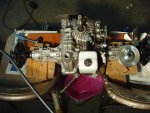

Transmission is out and gear compartment drained- about 1.3 liter. The fan is nylon, held on by a locking (nylok) nut. Fan has a pattern of 6 holes around the top which looks intended for a spanner type wrench. Fan design is apparently to "wobble) a bit in run. No end float, but side to side about .020" play while locked in position. A 2 point spanner will not hold the fan against the unlocking torque applied (nut will not turn), as the spanner deflects (smears)the fan material. Tried two strap wrenches on the pulley which did not work (harbor freight junk now in the trash). Today will make 6 point spanner. As noted the hydro oil compartment cannot be filled or easily drained without removal of the aluminum cover cap held down by a cap screw which is set under the fan pulley lower rim. This tranny is a very pretty thing and a pity it is hidden within the chassis box. Below the fan nut is a large washer possibly keyed to the input shaft. Maybe a vice grip can be used on it to hold the shaft/pulley for loosening.

Most time was spent in set up. Used cherry picker to raise tractor. Worked well. Have procedure for the curious few. (Not done yet)

Edit: Nope, washer spins. Finally pinched bottom pulley rim with vise grip to stop against trans casting. Easy nut removal. The wobble is due to apparent slight taper of shaft splines. Pulley seated has almost no play, so perhaps a design factor. The 6 fan holes are not meant for spanner removal-very thin.

Overnight drip drain of gear chamber produced another .6 liters of oil which is surprising to me, perhaps due to superior cling of synthetic oil? So total gear chamber drain= 1.9 liters. No wear particles noticed.

Most time was spent in set up. Used cherry picker to raise tractor. Worked well. Have procedure for the curious few. (Not done yet)

Edit: Nope, washer spins. Finally pinched bottom pulley rim with vise grip to stop against trans casting. Easy nut removal. The wobble is due to apparent slight taper of shaft splines. Pulley seated has almost no play, so perhaps a design factor. The 6 fan holes are not meant for spanner removal-very thin.

Overnight drip drain of gear chamber produced another .6 liters of oil which is surprising to me, perhaps due to superior cling of synthetic oil? So total gear chamber drain= 1.9 liters. No wear particles noticed.

Last edited: