And I work one of those companies that had me accounting for every minute I work for them on paper. Boy I hated it.

Don't take wrong but I do charge for the hardware used but I don't just make up items replaced that weren't replaced. Now this I have seen other shops doing as for charging for items not even used.

I do charge for fuel used as the customer should bring their equipment with fuel, not empty tanks. Oh my customers tried that on me years ago but found out that I would add fuel and charge them.

And I don't overcharge for hardware used either. That is why I buy the hardware from McMaster-Carr instead from the equipment OEMs. And I do save hardware from other equipment and don't charge for it when it is used.

Now shop rags are a reusable item if washed. The rags I have right now are the same rags I brought three years ago. De-greasers and spray lubes are just wrote off as part of the service provided. A little goes a long way of these items.

There are rare cases where I partly charge for new tool that may never get used again. Some those are very expensive for an one time use but got to have them in order to do the job. This is usually the ATV/UTV tools as those limited serviced items. Other tools that are frequently used are just part doing business. Probably if I add all the tools I now have I probably have well over $10K invested and I get paid back everyday for using them via my labor charges.

As a business I do expect to spend money on storage items they simply make keeping track of items easier. Most of us have tools of the trade to keep track of so storage boxes and cabinets are normal business expense and not something we charge customers for.

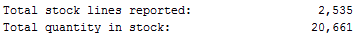

Currently I have about 30 large storage bins with multiple small bins in each. There is no way I could where parts is with using a bin system. I have only 2500+ different items in stock.