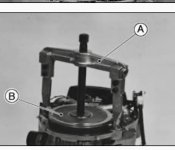

Any tips as to how I should attempt to remove the flywheel from my Kawasaki FH580v? As you can see in the photo it is held on by bolt, not by nut and there are no holes to attach a wheel puller. I've watched several videos, but none seem to apply to this engine. I'm trying to access the breather cover/gasket in hopes of stopping an oil leak. I've applied a good dose of PB Blaster penetrating oil and realize it might take more and plenty of time.

Thanks

Thanks