bassadict69

Active Member

- Joined

- Apr 2, 2014

- Threads

- 17

- Messages

- 55

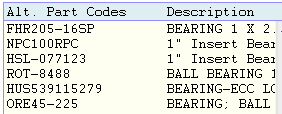

My deck is REALLY loud when the blades are engaged and I pretty sure it's the pulley bearings or spindle bearings. I would like to change them all...do all the bearings have bearings? Just trying to formulate a parts list before I get a chance to pull the mower out and look things over.