Alex Ethridge

Active Member

- Joined

- May 25, 2019

- Threads

- 18

- Messages

- 77

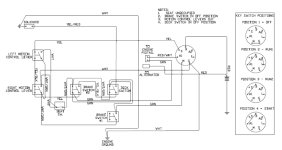

I want to thank everyone here for their help as it has validated my belief that this intermittent problem is related to the safety switches. I think maybe I'll order safety switches one at a time and replace them one at a time until I hit on the one that fixes the problem. Diagnosing them by shunting is going to be a problem for me as I don't know whether switches are normally open or normally closed. AND some of these switches have four terminals which further confuses things for me.

Until I hit on the solution, I do have a back-door way of starting it.

Superfluous and useless information: My dad, long gone now, was a master electrician and could make sense of every schematic I ever brought to him. He was a troubleshooter at a heavy industrial manufacturing plant with punches, shears and presses as big as a house. I don't know how many times since he's gone that I have wished I could ask him a question. But thanks to his influence, at least I can wire a house and troupleshoot any appliance I and my family have ever owned.

Until I hit on the solution, I do have a back-door way of starting it.

Superfluous and useless information: My dad, long gone now, was a master electrician and could make sense of every schematic I ever brought to him. He was a troubleshooter at a heavy industrial manufacturing plant with punches, shears and presses as big as a house. I don't know how many times since he's gone that I have wished I could ask him a question. But thanks to his influence, at least I can wire a house and troupleshoot any appliance I and my family have ever owned.