You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Online small engine repair schools?

#1

B

Briggs1919

B

Briggs1919

Hi,

I was looking to find inexpensive small engine repair training available online. I know pennfoster and briggs and stratton have training material available but they are rather expensive. I found a free course at evoclearning.com but wanted to know if there are some used resources I where I can find repair books or guides. I am interested in learning more about small engine repair and possibly fixing them on the side.

Also, does it matter if a school says it's accredited? Do I need an accredited school to learn small engine repair? Or is it more practice than anything else?

I was looking to find inexpensive small engine repair training available online. I know pennfoster and briggs and stratton have training material available but they are rather expensive. I found a free course at evoclearning.com but wanted to know if there are some used resources I where I can find repair books or guides. I am interested in learning more about small engine repair and possibly fixing them on the side.

Also, does it matter if a school says it's accredited? Do I need an accredited school to learn small engine repair? Or is it more practice than anything else?

#2

P

Pumper54

P

Pumper54

Couple of places I would start would be the local library and look for any books on small engine repair, also you can go online at YouTube and search for the millions of videos on small engine repair. Find a small engine that you can play with and tear it apart, make sure you document what you do as you take it apart and keep everything labeled and clean. That way you will be able to put it back together after you break it down to its basic parts.

Tom

Tom

#3

B

bertsmobile1

B

bertsmobile1

I had been playing with vintage motorcycles for better he 30 years when I bought the small engine repair run which I thought would be a doddle.

What a steep learning curve.

There are hundreds of books about repairing small engines and most of them are not much chop.

Down here we call them coffee table ( if they are full of photos ) or bedside ( no pictures ) books.

Lots of information so general in nature as to be useless.

The best books are the John Deer Technical manuals as they tell you how the bits work and how to test them and what order to test them.

Most technical college libraries will have them and some are available from the web.

However GOOD & CHEAP are mutually exclusive. It costs money to write good manuals.

Other than that, You Tube is good once you sort out the shaved monkeys with a camera from those who actually know something.

Taryl Fixes All & Donnyboy87 are very good, subscribe to their channels and run through the entire play list.

A lot of parts suppliers also have videos, e-eplacement parts, Jacks small engines.

What a steep learning curve.

There are hundreds of books about repairing small engines and most of them are not much chop.

Down here we call them coffee table ( if they are full of photos ) or bedside ( no pictures ) books.

Lots of information so general in nature as to be useless.

The best books are the John Deer Technical manuals as they tell you how the bits work and how to test them and what order to test them.

Most technical college libraries will have them and some are available from the web.

However GOOD & CHEAP are mutually exclusive. It costs money to write good manuals.

Other than that, You Tube is good once you sort out the shaved monkeys with a camera from those who actually know something.

Taryl Fixes All & Donnyboy87 are very good, subscribe to their channels and run through the entire play list.

A lot of parts suppliers also have videos, e-eplacement parts, Jacks small engines.

#4

Boobala

Boobala

Ran across this on-line ... contains some useful information and links to other sources too !

https://www.repairfaq.org/sam/lmfaq.htm#lmtoc

https://www.repairfaq.org/sam/lmfaq.htm#lmtoc

#5

P

Pumper54

P

Pumper54

Bert,

"Other than that, You Tube is good once you sort out the shaved monkeys with a camera from those who actually know something.

Taryl Fixes All & Donnyboy87 are very good, subscribe to their channels and run through the entire play list."

Killing me here with the "shaved monkey" but you are correct with the two people you listed as being good. I have checked out both and find their info to be easy to understand and to the point.

Tom

"Other than that, You Tube is good once you sort out the shaved monkeys with a camera from those who actually know something.

Taryl Fixes All & Donnyboy87 are very good, subscribe to their channels and run through the entire play list."

Killing me here with the "shaved monkey" but you are correct with the two people you listed as being good. I have checked out both and find their info to be easy to understand and to the point.

Tom

#7

B

bertsmobile1

The biggest selling push mower down here was Victa and a one time they had better than 75% of the market.

However there is no dediacated repair vidoes till a couple of school kids set up a video channel.

On this channel they tell you to "fix" a mower that is running too fast by stuffing foam in the air tube .

There is a very clever stop switch inbuilt into the carb cam which they tell you is a "problem" so you have to replace it with a toggle switch.

The rubber boot ofr the switch is $ 2.00 a toggle switch is $ 5.00 + extra wiring.

B

bertsmobile1

Bert,

"Other than that, You Tube is good once you sort out the shaved monkeys with a camera from those who actually know something.

Taryl Fixes All & Donnyboy87 are very good, subscribe to their channels and run through the entire play list."

Killing me here with the "shaved monkey" but you are correct with the two people you listed as being good. I have checked out both and find their info to be easy to understand and to the point.

Tom

The biggest selling push mower down here was Victa and a one time they had better than 75% of the market.

However there is no dediacated repair vidoes till a couple of school kids set up a video channel.

On this channel they tell you to "fix" a mower that is running too fast by stuffing foam in the air tube .

There is a very clever stop switch inbuilt into the carb cam which they tell you is a "problem" so you have to replace it with a toggle switch.

The rubber boot ofr the switch is $ 2.00 a toggle switch is $ 5.00 + extra wiring.

#9

B

bertsmobile1

Got that one totally wrong Donyboy73 is who you are looking for.

Try this link

https://www.facebook.com/Donyboy73-The-Small-Engine-Doctor-on-Youtube-234040803408166/

B

bertsmobile1

I can't find Donnyboy87 anywhere.

Got that one totally wrong Donyboy73 is who you are looking for.

Try this link

https://www.facebook.com/Donyboy73-The-Small-Engine-Doctor-on-Youtube-234040803408166/

#11

StarTech

StarTech

The best way to learn the repairs is to as an apprentice (hands on) so you get the basic knowledge from an experienced person then you can build on that by reading service manuals and applying the info provided in those manuals.

As said I surely would not want a new surgeon doing surgery unsupervised. And it same with other repairs too. Besides most school training is out of date by the time they start training you.

As said I surely would not want a new surgeon doing surgery unsupervised. And it same with other repairs too. Besides most school training is out of date by the time they start training you.

#12

Fish

Ask questions, listen to the guys here, but always do tests to know what needs replaced, not listen to the guy that says "Put a new coil on it". Listen to the guy giving you things to check, to find out the problem, before ordering any parts.

Get started that way, before spending money on courses that will never pay for themselves.

I started for a small dealer, promised to work cheap to get to learn, then you can see the business side of it too. Just to get started.

It hasn't been the greatest career, but with the way things are going, it may be quite lucrative fairly soon.

Fish

Save your money on the courses. Start with an engine that doesn't run, and start on it. Start a new thread here, with pics, and brand and model numbers.Hi,

I was looking to find inexpensive small engine repair training available online. I know pennfoster and briggs and stratton have training material available but they are rather expensive. I found a free course at evoclearning.com but wanted to know if there are some used resources I where I can find repair books or guides. I am interested in learning more about small engine repair and possibly fixing them on the side.

Also, does it matter if a school says it's accredited? Do I need an accredited school to learn small engine repair? Or is it more practice than anything else?

Ask questions, listen to the guys here, but always do tests to know what needs replaced, not listen to the guy that says "Put a new coil on it". Listen to the guy giving you things to check, to find out the problem, before ordering any parts.

Get started that way, before spending money on courses that will never pay for themselves.

I started for a small dealer, promised to work cheap to get to learn, then you can see the business side of it too. Just to get started.

It hasn't been the greatest career, but with the way things are going, it may be quite lucrative fairly soon.

#13

Tiger Small Engine

Fish-Why do you say “the way things are going, it may be quite lucrative soon.” I realize the world is strange these days and unstable. Just wondering what you meant.

As far as finding a shop willing to teach you as an apprenticeship, I would say that is a very long shot. As far as a person willing to spend days, weeks, months m, and years helping and training you, I would say even a longer shot.

Best way to learn in many cases is to watch the right videos, read forums, such as this one, and refer to service manuals. While you are doing this online teaching, you are going hands on with equipment. At some point you have to jump in and fake it until you make it. Then, after say three years, you begin to see patterns and really understand the needed skills to succeed. Watching a couple of YouTube videos to repair a problem ain’t gonna cut it for a person with little mechanical background.

Tiger Small Engine

Save your money on the courses. Start with an engine that doesn't run, and start on it. Start a new thread here, with pics, and brand and model numbers.

Ask questions, listen to the guys here, but always do tests to know what needs replaced, not listen to the guy that says "Put a new coil on it". Listen to the guy giving you things to check, to find out the problem, before ordering any parts.

Get started that way, before spending money on courses that will never pay for themselves.

I started for a small dealer, promised to work cheap to get to learn, then you can see the business side of it too. Just to get started.

It hasn't been the greatest career, but with the way things are going, it may be quite lucrative fairly soon.

Fish-Why do you say “the way things are going, it may be quite lucrative soon.” I realize the world is strange these days and unstable. Just wondering what you meant.

As far as finding a shop willing to teach you as an apprenticeship, I would say that is a very long shot. As far as a person willing to spend days, weeks, months m, and years helping and training you, I would say even a longer shot.

Best way to learn in many cases is to watch the right videos, read forums, such as this one, and refer to service manuals. While you are doing this online teaching, you are going hands on with equipment. At some point you have to jump in and fake it until you make it. Then, after say three years, you begin to see patterns and really understand the needed skills to succeed. Watching a couple of YouTube videos to repair a problem ain’t gonna cut it for a person with little mechanical background.

#14

StarTech

StarTech

Well techs faking is why I snag a lot from my competitors. They might have bigger and fancier shops then I do. But they are just screwing their customers some are referring other to my shop. This year nearly a third of my business gross income came from these referrals as these other shop are hiring inexperience techs and they don't a experienced tech backing them up.

When those techs can't find a blown head gasket, clean a carburetor properly, or even find a bad spark plug; you got what Space Cadet they have working for them.

If I was willing to cheat my customers I probably have a fancy shop too but I run an honest shop and just want to make a honest living.

And you can't simply unscrew the top of your head and pour in the info either you got to have ability first. I started out assembling a 1957 Oldsmobile V8 when I was in the second grade with an experienced mechanic supervising my work. Yes I made mistakes then and still do at times but I learned to ask for help when I need it and am willing to help others when asked.

When those techs can't find a blown head gasket, clean a carburetor properly, or even find a bad spark plug; you got what Space Cadet they have working for them.

If I was willing to cheat my customers I probably have a fancy shop too but I run an honest shop and just want to make a honest living.

And you can't simply unscrew the top of your head and pour in the info either you got to have ability first. I started out assembling a 1957 Oldsmobile V8 when I was in the second grade with an experienced mechanic supervising my work. Yes I made mistakes then and still do at times but I learned to ask for help when I need it and am willing to help others when asked.

#15

B

bertsmobile1

B

bertsmobile1

Yep

A shop that charges $ 120/ hr ( Aus ) then has the affrontory to add line items like ;-

service fuel

service oil

shop rags

degreaser

Silicon

Followed by line items fro each & every nut bolt & washer , most of which of course were not replaced

Will not keep their customers for very long

Accountants of course like this because they need to have their computer account for everything short of the air the techs breathe & the water used to flush the toilet .

A shop that charges $ 120/ hr ( Aus ) then has the affrontory to add line items like ;-

service fuel

service oil

shop rags

degreaser

Silicon

Followed by line items fro each & every nut bolt & washer , most of which of course were not replaced

Will not keep their customers for very long

Accountants of course like this because they need to have their computer account for everything short of the air the techs breathe & the water used to flush the toilet .

#16

StarTech

StarTech

And I work one of those companies that had me accounting for every minute I work for them on paper. Boy I hated it.

Don't take wrong but I do charge for the hardware used but I don't just make up items replaced that weren't replaced. Now this I have seen other shops doing as for charging for items not even used.

I do charge for fuel used as the customer should bring their equipment with fuel, not empty tanks. Oh my customers tried that on me years ago but found out that I would add fuel and charge them.

And I don't overcharge for hardware used either. That is why I buy the hardware from McMaster-Carr instead from the equipment OEMs. And I do save hardware from other equipment and don't charge for it when it is used.

Now shop rags are a reusable item if washed. The rags I have right now are the same rags I brought three years ago. De-greasers and spray lubes are just wrote off as part of the service provided. A little goes a long way of these items.

There are rare cases where I partly charge for new tool that may never get used again. Some those are very expensive for an one time use but got to have them in order to do the job. This is usually the ATV/UTV tools as those limited serviced items. Other tools that are frequently used are just part doing business. Probably if I add all the tools I now have I probably have well over $10K invested and I get paid back everyday for using them via my labor charges.

As a business I do expect to spend money on storage items they simply make keeping track of items easier. Most of us have tools of the trade to keep track of so storage boxes and cabinets are normal business expense and not something we charge customers for.

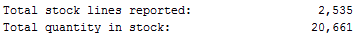

Currently I have about 30 large storage bins with multiple small bins in each. There is no way I could where parts is with using a bin system. I have only 2500+ different items in stock.

Don't take wrong but I do charge for the hardware used but I don't just make up items replaced that weren't replaced. Now this I have seen other shops doing as for charging for items not even used.

I do charge for fuel used as the customer should bring their equipment with fuel, not empty tanks. Oh my customers tried that on me years ago but found out that I would add fuel and charge them.

And I don't overcharge for hardware used either. That is why I buy the hardware from McMaster-Carr instead from the equipment OEMs. And I do save hardware from other equipment and don't charge for it when it is used.

Now shop rags are a reusable item if washed. The rags I have right now are the same rags I brought three years ago. De-greasers and spray lubes are just wrote off as part of the service provided. A little goes a long way of these items.

There are rare cases where I partly charge for new tool that may never get used again. Some those are very expensive for an one time use but got to have them in order to do the job. This is usually the ATV/UTV tools as those limited serviced items. Other tools that are frequently used are just part doing business. Probably if I add all the tools I now have I probably have well over $10K invested and I get paid back everyday for using them via my labor charges.

As a business I do expect to spend money on storage items they simply make keeping track of items easier. Most of us have tools of the trade to keep track of so storage boxes and cabinets are normal business expense and not something we charge customers for.

Currently I have about 30 large storage bins with multiple small bins in each. There is no way I could where parts is with using a bin system. I have only 2500+ different items in stock.

#17

B

bertsmobile1

B

bertsmobile1

workshop consumables get adsorbed into the labour rate which I just put up for the first time in 15 years .

IT will go up bi-annually for now on

Same story with fuel particularly as I test gear by cutting my own grass

Now if they were charging $ 50/hr then sure add some consumables but at $ 120 /hr ( wage rate is around $ 35 / hr so on costed labour would be $ 70 at best .

IT will go up bi-annually for now on

Same story with fuel particularly as I test gear by cutting my own grass

Now if they were charging $ 50/hr then sure add some consumables but at $ 120 /hr ( wage rate is around $ 35 / hr so on costed labour would be $ 70 at best .

#18

Tiger Small Engine

The John Deere dealer near by charges $195/hour for labor (ridiculously high). All consumables except grease are in my labor charge.

I do get equipment from other shops that was not fixed properly, but not that often. I realize that “faking it until you make it” is not the way to go. My point is, at some point you have to put the theory and books down, and get your hands dirty.

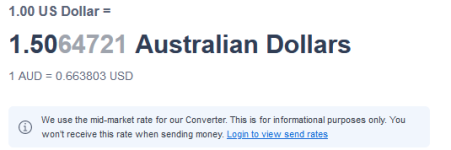

Bertsmobile-What is the exchange rate Australia vs U.S. for money? Average small engine labor rate in my area is $100/hour. Remember, these shops have employee payroll, rent/mortgage, insurance, lots of general overhead. I am a one person shop with almost none of that, and will be increasing to $75/hour next year on labor.

Tiger Small Engine

workshop consumables get adsorbed into the labour rate which I just put up for the first time in 15 years .

IT will go up bi-annually for now on

Same story with fuel particularly as I test gear by cutting my own grass

Now if they were charging $ 50/hr then sure add some consumables but at $ 120 /hr ( wage rate is around $ 35 / hr so on costed labour would be $ 70 at best .

The John Deere dealer near by charges $195/hour for labor (ridiculously high). All consumables except grease are in my labor charge.

I do get equipment from other shops that was not fixed properly, but not that often. I realize that “faking it until you make it” is not the way to go. My point is, at some point you have to put the theory and books down, and get your hands dirty.

Bertsmobile-What is the exchange rate Australia vs U.S. for money? Average small engine labor rate in my area is $100/hour. Remember, these shops have employee payroll, rent/mortgage, insurance, lots of general overhead. I am a one person shop with almost none of that, and will be increasing to $75/hour next year on labor.

#19

StarTech

StarTech

Tiger as two days ago.

So it is about a third higher. The real of exchange will be when you actually transfer the money.

The last track I had of JD labor rate two years ago was $100 / hr here. Yes I am personally at $65/hr or if I was down under $98/hr. And I have 10K in overhead so far this year. Now of course expensives are going up this and next month as I got to repair some tools and replace/add others for the coming year. Right now it is the 40 year compressor that broke but have already a replacement pump for it.

I doubt I raise my rates next year as inflation seems to be leveling off. Besides I be drawing my SS by June next year too then the shop will be something just to keep me out of trouble. And of course I could charge closer to real time labor times.

So it is about a third higher. The real of exchange will be when you actually transfer the money.

The last track I had of JD labor rate two years ago was $100 / hr here. Yes I am personally at $65/hr or if I was down under $98/hr. And I have 10K in overhead so far this year. Now of course expensives are going up this and next month as I got to repair some tools and replace/add others for the coming year. Right now it is the 40 year compressor that broke but have already a replacement pump for it.

I doubt I raise my rates next year as inflation seems to be leveling off. Besides I be drawing my SS by June next year too then the shop will be something just to keep me out of trouble. And of course I could charge closer to real time labor times.

#20

Fish

Fish

Just out of curiousity, what are experienced small engine mechanics making hourly these days?

#21

Tiger Small Engine

Tiger Small Engine

If you go online and check, supposedly the median salary for small engine mechanics is $36,000 per year, which seems pretty low to me.Just out of curiousity, what are experienced small engine mechanics making hourly these days?

#22

Fish

Fish

Yeah, it is pretty dang low around here.If you go online and check, supposedly the median salary for small engine mechanics is $36,000 per year, which seems pretty low to me.

#23

B

bertsmobile1

B

bertsmobile1

In Oz the rate is around $ 75,000 /pa which is $ 15,000 less than the average wage

The the shops wonder why they can not get trades people .

The the shops wonder why they can not get trades people .

#24

D

DaveTN

D

DaveTN

LMAO at Shaved Monkeys! Yep I’ve seen a bunch of those UNSHAVED APES too,

especially down South where I live. Thanks for a great visual laugh. That Taryl guy

looks like one but he’s a PhD on small engines. And more than a few aren’t shaved.

I could use a Bigfoot shaved or not to help me pick up and move those big heavy units.

especially down South where I live. Thanks for a great visual laugh. That Taryl guy

looks like one but he’s a PhD on small engines. And more than a few aren’t shaved.

I could use a Bigfoot shaved or not to help me pick up and move those big heavy units.

#25

Fish

Fish

It is pretty bad when the small engine mechanics can quit and go to work at McDonalds, and get a raise.

I should have gotten into working on boat motors.

I should have gotten into working on boat motors.

#26

B

bertsmobile1

B

bertsmobile1

when I finally graduated a freshly minted 4 year graduate metallurgist was paid $ 8,000/pa. a 3 year certificate accountant was paid $ 15,000/pa and a 2 year trained book keeper $ 11,000/.pa . Needless to say I kept on at it doing 4 more diplomas part time but after 8 year I was told to retain the job I had been doing for over a year I had to do a MBA as it was a "management " job & not a technical one.

I did 6 months of the MBA course and realised that to succeede I would have to become totally dehumanised so I left & drove taxis for a while, while doing a masters in material science ( never finished it either ). As a cab driver I was making $ 18,000 /pa

The I went into international satchels riding a motorcycle and was turning over $ 45,000/pa by which time graduate metallurgist salaries had risen to $ 11,000/pa .

Now I am not the quickest witt but it became abundantly clear that trained professionals in manufacturing were not regarded as essential by the accountants with MBA's One by one all of my graduate year got sacked & re-employed on short term contracts so eventually I had 5 of them working for me as fashion couriers earning double what they got paid as graduates till most went overseas , in particular to South Africa

I did 6 months of the MBA course and realised that to succeede I would have to become totally dehumanised so I left & drove taxis for a while, while doing a masters in material science ( never finished it either ). As a cab driver I was making $ 18,000 /pa

The I went into international satchels riding a motorcycle and was turning over $ 45,000/pa by which time graduate metallurgist salaries had risen to $ 11,000/pa .

Now I am not the quickest witt but it became abundantly clear that trained professionals in manufacturing were not regarded as essential by the accountants with MBA's One by one all of my graduate year got sacked & re-employed on short term contracts so eventually I had 5 of them working for me as fashion couriers earning double what they got paid as graduates till most went overseas , in particular to South Africa

#28

1

1madmouse

1

1madmouse

Nowadays you had better know more than 1 trade. Service is the only one everybody will need ongoing. Then you find that when you retire, SSI takes Medi Care of the top of whatever you get and COL raises never keep up with inflation. And a lot of people just don't get why raising the minimum wage isn't going to help anyone, quite the opposite. Where do they think the extra wage is coming from? Ain't no money trees around here. I don't know how you guys can run your shops alone without killing yourselves and still make a decent living.

#29

StarTech

Running a small shop is a major undertaking when you got to be the chief cook and bottle washer. Yes I spend 10 hr / 6 days in the shop and then another 4-6 hrs working on finding parts and the bookkeeping for very little profit. I am looking forward to drawing my SS and the medicare coverage coming up in June this year. Then at least I will have small steady income but I will still need to keep on working in this field until the battery power equipment takes over as OEM are refusing to provide info and parts for most of smaller equipment. Since I work main outside and the shop is at my home I don't have the overhead that a brick and mortar shop has.

As for minimum wage when it increases so does everything else which usually takes more than worker gets in the raise.

One drawback this year is also I am having to do things at cost due the Moron Idiots at the IRS refusing to get my account straighten out which they mess up in 2018. I finally had it with them and no going to pay taxes to them until it is straighten out. I figure the best to achieve this was to switch to a non profit mode and depend on my SS later this year.

StarTech

Your darn toot'n. I started out in electronics but as things got cheaper and cheaper the need for a decent repairman became obsolete. I managed 16 yrs but had take a new field of repairs.Nowadays you had better know more than 1 trade. Service is the only one everybody will need ongoing. Then you find that when you retire, SSI takes Medi Care of the top of whatever you get and COL raises never keep up with inflation. And a lot of people just don't get why raising the minimum wage isn't going to help anyone, quite the opposite. Where do they think the extra wage is coming from? Ain't no money trees around here. I don't know how you guys can run your shops alone without killing yourselves and still make a decent living.

Running a small shop is a major undertaking when you got to be the chief cook and bottle washer. Yes I spend 10 hr / 6 days in the shop and then another 4-6 hrs working on finding parts and the bookkeeping for very little profit. I am looking forward to drawing my SS and the medicare coverage coming up in June this year. Then at least I will have small steady income but I will still need to keep on working in this field until the battery power equipment takes over as OEM are refusing to provide info and parts for most of smaller equipment. Since I work main outside and the shop is at my home I don't have the overhead that a brick and mortar shop has.

As for minimum wage when it increases so does everything else which usually takes more than worker gets in the raise.

One drawback this year is also I am having to do things at cost due the Moron Idiots at the IRS refusing to get my account straighten out which they mess up in 2018. I finally had it with them and no going to pay taxes to them until it is straighten out. I figure the best to achieve this was to switch to a non profit mode and depend on my SS later this year.

#30

K

Kevin Dibling

K

Kevin Dibling

I am a licensed small engine tech and those channels are good also Elimanator Perormance is a good neI had been playing with vintage motorcycles for better he 30 years when I bought the small engine repair run which I thought would be a doddle.

What a steep learning curve.

There are hundreds of books about repairing small engines and most of them are not much chop.

Down here we call them coffee table ( if they are full of photos ) or bedside ( no pictures ) books.

Lots of information so general in nature as to be useless.

The best books are the John Deer Technical manuals as they tell you how the bits work and how to test them and what order to test them.

Most technical college libraries will have them and some are available from the web.

However GOOD & CHEAP are mutually exclusive. It costs money to write good manuals.

Other than that, You Tube is good once you sort out the shaved monkeys with a camera from those who actually know something.

Taryl Fixes All & Donnyboy87 are very good, subscribe to their channels and run through the entire play list.

A lot of parts suppliers also have videos, e-eplacement parts, Jacks small engines.

#31

1

1madmouse

1

1madmouse

I went with Property Maintenance for many years and it has kept me busy because people always need something done or fixed and I don't have to have a shop. Put my mechanical, electrical, and plumbing experience to good use. I have done much more plus college, but like was said here, that wasn't any guarantee of making good money. I figure 49 years of working was enough and retired.Your darn toot'n. I started out in electronics but as things got cheaper and cheaper the need for a decent repairman became obsolete. I managed 16 yrs but had take a new field of repairs.

Running a small shop is a major undertaking when you got to be the chief cook and bottle washer. Yes I spend 10 hr / 6 days in the shop and then another 4-6 hrs working on finding parts and the bookkeeping for very little profit. I am looking forward to drawing my SS and the medicare coverage coming up in June this year. Then at least I will have small steady income but I will still need to keep on working in this field until the battery power equipment takes over as OEM are refusing to provide info and parts for most of smaller equipment. Since I work main outside and the shop is at my home I don't have the overhead that a brick and mortar shop has.

As for minimum wage when it increases so does everything else which usually takes more than worker gets in the raise.

One drawback this year is also I am having to do things at cost due the Moron Idiots at the IRS refusing to get my account straighten out which they mess up in 2018. I finally had it with them and no going to pay taxes to them until it is straighten out. I figure the best to achieve this was to switch to a non profit mode and depend on my SS later this year.