You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

PTO not engaging

#1

PTmowerMech

PTmowerMech

13WQ93KP011 Super bronco

Running at full throttle, battery is charging over 13v. Getting about 14v in and out of the PTO with the switch pulled/on. (almost nothing when switch is off)

But it's not engaging. The ohms are 0.00 on the tractor. So I'm thinking it's just a bad PTO.

Is there anything else that needs to be checked before I make that call?

Also, can you check the ohms with the PTO on the tractor? Or does it being grounded to the crankshaft affect that reading?

Running at full throttle, battery is charging over 13v. Getting about 14v in and out of the PTO with the switch pulled/on. (almost nothing when switch is off)

But it's not engaging. The ohms are 0.00 on the tractor. So I'm thinking it's just a bad PTO.

Is there anything else that needs to be checked before I make that call?

Also, can you check the ohms with the PTO on the tractor? Or does it being grounded to the crankshaft affect that reading?

#2

StarTech

StarTech

Hmmm. Are sure you engaging the clutch or just pulling the switch? To me engaging means it is clicking and trying to latch up.

But yes the PTO clutch field can check on the mower as it is normally an isolated winding. Across the field windings you need to have at least 1.7 ohms [with something like 3.5 ohms being closer to normal]. Anything below this indicates either a shorted or partially shorted field. Also check from either one the field terminals and frame ground should be an open circuit if not then there is a short to ground. If you indeed getting 12V in and out then the grounding relay is fried or you have bad wiring or bad ground.

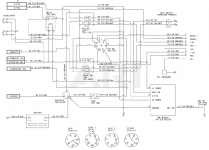

See schematic below.

But yes the PTO clutch field can check on the mower as it is normally an isolated winding. Across the field windings you need to have at least 1.7 ohms [with something like 3.5 ohms being closer to normal]. Anything below this indicates either a shorted or partially shorted field. Also check from either one the field terminals and frame ground should be an open circuit if not then there is a short to ground. If you indeed getting 12V in and out then the grounding relay is fried or you have bad wiring or bad ground.

See schematic below.

#3

PTmowerMech

When I pull the switch, the voltage through the PTO harness jumps up to about 14v. I get that on both wires with the multimeter grounded to the engine.

The PTO doesn't click.

PTmowerMech

Hmmm. Are sure you engaging the clutch or just pulling the switch? To me engaging means it is clicking and trying to latch up.

But yes the PTO clutch field can check on the mower as it is normally an isolated winding. Across the field windings you need to have at least 1.7 ohms [with something like 3.5 ohms being closer to normal]. Anything below this indicates either a shorted or partially shorted field. Also check from either one the field terminals and frame ground should be an open circuit if not then there is a short to ground. If you indeed getting 12V in and out then the grounding relay is fried or you have bad wiring or bad ground.

See schematic below.

View attachment 60658

When I pull the switch, the voltage through the PTO harness jumps up to about 14v. I get that on both wires with the multimeter grounded to the engine.

The PTO doesn't click.

#4

StarTech

StarTech

Please what I posted as it likely you have two problems

- Shorted PTO clutch windings if you indeed reading zero ohms across the windings.

- And a burn out grounding relay.

- Still can be also bad wiring cause by the shorted clutch.

#5

PTmowerMech

PTmowerMech

#6

sgkent

sgkent

someone posted a while back that the connector on theirs rotted internally. Make sure the PTO is actually getting voltage and that the ground connection is good too.

#7

StarTech

StarTech

Yes F56 [Packard, GM, Aptiv] terminals do break along the spring hinge causing loose connections. And many mowers uses these terminals. I just keep a good supply of them on hand here.someone posted a while back that the connector on theirs rotted internally. Make sure the PTO is actually getting voltage and that the ground connection is good too.

#8

PTmowerMech

PTmowerMech

Ok, I'm completely lost now.

Installed the new clutch and still nothing. I pulled the flat plate out of the seat safety connection and the started working.

Here's the kicker(s)

With the seat safety switch connection plate pulled out, if the PTO is on, and I get up off the seat, the engine dies.

With the old PTO on it, I was getting 14v to the PTO with the switch on. No juice with switch off.

Was getting no ohms. (and still not getting any, after I took it off and tested it again)

Also, I connected my jumper battery to the PTO, now it's clicking like it's supposed to.

Why wouldn't the PTO come on, while it was on the mower, with juice going to it?

Installed the new clutch and still nothing. I pulled the flat plate out of the seat safety connection and the started working.

Here's the kicker(s)

With the seat safety switch connection plate pulled out, if the PTO is on, and I get up off the seat, the engine dies.

With the old PTO on it, I was getting 14v to the PTO with the switch on. No juice with switch off.

Was getting no ohms. (and still not getting any, after I took it off and tested it again)

Also, I connected my jumper battery to the PTO, now it's clicking like it's supposed to.

Why wouldn't the PTO come on, while it was on the mower, with juice going to it?

#9

StarTech

StarTech

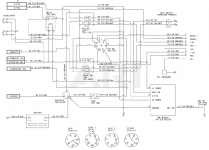

You can juice going to it all day but if the juice don't flow out it will not work. But the relay circled isn't working the clutch will not work. Do this temporary. Connect the clutch and probe the connector and find which wire has 12v on it the PTO switch is on. [Just in they change the wire color code]. Now connect a long jumper to the other terminal. Reconnect the clutch. Take that long jumper and ground to the frame. This should allow the PTO clutch to operate and prove that you have a grounding issue related to the relay. It might be burned relay contacts as this disengages the PTO in reverse unless the RMC button is pushed for mow in reverse.

#10

PTmowerMech

Ok, I'll see what that does.

If the relay is bad, why does the PTO now kick on turns the blades fine (since I removed the connector plate from the seat switch)?

PTmowerMech

You can juice going to it all day but if the juice don't flow out it will not work. But the relay circled isn't working the clutch will not work. Do this temporary. Connect the clutch and probe the connector and find which wire has 12v on it the PTO switch is on. [Just in they change the wire color code]. Now connect a long jumper to the other terminal. Reconnect the clutch. Take that long jumper and ground to the frame. This should allow the PTO clutch to operate and prove that you have a grounding issue related to the relay. It might be burned relay contacts as this disengages the PTO in reverse unless the RMC button is pushed for mow in reverse.

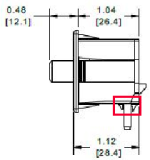

View attachment 60773

Ok, I'll see what that does.

If the relay is bad, why does the PTO now kick on turns the blades fine (since I removed the connector plate from the seat switch)?

#11

StarTech

StarTech

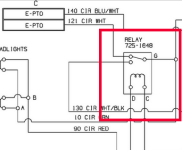

Are referring to the connector shorting strip of that Delta 6444 switch?

If so then it is likely it was not un-shorting when connecting the connector to the switch. There two styles of the 6444 swithc that would work on this mower. One is for with the shorting strip and one is not. That shorting strip just prevents the operator from simply removing the connector to by the seat switch. On unit the shorting connector the connector must be fully plugged and held tightly to the switch.

If so then it is likely it was not un-shorting when connecting the connector to the switch. There two styles of the 6444 swithc that would work on this mower. One is for with the shorting strip and one is not. That shorting strip just prevents the operator from simply removing the connector to by the seat switch. On unit the shorting connector the connector must be fully plugged and held tightly to the switch.

#12

PTmowerMech

Yes, that one. After I pulled it out, the PTO would engage and turn the blades (via the PTO switch). I mowed for about 20 minutes afterwards.

But like I said, with this connector removed from the seat switch harness, now if I take my weight off the seat, it kills the engine. (connecter plate (as you have in the picture) removed from the harness, and harness plugged into the seat safety switch)

PTmowerMech

Are referring to the connector shorting strip of that Delta 6444 switch?

View attachment 60776

If so then it is likely it was not un-shorting when connecting the connector to the switch. There two styles of the 6444 swithc that would work on this mower. One is for with the shorting strip and one is not. That shorting strip just prevents the operator from simply removing the connector to by the seat switch. On unit the shorting connector the connector must be fully plugged and held tightly to the switch.

Yes, that one. After I pulled it out, the PTO would engage and turn the blades (via the PTO switch). I mowed for about 20 minutes afterwards.

But like I said, with this connector removed from the seat switch harness, now if I take my weight off the seat, it kills the engine. (connecter plate (as you have in the picture) removed from the harness, and harness plugged into the seat safety switch)

#13

StarTech

StarTech

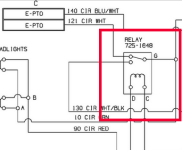

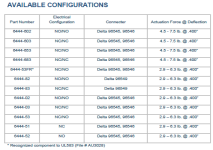

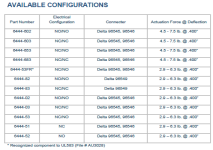

That shorting was the problem or someone had replaced the Delta 6444-82 with a Delta 6444-02 or 6444-602 switch. The way you tell is the color of the switch. And the 6444-82 will have tiny projections at the terminals.

These are the two Stens sells. Sorry I haven't found a source for the terminal housing as of yet. But the terminals themselves are available thru Mouser, just got to know which which gauge wires you have.

6444-82 > Stens 430-420 > Grey housing with black bottom

6444-602 > Stens 430-780 > Grey housing with grey bottom

If you install a 6444-602/6444-02 in place of a 6444-82 you would have the problem that you resolved. Not too many shops are aware of the differences and would sell the wrong switch even though they are the same electrically; just not the same physically. I stock only the Stens 430-420 as it works in place of the 430-780 as it doesn't matter as it is the connector housing that matters if you wish to maintain the equipment factory safety feature.

The 6444-82 will the tiny projections at the terminals as indicated in the following diagram by the red box.

And I have seen that if the connector housing doesn't fit tight to have problems too. To me the design is not that good in the first place as those projections needs to be a little longer I think.

I think there is also an all black version out there which would the 6444-82 before they settled on the current version.

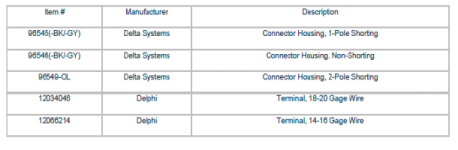

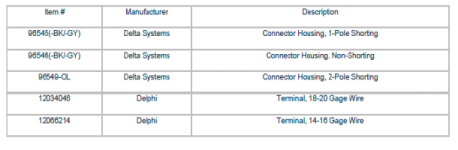

As for the shorting strip the one you remove is the two pole version. There is an one version of it in some applications.

These the available styles of the 6444 series switch

This is the connector housing info.

The 96549-OL is the one with the strip you removed.

Hopefully I haven't confused you by now.

These are the two Stens sells. Sorry I haven't found a source for the terminal housing as of yet. But the terminals themselves are available thru Mouser, just got to know which which gauge wires you have.

6444-82 > Stens 430-420 > Grey housing with black bottom

6444-602 > Stens 430-780 > Grey housing with grey bottom

If you install a 6444-602/6444-02 in place of a 6444-82 you would have the problem that you resolved. Not too many shops are aware of the differences and would sell the wrong switch even though they are the same electrically; just not the same physically. I stock only the Stens 430-420 as it works in place of the 430-780 as it doesn't matter as it is the connector housing that matters if you wish to maintain the equipment factory safety feature.

The 6444-82 will the tiny projections at the terminals as indicated in the following diagram by the red box.

And I have seen that if the connector housing doesn't fit tight to have problems too. To me the design is not that good in the first place as those projections needs to be a little longer I think.

I think there is also an all black version out there which would the 6444-82 before they settled on the current version.

As for the shorting strip the one you remove is the two pole version. There is an one version of it in some applications.

These the available styles of the 6444 series switch

This is the connector housing info.

The 96549-OL is the one with the strip you removed.

Hopefully I haven't confused you by now.

#14

PTmowerMech

Confused? Totally. But not for long. The details in all of this will make perfect sense once the part numbers and description of the parts start matching up with what's supposed to be in place. Like a puzzle that starts coming together.

Thanks man.

PTmowerMech

That shorting was the problem or someone had replaced the Delta 6444-82 with a Delta 6444-02 or 6444-602 switch. The way you tell is the color of the switch. And the 6444-82 will have tiny projections at the terminals.

These are the two Stens sells. Sorry I haven't found a source for the terminal housing as of yet. But the terminals themselves are available thru Mouser, just got to know which which gauge wires you have.

6444-82 > Stens 430-420 > Grey housing with black bottom

6444-602 > Stens 430-780 > Grey housing with grey bottom

If you install a 6444-602/6444-02 in place of a 6444-82 you would have the problem that you resolved. Not too many shops are aware of the differences and would sell the wrong switch even though they are the same electrically; just not the same physically. I stock only the Stens 430-420 as it works in place of the 430-780 as it doesn't matter as it is the connector housing that matters if you wish to maintain the equipment factory safety feature.

The 6444-82 will the tiny projections at the terminals as indicated in the following diagram by the red box.

View attachment 60780

And I have seen that if the connector housing doesn't fit tight to have problems too. To me the design is not that good in the first place as those projections needs to be a little longer I think.

I think there is also an all black version out there which would the 6444-82 before they settled on the current version.

As for the shorting strip the one you remove is the two pole version. There is an one version of it in some applications.

These the available styles of the 6444 series switch

View attachment 60778

This is the connector housing info.

View attachment 60779

The 96549-OL is the one with the strip you removed.

Hopefully I haven't confused you by now.

Confused? Totally. But not for long. The details in all of this will make perfect sense once the part numbers and description of the parts start matching up with what's supposed to be in place. Like a puzzle that starts coming together.

Thanks man.

#15

B

bertsmobile1

B

bertsmobile1

And doubly so from me as I can now order a plug to make a service starting bypass next time I put an order on MouserConfused? Totally. But not for long. The details in all of this will make perfect sense once the part numbers and description of the parts start matching up with what's supposed to be in place. Like a puzzle that starts coming together.

Thanks man.

#16

StarTech

I have yet to find them. I going to try and see if Delta Systems is willing to sell a small amount of them (at a fair price) or tell me who I can go through to get them at a fair price. So far every mower OEM just wants to sell a complete harness. Changing out these harnesses is time consuming when it would be a lot quicker and simpler to just change the housings.

StarTech

If you know the alternate PN for the connector housing with the two pole shorting strip I would like to have it so I can order them from Mouser myself. So far my searches of Mouser have been fruitless. It looks like these housing are unique to Delta Systems 9444 switches.And doubly so from me as I can now order a plug to make a service starting bypass next time I put an order on Mouser

I have yet to find them. I going to try and see if Delta Systems is willing to sell a small amount of them (at a fair price) or tell me who I can go through to get them at a fair price. So far every mower OEM just wants to sell a complete harness. Changing out these harnesses is time consuming when it would be a lot quicker and simpler to just change the housings.

#17

B

bertsmobile1

B

bertsmobile1

No I was going to use the numbers you posted to look them up

Mouser must have the worlds most user unfriendly catalogue I have ever been forced to use

But at least I can get the stuff for less than $ 2 a terminal as no one retails Delpi terminals at all down here, just Lucas .

Mouser must have the worlds most user unfriendly catalogue I have ever been forced to use

But at least I can get the stuff for less than $ 2 a terminal as no one retails Delpi terminals at all down here, just Lucas .

#18

StarTech

StarTech

Considering the amount stuff they carry it not too bad just most times you got to have the manufacture's part number. In the case here I thinking there two things working against me. 1st> The two pole connector housings are fairly new on the market. 2nd> They are currently just use in our industry. At least Stens has the 1 pole version with shorting strip.No I was going to use the numbers you posted to look them up

Mouser must have the worlds most user unfriendly catalogue I have ever been forced to use

But at least I can get the stuff for less than $ 2 a terminal as no one retails Delpi terminals at all down here, just Lucas .

#20

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

Think about it! 14 volts on both sides ( both wires) of the coil means you are not completing the ground seeking side of the circuit, because if you were, the voltage on that ground side wire would be near zero. Trace this reason and find the problem.When I pull the switch, the voltage through the PTO harness jumps up to about 14v. I get that on both wires with the multimeter grounded to the engine.

The PTO doesn't click.

#21

PTmowerMech

PTmowerMech

Update on this mower. I think I mentioned that I told the guy there was still an electrical issue when he picked it up. It wouldn't mow in reverse, even with the switch on reverse and the button pushed. Customer told me not to worry about it. He didn't want to put any more money into it.

Two days ago, I get a call from my brother, who knows them very well. He said he got a call from the guy. Said he was mowing, and everything was working great. He parked it for a few minutes to take a break. When he walked back outside, the mower was in flames.

I don't know if it was an electric issue that started the fire. But I do know the engine & frame was covered in 1/4" of oil from a couple of leaks that had gone on for the last several years. I asked him if he wanted me to fix the leaks, he said it was cheaper to just add oil. lol

Two days ago, I get a call from my brother, who knows them very well. He said he got a call from the guy. Said he was mowing, and everything was working great. He parked it for a few minutes to take a break. When he walked back outside, the mower was in flames.

I don't know if it was an electric issue that started the fire. But I do know the engine & frame was covered in 1/4" of oil from a couple of leaks that had gone on for the last several years. I asked him if he wanted me to fix the leaks, he said it was cheaper to just add oil. lol