It says Craftsman model 917.275901Flip up the seat and look on the bottom of the seat pan. You will see a model number and a serial number. Here’s the deal, some Craftsman mowers were made by MTD and some were made by AYP/Husqvarna.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swapping Kohler CV730S for a B&S 44N877 - can't figure out 6-pin harness

- Thread starter cmrho

- Start date

More options

Export threadGet you some masking tape and label the wires coming off of the ignition switch to wiring harnesses of the Kohler engine. You may have to take the switch out and make note of the lettering on the back of the switch. This will go a long way in helping you to get you up and running.

- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,872

Thanks all. I cut open the harness on the CV730 and did confirm what y'all said. There are 2 red wires to the carb sol. One appears to be activated at the same time as the starter sol (so when the key is turned to the start position). But then that wire goes neutral when the key goes back to the on position. So then the other red wire, which is jumpered to the alternator, activates the carb sol.? The diodes in both the red wires eliminates current backfeed, particularly to the starter sol. I have everything figured out except: How does the old harness setup kill the new engine? I'm guessing that in the old engine, it cuts the connection to the red wire powering the carb sol. while the engine is running, which kills the engine. I don't have that on the new engine. All I have is a single grey wire that goes to the carb sol., not 2. Do I jumper the new carb sol. wire to the alternator in addition to the old harness starter wire?

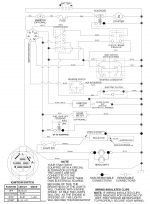

Thanks for this. I'm not an electronics technician by training, but see what you're talking about. So this means that the fuel solenoid needs to be jumpered to the alternator correct? So when the engine is running, the solenoid activates?Ahh now I see what is needed. Look at the fuel solenoid and regulator connection on the following diagram. They are tied together. Also the ignition switch is not wired the same as in the Kohler service manual.

Your mower wiring schematic

View attachment 57538

Do you own a test light and a VOA meter is you do you can test the switch an each position as to what they do. Key off probe the wire for continuity to ground this would be the ignition kill circuit. Turn to run position and probe with test light that would be fuel solenoid and charge wire if you get two circuits. If just one fuel solenoid. Turn key to start position that one would be the starter exciter wire. If you have a blue wire with a red jumper that will be fuel solenoid wire and it has to have a diode in it when you connect it to the gray wire. Probe the wires that were hot in the run position and turn key to start position if one of them goes out that will be the fuel solenoid wire and you have to have a diode in wire and the blue wire with the red jumper so they will not feed back into the other circuits.

Great tips. Thanks!Do you own a test light and a VOA meter is you do you can test the switch an each position as to what they do. Key off probe the wire for continuity to ground this would be the ignition kill circuit. Turn to run position and probe with test light that would be fuel solenoid and charge wire if you get two circuits. If just one fuel solenoid. Turn key to start position that one would be the starter exciter wire. If you have a blue wire with a red jumper that will be fuel solenoid wire and it has to have a diode in it when you connect it to the gray wire. Probe the wires that were hot in the run position and turn key to start position if one of them goes out that will be the fuel solenoid wire and you have to have a diode in wire and the blue wire with the red jumper so they will not feed back into the other circuits.

Did as you said. Nothing is making sense. Even with the seat switch and brake switch activated, I'm getting no current on any of the wires coming off the harness in either the on or start position. But weirdly, I get current on a few of them when the key is completely off. I am completely stumped.Great tips. Thanks!

Well, I'm at my wit's end. Nothing is making sense. I suspect there's a kill switch somewhere that I don't know about. But I'm not getting any current through any of the wires coming out of the switch when in the on position. I might throw in the towel and just buy a new mower. Anyone want to buy a brand new Briggs & Stratton engine, lol? Thanks for the help y'all.

- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,872

This why professional like me go to school when are young to learn things like how to read schematics. Personally I spent two year going to a technical school. Even many repair shops in my aread have techs that have no idea of what they are actually doing and just guess at it. Every year I get multiple jobs where the local shop have screwed up a customer's mower wiring. This includes the local JD dealer that cant find a bad oil pressure switch, loose connection, or even a bad spark plug.

No wonder one my customers brought a Z950M from the dealer but will not let them even touch it under warranty.

It is much cheaper to let a confident mechanic install your engine than buy a new mower since you have already gone the process of buying a new engine.

No wonder one my customers brought a Z950M from the dealer but will not let them even touch it under warranty.

It is much cheaper to let a confident mechanic install your engine than buy a new mower since you have already gone the process of buying a new engine.