You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Safety-switch-related, no-starting problem?

#1

A

Alex Ethridge

A

Alex Ethridge

Husqvarna ZT3016.

This is an intermittent problem, sometimes starts by turning the key, sometimes behaves as though there were no battery in it at all.

The facts:

This is an intermittent problem, sometimes starts by turning the key, sometimes behaves as though there were no battery in it at all.

The facts:

- The battery is good and has a full charge.

- Shunting the under-seat safety switch produced no effect.

- I checked checked the switch plungers for both for both right and left control arms and visibly, they appear to function as designed but I have not actually checked continuity.

- I have not checked the hand-brake safety switch yet.

- Turned on the ignition, placed all levers and controls properly for starting, then shunting the battery positive terminal to the starter will start the engine and the mower works as it should.

#3

B

bertsmobile1

B

bertsmobile1

A dirty plunger on a safety switch will do this

A loose safety switch will do this

a wire fatigued through at the crimp will do this

A bad battery ground will do this

A bad solenoid ground will do this

When faced with one of these problems , I pull the key switch plug & jump the B & S terminals

Then it is a case of poking & proding everything till you hear the solenoid Trip

A loose safety switch will do this

a wire fatigued through at the crimp will do this

A bad battery ground will do this

A bad solenoid ground will do this

When faced with one of these problems , I pull the key switch plug & jump the B & S terminals

Then it is a case of poking & proding everything till you hear the solenoid Trip

#4

A

Alex Ethridge

A

Alex Ethridge

Pardon my ignorance please but exactly what are the B & S terminals? I assume the S is for starter but what does the B stand for?A dirty plunger on a safety switch will do this

A loose safety switch will do this

a wire fatigued through at the crimp will do this

A bad battery ground will do this

A bad solenoid ground will do this

When faced with one of these problems , I pull the key switch plug & jump the B & S terminals

Then it is a case of poking & proding everything till you hear the solenoid Trip

#5

B

bertsmobile1

B

bertsmobile1

Battery

Some switches will have tiny letters cast into the back of the switch

B attery

S tart

G round

L ights

A lternator

Etc etc etc

The Battery terminal is usually plain red and funny enough should show battery voltage all the time .

If not then the fuse holder is suspect

I can not find any listing for a ZT 3016 so If you want more specific help please post the model product & Serial numbers from the ID tag or just post a photo of the tag .

Some switches will have tiny letters cast into the back of the switch

B attery

S tart

G round

L ights

A lternator

Etc etc etc

The Battery terminal is usually plain red and funny enough should show battery voltage all the time .

If not then the fuse holder is suspect

I can not find any listing for a ZT 3016 so If you want more specific help please post the model product & Serial numbers from the ID tag or just post a photo of the tag .

#6

A

Alex Ethridge

A

Alex Ethridge

Battery

Some switches will have tiny letters cast into the back of the switch

B attery

S tart

G round

L ights

A lternator

Etc etc etc

The Battery terminal is usually plain red and funny enough should show battery voltage all the time .

If not then the fuse holder is suspect

I can not find any listing for a ZT 3016 so If you want more specific help please post the model product & Serial numbers from the ID tag or just post a photo of the tag .

#8

H

hlw49

H

hlw49

Could be the pto switch since the start circuit runs through it. Sometimes if you jiggle the pto switch it will work intermittently. Also look at the terminals in the terminal block and see if any of them have the center tab broken off in them.

#9

StarTech

Well it took a while to find a readable schematic. The following is the stupid diagram Husqvarna put in most of the zt3016 owners manuals.

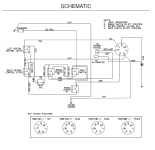

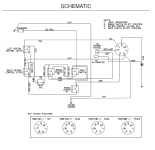

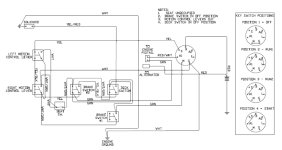

But here is a readable schematic for the mower.

You have four switches in the starter circuit besides the ignition switch. Two motion control levers, brake switch, and PTO (deck switch). Note the brake has two switches.

And it looks like Husqvarna was too cheap to even put a fuse in this mower wiring harness. Just note there may be one anyway between the battery and the ignition switch.

Since voltage runs thru these switches the contacts tends to burn and become intermittent.

StarTech

Of course shunting (jumpering) the seat has no effect. That only effects the magneto kill circuit. Btw by doing this you are telling the mower that no one is in the seat. Also being a single pole switch the connector most likely has a shorting strip to prevent you from simply unplugging it.Husqvarna ZT3016.

This is an intermittent problem, sometimes starts by turning the key, sometimes behaves as though there were no battery in it at all.

The facts:

So where should I start looking for the problem?

- The battery is good and has a full charge.

- Shunting the under-seat safety switch produced no effect.

- I checked checked the switch plungers for both for both right and left control arms and visibly, they appear to function as designed but I have not actually checked continuity.

- I have not checked the hand-brake safety switch yet.

- Turned on the ignition, placed all levers and controls properly for starting, then shunting the battery positive terminal to the starter will start the engine and the mower works as it should.

Well it took a while to find a readable schematic. The following is the stupid diagram Husqvarna put in most of the zt3016 owners manuals.

But here is a readable schematic for the mower.

You have four switches in the starter circuit besides the ignition switch. Two motion control levers, brake switch, and PTO (deck switch). Note the brake has two switches.

And it looks like Husqvarna was too cheap to even put a fuse in this mower wiring harness. Just note there may be one anyway between the battery and the ignition switch.

Since voltage runs thru these switches the contacts tends to burn and become intermittent.

#10

B

bertsmobile1

B

bertsmobile1

AFAIK there are no Husqvarna service manuals available in any form at any level for their mowers .

Wiring diagrams are usually at the start of the parts books or end of the owners instruction books .

The top one Star posted is on the last page of your owners manual and is actually the schmetic that would be used by the loom maker not a service tech.

The lower one I would like to know where Star got it from as the top one is near useless .

Wiring diagrams are usually at the start of the parts books or end of the owners instruction books .

The top one Star posted is on the last page of your owners manual and is actually the schmetic that would be used by the loom maker not a service tech.

The lower one I would like to know where Star got it from as the top one is near useless .

#11

A

Alex Ethridge

A

Alex Ethridge

I want to thank everyone here for their help as it has validated my belief that this intermittent problem is related to the safety switches. I think maybe I'll order safety switches one at a time and replace them one at a time until I hit on the one that fixes the problem. Diagnosing them by shunting is going to be a problem for me as I don't know whether switches are normally open or normally closed. AND some of these switches have four terminals which further confuses things for me.

Until I hit on the solution, I do have a back-door way of starting it.

Superfluous and useless information: My dad, long gone now, was a master electrician and could make sense of every schematic I ever brought to him. He was a troubleshooter at a heavy industrial manufacturing plant with punches, shears and presses as big as a house. I don't know how many times since he's gone that I have wished I could ask him a question. But thanks to his influence, at least I can wire a house and troupleshoot any appliance I and my family have ever owned.

Until I hit on the solution, I do have a back-door way of starting it.

Superfluous and useless information: My dad, long gone now, was a master electrician and could make sense of every schematic I ever brought to him. He was a troubleshooter at a heavy industrial manufacturing plant with punches, shears and presses as big as a house. I don't know how many times since he's gone that I have wished I could ask him a question. But thanks to his influence, at least I can wire a house and troupleshoot any appliance I and my family have ever owned.

#12

StarTech

As I said several of the RZ3016 owners manuals had the first diagram in them. I provide it as just show how stupid the OEM owners manual were for some revisions.

StarTech

I was researching the owners manuals using the layman's model number RZ3016 then I switched over to using the actual model number along with the revision level through Husqvarna when I came across the owners manual with the good schematics. It was actually on page 28 of 36 of the owners manual.AFAIK there are no Husqvarna service manuals available in any form at any level for their mowers .

Wiring diagrams are usually at the start of the parts books or end of the owners instruction books .

The top one Star posted is on the last page of your owners manual and is actually the schmetic (schematic) that would be used by the loom maker not a service tech.

The lower one I would like to know where Star got it from as the top one is near useless .

As I said several of the RZ3016 owners manuals had the first diagram in them. I provide it as just show how stupid the OEM owners manual were for some revisions.

#13

A

Alex Ethridge

A

Alex Ethridge

I want to thank everyone here for their help as it has validated my belief that this intermittent problem is related to the safety switches. I think maybe I'll order safety switches one at a time and replace them one at a time until I hit on the one that fixes the problem. Diagnosing them by shunting is going to be a problem for me as I don't know whether switches are normally open or normally closed. AND some of these switches have four terminals which further confuses things for me.

Superfluous and useless information: My dad, long gone now, was a master electrician and could make sense of every schematic I ever brought to him. He was a troubleshooter at a heavy industrial manufacturing plant with punches, shears and presses as big as a house. I don't know how many times since he's gone that I have wished I could ask him a question. But thanks to his influence, at least I can wire a house and troupleshoot any appliance I and my family have ever owned.

That's how I looked up the manual I have been using, by actual model number. It has a schematic I can read on page 46 of 56.I was researching the owners manuals using the layman's model number RZ3016 then I switched over to using the actual model number along with the revision level through Husqvarna when I came across the owners manual with the good schematics. It was actually on page 28 of 36 of the owners manual.

As I said several of the RZ3016 owners manuals had the first diagram in them. I provide it as just show how stupid the OEM owners manual were for some revisions.

#14

StarTech

Now on the schematic the motion control arms are in neutral (outboard position) which means the switches are depressed (opposite of the switch rest position). The brake and PTO (deck switch) are shown the the rest position (ie not depressed).

If you are going to use plug and play I would suggest first replacing both of the motion control arms switches as they are the ones that tend to go out the most as they receive the most wear.

StarTech

Well the two pole switches in the diagram contains one pole normally closed and the other pole normally open (referencing switch non depressed rest position). On the switch terminal themselves the normal closed pole will be labelled NC (for normally closed).I want to thank everyone here for their help as it has validated my belief that this intermittent problem is related to the safety switches. I think maybe I'll order safety switches one at a time and replace them one at a time until I hit on the one that fixes the problem. Diagnosing them by shunting is going to be a problem for me as I don't know whether switches are normally open or normally closed. AND some of these switches have four terminals which further confuses things for me.

Until I hit on the solution, I do have a back-door way of starting it.

Superfluous and useless information: My dad, long gone now, was a master electrician and could make sense of every schematic I ever brought to him. He was a troubleshooter at a heavy industrial manufacturing plant with punches, shears and presses as big as a house. I don't know how many times since he's gone that I have wished I could ask him a question. But thanks to his influence, at least I can wire a house and troupleshoot (troubleshoot) any appliance I and my family have ever owned.

Now on the schematic the motion control arms are in neutral (outboard position) which means the switches are depressed (opposite of the switch rest position). The brake and PTO (deck switch) are shown the the rest position (ie not depressed).

If you are going to use plug and play I would suggest first replacing both of the motion control arms switches as they are the ones that tend to go out the most as they receive the most wear.

#15

A

Alex Ethridge

A

Alex Ethridge

Yes, I've ordered one of those for diagnostic. There are (according to the parts manual) four of that switch on the mower; however, the way the schematic is drawn, it looks like there are five but one of them must be a different part number. Anyway, I'll check the ignition switch tomorrow and if that isn't it, I'll wait on the control arm switch to get here and substitute those one at a time.

#16

StarTech

StarTech

Yes the deck switch is a snap-in design where the other four are bolt (screw) and nut mounted.

And as I said on the control arm switches I would replace both at the same as they are equally worn. And if anything like the ones I deal with replacing one usual means the mower will back in short order for the other to be replaced. I deal with cub Cadet ZTR where they disengage the PTO electric PTO clutch in full reverse so their contacts get burned from constant diesengaging and re-engaging the clutch.

But of course in shop setting it saves time when I do both as if I don't it means I have to get the tools, parts out, and do paperwork a second time. Considering as busy as the one person shop is I don't have time to waste.

And as I said on the control arm switches I would replace both at the same as they are equally worn. And if anything like the ones I deal with replacing one usual means the mower will back in short order for the other to be replaced. I deal with cub Cadet ZTR where they disengage the PTO electric PTO clutch in full reverse so their contacts get burned from constant diesengaging and re-engaging the clutch.

But of course in shop setting it saves time when I do both as if I don't it means I have to get the tools, parts out, and do paperwork a second time. Considering as busy as the one person shop is I don't have time to waste.

#17

B

bertsmobile1

B

bertsmobile1

THe cranking circuit is a daisy chain so power has to pass through all of them

Thus they are usually NO switches which is why I suggested to jump the plugs an still suggest to do that as some of these switches can only be replaced after all of the body work is removed

All of the safety switches are the same construction.

The external terminals extend into the body and the plunger has a strip of copper which will either make or break connections .

Thus they all connect FLAT to FLAT on the plug which should be obvious because of the colour coding

In your case they will all be yellow either solid or with a trace ,

A common practice is to change the trace between switches because it makes construction of the loom easier .

Thus they are usually NO switches which is why I suggested to jump the plugs an still suggest to do that as some of these switches can only be replaced after all of the body work is removed

All of the safety switches are the same construction.

The external terminals extend into the body and the plunger has a strip of copper which will either make or break connections .

Thus they all connect FLAT to FLAT on the plug which should be obvious because of the colour coding

In your case they will all be yellow either solid or with a trace ,

A common practice is to change the trace between switches because it makes construction of the loom easier .