Bert have you not read my first post ?

I have the wiring schematic already.

What I was hoping for when I started this thread was someone who had this problem and would have told me.

Could have saved a few steps.

You keep talking to me like I'm an idiot.

No, I have not bought a highlighter marker yet to backtrack the circuit. Forgive me your lordship.

I don't need "Join the pink wire to the green wire and cut the blue one just past the yellow wire junction"

When I find the functions of the safety switches it will be very easy to trace the circuits.

I will have time today to compare the problem machine to my friends other 3 SCAG walk behind units.

There are one other 36" and two 48".

Thanks for your input.

Yes I read your first post, several times

And I do appreciate that many people struggle with reading circuit diagrams.

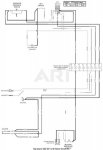

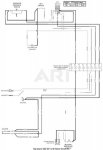

The diagram that you put a link to in your post #18 yesterday shows

THE WIRING HARNESS NOT THE CIRCUITS

When I actually checked that link I understood why you were struggling to work out the mowers wiring so I posted a link to a CIRCUIT DIAGRAM which is a totally different animal

Since then I found the rest of the diagram as the link I posted yesterday only had the engine plug to handlebar section on it.

It appears that Scag publish it in 3 different ways, engine side, handle bar side and full diagram, however the full diagram does not show the diode.

But the diode will have less than nothing to do with grounding the magneto so has less than no impact on the no spark problem, being that is is on a power wire and all magneto wires are ground wires.

So here is the full wiring diagram, it was there all along I just had not gone deep enough into the parts breakdown to find it the first time , lazy me.

When you said you had a wiring diagram this is what I assumed you were looking at.

As you were not then what I posted would have been confusing .

All of the switches in this diagram are shown in the OFF position , ie key off, no operator ( assume this is a bail handle of some sort ) and blades off .

Now the diagram is bad as the white wire which is shown as a double thin black line did not copy properly so lumps of it are missing but the important bit, which plugs & what terminals is shown so if it is confusing, just print it out & join the wires together.

And with this I am out of here.

Note the pins on the PTO switch are numbered in the diagram ( look hard ) but not all PTO switches have the pins numbers on them.