Just a follow up to finish discussing my fixes. I've fixed just about everything so far... there were a few more problems...

- Accelerator bracket replacement

- I replaced the old accelerator bracket with a new one, but this was while replacing all the internal belts

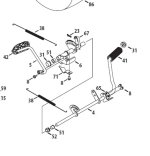

- View attachment 60983

- In order to replace this I had to drop the blade deck and take off all the springs connected to the shaft this bracket is connected to.

- There is a strange circular retaining clip in front of this bracket that has to be forced off (see item #31 in the diagram below)

- The kotter pin (part #23) has to be removed and then the strange wrench like brace has to be separated from the bracket.

- Once part 71 is removed (the mounting bracket for the shaft) then the accelerator bracket can slide off.

- View attachment 60984

- The new bracket did not have tapped screw holes for the pedal to mount in to - I had to tap it with a 5/16 18 thread count tap.

- See the "Illustrated Parts Manual" for the transmatic 780 to get these same diagrams.

- I had to replace the transmission pulley that sits underneath the driver's seat as it had become stripped:

- View attachment 60985

- The flange nut on the top was seized in place, making it impossible to remove the pulley without impact tools.

- I was able to drop the transmission off the tractor, manipulate its orientation and have just enough room to use a 23mm service wrench holding the underside of the transmission hub against the frame and a 7/8" impact socket with an extension and a U joint to remove the flange nut.

- I had to order a replacement pulley and hub as both were stripped beyond usability - you can see a side by side comparison here:

- View attachment 60986

- Also I had to get a small pulley puller from Autozone in order to get the hub off the splined transmission shaft.

- My tractor was in disassembled state for quite a while as I collected all the parts and tools I needed:

View attachment 60987

- Belts required replacement

- The deck belt had slipped off multiple times and was either sized incorrectly or stretched out too far.

- The internal belts looked serviceable but it seemed like the right time to swap them

- I could not find a correctly sized transmission belt, but the original showed no signs of wear (probably because it doesn't slip across the pulleys like the other belts) so I left it in place. It is working so far.

- Idler pulleys & bracket needed replacement

- The old idler pulleys had been damaged by the belt slipping off. It seemed that they were not in proper alignment on top of the blade deck:

- View attachment 60988

- I ordered a new bracket for the idler pulley that is connected directly to the PTO cable (the nearest pulley in this image), replacement idler pulleys and replacement "brakes" for the idlers. I also got new belt retainer brackets (those black guards that stick up and over the pulleys)

- The new bracket did not come with tapped screw holes for the brake so I, again, had to tap new holes into it. It needed a 1/4 20 thread count tap for those screws.

- Ironically the new bracket seemed identical to the old one in terms of its shape so I don't think the bracket was playing a part. I replaced it to be certain

- View attachment 60989

- I should have taken a picture of the entire deck reassembled but I was tired and wanted to mow the lawn

Here is the newly assembled bracket and idler with the new brake and belt guard. Notice that the new belt guard does not stick out over the top of the pulley. That will be super nice for replacing the belt as the older design required removal of the entire assembly. Now it can be done with just the pulley out.

Here is the newly assembled bracket and idler with the new brake and belt guard. Notice that the new belt guard does not stick out over the top of the pulley. That will be super nice for replacing the belt as the older design required removal of the entire assembly. Now it can be done with just the pulley out.

- View attachment 60990

- After all this it decided that it wouldn't start anymore

- Turns out the PTO lever isn't returning home all the way so it has to be pushed further back towards "PTO off" in order to start the mower. I can live with that for now.

- I just took it out for a spin

- The new blade deck idler pulley aligns better with the main crankshaft pulley - I think the belt geometry is better than before

- The new belt guards also seem to be keeping the belt in place.

- The new transmission pulley combined with the new accelerator bracket have greatly improved the speed of the mower. Still not as fast as I'd like, but a lot better.

So my $500 mower has turned into about a $1300 mower after factoring in new tools, parts etc. Not quite the "deal" I was looking for but it works and it was a little less expensive than a new one. I've also learned *a lot* about small engine repair, carburetors etc. Hopefully this thing continues to run for a few more years.

Man I want to go buy an electric