You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grass isn't cut between the blades.

- Thread starter SGray

- Start date

More options

Export threadskippymud

Active Member

- Joined

- Nov 21, 2016

- Threads

- 13

- Messages

- 65

That is a giant swath of truly uncut grass, in a straight line no less. Maybe check to see if one of your blades (center) is mounted upside down by remote chance. I have an old non-tech Jacbsen 46" and I don't have this problem when I mow any grass

Attachments

SeniorCitizen

Lawn Addict

- Joined

- Aug 28, 2010

- Threads

- 147

- Messages

- 2,335

Previously mentioned , the mower is being ask to do a job it wasn't designed to do .

This pic of blade overlap is difficult to see , but if blade overlap is sufficient a straight line can't be drawn parallel to the tractor length when any 2 adjacent blades are at 90° to the tractor . That's he purpose of a 3 blade geometry .

This pic of blade overlap is difficult to see , but if blade overlap is sufficient a straight line can't be drawn parallel to the tractor length when any 2 adjacent blades are at 90° to the tractor . That's he purpose of a 3 blade geometry .

Thanks for all the recommendations/advice. I have a new long blade belt for the center/left blades and I'll get it installed this morning to see if that helps with the uncut grass striping on the left side. I don't have a short blade belt for the right blade, so I'll get one ordered and replace it soon. I'll also measure my blades to make sure they are 20.5".

Attachments

The total length of the blades is not necessarily equal to the the width of the cut because they are mounted in an offset angle from each other.I'll measure them tomorrow. I have a 60" mower, so I assume the blades should be around 20" each. I remember reading that the Cub Cadet Tank mower has overlapping blades and the pulleys and belts have teeth so that the blades are positioned at 90 degrees to each other when the belt is installed so the blades won't hit each other when turning. The teeth in the belt and pulleys prevent the belt from slipping as you don't want the blades to hit each other. The overlapping blades keep the striping from happening. Yep, I just found it online. The 60" mowing deck uses three 21" blades. That's 63" of blades for a 60" deck. Maybe Gravely should consider this design.

Make sure the blades are mounted in the proper direction

What is the length of an original blade? Compare it to the ones you have.They may be shorter than the original.

Is there a mounting angle adjustment for your deck?The angle of the deck in relation to travel direction will affect the cutting width.If the left side is offset further back than the right aside,it will create a missed spot in the grass and also reduce total cut width.Check your actual cutting path width.

The 20.5” measurement is taken diagonally.Thanks for all the recommendations/advice. I have a new long blade belt for the center/left blades and I'll get it installed this morning to see if that helps with the uncut grass striping on the left side. I don't have a short blade belt for the right blade, so I'll get one ordered and replace it soon. I'll also measure my blades to make sure they are 20.5".

How to Measure Lawn Mower Blades - Fisher Barton

Learn how to accurately measure a lawn mower blade in inches and millimeters to find the right replacement in our latest blog.

bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

The width of the blade is also important

A common problem is people fit a 3" wide blade of the same length as the original 2" wide blade thinking the bigger blade will be stronger & last longer

But it is actually a tiny bit shorter because it is a diagonal length so you do not get enough overlap and this leaves an uncut line

So slip the deck off or get under the mower and turn the blades so they are in line with each other

The gap between the two blades should be no more than around 1/8"

To save metal modern decks are shorter front to back so there is less space for overlap without the blades hitting

Old 42" decks used to have blades from 21.5" to 21.75"

But now days they are either just 21" so need replacing almost every season or 21.25" tops

A common problem is people fit a 3" wide blade of the same length as the original 2" wide blade thinking the bigger blade will be stronger & last longer

But it is actually a tiny bit shorter because it is a diagonal length so you do not get enough overlap and this leaves an uncut line

So slip the deck off or get under the mower and turn the blades so they are in line with each other

The gap between the two blades should be no more than around 1/8"

To save metal modern decks are shorter front to back so there is less space for overlap without the blades hitting

Old 42" decks used to have blades from 21.5" to 21.75"

But now days they are either just 21" so need replacing almost every season or 21.25" tops

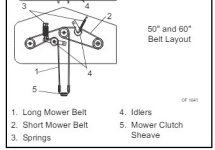

Add a spring to the springs (#3) to add tension to the left belt around the pulley because it is longer than the distance around the shorter side of the right pulley.These springs can get weak over time,and that will make the left side slip easier than the right side.This is why the factory installed multiple springs on the idler on the left side blade.Thanks for all the recommendations/advice. I have a new long blade belt for the center/left blades and I'll get it installed this morning to see if that helps with the uncut grass striping on the left side. I don't have a short blade belt for the right blade, so I'll get one ordered and replace it soon. I'll also measure my blades to make sure they are 20.5".

Do this before installing new belt,you may not need a new belt after all,just save it for later.

Take off one spring and take it to a hardware store for comparison.A same diameter,shorter spring will be good,as long at the wire of the spring is the same gauge diameter is the same.You should be able to tell the difference by pulling on them to compare.All new springs of the stronger type will be better.Stronger is better,up to a point.Excessively strong springs will shorten the idler bearing life.

After years of slipping,the left side pulley may be worn to the point where it is not gripping the belt properly.The pulley pulls on the SIDES of the belt,not the center.That is why the profile of the belt is tapered,like driving a wedge into a block of wood.

The belt should not go so deep that it hits the bottom of the pulley.The shiny side of the pulley should look to be the same width as all the other pulleys

If this is the case,which I suspect,change the pulley and the belt(after adding springs to idler).

Put a little paint or lipstick on the pulley shiny inside and compare to the right side pulley to see if the groove in the pulleys is the same width.

Last edited:

Tiger Small Engine

Lawn Addict

- Joined

- Dec 7, 2022

- Threads

- 3

- Messages

- 1,659

Add a spring to the springs (#3) to add tension to the left belt around the pulley because it is longer than the distance around the shorter side of the right pulley.These springs can get weak over time,and that will make the left side slip easier than the right side.This is why the factory installed multiple springs on the idler on the left side blade.

Do this before installing new belt,you may not need a new belt after all,just save it for later.

Take off one spring and take it to a hardware store for comparison.A same diameter,shorter spring will be good,as long at the wire of the spring is the same gauge diameter is the same.You should be able to tell the difference by pulling on them to compare.All new springs of the stronger type will be better.Stronger is better,up to a point.Excessively strong springs will shorten the idler bearing life.

After years of slipping,the left side pulley may be worn to the point where it is not gripping the belt properly.The pulley pulls on the SIDES of the belt,not the center.That is why the profile of the belt is tapered,like driving a wedge into a block of wood.

The belt should not go so deep that it hits the bottom of the pulley.The shiny side of the pulley should look to be the same width as all the other pulleys

If this is the case,which I suspect,change the pulley and the belt(after adding springs to idler).

Put a little paint or lipstick on the pulley shiny inside and compare to the right side pulley to see if the groove in the pulleys is the same width.

The fact that the dealer had your mower a month, fixed nothing, and said it was the best he could do and gave up, is mind boggling.

I replaced the long belt for the left and center blades and it made no difference. The blades are 20.5" in length, measured diagonally. The long belt spring is supposed to be 13-13.25" in length. I have it stretched a bit more to 13.5" to add some tension to the belt on the sheaves. The 2 stripes are still there. I dropped it off with my local equipment rental company yesterday that also does maintenance on mowers, weed eaters, tractors, skid steers, etc. The mechanic there thinks the problem might be related to my broken anti-scalp wheels on the front of the deck. He's going to give my engine a tune-up, replaced the anti-scalp wheels, level the deck, etc., and we'll see if the problems persist or not. Thanks everyone for your ideas and suggestions.