You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Impressions: newGT48XLSi

#1

M

motoman

M

motoman

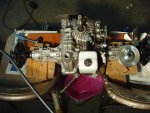

Bad hip just when ole dyt4000 lost a cylinder. I cannot presently t-shoot to see if more life is in it so I bought a new Husqy. Although I wanted Kaw I settled on....drum roll ....ANOTHER INTEK????? Yep . I have ranted about this engine and yet after 5 yrs on the forum people (and the dealer)have convinced me that Kaw has problems too. This one is the "endurance" which seems to mean chrome valve stems and a presumably better air filter. But looks the same mostly. So now I am fretting about getting an oil cooler on it asap , oil pressure gauge, and oil temp gauge.

Today I mowed. I like the variable go pedal, but do not like the fail safe procedure for trying to back up with blades on. The seat is back too far and when I looked beneath there are three places for slider slot clamping via cap screws and big washers. Only one is present. The rear slanted hitch plate was punched and the bottom edge is sharp enough to shave with. The oil drain plug has been carefully blocked with a plastic grill making it impossible to drain the oil. The grill looks like it is plastic riveted on so it cannot be removed. WTF? The fabricated deck is awesome looking , but I never had a problem for 12 years with the Craftsman formed one. The smart key seems to work ok now, but I wonder long run? I got the K 66 with locking diff , but have not used it. More later. Please correct me if I am wrong, 2 hours so far. Just remembered to mention an initial impression of the battery hold downs. Plastic "ears" with no cross over clamping, just the edges of the bat ,which will not provide a corrosion path, but which seem very anemic. We'll see.

Today I mowed. I like the variable go pedal, but do not like the fail safe procedure for trying to back up with blades on. The seat is back too far and when I looked beneath there are three places for slider slot clamping via cap screws and big washers. Only one is present. The rear slanted hitch plate was punched and the bottom edge is sharp enough to shave with. The oil drain plug has been carefully blocked with a plastic grill making it impossible to drain the oil. The grill looks like it is plastic riveted on so it cannot be removed. WTF? The fabricated deck is awesome looking , but I never had a problem for 12 years with the Craftsman formed one. The smart key seems to work ok now, but I wonder long run? I got the K 66 with locking diff , but have not used it. More later. Please correct me if I am wrong, 2 hours so far. Just remembered to mention an initial impression of the battery hold downs. Plastic "ears" with no cross over clamping, just the edges of the bat ,which will not provide a corrosion path, but which seem very anemic. We'll see.

#3

M

motoman

M

motoman

Continuing...Apology to Husqy. The seat "should" only have one bolt/washer underneath per manual AND the seat has an adjustment lever on the left side. My bad and glad I found it. I believe this garden tractor is a couple hundred pound heavier than my dyt 4000 and now that I have driven it around it is less snappy due to the same rated Intek. I have learned that for reverse to continue cutting there is a smart button entry to allow it. So far the smart ignition button has worked out and may be worthwhile if it holds up. The arm rests are not so useful to me, but may be to someone mowing a large area. There is a cruise control I have not tried yet. Something about the deck construction causes an irritating "drone" with blades engaged which comes through the ear guards I am using. I hope others can report it is just me or that I can try some different ear protection and change it. After my last 2 hour mow I was not real happy with that noise. The chassis my be a little longer than the Crafstman dyt 4000 as there seems to be better clearance around the back of the Intek (ignoring the perforated plastic shield I mentioned which inhibits oil change on the right side ). The potential is there for a fan based oil cooler which I am considering. But first I will put removability into the right side shield for oil change and to install an oil temp gauge as I have done on the dyt 4000. Once operable, and if I see typical (to me) 280F-300F oil temp I will install an oil cooler/gauge and fan. I see there are some cheap thermostats now available and may consider them because in winter I must drive a lot to bring dyt 4000 engine up to 180+F. I have accidentally engaged the K66 locker button and heard an impressive engagement related sound , solenoid actuation of lever (s)?, but have not studied the tranny up close, nor tried the locker. Although I have not studied it up close it looks like Briggs revised the cooling air shielding on the engine compared with my old Intek. . And... as someone said, the gas gauge is hard to read due to the opaque mostly and you must look down between legs to see it. More as it is fit to print :laughing:

#5

M

motoman

M

motoman

Forgot earlier to mention that the owners manual it came with is sorely lacking IMO. It does not have the detail, nor cover the topics which the dyt4000 does. I found a download online which is prompted by the Husqy materials included, but I am still not too impressed. I looked further to get detail on the "Endurance" model of Intek which apparently fits between the base engine on the dyt4000 and the "Elite," but the "manual" from Briggs included in my packet is very disappointing. It promises a lot on the cover, showing 3 model series :400000.440000, and 49000 all three known as Professional series. The GT48XLSi (mine) apparently has the middle grade engine discerned from a label on the engine. When you open the "manual" there are interesting pictures of the engines with no nomenclature and item bubble numbers promising a list ,,, but no list. These pictures show an external oil cooler bolted to the driver's side of the fan shroud. Without detail one cannot tell if some fan air is being forced through the shroud to the oil cooler. I think not as I have seen several pictures of Kohler oil coolers which never show a fan. So are they reducing oil temp by 40F in relatively still air? This default and pathetic attempt to include useful material for the owner is baffling and shortsighted IMO. Among the three engines specs is a slight change in bore stroke on the top model-more oversquare.

I am looking for a separate manual for this Intek, but all I see is the one I already have. One more item. I passed on a battery float charger at the Husqy dealer as I had just bought a Schumaker. The Husqy dash has a neat 2 pin female connector with a cover. I am wondering if I should price it out. In the owner's manual they say disconnect bat ground before charging. An additional step perhaps not necessay. The deck has a hose connection which the dealer says works well-not tried. The dealer also commented that the grass baggers are not favored due to pickup clogging problems which seemed odd since most owners know damp and wet grass will clog the most chutes? I will see if I can adapt the Craftsman 3 bag system to this tractor by some welding and maybe a formed fiberglass adaptor fitting the Husqy deck and the Craftsman tube. More if worthwhile. Correct and help me as necessary.

I am looking for a separate manual for this Intek, but all I see is the one I already have. One more item. I passed on a battery float charger at the Husqy dealer as I had just bought a Schumaker. The Husqy dash has a neat 2 pin female connector with a cover. I am wondering if I should price it out. In the owner's manual they say disconnect bat ground before charging. An additional step perhaps not necessay. The deck has a hose connection which the dealer says works well-not tried. The dealer also commented that the grass baggers are not favored due to pickup clogging problems which seemed odd since most owners know damp and wet grass will clog the most chutes? I will see if I can adapt the Craftsman 3 bag system to this tractor by some welding and maybe a formed fiberglass adaptor fitting the Husqy deck and the Craftsman tube. More if worthwhile. Correct and help me as necessary.

#6

M

motoman

M

motoman

The dash mounted battery connector has a live cursor blinking. The smart switch provides battery condition at startup if you want via red yellow green leds . Dustcap covers two male pin contacts (correction to earlier) which are odd ball to me as I tried to find a mating female in my grab bad and could not. The connector seems to be a "CTEK" which is a brand name and the name of the float charger sold for this tractor, around $60 online. I am trying to adapt my Schumaker float charger to those pins, Otherwise just the common clamp connectors to the battery.

#7

M

motoman

M

motoman

Daughter helping haul cut weeds . At start we noticed the smart key bat led was blinking half charge so we decided to run the tractor with no shut off to charge. It worked except she ran out of gas. I had noticed a reserve gas valve under the seat (but I missed this if it was in the manual). Expecting a stiff action I was pleased to turn it easily and within one extra jab on the smart key the reserve gas was flowing. Very cool.

#9

B

bertsmobile1

B

bertsmobile1

If you use the deck washout it is essential that after the water is turned off you drive over a dry hard surface and leave the deck running about 10 minutes to dry off.

Otherwise you will end up replacing a lot more spindles & bearings that you would like to do.

Just like the Craftsman, the deck needs to be kept clean on the top so the vents around the spindles can work and for this you really need a blower as loose cut grass does not wash off.

I use an air duster with a 4' long nozel so I can get under the pulley guards and into the frame rails without standing on my head ( way too old for that ) or eating grass ( got cows to do that ).

Not a big fan of worry gauges but if you feel more confident with them installed then go ahead it is your mower after all so kit it out as you like.

Try to avoid fitting anything to the cowel that makes it harder to remove as removing it regularly and blowing clean the cooling fins is one of the easiest and most beneficial maintenance jobs you can do.

Using the long air duster to blow dust out from under the flywheel does the alternator a power of good as well.

Otherwise you will end up replacing a lot more spindles & bearings that you would like to do.

Just like the Craftsman, the deck needs to be kept clean on the top so the vents around the spindles can work and for this you really need a blower as loose cut grass does not wash off.

I use an air duster with a 4' long nozel so I can get under the pulley guards and into the frame rails without standing on my head ( way too old for that ) or eating grass ( got cows to do that ).

Not a big fan of worry gauges but if you feel more confident with them installed then go ahead it is your mower after all so kit it out as you like.

Try to avoid fitting anything to the cowel that makes it harder to remove as removing it regularly and blowing clean the cooling fins is one of the easiest and most beneficial maintenance jobs you can do.

Using the long air duster to blow dust out from under the flywheel does the alternator a power of good as well.

#10

M

motoman

M

motoman

Bert, Yes I am leery of the hose cleanout also as I have run over mostly damp to wet grass for 12 years with my lowly stamped deck on the dyt 4000 with no spindle changeout or perforation. I do, however, sharpen about 3 times summer and end up chiseling adobe coating from the deck (mud and dried weeds/grass) . The load I typically get from that excercise is about 5-6 flat shovel-fulls. I feel that has ******** rust and allowed the deck to dry . Re gauges...I understand how pros who constantly repair needless damage of clients' machines develop a kind of cynicism (maybe for all mowers). But for the odd ball minority gauges can prolong life of the big box machines. motoman

Edit. I have an air compressor and an H Frt quick attach "wand" of about 2 feet with trigger which I clean up the tractor with after every mow. You can reach into the chute opening and the diffused 100 psi will detach the thatch also if moist enough. I always direct the air accross the front of the intek carburettor and the pointy tip allows blast into little openings in the air shrouding, as well as cleaning up the weeping oil points for closer inspection. When done there is a big ring of debris and grass around the tractor. I have read others do this too. From the volume of grass and weed clippiings I dislodge around the deck pulleys it would seem these masses could end up stretching or damaging the drive belts if not removed.

Edit. I have an air compressor and an H Frt quick attach "wand" of about 2 feet with trigger which I clean up the tractor with after every mow. You can reach into the chute opening and the diffused 100 psi will detach the thatch also if moist enough. I always direct the air accross the front of the intek carburettor and the pointy tip allows blast into little openings in the air shrouding, as well as cleaning up the weeping oil points for closer inspection. When done there is a big ring of debris and grass around the tractor. I have read others do this too. From the volume of grass and weed clippiings I dislodge around the deck pulleys it would seem these masses could end up stretching or damaging the drive belts if not removed.

#11

M

motoman

M

motoman

Two more hours mowing today. The seat bracket is chintzy . While the seat unit is ok the main hinge bracket flexes like a tin can lid when raising seat. Also I am still bothered by the one bolt hold down of the seat to its frame. Nothing has broken or loosened, but I can not help noting the contrast between the seat bracket and the deck with its Humvee armor plate and electric weld seams. Guess like cars the bean counters had to attack somewhere,

I had accidentally engaged the diff locker and was lamenting the poor turning radius and the tendency for the tractor to understeer (wheels turned , but goes straight) and diminished radius turning. This went away when the dash locker switch was turned off. I did not tear up any grass , BTW, as some have reported, with the diff locked. Probably cause I was going really slow with my healing hip. I did use the locker once purposely when tractor drive wheel fell into a wet rut. Turned on the dash switch and two light jabs of go pedal had me out in a jiffy...VERY SWEET ...and what I was hoping for after 12 years of slipping and sometimes having to shovel out.

I mentioned the nice little dash flush float bat charger connector and the dedicated Husqy-sold CTEK ( I think) , but I had committed to a Schumaker float charger (Walmart} which I like. It came with a nice little pigtail jumper harness with battery bolt- sized eyelets so I put that on and can now more easily charge the beast.

Edit: The air cleaner is a "sock" type with a round pleated paper body bonded to a black flexible "neck." After years of catering to the old Intek paper/sponge flat inserts and a very long rubber perimeter seal (rectangle) which just barely worked I checked the Husqy air filter before mowing. The lid has the same two captive pinch and turn screws, but that lid just covers the sock. The sock's rubber neck is pulled off and pushed on to a spout. I don't like the feel of the installed neck on spout. It did not come with a clamp, but I will put one on. The fact that you can pull it off bothers me (tight seal?). I did not see any dust tracks from the first mows, but I want a seal. Perhaps Intek (or Husqy?) was afraid users would complain of "bonding" which might require extra effort or even cutting the neck to remove (like a radiator hose). I will risk it. A clamp goes on. Credit due to the attempt to improve installation.I wonder about filter life under dusty weed duty as I used to clean the foam insert after even one mow. Better buy about 6 of the socks. The filter does go on in about 1/10 the time.

I had accidentally engaged the diff locker and was lamenting the poor turning radius and the tendency for the tractor to understeer (wheels turned , but goes straight) and diminished radius turning. This went away when the dash locker switch was turned off. I did not tear up any grass , BTW, as some have reported, with the diff locked. Probably cause I was going really slow with my healing hip. I did use the locker once purposely when tractor drive wheel fell into a wet rut. Turned on the dash switch and two light jabs of go pedal had me out in a jiffy...VERY SWEET ...and what I was hoping for after 12 years of slipping and sometimes having to shovel out.

I mentioned the nice little dash flush float bat charger connector and the dedicated Husqy-sold CTEK ( I think) , but I had committed to a Schumaker float charger (Walmart} which I like. It came with a nice little pigtail jumper harness with battery bolt- sized eyelets so I put that on and can now more easily charge the beast.

Edit: The air cleaner is a "sock" type with a round pleated paper body bonded to a black flexible "neck." After years of catering to the old Intek paper/sponge flat inserts and a very long rubber perimeter seal (rectangle) which just barely worked I checked the Husqy air filter before mowing. The lid has the same two captive pinch and turn screws, but that lid just covers the sock. The sock's rubber neck is pulled off and pushed on to a spout. I don't like the feel of the installed neck on spout. It did not come with a clamp, but I will put one on. The fact that you can pull it off bothers me (tight seal?). I did not see any dust tracks from the first mows, but I want a seal. Perhaps Intek (or Husqy?) was afraid users would complain of "bonding" which might require extra effort or even cutting the neck to remove (like a radiator hose). I will risk it. A clamp goes on. Credit due to the attempt to improve installation.I wonder about filter life under dusty weed duty as I used to clean the foam insert after even one mow. Better buy about 6 of the socks. The filter does go on in about 1/10 the time.

#12

B

Bicklebok

B

Bicklebok

Thank you for the update. That locker feature sounds like a handy feature that would come in handy.

Glad you discoverd the shulmer charger. You can buy extra pigtails on amazon and install them on other equipment too. Thats what i did.

Glad you discoverd the shulmer charger. You can buy extra pigtails on amazon and install them on other equipment too. Thats what i did.

#14

B

bertsmobile1

Could overheat the belt however will catch alight.

Next to restarting a mower with fuel splashed around everywhere or refuling a running mower, excessive grass build up on the deck starts a lot of fires and is real hard to put out under the pulley covers.

Next problem is the wet grass is quite acid and attacks any bare metal, promoting wear . Once you get a scratch in the powder coating wet grass will lift the paint in no time flat and eat through the deck.

So yes blow it off.

Blowing off the underside of the deck and keeping it clean will aid the airflow under the deck and yield a better cut.

A pair of flat topped ramps to run the front up will give you a nice height to get the air duster under the deck particularly if you can find a longer one.

I got a 4' one from a truck supply shop, bought a case of them and flog them to my customers.

B

bertsmobile1

Bert, Yes I am leery of the hose cleanout also as I have run over mostly damp to wet grass for 12 years with my lowly stamped deck on the dyt 4000 with no spindle changeout or perforation. I do, however, sharpen about 3 times summer and end up chiseling adobe coating from the deck (mud and dried weeds/grass) . The load I typically get from that excercise is about 5-6 flat shovel-fulls. I feel that has ******** rust and allowed the deck to dry . Re gauges...I understand how pros who constantly repair needless damage of clients' machines develop a kind of cynicism (maybe for all mowers). But for the odd ball minority gauges can prolong life of the big box machines. motoman

Edit. I have an air compressor and an H Frt quick attach "wand" of about 2 feet with trigger which I clean up the tractor with after every mow. You can reach into the chute opening and the diffused 100 psi will detach the thatch also if moist enough. I always direct the air accross the front of the intek carburettor and the pointy tip allows blast into little openings in the air shrouding, as well as cleaning up the weeping oil points for closer inspection. When done there is a big ring of debris and grass around the tractor. I have read others do this too. From the volume of grass and weed clippiings I dislodge around the deck pulleys it would seem these masses could end up stretching or damaging the drive belts if not removed.

Could overheat the belt however will catch alight.

Next to restarting a mower with fuel splashed around everywhere or refuling a running mower, excessive grass build up on the deck starts a lot of fires and is real hard to put out under the pulley covers.

Next problem is the wet grass is quite acid and attacks any bare metal, promoting wear . Once you get a scratch in the powder coating wet grass will lift the paint in no time flat and eat through the deck.

So yes blow it off.

Blowing off the underside of the deck and keeping it clean will aid the airflow under the deck and yield a better cut.

A pair of flat topped ramps to run the front up will give you a nice height to get the air duster under the deck particularly if you can find a longer one.

I got a 4' one from a truck supply shop, bought a case of them and flog them to my customers.

#15

M

motoman

M

motoman

Another hour mowing , and getting adjusted to this mower. At first I was pressing the go pedal too hard making drag race starts, some of which removed skin from forehead as I plowed through low hanging , scraggly branches of my fruit trees. I have learned that the pedal is calibrated very well...press lightly and go slowly, press hard and (almost) do wheelie. Also this pedal has excellent braking feature when letting off the machine stops without application of the brake. The reverse pedal is very small and relatively difficult to engage. It seems Husqy has gone to great pains to inhibit accidental backup with this action AND the smart button flashing red. OK, I guess, it it saves a terrible accident, but kind of a pain compared with my old Craftsman.

In case you had read my earlier comment about the sharp, shave- ready edge of the hitch plate...Husqy (unwittingly I'm sure) has built in a second razor blade edge on the rearward seat plate. I can still see the engineering boiler plate statement on all mechanical drawings..."break, remove all sharp edges..." This oversight is not major, but clearly shows a painter ( or coater) somewhere hanging and painting parts with his bandaged hands without a word to the (missing?) quality dude. Doubtful this would happen in Japan, Yes, these edges can be removed with several file strokes by the consumer, but why should that be?

EDIT; The oil level has stayed up since new. On the stick it looks like 30W. I guess this shows good ring seating. (I know they did not pour Bon Ami into the engine to achieve this).

The droning still bothers me ,, a kind of whum, whum , whum, instead of an audible constant whir I am used to on the Craftsman.

Please note I am pretty happy with the new machine.

In case you had read my earlier comment about the sharp, shave- ready edge of the hitch plate...Husqy (unwittingly I'm sure) has built in a second razor blade edge on the rearward seat plate. I can still see the engineering boiler plate statement on all mechanical drawings..."break, remove all sharp edges..." This oversight is not major, but clearly shows a painter ( or coater) somewhere hanging and painting parts with his bandaged hands without a word to the (missing?) quality dude. Doubtful this would happen in Japan, Yes, these edges can be removed with several file strokes by the consumer, but why should that be?

EDIT; The oil level has stayed up since new. On the stick it looks like 30W. I guess this shows good ring seating. (I know they did not pour Bon Ami into the engine to achieve this).

The droning still bothers me ,, a kind of whum, whum , whum, instead of an audible constant whir I am used to on the Craftsman.

Please note I am pretty happy with the new machine.

#16

B

Bicklebok

B

Bicklebok

Glad youre enjoying it. Im still gettimg used to a Hisqvarna PZT48 I bought used a few weeks ago. Just put new blades on it and it is exceeding my expectations!

#18

M

motoman

M

motoman

Got off my backsides and downloaded the operators and parts manuals, over 60 pp. Learned a couple things. (Why wasn't the manual, at least, included with the new purchase?)

I beefed earlier about the oil plug and drainage being blocked. The manual shows that what I called a grill they call a "dash cover," and what seemed like plastic rivets are sliding ?buttons" which allow the covers to be removed We'll see. Noticed the parts manual shows a cross over bracket holding the battery down. And puzzling is the exploded pic of the K 66 trans with what looks like a fillable tank. Is that an expansion tank? The text in the manual says no service possible, sealed at factory. There is a schematic of the same zerks I have on the dyt 4000 with no instruction on the bolt- on deck covers.nor intervals.

I beefed earlier about the oil plug and drainage being blocked. The manual shows that what I called a grill they call a "dash cover," and what seemed like plastic rivets are sliding ?buttons" which allow the covers to be removed We'll see. Noticed the parts manual shows a cross over bracket holding the battery down. And puzzling is the exploded pic of the K 66 trans with what looks like a fillable tank. Is that an expansion tank? The text in the manual says no service possible, sealed at factory. There is a schematic of the same zerks I have on the dyt 4000 with no instruction on the bolt- on deck covers.nor intervals.

#19

BlazNT

Go to manufacture web site and down load the manual. It will give the oil change times.

BlazNT

Got off my backsides and downloaded the operators and parts manuals, over 60 pp. Learned a couple things. (Why wasn't the manual, at least, included with the new purchase?)

I beefed earlier about the oil plug and drainage being blocked. The manual shows that what I called a grill they call a "dash cover," and what seemed like plastic rivets are sliding ?buttons" which allow the covers to be removed We'll see. Noticed the parts manual shows a cross over bracket holding the battery down. And puzzling is the exploded pic of the K 66 trans with what looks like a fillable tank. Is that an expansion tank? The text in the manual says no service possible, sealed at factory. There is a schematic of the same zerks I have on the dyt 4000 with no instruction on the bolt- on deck covers.nor intervals.

Go to manufacture web site and down load the manual. It will give the oil change times.

#20

M

motoman

M

motoman

Blaz, You are saying the tank is a filler spot and that Husqv is wrong about "sealed?" I do have a page from Tufftorque which shows the oil specs. Thanks

#21

M

motoman

M

motoman

OK, Went to Tuff Torque site. Got a good photo guide on the K66. Then to another section on intervals. The site generally echos the Husqv "not necessary" to change oil, but does say changing will prolong life. Only interval noted is after first 50 hrs. Also noted a nice picture of the widely used K 46 and some words about adding oil to it (must remove). 5W50 synthetic auto oil, both.

#22

M

motoman

M

motoman

Per downloaded manual the "dash cover" does come off with a hard pull. This gives access to the oil drain plug. Have not tried to remove the other side which should access the oil filter

#23

M

motoman

M

motoman

The front chassis looks same as the dyt 4000 , measured 12 gauge steel. The Husky rear hitch plate is 10 gauge. This confirms the stiffer chassis claim for so called Garden Tractors fit to drag earth engaging equipment.

My earlier talk about clamping the air filter neck was from some dream, I guess. It cannot be done. I did take another look for dust tracks getting by into the intake, but so far good. I imagine repeated removal of this rubber necked filter is not a good idea. Perhaps leave it on until you remove to replace.

A little plumbers silicone smeared on the dash cover engagement nubbins makes attachment much easier, I am doubtful about these plastic parts' life expectancy exposed to heat.

The deck pulley zerks are difficult to access , especially the middle one. They require 90 degree adapters I do not have.

Another cheap touch. The engagement release at the back has morphed from a nice galvo rod with stop (dyt 4000) to a cheap piece of bent wire. (bean counters).

Finally was able to check the K66 expansion tank oil level by standing on my head with the right rear wheel removed. Still could not see tank graduations, but there was a very low level of oil present like that shown in the TuffTorque download.

Edit: the two deck pulley covers are a pain with 4 bolts per side. I prefer the dyt 4000 semi open poly covers. Husqy must have had serious incidents or be in fear of serious incidents to have armored -up the deck like that. Over kill IMO

My earlier talk about clamping the air filter neck was from some dream, I guess. It cannot be done. I did take another look for dust tracks getting by into the intake, but so far good. I imagine repeated removal of this rubber necked filter is not a good idea. Perhaps leave it on until you remove to replace.

A little plumbers silicone smeared on the dash cover engagement nubbins makes attachment much easier, I am doubtful about these plastic parts' life expectancy exposed to heat.

The deck pulley zerks are difficult to access , especially the middle one. They require 90 degree adapters I do not have.

Another cheap touch. The engagement release at the back has morphed from a nice galvo rod with stop (dyt 4000) to a cheap piece of bent wire. (bean counters).

Finally was able to check the K66 expansion tank oil level by standing on my head with the right rear wheel removed. Still could not see tank graduations, but there was a very low level of oil present like that shown in the TuffTorque download.

Edit: the two deck pulley covers are a pain with 4 bolts per side. I prefer the dyt 4000 semi open poly covers. Husqy must have had serious incidents or be in fear of serious incidents to have armored -up the deck like that. Over kill IMO

#24

M

motoman

M

motoman

Just bumped alive ( I hope) a separate thread here about an overheating TuffTorque locking axle. Hope for response.

#25

M

motoman

M

motoman

The oil drain gizmo is the same as on the Craftsman which had never worked well, but was able to stay together for 12 years. Tried to drain the Husqy and the thing pulled apart down to the o rings under the rubber cover. About a quart of used onto the garage floor before I could recover. I wanted to put in a brass drain plug but could not get a socket over the Husqy 15/16"hex. The reason is that the bottom flat of the hex was purposely set flush with the metal frame. I could not think of why, except that perhaps some had loosened , leaked and burned up a motor, and this was a fail safe for the plug. But I was really surprised when I loosened the motor bolts temporarily to remove that plug. The plug is a thin,cast galvanize coated one with only 3 threads engaged. It was Teflon taped and not leaking, but only finger tight. Perhaps the assembler was afraid the plug would break tightening it to the next flat. It made me think of the Craftsman Intek pan bolts several of which which eventually loosened, and missed by me, sat trapped on their heads waiting to be found. Actually petty clever and not a coincidence IMO.

The Depo stepper gauge is in and weird it is before start up. It has a dark lens and does not show anything til the engine is started- like a one-eyed Cyclops in the Greek stories. Only ran for proof in garage and only to 135F. Full report to follow.

Edit, Plug is more accurately, a zinc casting and weak IMO

The Depo stepper gauge is in and weird it is before start up. It has a dark lens and does not show anything til the engine is started- like a one-eyed Cyclops in the Greek stories. Only ran for proof in garage and only to 135F. Full report to follow.

Edit, Plug is more accurately, a zinc casting and weak IMO

#26

O

Oldaarpy

O

Oldaarpy

Motoman

I bought the 52" deck version of your tractor last August. So far I love it. A set of chains and 50lbs on each of the wheels and you can't stop it. I also purchased the Husky battery tender gizmo and that also works like a charm. Do yourself a favor and buy the Husky seat cover...much more comfortable after a few hours of mowing! Wifie picked up an older style Husky seat cover on Ebay for less than $25. It's not made for seats with arm rests but if you're careful and cut bolt holes in it just big enough for the bolts the actual arm rest/seat connect plates act as clamps and it won't move or tear out. It has 'net' srorage in the back and should save the seat from damage.

When switching to posi-drive make sure you come to a complete stop before engaging or disengaging. There's a pin that moves and could easily be sheared off. I bought a snowplow (big mistake, buy the dozer blade) and the tractor was pushing 15" of heavy snow on flat terrain. My land is two acres and all hills with some better than 30 degrees and the tractor runs up and down like there's no tomorrow. No trans problems there with over-heating, and I was out mowing in 95 degree weather.

The hose cleaner sucks (don't they all) and the deck tends to clog up if it's not set up right. Make sure you grease the mandrels half way through the season, I guess you know that, as these as supposedly "heavier duty" and undoubtedly more expensive to replace. I used POR-13 on another deck with clogging problems and it helped, if you start having troubles with that issue!

This is my second Husky and that one bolt seat deal is standard...go figure. The plastic piece that comes off before you can change the oil loosens up a little the more you use it. I'm not sure why it's there.

Enjoy the new toy and hope recovery is fast......Aarpy

I bought the 52" deck version of your tractor last August. So far I love it. A set of chains and 50lbs on each of the wheels and you can't stop it. I also purchased the Husky battery tender gizmo and that also works like a charm. Do yourself a favor and buy the Husky seat cover...much more comfortable after a few hours of mowing! Wifie picked up an older style Husky seat cover on Ebay for less than $25. It's not made for seats with arm rests but if you're careful and cut bolt holes in it just big enough for the bolts the actual arm rest/seat connect plates act as clamps and it won't move or tear out. It has 'net' srorage in the back and should save the seat from damage.

When switching to posi-drive make sure you come to a complete stop before engaging or disengaging. There's a pin that moves and could easily be sheared off. I bought a snowplow (big mistake, buy the dozer blade) and the tractor was pushing 15" of heavy snow on flat terrain. My land is two acres and all hills with some better than 30 degrees and the tractor runs up and down like there's no tomorrow. No trans problems there with over-heating, and I was out mowing in 95 degree weather.

The hose cleaner sucks (don't they all) and the deck tends to clog up if it's not set up right. Make sure you grease the mandrels half way through the season, I guess you know that, as these as supposedly "heavier duty" and undoubtedly more expensive to replace. I used POR-13 on another deck with clogging problems and it helped, if you start having troubles with that issue!

This is my second Husky and that one bolt seat deal is standard...go figure. The plastic piece that comes off before you can change the oil loosens up a little the more you use it. I'm not sure why it's there.

Enjoy the new toy and hope recovery is fast......Aarpy

#27

ken_clifton

That is good on the gauge Motoman. I am looking forward to some numbers on those engine oil temps when it is doing some work!

I saw the other thread on the transmission oil temp. It made me think back to year 1 with my Scag, when I checked the hydraulic oil after 3 hours of mowing. I unscrewed the cap and smoke came out. I know it is a different application and all, but right after that I put a power steering cooler in the line.

When designers have closed systems like this with no real way for heat to dissipate is that a realistic use case? On air craft they use the term "standard day" which is at sea level, Altimeter:29.92 in/Hg at 15 °C (59 °F). Not many folks are doing most of their mowing when the temp is 59 deg F...

ken_clifton

ken_clifton

The Depo stepper gauge is in and weird it is before start up. It has a dark lens and does not show anything til the engine is started- like a one-eyed Cyclops in the Greek stories. Only ran for proof in garage and only to 135F. Full report to follow.

That is good on the gauge Motoman. I am looking forward to some numbers on those engine oil temps when it is doing some work!

I saw the other thread on the transmission oil temp. It made me think back to year 1 with my Scag, when I checked the hydraulic oil after 3 hours of mowing. I unscrewed the cap and smoke came out. I know it is a different application and all, but right after that I put a power steering cooler in the line.

When designers have closed systems like this with no real way for heat to dissipate is that a realistic use case? On air craft they use the term "standard day" which is at sea level, Altimeter:29.92 in/Hg at 15 °C (59 °F). Not many folks are doing most of their mowing when the temp is 59 deg F...

ken_clifton

#28

M

motoman

M

motoman

Aarpy, Thanks for the tips . I did not know about the mandrels. l guess I'll have to make a 90 deg adapter for the grease gun or buy one. The hip is ceramic. Put it off way too long. motorman Edit Your comments on snow ability very good. I have hand shoveled a long driveway for years.

Ken, I will probably mow soon . Right now in Aug heat only the dandelions keep growing. I will try also to say something about the K 66 case temp I can measure with my KE thermometer. Then , perhaps a stretch, apply the sump oil/case forumula to derive likely K66 oil temp??? motoman

Ken, I will probably mow soon . Right now in Aug heat only the dandelions keep growing. I will try also to say something about the K 66 case temp I can measure with my KE thermometer. Then , perhaps a stretch, apply the sump oil/case forumula to derive likely K66 oil temp??? motoman

#29

M

motoman

M

motoman

Today is over 90F and I took Husqy out to see how the new gauge works and how hot the oil got. The mowing was not really "work" as I was cutting dandelion stems and that work was really just the blades turning. Nevertheless I was pleased because this Intek DOES seem to run cooler that the dyt4000. I could not run the dyt and read its Beedee gauge to compare ,because it still only has one cylinder running.

After 10 minutes, 210F; after 30 minutes 235F and much more stable than the other Intek which would easily swing temps.I finally saw 240F but that was it . The "mowing" was in and out of tree shadows. This engine likes to run fast and temp raises about 5 degrees at idle. Pulling under shade and then lifting the cover vs closing it did not affect temps much, finally down to 229F after about 5 minutes. The old Intek with cooler would drop 50 degrees from e.g., 280F after pulling into shade with cover open ,and fan at idle in about 5-10 minutes (after hard work),

So , although, Briggs only openly says? this engine has chrome valve stems and different air cleaner , seems like some homework was performed on cooling. But this was not really a test except for the ambient temp. The dyt4000 was pretty stable this time of year with just a trailer hauling trimmings-around the same temp if I remember correctly. But its temp skyrocketed with hard work, so I will have to reserve final judgement. The Depo gauge cannot be read in bright sunlight, but the led is bright and tracks the stepper pointer well. Running 5W-30 Mobil One.

After 10 minutes, 210F; after 30 minutes 235F and much more stable than the other Intek which would easily swing temps.I finally saw 240F but that was it . The "mowing" was in and out of tree shadows. This engine likes to run fast and temp raises about 5 degrees at idle. Pulling under shade and then lifting the cover vs closing it did not affect temps much, finally down to 229F after about 5 minutes. The old Intek with cooler would drop 50 degrees from e.g., 280F after pulling into shade with cover open ,and fan at idle in about 5-10 minutes (after hard work),

So , although, Briggs only openly says? this engine has chrome valve stems and different air cleaner , seems like some homework was performed on cooling. But this was not really a test except for the ambient temp. The dyt4000 was pretty stable this time of year with just a trailer hauling trimmings-around the same temp if I remember correctly. But its temp skyrocketed with hard work, so I will have to reserve final judgement. The Depo gauge cannot be read in bright sunlight, but the led is bright and tracks the stepper pointer well. Running 5W-30 Mobil One.

#30

ken_clifton

ken_clifton

Thanks for posting that Motoman.

It will be interesting to see how things go when it is doing some hard work. Briggs may have some design changes there that help. It seems like some of the piston skirts and other parts are Teflon coated on some of the engines -- not sure which ones.

I probably should start a new thread on this topic of Intek design changes, but I have used some parts from the "Vanguard" vertical shaft on my engine. For reference the model and type number of one is: 49V677-0001-G1

While Briggs is calling it a "Vanguard" most of the internal parts if you look at the parts diagram look very close to the older Intek series. What I was told is that Vanguards are assembled in the USA by one person -- each engine is completely built by one employee. Most of the "hard" parts have a "5" at the start of the part number, but many of the gasket part numbers are shared with the older Intek series. Don' be fooled by the outer plastic cover, if you remove that outer shield the blower housing looks almost identical. Notice they have a canister air filter fitted too. The 810cc is very close to my current Intek.

Here are some links...

Parts: Link: https://www.jackssmallengines.com/jacks-parts-lookup/manufacturer/briggs-stratton/400000-699999-series/49v600-to-49v699

Briggs Info Page: https://www.vanguardengines.com/na/en_us/engines/810cc-vtwin-vertical-shaft.html

ken_clifton

It will be interesting to see how things go when it is doing some hard work. Briggs may have some design changes there that help. It seems like some of the piston skirts and other parts are Teflon coated on some of the engines -- not sure which ones.

I probably should start a new thread on this topic of Intek design changes, but I have used some parts from the "Vanguard" vertical shaft on my engine. For reference the model and type number of one is: 49V677-0001-G1

While Briggs is calling it a "Vanguard" most of the internal parts if you look at the parts diagram look very close to the older Intek series. What I was told is that Vanguards are assembled in the USA by one person -- each engine is completely built by one employee. Most of the "hard" parts have a "5" at the start of the part number, but many of the gasket part numbers are shared with the older Intek series. Don' be fooled by the outer plastic cover, if you remove that outer shield the blower housing looks almost identical. Notice they have a canister air filter fitted too. The 810cc is very close to my current Intek.

Here are some links...

Parts: Link: https://www.jackssmallengines.com/jacks-parts-lookup/manufacturer/briggs-stratton/400000-699999-series/49v600-to-49v699

Briggs Info Page: https://www.vanguardengines.com/na/en_us/engines/810cc-vtwin-vertical-shaft.html

ken_clifton

#31

M

motoman

M

motoman

Ken, It would be interesting to read your summary of actual and likely design changes to Intek engines. "Little things" do make a difference in output as we know from hotrodding, but I do not think little things can change hot oil temps. Seems like it would take more, and so the real proof of "apparent" improvement in the Husqy will have to wait on some real work.

One other thing. The Husqy Intek likes to run wide open to cool its oil, but I never found that with the dyt4000. The oil flow in the Husky seems to pass oil over a cooler place where it drops some heat. The reaction is about 1 minute. I do not know if that could just be the fan effect. The dyt Intek reacts also, but it has the cooler/fan. Can you relate any of this to diesel trucks we hear idling at truck stops while their drivers take a break? The dyt cooled best at idle , hood up, fan on, and very quickly.

Incidentally, with my pseudo-science one question is accuracy of gauges. I had refereed the Beedee analog gauge with my KE temp coupler and did find the Beedee a little high (10-15Degrees) at 300F. I have not checked the Depo. motoman

One other thing. The Husqy Intek likes to run wide open to cool its oil, but I never found that with the dyt4000. The oil flow in the Husky seems to pass oil over a cooler place where it drops some heat. The reaction is about 1 minute. I do not know if that could just be the fan effect. The dyt Intek reacts also, but it has the cooler/fan. Can you relate any of this to diesel trucks we hear idling at truck stops while their drivers take a break? The dyt cooled best at idle , hood up, fan on, and very quickly.

Incidentally, with my pseudo-science one question is accuracy of gauges. I had refereed the Beedee analog gauge with my KE temp coupler and did find the Beedee a little high (10-15Degrees) at 300F. I have not checked the Depo. motoman

#32

M

motoman

M

motoman

I have been reading about the grass collector system for the Husqy and the eye-watering price, ?$1000. Someone said another pulley driven fan is added, etc, etc. No wonder the dealer did not elaborate when I plunked down the tractor money. If anyone has solved this for a sane price it would be good to hear. In a couple weeks I will be buried in leaves . That was one thing the dyt4000 did well , fill the 3 bins with dry or freeze-dry leaves. Guess I will have to fix the Intek.

#33

M

motoman

M

motoman

The dash ammeter and hour meter gauge hole sizes are 52 mm which is one standard . For anyone interested a typical probe is 1/8 NPT which can run inside an oil drain plug. Lowes still sells a nice brass adaptor to fit the Intek sump with a 1/8

NPT threaded hole in the center. I am running both these without tape. The oil plug hex size is smaller so there is no problem fouling the frame. Old Lowes pn BF-776NL, new pn A-776 110.

NPT threaded hole in the center. I am running both these without tape. The oil plug hex size is smaller so there is no problem fouling the frame. Old Lowes pn BF-776NL, new pn A-776 110.

#34

ken_clifton

ken_clifton

Motoman,

Just curious, where is your probe fitted? I assume it is in the sump. As you probably remember mine is in the oil line right before the remote oil filter.

I am sure there is all kinds of room for variance. I was careful when measuring my boiler gauge probe to be sure about 1/8 in of the probe was actually in the oil flow -- it is in the top of a 3/8 NPT tee right before the filter.

I wish that I had an IR heat gauge to read the temp on the output of the oil cooler. The delta between input and output would be interesting. My first thought is something in the sump where all the oil is sitting might be more accurate, but then again, my lines are 1/2 inch and there is a whole lot of flow there...

I guess the only way to compare apples to apples would be to fit a gauge in the same spot as yours...

ken_clifton

Just curious, where is your probe fitted? I assume it is in the sump. As you probably remember mine is in the oil line right before the remote oil filter.

I am sure there is all kinds of room for variance. I was careful when measuring my boiler gauge probe to be sure about 1/8 in of the probe was actually in the oil flow -- it is in the top of a 3/8 NPT tee right before the filter.

I wish that I had an IR heat gauge to read the temp on the output of the oil cooler. The delta between input and output would be interesting. My first thought is something in the sump where all the oil is sitting might be more accurate, but then again, my lines are 1/2 inch and there is a whole lot of flow there...

I guess the only way to compare apples to apples would be to fit a gauge in the same spot as yours...

ken_clifton

#35

M

motoman

M

motoman

The probe is in the sump drain plug at the right side of the pan. When screwed in about 1/8" of the probe tip protrudes beyond the plug. So the oil temp depends upon a full sump plus sloshing. With this set up the sense wire (s) must be disconnected to drain oil. This setup uses two wires. I took an HF socket and cut a slot on the side for the pig tail when torqueing the plug in or out. I looked around for another place, but felt the pan was too thin to create a hole. BTW yesterday I again observed a 5 degree rise in temp after shutting off-a heat soak.

You probably know some relatively cheap DVMs have a KE temp function. The lead tip is a fused ball of two wires which react to temp. Very accurate, but not easy to use as the tiny ball tip is fragile and must be held

on the surface to measure. That is how I will measre the K 66 case temp one day soon.

You probably know some relatively cheap DVMs have a KE temp function. The lead tip is a fused ball of two wires which react to temp. Very accurate, but not easy to use as the tiny ball tip is fragile and must be held

on the surface to measure. That is how I will measre the K 66 case temp one day soon.

#36

M

motoman

M

motoman

Located a 90 deg slip- on grease nipple and was able to grease the middle pulley zerk. If you have big hands forget it. First attempt could not hold nipple on square and missed. Second attempt ok. Unlike the dyt 4000 where I sneaked through the left side over the deck, the Husqy was reversed ; over the right side of the deck with my lever gun laying on the deck. Mostly by feel. It is tempting to plot an access hole through the floor board (sheet metal). With a strong light looking down from the steering shaft it looks like it might be possible with an extra long grease hose to lube from a hunched position, instead of lying flat out. An air gease gun would make things easier. If anyone has a solution to this PIA, please advise.

#37

M

motoman

M

motoman

Last update until warm weather and heavy work. (I don't have a blade for snow, but considering it). The dash now includes an oil pressure gauge...

On the (sick) dyt 4000 I put on a mechanical oil pressure gauge with a nylon line, but it kept blowing at the filter fitting. Then I went electric . It was 4 times the cost with the sender but promised a lot and delivered leak free for a number of years. But in the last couple years it started periods of erratic fluttering after hard, hot use with rough terrain...So....

I put on a mechanical gauge , but this time with copper line. I have read it will break so I put in gentle service loops and two rubber stabilizers for vibration damping. The connection at the filter port and the gauge have brass compression rings. You cannot reuse old compression rings. To avoid paying for a whole kit I was able to buy bulk 1/8" line at an auto store and found an on- line source for round compression rings (vs the pointy style). By adding a little washer on top of the ring , the screw caps seemed to lock the lines. We will see.

The dash had an imprinted cutout on left side above the cigarette lighter (reserved for the Brits?). The gauge is a push fit there and visible through the steering wheel spoke cutout. So...ammeter regular place, oil temp gauge to its right, time meter sheltered inside the cowl.

Reading with 5W 30, hot idle about 20 psi, full throttle 40 psi.

On the (sick) dyt 4000 I put on a mechanical oil pressure gauge with a nylon line, but it kept blowing at the filter fitting. Then I went electric . It was 4 times the cost with the sender but promised a lot and delivered leak free for a number of years. But in the last couple years it started periods of erratic fluttering after hard, hot use with rough terrain...So....

I put on a mechanical gauge , but this time with copper line. I have read it will break so I put in gentle service loops and two rubber stabilizers for vibration damping. The connection at the filter port and the gauge have brass compression rings. You cannot reuse old compression rings. To avoid paying for a whole kit I was able to buy bulk 1/8" line at an auto store and found an on- line source for round compression rings (vs the pointy style). By adding a little washer on top of the ring , the screw caps seemed to lock the lines. We will see.

The dash had an imprinted cutout on left side above the cigarette lighter (reserved for the Brits?). The gauge is a push fit there and visible through the steering wheel spoke cutout. So...ammeter regular place, oil temp gauge to its right, time meter sheltered inside the cowl.

Reading with 5W 30, hot idle about 20 psi, full throttle 40 psi.

#38

M

motoman

M

motoman

I know I said enough, but a couple items.

The 60 page download of the manual mentioned earlier can be reduced by stopping at the English portion.

Sighting gas level is easier from the rear of the tractor if it has about a gallon or more. You can see it in the top of the tank just under the seat.

The tractor now has about 15 hours.

A quick description of the oil pressure take-off from the filter casting: To avoid a 180 degree reversal of the line toward the dash I used some brass fittings from Lowes-all 1/8 NPT. On the dyt 4000 I feel the reversal loop of the nylon line stressed the compression joint and contributed to leakage and separation. Anyway starting at the foward-facing 1/8 plug . You must remove the oil filter to gain working room. Remove the plug. Use a 90 deg 1/8 male/female and tighten it so the female is facing outward (parallel to the filter). Get a 1/8 male/male "nipple" (small pipe actually) about 3" long. This will extend out far enough to drop the line routing below the filter. Another 1/8 female/female fitting pointing slightly down will accept the compression fitting, and allow the copper line to be routed along the frame and then up to the dash. I did have to relieve the plastic dash cover near the frame for line clearance. (Using an oil cooler "sandwich" avoids this exercise as it will have a dash-pointed port to use).

The starter is jamming on startup when cold. It feels like the primitive British cars I used to own. Stopping the crank unlocks the jammed condition. I may have to go in on this. I am way too far from the dealer I purchased from and the local one is doubtful. Neither do I have a truck. No jamming when hot. Tooth engagement? Solenoid? You comments or experience appreciated.

The 60 page download of the manual mentioned earlier can be reduced by stopping at the English portion.

Sighting gas level is easier from the rear of the tractor if it has about a gallon or more. You can see it in the top of the tank just under the seat.

The tractor now has about 15 hours.

A quick description of the oil pressure take-off from the filter casting: To avoid a 180 degree reversal of the line toward the dash I used some brass fittings from Lowes-all 1/8 NPT. On the dyt 4000 I feel the reversal loop of the nylon line stressed the compression joint and contributed to leakage and separation. Anyway starting at the foward-facing 1/8 plug . You must remove the oil filter to gain working room. Remove the plug. Use a 90 deg 1/8 male/female and tighten it so the female is facing outward (parallel to the filter). Get a 1/8 male/male "nipple" (small pipe actually) about 3" long. This will extend out far enough to drop the line routing below the filter. Another 1/8 female/female fitting pointing slightly down will accept the compression fitting, and allow the copper line to be routed along the frame and then up to the dash. I did have to relieve the plastic dash cover near the frame for line clearance. (Using an oil cooler "sandwich" avoids this exercise as it will have a dash-pointed port to use).

The starter is jamming on startup when cold. It feels like the primitive British cars I used to own. Stopping the crank unlocks the jammed condition. I may have to go in on this. I am way too far from the dealer I purchased from and the local one is doubtful. Neither do I have a truck. No jamming when hot. Tooth engagement? Solenoid? You comments or experience appreciated.

#39

M

motoman

M

motoman

Ole Red Craftsman DYT 4000 is running again. Took 24 hours labor, mostly cleaning oil sludge off the heat shields behind the carb and the vertical surface of the sump. Before removing head #l 1 took compression reading. Both 130 cold, but after running engine about 5 minutes with cyl #1 hitting I took another compression reading and # 1 had dropped 10 psi while #2 was still at 130. With that and the sludge from the cyl 1 area I decided to look at the head gasket. No obvious track, but a dark crosshatch on the cylinder and head towards the exhaust side . No dark oil in the pushrod tunnels. After reassembly no life at all in cyl #1 which was not highly motivating. This time cyl #1 would not even start, Swapped plugs , no. Checked spark at #1, none. So spark became suspect. Removed shroud and looked at #1 spark unit. Looked like the leading side was gapped , and yes sitting at.020." Reduced to .010"and fired up!! Was gasket necessary? Unknown, but had it on hand and what a mess that oil sludge was. Now I can pick up some leaves!

#40

ken_clifton

ken_clifton

Glad you got it going again Motoman. The area you mention with the oil sludge is in close proximity to the crankcase breather on the Intek. I replaced my PCV/breather when I had the carb, intake and airbox off.

The manual says that the flywheel needs to be pulled, but that was not necessary. The reason I replaced the PCV/Breather is the rubber hose that comes out the top and then turns 90 degrees into the airbox was leaking oil. The PCV/breather checked out okay, but the rubber hose gets a lot of vibration causing the rubber to metal joint to become worn and loose. It has been dry ever since -- just fyi.

Best,

ken_clifton

The manual says that the flywheel needs to be pulled, but that was not necessary. The reason I replaced the PCV/Breather is the rubber hose that comes out the top and then turns 90 degrees into the airbox was leaking oil. The PCV/breather checked out okay, but the rubber hose gets a lot of vibration causing the rubber to metal joint to become worn and loose. It has been dry ever since -- just fyi.

Best,

ken_clifton

#41

M

motoman

M

motoman

Ken, Thanks, If that is the culprit a lot of work for a simple fix-ha ha. From new I did have problems with dirty intake throat and could not figure it out. At about year two I finally found that the 90 degree rubber connection had not been seated by the factory at the bottom of its annular groove in the intake hole (could not see it from above).. That had let the Intek suck dirt while I carefully cleaned and changed the air cleaner above. I just read on another site that Briggs actually replaced engines due to this problem. How mine survived is a mystery.

As noted the engine runs ok now but surges like governor is working even in constant state. I will look at the springs.

Something I found I did not mention previously. While cleaning the head I noticed one edge of the casting had a shiny mark. I intended to "clearance" it before assembly, but forgot. After I found the spark module rotated .010" beyond spec at the right side I guess it was a contact point with the head? Vibration?

As noted the engine runs ok now but surges like governor is working even in constant state. I will look at the springs.

Something I found I did not mention previously. While cleaning the head I noticed one edge of the casting had a shiny mark. I intended to "clearance" it before assembly, but forgot. After I found the spark module rotated .010" beyond spec at the right side I guess it was a contact point with the head? Vibration?

#42

M

motoman

M

motoman

Needing to "lay in " some filters for the new machine some trivia from online and strolling H Depot and Lowes. The air cleaner spec'd on the Husky hood, 591334 is apparently superseded by 594201 , both without foam wrap. Came across pn 5428K which appears the same , but with foam wrap. On a hook at HDepot was item of interest, a John Deere air cleaner about an inch longer with foam, GY21055, but pricey. Not sure about the spigot fit. Might try it.

The small oil filter did not appear in the big box stores (or I missed it) pn 795137 (?possibly 696854)

The breather part for the dyt 4000 Intek mentioned earlier is 792185. Could not find the rubber goose neck available separate. Online.

The small oil filter did not appear in the big box stores (or I missed it) pn 795137 (?possibly 696854)

The breather part for the dyt 4000 Intek mentioned earlier is 792185. Could not find the rubber goose neck available separate. Online.

#43

ken_clifton

Motoman,

I believe just the hose is B/S part number 792184 now.

Amazon shows the rubbler hose p/n 792184 as available, albeit for around $11.00, which sounds steep to me.

They have the entire PCV/Breather with the hose and gasket 792185 for around $18.00 -- I am sure it is cheaper elsewhere.

These rubber items sure do not hold up well on the Briggs. My Intek used to have a rubber hose from the valve cover to the fuel pump -- the pulse line. I could only go about 1 year, and sometimes not even that before those hoses would split, and they were not cheap either. I finally just ordered some of the Vanguard cast aluminium valve covers (very inexpensive by the way) and drilled and pipe-tapped the one on that side with a 90 degree barb fitting. Now I use standard 1/4 inch fuel line there. It has never split.

Best,

ken_clifton

ken_clifton

The breather part for the dyt 4000 Intek mentioned earlier is 792185. Could not find the rubber goose neck available separate. Online.

Motoman,

I believe just the hose is B/S part number 792184 now.

Amazon shows the rubbler hose p/n 792184 as available, albeit for around $11.00, which sounds steep to me.

They have the entire PCV/Breather with the hose and gasket 792185 for around $18.00 -- I am sure it is cheaper elsewhere.

These rubber items sure do not hold up well on the Briggs. My Intek used to have a rubber hose from the valve cover to the fuel pump -- the pulse line. I could only go about 1 year, and sometimes not even that before those hoses would split, and they were not cheap either. I finally just ordered some of the Vanguard cast aluminium valve covers (very inexpensive by the way) and drilled and pipe-tapped the one on that side with a 90 degree barb fitting. Now I use standard 1/4 inch fuel line there. It has never split.

Best,

ken_clifton

#44

M

motoman

M

motoman

Ken, I will look for the pn you suggested for the hose. Odd your experience with the little fuel pump hose as mine has lasted 12 years. Sounds like yours was not the fuel/oil proof stuff, perhaps just black vacuum line, or Chinese copy? BTW looks like Jacks is the way to go for the whole breather assy with tube for $12 plus ship- a picture pops up either there or partstree. I see two fuel filters on one of your pics (??). thanks

#45

ken_clifton

Ah, yes, the two fuel filters... Here is the story behind that:

The first filter is really just a screen -- notice it is red in color. It is a WIX strainer filter for diesel engines -- around 150 microns. That is installed prior to the fuel pump. This is because if you put too fine of a filter between a gravity fed fuel tank and the pump it can cause issues. On the SCAG the fuel tank is only about 3-4 inches above the filter and the fuel liine is about 3 feet long. Putting a fine filter like the normal 25 micron Briggs is just asking for trouble in hot weather especially.

The second filter is a fine 12 micron (if memory serves) located between the fuel pump and the carburetor. At this point in the system the fuel pump is "pushing/pumping" the fuel, so it has sufficient force to overcome the restriction caused by the fine fuel filter.

This is the normal setup for most racing -- a strainer or screen prior to the fuel pump and then a fine fuel filter between the pump and the carburetor. This has worked well for me for many years. I seldom if ever change the strainer, only the fine 12 micron filter.

ken_clifton

ken_clifton

I see two fuel filters on one of your pics (??). thanks

Ah, yes, the two fuel filters... Here is the story behind that:

The first filter is really just a screen -- notice it is red in color. It is a WIX strainer filter for diesel engines -- around 150 microns. That is installed prior to the fuel pump. This is because if you put too fine of a filter between a gravity fed fuel tank and the pump it can cause issues. On the SCAG the fuel tank is only about 3-4 inches above the filter and the fuel liine is about 3 feet long. Putting a fine filter like the normal 25 micron Briggs is just asking for trouble in hot weather especially.

The second filter is a fine 12 micron (if memory serves) located between the fuel pump and the carburetor. At this point in the system the fuel pump is "pushing/pumping" the fuel, so it has sufficient force to overcome the restriction caused by the fine fuel filter.

This is the normal setup for most racing -- a strainer or screen prior to the fuel pump and then a fine fuel filter between the pump and the carburetor. This has worked well for me for many years. I seldom if ever change the strainer, only the fine 12 micron filter.

ken_clifton

#46

ken_clifton

The different series of Inteks use different pulse hoses to the fuel pump. Some have a straight up hose from the valve cover to the pump. Others have hoses with a sharp 90 degree bend. Mine had the sharp 90 degree bend, it is Briggs & Stratton p/n 793147 Vacuum Hose (click for photo at Amazon). They all appear to be made in China. I got one from Jacks, another two from Morrison Outdoor Power, and one from Amazon. None of them held up for very long.

I would have to get out a magnifying glass to see the crack but they all did it. A couple of times when I didn't have one on hand, I would use some silicone rtv to patch the crack.. I am just glad I don't have to mess with that trash any longer. The cast aluminum O.E. Briggs valve covers from their "Vanguard" Intek look alike are real good, but the boxes said made in China too. I believe they were $11 each. I like them much better than the stamped steel covers -- which I think actually cost more ?

ken_clifton

ken_clifton

Ken, I will look for the pn you suggested for the hose. Odd your experience with the little fuel pump hose as mine has lasted 12 years. Sounds like yours was not the fuel/oil proof stuff, perhaps just black vacuum line, or Chinese copy?

The different series of Inteks use different pulse hoses to the fuel pump. Some have a straight up hose from the valve cover to the pump. Others have hoses with a sharp 90 degree bend. Mine had the sharp 90 degree bend, it is Briggs & Stratton p/n 793147 Vacuum Hose (click for photo at Amazon). They all appear to be made in China. I got one from Jacks, another two from Morrison Outdoor Power, and one from Amazon. None of them held up for very long.

I would have to get out a magnifying glass to see the crack but they all did it. A couple of times when I didn't have one on hand, I would use some silicone rtv to patch the crack.. I am just glad I don't have to mess with that trash any longer. The cast aluminum O.E. Briggs valve covers from their "Vanguard" Intek look alike are real good, but the boxes said made in China too. I believe they were $11 each. I like them much better than the stamped steel covers -- which I think actually cost more ?

ken_clifton

#47

M

motoman

M

motoman

I did notice the boxes and they are very dressy. Thanks for the explanation on the two fuel filters.

#48

M

motoman

M

motoman

Early on I thought the 44N ...engine (Endurance) might be a little different. Saw an old blog stating the fan is bigger, but I measured the top as the same. The JDeere filter MIU 11513 may be for a 21 hp Briggs single. Seems to have the same 1-1/2" ID and is 1 inch longer. Looks like the Husky (Intek) cover would require relief to accept that length. It was stated the oil filter crosses to Fram PH 3656 or PH 8170. I have had some problem with a Fram filter thread on an auto application recently. The lead thread defective and would not start.

#49

ken_clifton

ken_clifton

Hi Motoman,

Not to sound bad, but I have never liked Fram filters. If you ever cut one open you will see the cardboard end caps. Folks get into real long discussions about all this, but just give me some metal end caps and decent media. Personally I will never use Fram.

From the WIX filter reference, here are the specs on the original yellow (long life) Briggs oil filter:

OE Briggs OIL FILTER

Part Number: 696854

SPECS

Equipment Type Lawn Mower

Equipment Type Walk Behind Mower

Equipment Type Commercial Mower

Height 2 1/4"

Micron 28

OD 3"

7-9 PSI pressure relief

Anti-drain

Thread Size 3/4" -16

---------------------------------------

I used to run a WIX 51348 or NAPA 1348 filter. It is a little bit longer filter with more media, same thread size and 20 micron filtration.

Best,

ken_clifton

Not to sound bad, but I have never liked Fram filters. If you ever cut one open you will see the cardboard end caps. Folks get into real long discussions about all this, but just give me some metal end caps and decent media. Personally I will never use Fram.

From the WIX filter reference, here are the specs on the original yellow (long life) Briggs oil filter:

OE Briggs OIL FILTER

Part Number: 696854

SPECS

Equipment Type Lawn Mower

Equipment Type Walk Behind Mower

Equipment Type Commercial Mower

Height 2 1/4"

Micron 28

OD 3"

7-9 PSI pressure relief

Anti-drain

Thread Size 3/4" -16

---------------------------------------

I used to run a WIX 51348 or NAPA 1348 filter. It is a little bit longer filter with more media, same thread size and 20 micron filtration.

Best,

ken_clifton

#50

M

motoman

M

motoman

Ken, Thanks for the tips again. Others also dislike FRAM. I will look at WIX and NAPA.

#52

M

motoman

M

motoman

Experts say an engine needs to see 200F + temp to drive out moisture /condensation. At 40F here and running about 20 minutes with light hauling the Intek would not rise past 168F. Idling will not change that. I guess this says repeated running like this is not good and relies entirely on oil additives to deal with trapped moisture which would seem to finally reach their limit , allowing corrosion and sludging to begin.This temp being read on a Depo electronic gauge. (Never happy , right? Usually too hot. Where are the 3 bears?)

#53

M

motoman

M

motoman

Snow and ice so tried the Husqy locking diff. It pushed right through 4" snow although it would not turn sharply at speed and plowed straight ahead , pushing the turned front wheels. Slowing down avoided this mostly. All this was on level ground. Then I started down a slight incline and began to spin. Turned back. Perhaps need chains and weights. I was expecting to get "beached" on snow under the deck, but that did not happen. A good first attempt, I think.

#54

B

bertsmobile1

It is not a magic number, but a combination of heat & time.

We used to "dry" samples for assay at a variety of temperatures some very low to prevent vapourising parts of the sample.

Some times it might take a week till we got a constant weight if the temperature was very low.

B

bertsmobile1

Experts say an engine needs to see 200F + temp to drive out moisture /condensation. At 40F here and running about 20 minutes with light hauling the Intek would not rise past 168F. Idling will not change that. I guess this says repeated running like this is not good and relies entirely on oil additives to deal with trapped moisture which would seem to finally reach their limit , allowing corrosion and sludging to begin.This temp being read on a Depo electronic gauge. (Never happy , right? Usually too hot. Where are the 3 bears?)

It is not a magic number, but a combination of heat & time.

We used to "dry" samples for assay at a variety of temperatures some very low to prevent vapourising parts of the sample.

Some times it might take a week till we got a constant weight if the temperature was very low.

#55

M

motoman

M

motoman

Today 43F and put a moderate load on the Intek. The blacktop street was loaded with still frozen twigs and pine needles. Pulled a lawn aerator rake ( the kind with the spring wire teeth) on the blacktop, loosening the stuff and with the blades running to blow the road clean, slight hill. After one hour the max oil temp on the Depo gauge was 189F. So I guess it would take some snow blade work with this setup to reach target 200F+ in winter temps? Anyone try a circular restrictor on the fan intake? (Would not recommend this without a gauge)

#56

M

motoman

M

motoman

Today 49F, same task as above. Oil temp reached 198F pulling the little rake and "blowing" with the blades on. Then on level , about 6 blocks round trip to mail box, oil temp 187F, so the "work" contributed 11 degrees F to oil temp. I think this (heavier) machine uses more gas than Craftsman dyt4000, same engine, but have not measured ....and...can the 6 degree hotter ambient air through the intake raise oil temp 9 degrees F???

#57

M

motoman

M

motoman

Late cold/wet spring here, Just finished spreading 1000 lb of granular lime with a Brinley spreader which is ground driven with 11 star wheels, 40-50lb bags per shot. Ambient 50F. Intek registered max 185F on oil temp gauge. First half way "work" this season. The Intek has developed an intermittent hesitation to start after shutdown while hot. Requires two or three pushes of "smart starter" button. Sensation is low or empty fuel bowl, or ? balky? gas shutoff solenoid. Not a major problem, but a glitch. The previously mentioned "jamming" on starter application is still occasional. This thing uses more gas than my "ultra light" DYT 4000 so I find myself shutting down while e.g., I load the next bag of lime in order to save some gas. Interesting to me that the "load" of the relatively light "rake" used to clear the roadway (above in thread) produces the same oil temp as the Brinley which is digging in and a much greater load. Hmmmm? Hope y'all are having a good mowing season.

#58

ken_clifton

Hi Motoman,

Sounds like the o-rings in the bottom of that Intek carb might be starting to go. I guess that I can't complain -- mine lasted 8 years. They sit in fuel all the time and eventually start releasing pieces of rubber that clog the jets. The symptoms are exactly what you describe. I thought it was the fuel pump for the longest time.

Regarding oil temps, my SCAG Tiger Cub's oil temp was running about 220 in February when I had to mow. The ambient temps were about 60 degrees. Higher throttle settings directly relate to higher oil temps for me. I know there is a lot of talk in these forums about running the mowers wide-open. I don't do that. It would be interesting to see if the CHT tracks the oil temps...

Best,

Ken C.

ken_clifton

Requires two or three pushes of "smart starter" button. Sensation is low or empty fuel bowl, or ? balky? gas shutoff solenoid.

Hi Motoman,

Sounds like the o-rings in the bottom of that Intek carb might be starting to go. I guess that I can't complain -- mine lasted 8 years. They sit in fuel all the time and eventually start releasing pieces of rubber that clog the jets. The symptoms are exactly what you describe. I thought it was the fuel pump for the longest time.