Hi there,

I am trying to figure out what is going wrong with my 125b leaf blower. Any advice would be appreciated.

I was running it fine on Husqvarna 50:1 mix (I just mix the small bottle with 5 l gas as recommended) with premium fuel (stabilizer added to can right on pumping) and then I added a tank of Trufuel 50:1 premix in the hopes of cleaning the engine out a bit (maybe Moto Mix is better for this?). At that point I started to see issues. The engine started to run differently and I tried adjusting the carb. I went too low on the high speed adjuster and the engine just cut out and wouldn't start again.

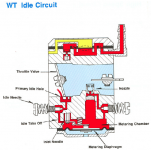

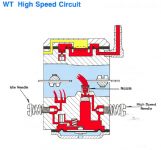

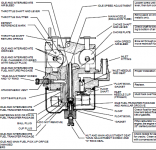

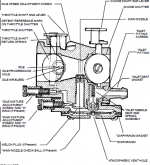

At this point I cleaned the carburetor out with carb cleaner after taking it apart. The carb components appeared to be in decent condition with no bends or brittleness. I still ordered a rebuild kit anyways just to keep things in good order. I had already cleaned the spark arrestor a few weeks but checked it and the muffler again. There was no significant buildup behind it or on the spark arrestor. What I did notice was the piston had some black oil on it... I also checked the spark plug for spark and found it had some but didn't seem strong. However, it had oil fouling. So I cleaned it off and reinstalled it. New one is on the way. The engine started up and I adjusted the low and high speed carb screws until it was running well. Both seem to be on the faster side but I can't idle it with the idle speed too low or it cuts out. Do i need to adjust the Phillips idle screw more? I ran it for about 7 minutes full throttle and then it cut out. I was able to get it to restart and finished blowing the driveway off today (about 4-5 more minutes).

Is there enough information here to begin looking deeper into this problem? I ordered a compression tester and a multimeter but I don't know if these will be helpful to diagnose this issue.

I am trying to figure out what is going wrong with my 125b leaf blower. Any advice would be appreciated.

I was running it fine on Husqvarna 50:1 mix (I just mix the small bottle with 5 l gas as recommended) with premium fuel (stabilizer added to can right on pumping) and then I added a tank of Trufuel 50:1 premix in the hopes of cleaning the engine out a bit (maybe Moto Mix is better for this?). At that point I started to see issues. The engine started to run differently and I tried adjusting the carb. I went too low on the high speed adjuster and the engine just cut out and wouldn't start again.

At this point I cleaned the carburetor out with carb cleaner after taking it apart. The carb components appeared to be in decent condition with no bends or brittleness. I still ordered a rebuild kit anyways just to keep things in good order. I had already cleaned the spark arrestor a few weeks but checked it and the muffler again. There was no significant buildup behind it or on the spark arrestor. What I did notice was the piston had some black oil on it... I also checked the spark plug for spark and found it had some but didn't seem strong. However, it had oil fouling. So I cleaned it off and reinstalled it. New one is on the way. The engine started up and I adjusted the low and high speed carb screws until it was running well. Both seem to be on the faster side but I can't idle it with the idle speed too low or it cuts out. Do i need to adjust the Phillips idle screw more? I ran it for about 7 minutes full throttle and then it cut out. I was able to get it to restart and finished blowing the driveway off today (about 4-5 more minutes).

Is there enough information here to begin looking deeper into this problem? I ordered a compression tester and a multimeter but I don't know if these will be helpful to diagnose this issue.