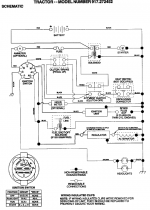

Thanks for the replies, I am almost sure I have the two-wire type switch as this is a 2002 LTX1000 Craftsman. Don't think I'll be checking on this today tho because it is only 4 above today. I'll check the switch with an om meter before a disconnect to make sure how it works. I'll agree the cinder block is not an option.The tractor is a Craftsman 917.272452 with the 21.5 HP Briggs 42" deck

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Checking noises but can't leave the seat !!!

- Thread starter OldDiyer

- Start date

More options

Export thread- Joined

- Feb 19, 2020

- Threads

- 121

- Messages

- 12,895

If it is using the NC switch as you said can I use a jumper wire across the terminals to do my testing of belts or pulleys? I have an automotive repair back round so I am aware of working around moving belts and pulleys. Believe me in my past I have seen guys do many crazy things around moving parts. I am happy that my unit has the safety switches and don't have any reason to start bypassing any of them. I know that to keep it running the brake needs to be set but with the seat switch bypassed can I leave the attachment lever engaged for testing the snow blower? Thanks again !!

- Joined

- Feb 19, 2020

- Threads

- 121

- Messages

- 12,895

Nope you can not jumper the switch. A NC switch is a normally closed switch. It plunger has to be depressed to become an open switch. The shorting strip in connector when unplugged would be the same as jumping switch and the same as if you are not on the seat which would kill the engine if the PTO is engage or the brake/clutch is off [up].

Now when seat is properly bypassed then yes with the parking brake/clutch set you leave the PTO engage and thing will stay running.

Now when seat is properly bypassed then yes with the parking brake/clutch set you leave the PTO engage and thing will stay running.

Some people just will not listen to anything so why are even typing things.

I was just wondering how people go about Keeping your tractor running when you are checking for problems if you can't leave the seat to keep safety switches in tacked ? The reason I'm asking is I am getting an odd noise from what sounds like belt or one of the pullies but can't tell for sure without being able to disingage attachment or get off the seat. This is on my blower attachment but could be any type of problems. Must be other people that have to do this alone and was wondering best way. Thanks

Good diagnosis start with a complete visual inspection. Engine off. Interesting what ya find. Remove belts to check for noisy or worn pulley bearing. Ya usually find the problem and other potential problems as well.I was just wondering how people go about Keeping your tractor running when you are checking for problems if you can't leave the seat to keep safety switches in tacked ? The reason I'm asking is I am getting an odd noise from what sounds like belt or one of the pullies but can't tell for sure without being able to disingage attachment or get off the seat. This is on my blower attachment but could be any type of problems. Must be other people that have to do this alone and was wondering best way. Thanks

Sam857us

Forum Newbie

- Joined

- Jan 8, 2022

- Threads

- 0

- Messages

- 1

The easiest, and safest way to do this, is to remove the main danger and a source of noise to help you find the issue. Remove the blades, and have another person on the seat, with their hand on the deactivation switch or lever, ready to disengage at the least sign of a hazard.I was just wondering how people go about Keeping your tractor running when you are checking for problems if you can't leave the seat to keep safety switches in tacked ? The reason I'm asking is I am getting an odd noise from what sounds like belt or one of the pullies but can't tell for sure without being able to disingage attachment or get off the seat. This is on my blower attachment but could be any type of problems. Must be other people that have to do this alone and was wondering best way. Thanks

I was just wondering how people go about Keeping your tractor running when you are checking for problems if you can't leave the seat to keep safety switches in tacked ? The reason I'm asking is I am getting an odd noise from what sounds like belt or one of the pullies but can't tell for sure without being able to disingage attachment or get off the seat. This is on my blower attachment but could be any type of problems. Must be other people that have to do this alone and was wondering best way. Thanks

Cusser

Well-Known Member

- Joined

- May 3, 2019

- Threads

- 16

- Messages

- 247

Yesterday, I thought it would be a good idea to use a piece of steel wool on the bare rotating shaft of a vacuum cleaner motor, to clean off residue from a burnt/broken belt. The shaft grabbed the steel wool pad instantly, I was lucky to only bang up a finger. I ended up using cloth sandpaper and cleaning off that shaft manually, with the vacuum cleaner off. Lesson learned, was NOT a good idea...

bkeller500

Well-Known Member

- Joined

- Jul 2, 2018

- Threads

- 7

- Messages

- 311

Good lesson learned. We have all been there. Just imagine the horror if one slipped as he leaned closer to a moving belt and got a shirt or jacket sleeve caught or even a hand or fingers pinched. I'm sure there are Pro's on this forum that have enough experience to run the machine and investigate at the same time but I bet most everyone of them have had a close call or two or an experience they regret.Yesterday, I thought it would be a good idea to use a piece of steel wool on the bare rotating shaft of a vacuum cleaner motor, to clean off residue from a burnt/broken belt. The shaft grabbed the steel wool pad instantly, I was lucky to only bang up a finger. I ended up using cloth sandpaper and cleaning off that shaft manually, with the vacuum cleaner off. Lesson learned, was NOT a good idea...

- Joined

- Feb 19, 2020

- Threads

- 121

- Messages

- 12,895

It one reason I refuse to wear a tie. I save my service manager one time where his got caught in the in feed section of a copier. Nearly choke him to death before I cut off the tie. Every since he wear a clip on version.

Also the forms bursters I worked had 8lbs between the rollers. Just think flat your hand or fingers be if got caught between them running at 500 fpm. And that was just the in feed side the out feed ran at twice that speed. NO wonder it was mandatory for me to write up the customer when I found the safety covers removed.

Also the forms bursters I worked had 8lbs between the rollers. Just think flat your hand or fingers be if got caught between them running at 500 fpm. And that was just the in feed side the out feed ran at twice that speed. NO wonder it was mandatory for me to write up the customer when I found the safety covers removed.