IT is a highly flawed design from the start and both AYP & JD use it

It was just OK on the older models like the LX Deers that had narrower wheels and not this idiot pretend near zero turn steering set up .

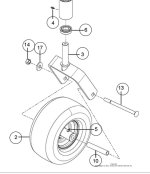

There is simply too much load on the bushing , it needs EP bentonite gear grease , not Lithium as specified , but the lack of proper sealing causes the bentonite grease to go off .

The grease nipples rarely seal as they are drilled through the weld by a blind machinist and rarely have any more than 1 turn of thread which does not work with a tapered thread seal .

I have tried just about everything and the only thing that actually worked long term was to drill the end of the Axel for a grease nipple and diagonally cross drill the shaft but thi has to be done every season without fail .

The strait cross drilling ended breaking the axel at the cross drilling

The axel is only induction hardened so lucky to be 0.001" of hardness.

The bush is a powder pressing and is supposed to be partially self lubricating

Every aftermarket parts maker sells the bushes

OEM part numbers

- Ariens21546832

- AYP 532009040, 9040H

- Honda 91051-771-000

- Husqvarna 532009040, 532124959, 539112899, 583670401, 594944401

- John DeereGX10059, M123811

- MTD 135236

- Murray 491334MA

- Toro 114-1640

Now I have been told that this tapered rollers can be made to fit

Stens 230-610 bit you have to make up spacers to fit between the inner cones then shim the wheel so there is no side play

I have not tried it

These 2 full length rollers have worked reasonably well but again I had to make up spacers for different wheels

I use them when the old bushes have under cut the axels .

Stens 230-616

Stens 230-693