Cajun power

Active Member

- Joined

- Apr 11, 2023

- Threads

- 1

- Messages

- 86

if you have PROFESSIONALLY FACED the upper cylinder head and main block? (I'm skeptical...not saying you did not do it...but there is a world of difference between DIY truing and professional).

so if you removed to much material, it may be difficult to actually get valve clearance set...no matter what you must reset valve clearance. PER THE SERVICE MANUAL...Lot of bad information out on the interwebs., And check that valve seats have not stepped out...makes sure the exhaust and intake valve are not borked with soot or heat damage like warp ...also look at exhaust ports...something soot gets cooked and that can cause overheat.

the gaskets you bought may be the wrong type. (for instance...on some mower engines the OEM gaskets have been improved and superceded with better materials...usually a composite, metal/fiber type. you will need to research this...there is alot of junk resellers out there who send wrong parts and not the upgraded parts...recheck everything.

your engine might be running way too lean...this overheat cycle over and over is going to eventually blow out head gaskets. Try to look for any air leaks and adjust the carb spot on.

the mayb be serious internal damage to oil pressure pump...if yours has one. most of the cheaper have slingers...some have an actual oil pump. If oil is not getting where it needs to go, overheat...head gaskets blow out. (and hopefully, only that!)

the cylinder head may be cracked. Sometimes it a very small micro crack that only creates problems after hot cycle. If you suspect this, you can either do a penetrant dye and black light inspection...or shadetree: do a hot cycle, shut mower off and as soon as you can set up and perform a leak down check...the latter might be able to

other causes could be head gasket bolts that have stretched or bolt threads in the head are borked. It's one of those things that can happen from improper torque but also getting slammed by overheat cycles over and over.

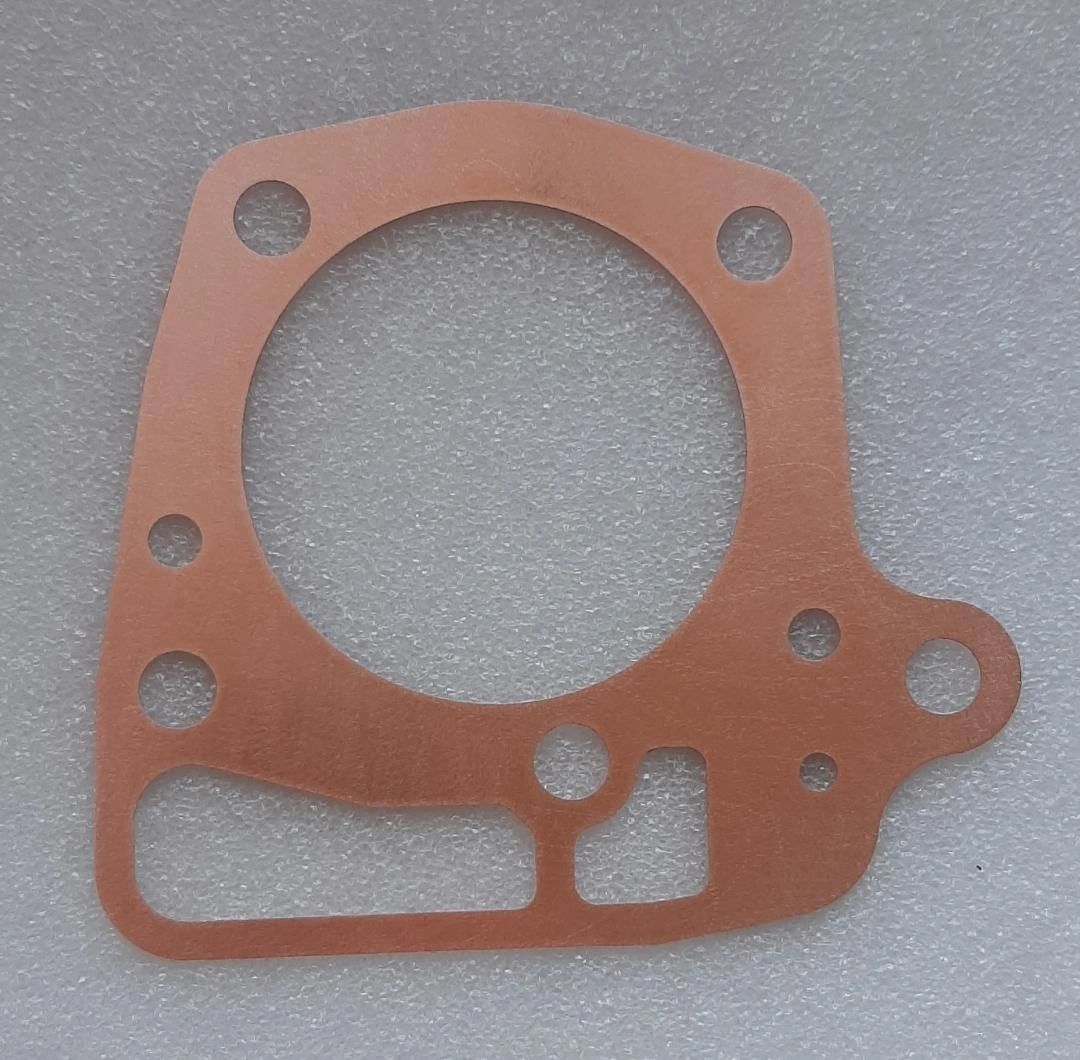

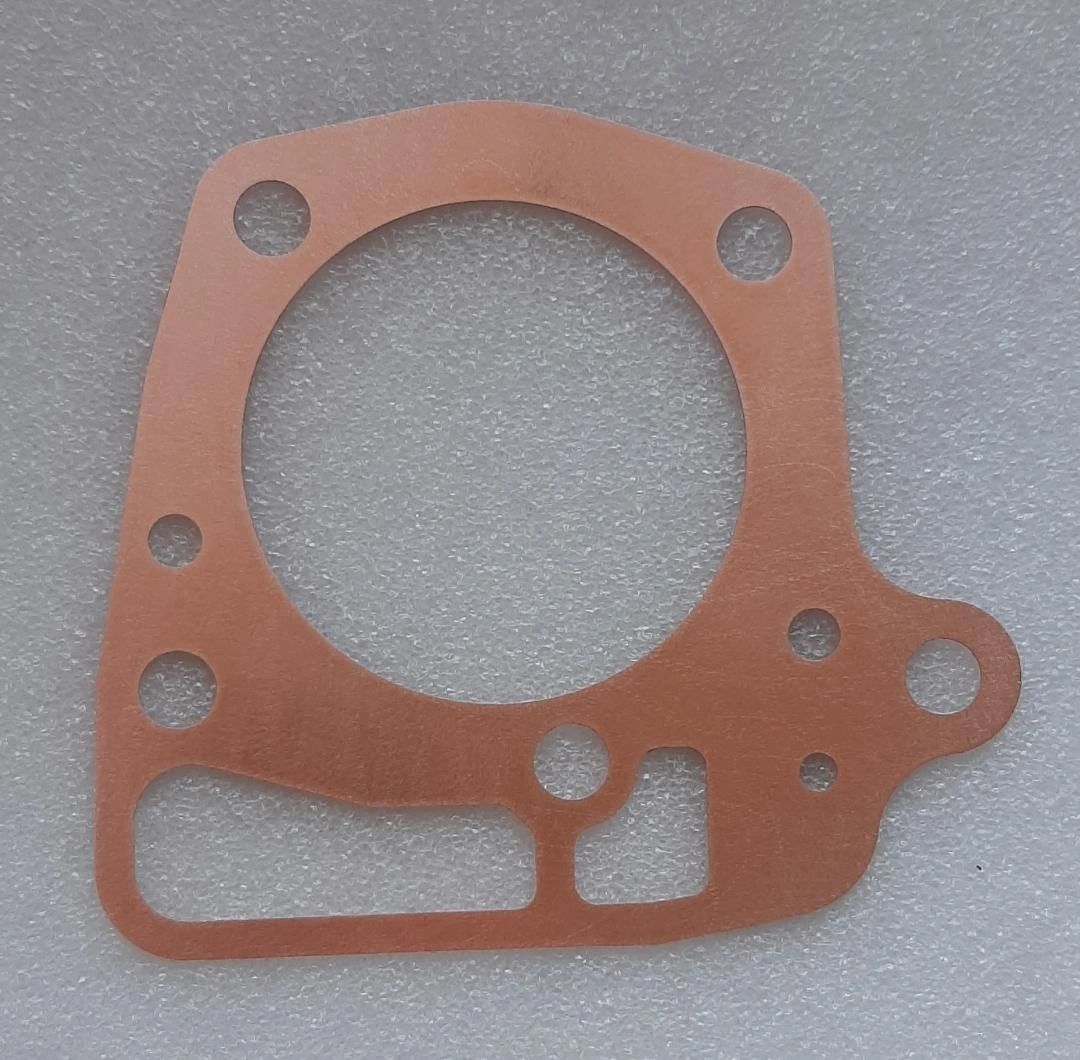

if you've done all these things and everything checks out..AND THE LEAK DOWN CHECK IS GOOD AND GOOD COMPRESSION then consider buying COPPER GASKETS...They are superior in almost every way...better squish, and far superior heat transfer. Here is an reputable company that I have recently bought copper gaskets to fit a kawasaki mower engine I rebuilt..

coppergaskets.us

coppergaskets.us

so if you removed to much material, it may be difficult to actually get valve clearance set...no matter what you must reset valve clearance. PER THE SERVICE MANUAL...Lot of bad information out on the interwebs., And check that valve seats have not stepped out...makes sure the exhaust and intake valve are not borked with soot or heat damage like warp ...also look at exhaust ports...something soot gets cooked and that can cause overheat.

the gaskets you bought may be the wrong type. (for instance...on some mower engines the OEM gaskets have been improved and superceded with better materials...usually a composite, metal/fiber type. you will need to research this...there is alot of junk resellers out there who send wrong parts and not the upgraded parts...recheck everything.

your engine might be running way too lean...this overheat cycle over and over is going to eventually blow out head gaskets. Try to look for any air leaks and adjust the carb spot on.

the mayb be serious internal damage to oil pressure pump...if yours has one. most of the cheaper have slingers...some have an actual oil pump. If oil is not getting where it needs to go, overheat...head gaskets blow out. (and hopefully, only that!)

the cylinder head may be cracked. Sometimes it a very small micro crack that only creates problems after hot cycle. If you suspect this, you can either do a penetrant dye and black light inspection...or shadetree: do a hot cycle, shut mower off and as soon as you can set up and perform a leak down check...the latter might be able to

other causes could be head gasket bolts that have stretched or bolt threads in the head are borked. It's one of those things that can happen from improper torque but also getting slammed by overheat cycles over and over.

if you've done all these things and everything checks out..AND THE LEAK DOWN CHECK IS GOOD AND GOOD COMPRESSION then consider buying COPPER GASKETS...They are superior in almost every way...better squish, and far superior heat transfer. Here is an reputable company that I have recently bought copper gaskets to fit a kawasaki mower engine I rebuilt..

KAWASAKI 11004-7026,FS730V,FX651V, FX69V, FX730V,LAWNMOWERS,9C3

Made in USA Thickness .016" solid copper Bore 3.110" Reusable if not damaged SHIPS FOR FREE USA ONLY INTERNATIONAL SHIPPING $13

coppergaskets.us

coppergaskets.us