I appreciate this additional comment about the break it's interesting because it's like you just slightly take your foot off the brake and the thing shoots off like a jackrabbit it's like I'm trying to figure out how to tone it down a bit which might be a separate issue I don't know. But here's what I can say so I drove it around the yard with no mower deck engaged + I didn't really hear the noise that much it's constant like a ringing noise which seems to only occur when the blades are engaged but it's not as bad as it was say yesterday. It also feels like when I do engage blades the mower engine is working a little harder than normal when the mower deck is perfectly fine I don't know for sure on this but I'll know if I blow another head gasket this is true.

Jim

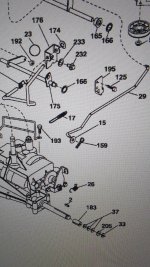

So I went to get on on the riding mower just to start it up I pressed a break in and then I take my foot off the brake there's this weird kind of loud clanging noise I've never actually heard it before I don't know what that means? I will try and upload a video to YouTube soonI appreciate this additional comment about the break it's interesting because it's like you just slightly take your foot off the brake and the thing shoots off like a jackrabbit it's like I'm trying to figure out how to tone it down a bit which might be a separate issue I don't know. But here's what I can say so I drove it around the yard with no mower deck engaged + I didn't really hear the noise that much it's constant like a ringing noise which seems to only occur when the blades are engaged but it's not as bad as it was say yesterday. It also feels like when I do engage blades the mower engine is working a little harder than normal when the mower deck is perfectly fine I don't know for sure on this but I'll know if I blow another head gasket this is true.

Jim

Thanks

Jim