. I must have a bastardized engine. The carburetor serial number matches a CV13 and 15 and not what is on a CV16. The fly wheel doesn't appear to be the correct one for a CV13/15 based on what you say. I don't know.

I think I'm going to get the Tecumsah coil (1A138-52-12) and see if I can get it running again. I don't know what else to do without spending a fortune.

#29

sgkent

sgkent

does the oil cap cover give a clue what engine this is? I looked at a lot of Kohler photos and that dipstick only appeared on a few, the CV730 for example. The style magnet on the flywheel only appears in some models too.

#30

V

VegetiveSteam

V

VegetiveSteam

It's definitely a Kohler.does the oil cap cover give a clue what engine this is? I looked at a lot of Kohler photos and that dipstick only appeared on a few, the CV730 for example. The style magnet on the flywheel only appears in some models too.

#31

sgkent

sgkent

That is probably true but the models mentioned early in the thread appear to have a different oil filler and flywheel magnet. I was hoping someone would look at the photo and recognize the engine. I mean you could have an engine that the flywheel and coil have both been swapped on. We see lots of strange things here.

#32

V

VegetiveSteam

V

VegetiveSteam

Of course that's exactly what I did. I looked at photo and recognized it as a Kohler. No question about it. It's a Kohler Command vertical shaft single cylinder. That blower housing and air filter and the upside down oil filter scream Kohler. 100% without a doubt.That is probably true but the models mentioned early in the thread appear to have a different oil filler and flywheel magnet. I was hoping someone would look at the photo and recognize the engine. I mean you could have an engine that the flywheel and coil have both been swapped on. We see lots of strange things here.

#33

W

Whalensdad

W

Whalensdad

I agree about the direct battery voltage. There isn't any going to it the coil and there never was. I purchased a KH-25-755-03 replacement for the rectifier. The stator had 2 wires, Black and Yellow. I connected them to the outer connections of the rectifier. I connected my red power lead to the center. This is how the wiring was setup in both the before and after.There should never be any direct battery voltage going to any magneto type ignition coil so I don't quite follow what you have going on there. I actually taught Kohler technicians for 27 years and you definitely have something cobbled together there. And from you pictures you do for sure have a Kohler CV engine. What was the regulator part number and what wires did you connect to it? The fuel solenoid and Speed Advance Module shouldn't have any connection to the stator. Those two components should be powered through the key switch.

#34

V

VegetiveSteam

V

VegetiveSteam

Where you now have the regulator/rectifier mounted was there anything mounted there before? Normally on a 3 amp system there is a blank plate there. The 15 amp systems use that regulator/rectifier and have two white wires coming off the stator. The center spade on the regulator goes to the B+ side of the battery.

#36

V

VegetiveSteam

V

VegetiveSteam

Yeah that's because it doesn't need a regulator/rectifier. It's actually serving no useful purpose. If you can get your hands on an actual correct 12 584 04-S I'd try that.

#38

StarTech

StarTech

Sorry the wiring posted is incorrect.

Personally I highly suggest the OP get a copy of the service manual.

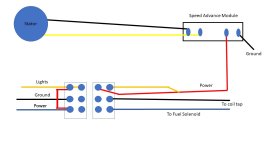

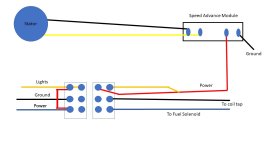

Wiring per the service manual for 3 amp system.

B+ Lead will have one 200v 3-5 amp diode in it. These do short out at times and need replacing.

Also note the stator brake is optional and may not even be wired. IE No green wire.

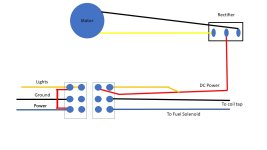

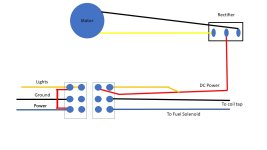

Wiring per Service manual for 15 amp system.

I hate to point this out but engine doesn't have the same flywheel as the CV11-CV15. Which is why the coil is not matching up.

With all the time wasted here it can be more productive just to dig out the high tension lead and replace it in the Tecumseh coil. It is replaceable with patience. Use a 7mm lead and a new terminal. straight or 90 degree version. Places like Oreilly's has the terminals. And probably one of local mower shops with have the lead. I know I buy all three in bulk here. Exacto knife is one of the tools needed along epoxy to seal the new lead.

Personally I highly suggest the OP get a copy of the service manual.

Wiring per the service manual for 3 amp system.

B+ Lead will have one 200v 3-5 amp diode in it. These do short out at times and need replacing.

Also note the stator brake is optional and may not even be wired. IE No green wire.

Wiring per Service manual for 15 amp system.

I hate to point this out but engine doesn't have the same flywheel as the CV11-CV15. Which is why the coil is not matching up.

With all the time wasted here it can be more productive just to dig out the high tension lead and replace it in the Tecumseh coil. It is replaceable with patience. Use a 7mm lead and a new terminal. straight or 90 degree version. Places like Oreilly's has the terminals. And probably one of local mower shops with have the lead. I know I buy all three in bulk here. Exacto knife is one of the tools needed along epoxy to seal the new lead.

#39

W

Whalensdad

W

Whalensdad

Thanks. Since the coil in the unit wasn't wired to the SAM in the first place, I just decided to go with another Tecumsah coil. It was cheaper than the time spent to replace the wire. I'll keep the old one as a spare. I'm keeping the rectifier though since I wasn't getting enough voltage to keep the battery charged. I don't think it will hurt. And yes, there was no green wire on my stator. Going through this thread helped me learn a lot about the engine I have. I'm guessing it was a rebuilt and someone swapped the flywheel at some point. This is what happens when you buy off craigslist. Thanks again for all of the advice.Sorry the wiring posted is incorrect.

Personally I highly suggest the OP get a copy of the service manual.

Wiring per the service manual for 3 amp system.

View attachment 62638

B+ Lead will have one 200v 3-5 amp diode in it. These do short out at times and need replacing.

Also note the stator brake is optional and may not even be wired. IE No green wire.

Wiring per Service manual for 15 amp system.

View attachment 62639

I hate to point this out but engine doesn't have the same flywheel as the CV11-CV15. Which is why the coil is not matching up.

With all the time wasted here it can be more productive just to dig out the high tension lead and replace it in the Tecumseh coil. It is replaceable with patience. Use a 7mm lead and a new terminal. straight or 90 degree version. Places like Oreilly's has the terminals. And probably one of local mower shops with have the lead. I know I buy all three in bulk here. Exacto knife is one of the tools needed along epoxy to seal the new lead.

#40

StarTech

StarTech

Yes there plenty of rig jobs out there. And they frustrate the **** out of me of how they just keep getting by with things.

Personally I have always try to keep thing as they are intended as I think of the next tech beside myself that may get my repaired equipment later.

But lately I have someone in the area that I patching things up and then I got to straighten the mess out. Just had two of those crappy repairs to show up in my shop. It takes at least twice as long as I have to undo all the rig work before I can repair the equipment.

I got a Kawasaki 3010 Mule here that I have already put in over 24 hrs of labor to get it back to good condition. Even then it came with a water leak due to a warp part. Plus I just reworked the parking brakes yesterday finding intentionally bent parts on the left rear. Hopefully I can get the CVT drive back on today before the rain gets here.

I had to stop and fix a Husqvarna 455 Rancher for a customer. Simple repair of replacing primer, fuel lines, re-tune the carburetor, and sharpen the chain but still takes time to do.

Personally I have always try to keep thing as they are intended as I think of the next tech beside myself that may get my repaired equipment later.

But lately I have someone in the area that I patching things up and then I got to straighten the mess out. Just had two of those crappy repairs to show up in my shop. It takes at least twice as long as I have to undo all the rig work before I can repair the equipment.

I got a Kawasaki 3010 Mule here that I have already put in over 24 hrs of labor to get it back to good condition. Even then it came with a water leak due to a warp part. Plus I just reworked the parking brakes yesterday finding intentionally bent parts on the left rear. Hopefully I can get the CVT drive back on today before the rain gets here.

I had to stop and fix a Husqvarna 455 Rancher for a customer. Simple repair of replacing primer, fuel lines, re-tune the carburetor, and sharpen the chain but still takes time to do.

#41

sgkent

sgkent

no question that Frankenstein repairs are a problem. The nightmare begins when something breaks or keeps wearing out and someone wants that fixed.

#42

W

Whalensdad

W

Whalensdad

I should have done my research before buying this. I was in a hurry last year and just made sure it ran. I looked for oil leaks but didn't inspect the engine closely. The label on the mower said B&S 17.5 HP Intek and it was advertised as a 17.5 HP mower. I didn't know what to look for and didn't realize it was not an Intek engine until I got home and went to purchase a new air filter for it. The seller wouldn't take it back, and I wasn't going to go to small claims court over it. I'm a handy guy and do a lot of my own auto repair work, so it's no big deal to do my own repairs. I had a spark plug wire lying around so I just rewired the original Tecumsah coil. I'll put it in tomorrow or Thursday and see how it goes. Thanks for all the suggestions.Yes there plenty of rig jobs out there. And they frustrate the **** out of me of how they just keep getting by with things.

Personally I have always try to keep thing as they are intended as I think of the next tech beside myself that may get my repaired equipment later.

But lately I have someone in the area that I patching things up and then I got to straighten the mess out. Just had two of those crappy repairs to show up in my shop. It takes at least twice as long as I have to undo all the rig work before I can repair the equipment.

I got a Kawasaki 3010 Mule here that I have already put in over 24 hrs of labor to get it back to good condition. Even then it came with a water leak due to a warp part. Plus I just reworked the parking brakes yesterday finding intentionally bent parts on the left rear. Hopefully I can get the CVT drive back on today before the rain gets here.

I had to stop and fix a Husqvarna 455 Rancher for a customer. Simple repair of replacing primer, fuel lines, re-tune the carburetor, and sharpen the chain but still takes time to do.

#43

W

Whalensdad

W

Whalensdad

So let me give you all the final update. I ordered a replacement tecumsah coil. While I was waiting I thought I would try to drill out the Kohler replacement to make it fit. That was a BIG waste of time. I mangled the coil and ruined it. The one thing I realized was the the coil wire was much longer than what the tecumsah came with, so I removed it (so not a total loss). The new coil came in and it LOOKED like it was the same as the old coil, but LOOKS can be deceiving. The metal bars were now too long and I couldn't mount it and have the fly wheel turn. UGH... So I took the old coil, removed the bad coil wire, put in the salvaged coil wire. Reinstalled my rebuilt/cleaned carb, old coil, and after getting fuel into the carb, it started right up. Next year I'll be rebuilding the deck, NOT