Just for grins went to check TDC more carefully & compare old flywheel to new. Old one clearly has thinner magnets. At TDC the coil is on 2nd magnet as it rotates clockwise.

The flywheel spins counter clockwise ( double check with your starter )

All engines fire before TDC

A magneto developes peak power as the leading magnet is just starting to pass the furthest leg of the coil.

Coils get positioned in different places according to the space available so in many cases the models will have identical looking flywheels but the key is in a different spot which is why I mark the flywheel and check it against TDC.

A lot of home mechanics get caught out because they do not understand the principles of magneto power generation.

The faster a coil passes a magnet the higher the voltage it produces

These engines are designed to be at peal coil power at full speed which is 7,000 to 12,000 rpmSo if you are getting a big fat spark at those speeds then you get a pathetic tiny spark at the 500 rpm pull start speed and the one at 1500 to 3000 rpm ( idle speed ) is not much better which is one reason why they burble at low speeds, because the engine is missing .

Home mechanics who are used to seeing big fat sparks that battery discharge ignitions ( called Kettering type ) give at idle see ( or don't see ) the tiny fril sparks these engines give off at cranking / idle speeds and assume they have a spark problem, when none exists .

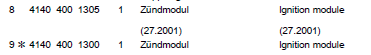

So they then start swapping ignition parts and end up with a mess because as Star has just shown, the manufacturers regularly change parts during a production run and not all parts will work with the others .