You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Craftsman 917272011 blades not engaging and kills engine

#1

2

2sellallcars

2

2sellallcars

new here, so have a craftsman 917272011 mower. runs like a champ. when running, i pull the knob for the blades to engage and it kills the motor. There is a wire set up that goes down to the bottom of the mower for i am assuming the clutch set up that makes the belt go around and shows continuity when the knob is pulled on. Not sure what else to do or look for. Any and all help is much appreciated. Thank you

#2

ILENGINE

ILENGINE

Does it die when you release the clutch/brake pedal also. also if you remove the deck beck and try to engage the deck does the engine stay running. If it dies with the pedal then most likely something to do with the seat switch. if it keeps running with the deck belt disconnected then something on the deck is jamming the blades.

#4

Cusser

You may find it easier to diagnose and repair if your drop the deck.

Cusser

From my experience with my own 2005 LT1000, when that has happened to me there has been a physical explanation for the deck mechanism not working, like something stuck or broken. Can you turn the blades by hand? Can you move the drive belt by hand?if it keeps running with the deck belt disconnected then something on the deck is jamming the blades.

You may find it easier to diagnose and repair if your drop the deck.

#6

2

2sellallcars

2

2sellallcars

So the clutch harness is bypassed and so seems to be the seat as well, cause I don’t have to be on it to start.

So I removed the deck belt from the bottom of the motor, pulled the engage knob up by the steering wheel and kills the motor.

So I removed the deck belt from the bottom of the motor, pulled the engage knob up by the steering wheel and kills the motor.

#7

StarTech

StarTech

Seat switches on these mowers tend to go bad due 12v running thru them. Also the operator present relay tends to go bad usually from moisture getting in it rusting the mechancial part to where it will not move.

If seat switch is bad or simply unplugged the relay will not operate at all; therefore the electric clutch will not even engage. If the seat switch connection is jumper-ed then the whole operator safety system is inoperative.

If seat switch is bad or simply unplugged the relay will not operate at all; therefore the electric clutch will not even engage. If the seat switch connection is jumper-ed then the whole operator safety system is inoperative.

#8

2

2sellallcars

2

2sellallcars

Will double check this evening and see what is bypassed. Thanks for your response back

#9

2

2sellallcars

2

2sellallcars

Back at it.

So I can either have the seat plugged in or disconnected a jumper, start the motor and it dies.

I also have the drive belt for the deck still disconnected.

i also disconnected the electric clutch wires. With the clutch pressed in or out , i pull the engage for the blades and kills the motor still.

I wonder if for some reason the pull knob for the blades is out or has the problem

Let me know what you think.

So I can either have the seat plugged in or disconnected a jumper, start the motor and it dies.

I also have the drive belt for the deck still disconnected.

i also disconnected the electric clutch wires. With the clutch pressed in or out , i pull the engage for the blades and kills the motor still.

I wonder if for some reason the pull knob for the blades is out or has the problem

Let me know what you think.

#10

shadetree#1

shadetree#1

from post #6 you wrote:

So the clutch harness is bypassed and so seems to be the seat as well, cause I don’t have to be on it to start.

Are you saying it will crank with the clutch not depressed?

Have you ever seen this mower operate correctly or is it a new to you mower?

Reason I ask is if you are saying it will crank and start with the clutch up and no one in the seat it appears someone has been hacking on the wiring harness and defeating the safety switches.

Here is a link to a owners manual for that rig.

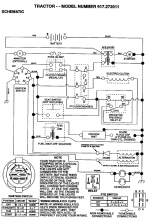

Troubleshooting on page 30, 31, 32, and wiring diagram on pg 33.

So the clutch harness is bypassed and so seems to be the seat as well, cause I don’t have to be on it to start.

Are you saying it will crank with the clutch not depressed?

Have you ever seen this mower operate correctly or is it a new to you mower?

Reason I ask is if you are saying it will crank and start with the clutch up and no one in the seat it appears someone has been hacking on the wiring harness and defeating the safety switches.

Here is a link to a owners manual for that rig.

Troubleshooting on page 30, 31, 32, and wiring diagram on pg 33.

#11

2

2sellallcars

2

2sellallcars

No sorry, when the motor running, and wether the clutch is in or out and then I pull engage knob out the motor dies.

And this is also with the deck belt disconnected

And this is also with the deck belt disconnected

#12

StarTech

StarTech

Hmmm. I assume that someone was able to read a simple electrical schematic. Apparently not.

That like the Cub Cadet that I am now repairing where the OM fried the connector at the brake switch. If weren't for my knowledge the customer would be replacing the $150 wiring harness along with several hours of labor disassembling and reassembling the mower. This is because most OEM will not sale the connectors only but insist on selling complete harnesses.

On the this Craftsman all the connectors and housings are available via alternate sources so it can be repair back to way the OEM had the harness.

That like the Cub Cadet that I am now repairing where the OM fried the connector at the brake switch. If weren't for my knowledge the customer would be replacing the $150 wiring harness along with several hours of labor disassembling and reassembling the mower. This is because most OEM will not sale the connectors only but insist on selling complete harnesses.

On the this Craftsman all the connectors and housings are available via alternate sources so it can be repair back to way the OEM had the harness.

#13

smalltimerpm

smalltimerpm

Is there 2 or 3 wires at the plug end that goes into the clutch? Some clutch wire harnesses have a resistor installed into them. The resistor creates voltage spikes from coming back into wire harness due to the clutch being magnetic. If the resistor is bad. Well... you have the result.

#14

R

riceski@gmail.com

SLOW DOWN OK -- - GO TO YOUTUBE AND SPEND SOME TIME THERE.

R

riceski@gmail.com

FROM MY EXPERIENCE SOME KRAFTSMAN MOWERS HAVE A LITTLE PIECE UNDER THE SEAT. I HAD A PRO WHO KNEW DUG IT OUT AND IT NEVER GAVE ME A PROBLEM AFTER THAN.new here, so have a craftsman 917272011 mower. runs like a champ. when running, i pull the knob for the blades to engage and it kills the motor. There is a wire set up that goes down to the bottom of the mower for i am assuming the clutch set up that makes the belt go around and shows continuity when the knob is pulled on. Not sure what else to do or look for. Any and all help is much appreciated. Thank you

SLOW DOWN OK -- - GO TO YOUTUBE AND SPEND SOME TIME THERE.

#16

StarTech

OP, Find the operator present relay and remove it then test. It is located in the operator steering tower.

StarTech

According to the schematic there is no reverse inhibit.Are you sure that it is in neutral and not reverse?

OP, Find the operator present relay and remove it then test. It is located in the operator steering tower.

#17

B

Bertrrr

B

Bertrrr

check the wires at the clutch for short to ground when you pull your clutch switch. If there is no reading to ground , it aint your switch , clutch or those wires. There are several safety relays that all tie in to the same circuit

I would hop 12 volts to the " clutch " wire + with engine running and see where that takes you.

You never said that the clutch is actually engaging and stopping the engine but with the belt off it's unlikely so probably the circuit for the safetys.

I would hop 12 volts to the " clutch " wire + with engine running and see where that takes you.

You never said that the clutch is actually engaging and stopping the engine but with the belt off it's unlikely so probably the circuit for the safetys.

#18

StarTech

StarTech

Personally I no longer solder wires together on mower but instead use terminal slices and heat shrink. The terminal splices takes less space than butt connectors. But of course I deal with terminal fuses that require the terminal splices as you can't solder these.

#19

T

TobyU

T

TobyU

Typically, in that situation, it is the clutch switch. I'm not really a fan of bypassing that switch even for test purposes because it just usually doesn't go bad that often. Normally it's on an MTD especially bolens or yard machines or a John Deere where the plunger isn't getting pushed in enough or the switch is little barbed fingers have popped out of the metal hole so it's not getting pushed in because of that but the switch itself is usually good and you can push it with your finger and hold it to check.

The way that system is supposed to work is it should crank and run even if you are not on the seat as long as the clutch is locked down in the parking brake position and the blades are turned off.

When it's running that way it will die as soon as you turn on the blades because there's nothing on the seat.

It's also worth mentioning I've seen some of these seat switches that have a small tab right in the middle of the wire connector that plugs onto the seat switch that is spring loaded that you can press in that stays pressed wants the connector is pressed on to the seat switch. It's important for this to be pressed into even if your bypassing it but that wouldn't give your symptoms.

I have used and I'll meet her on a couple of clutch switches but more commonly on the ones on the handles for zero turn that turn off the blades when you go into reverse because those have four wire connectors if I remember correctly and can be flaky and not changing the continuity back and forth the way it should if you compare it to a new switch even though it is doing something it's just not doing it right.

My guess on yours is a rubbed or bare wire somewhere in that kill switch wiring involving the seat or clutch but more than likely in the clutch area before it heads to the seat to end.

This whole system is about like any other riding mower that ends up going back to your coil and it simply grounds that coil tab wire to the frame to kill the ignition so if any part of that wire gets shorted to ground it's not going to have spark.

It is possible that it's your PTO switch because they do fail but I find weird problems like that more often on the commercial walk behind Toro's that have that plastic module box right near the PTO switch.

The way that system is supposed to work is it should crank and run even if you are not on the seat as long as the clutch is locked down in the parking brake position and the blades are turned off.

When it's running that way it will die as soon as you turn on the blades because there's nothing on the seat.

It's also worth mentioning I've seen some of these seat switches that have a small tab right in the middle of the wire connector that plugs onto the seat switch that is spring loaded that you can press in that stays pressed wants the connector is pressed on to the seat switch. It's important for this to be pressed into even if your bypassing it but that wouldn't give your symptoms.

I have used and I'll meet her on a couple of clutch switches but more commonly on the ones on the handles for zero turn that turn off the blades when you go into reverse because those have four wire connectors if I remember correctly and can be flaky and not changing the continuity back and forth the way it should if you compare it to a new switch even though it is doing something it's just not doing it right.

My guess on yours is a rubbed or bare wire somewhere in that kill switch wiring involving the seat or clutch but more than likely in the clutch area before it heads to the seat to end.

This whole system is about like any other riding mower that ends up going back to your coil and it simply grounds that coil tab wire to the frame to kill the ignition so if any part of that wire gets shorted to ground it's not going to have spark.

It is possible that it's your PTO switch because they do fail but I find weird problems like that more often on the commercial walk behind Toro's that have that plastic module box right near the PTO switch.

#20

K

kjonxx

K

kjonxx

Do you hear the clutch click if not try unplugging it then turn on. Could be shot. or pto switch is bad.

#21

J

Jack3q

J

Jack3q

I tend to agree with shadetree1, maybe check for short to ground on the deck knob wiring, can you unplug it?

#22

B

bertsmobile1

B

bertsmobile1

Just a thought

Electric clutches are a big current draw item.

If the clutch is bad as in dead short or the switch goes dead short then this might momentarily cut off power to the fuel solenoid which will also cause the engine to stop .

A bit left field but has been known to happen particularly if the battery is a little low or the charging system is not working as well as it could .

Electric clutches are a big current draw item.

If the clutch is bad as in dead short or the switch goes dead short then this might momentarily cut off power to the fuel solenoid which will also cause the engine to stop .

A bit left field but has been known to happen particularly if the battery is a little low or the charging system is not working as well as it could .

#23

StarTech

StarTech

#24

StarTech

But here an image of two 16ga wires joined by the splice. I don't think there is much bulk there

StarTech

As with even soldered wires you must stagger those connection points. Those splices are not much bigger than the 16 ga wires with insulation. The only difference is the heat shrink.There is a harness with multiple wires. If you put several of those, they add up.

But here an image of two 16ga wires joined by the splice. I don't think there is much bulk there

#25

StarTech

StarTech

Well you are a few hundred harnesses behind me then. Plus I have doing this for 40 yrs now.I did not stagger anything. I solder and shrinktube them. I spliced wherever they were cut. That was the 2nd wiring issue I had that was repaired. The first was the stator wire that was too close to the flywheel, was sheared off. Clean cut like a razor cut. I had ordered a new stator, and when I went to replace it, I found the sheared wire and realized the stator was still good. I replaced it anyway, and re-routed the 2 wires. The wiring on these mowers left a lot to be desired as far as quality. They seemed put together with carelessness and sloppiness.

#26

V

Vinnie S.

V

Vinnie S.

Um, no. I'm probably well ahead on you with working with harnesses. You see, wiring harnesses are in everything electrical/electronic. I have soldered far more wires and harnesses (since early 1980s), then you never ever crimped. And the one thing I have learned about soldering wire, that it is superior to the cheesy crimps that you use. Especially when you take oxidation resulting from being exposed to the elements. Another thing I learned in my 40+ years, is that the reason people don't solder, is because they can't. Not impressed with your 40 cheesy years. LOLWell you are a few hundred harnesses behind me then. Plus I have doing this for 40 yrs now.

#27

V

Vinnie S.

V

Vinnie S.

What a crap job. LOL. You charge people for that? LOLAs with even soldered wires you must stagger those connection points. Those splices are not much bigger than the 16 ga wires with insulation. The only difference is the heat shrink.

But here an image of two 16ga wires joined by the splice. I don't think there is much bulk there

View attachment 63498

#28

B

bertsmobile1

Keep this up & I will put some gloves on you both & sell tickets .

Back to the actual problem

If you make some short jumper wires with a blade terminal at both ends you can unplug the PTO switch and make the contacts shown in the bottom of the circuit diagram manually .

Problem goes away switch is bad

Problem persists then switch is good & problem is elsewhere .

B

bertsmobile1

OK you twoWhat a crap job. LOL. You charge people for that? LOL

Keep this up & I will put some gloves on you both & sell tickets .

Back to the actual problem

If you make some short jumper wires with a blade terminal at both ends you can unplug the PTO switch and make the contacts shown in the bottom of the circuit diagram manually .

Problem goes away switch is bad

Problem persists then switch is good & problem is elsewhere .

#29

StarTech

StarTech

I done decide to leave this thread and also decided ignore his crap from now on...just trying there was better way then having to solder everything. Beside I never seen the Briggs kill harnesses corroded.

#30

Scrubcadet10

Scrubcadet10

He left as well.

lets quit criticizing each others work as much, i've gotten several PM's of people leaving because of this. yeah, their work may not be as good as professional, let them figure it out on their own. If or when their work fails they can fix it again, and again, if they have to.

lets quit criticizing each others work as much, i've gotten several PM's of people leaving because of this. yeah, their work may not be as good as professional, let them figure it out on their own. If or when their work fails they can fix it again, and again, if they have to.

#31

T

TobyU

What matters to us individually it takes or how hard or easy it is to do it. I'm going to have to agree with him that a solder connection is one of the best out there especially if you wrap the wires first and then solder and then tape or heat shrink but wrapping them together can cause some bulk but normally that's not a concern on a mower.

Notice I said it's one of the best connections. I didn't say it was the best fix because I have never soldered a single wire on a lawn mower and I've been doing this for decades!

I don't have the time for all that!

Sure, he can come back and tell us how simple it is because he has a propane a small hand torch for one of those newfangled harbor freight instant pot instant cold $12.99 soldering tools but I don't play that game.

I have a set of crimpers some quick connects some cramp connectors some wire nuts some good 3M brand electrical tape and heat shrink.

Far faster for me too stretch, pope, twist.. or actually separate, cut, strip, insert and squeeze than it is to solder but again personal preference.

I don't have any problem with people with differences of opinion but we don't need to be jerks to each other..

My way is the best for me and your way is the best for you and his way is the best for him. Works out just fine. Lol

T

TobyU

No reason to leave and no reason to ignore anybody. You do it your way and he will do it his. I'll probably do it a third different way and we'll probably all three get the same end result that fixes the problem and that's really all that matters.I done decide to leave this thread and also decided ignore his crap from now on...just trying there was better way then having to solder everything. Beside I never seen the Briggs kill harnesses corroded.

What matters to us individually it takes or how hard or easy it is to do it. I'm going to have to agree with him that a solder connection is one of the best out there especially if you wrap the wires first and then solder and then tape or heat shrink but wrapping them together can cause some bulk but normally that's not a concern on a mower.

Notice I said it's one of the best connections. I didn't say it was the best fix because I have never soldered a single wire on a lawn mower and I've been doing this for decades!

I don't have the time for all that!

Sure, he can come back and tell us how simple it is because he has a propane a small hand torch for one of those newfangled harbor freight instant pot instant cold $12.99 soldering tools but I don't play that game.

I have a set of crimpers some quick connects some cramp connectors some wire nuts some good 3M brand electrical tape and heat shrink.

Far faster for me too stretch, pope, twist.. or actually separate, cut, strip, insert and squeeze than it is to solder but again personal preference.

I don't have any problem with people with differences of opinion but we don't need to be jerks to each other..

My way is the best for me and your way is the best for you and his way is the best for him. Works out just fine. Lol

#32

smalltimerpm

smalltimerpm

Well I think that's what they were doing and they both found a reason to leave and both found a reason to ignore! It's life...get them together and put a wrench in their hand after a year or 2 of working together they will agree on somethingNo reason to leave and no reason to ignore anybody. You do it your way and he will do it his. I'll probably do it a third different way and we'll probably all three get the same end result that fixes the problem and that's really all that matters.

What matters to us individually it takes or how hard or easy it is to do it. I'm going to have to agree with him that a solder connection is one of the best out there especially if you wrap the wires first and then solder and then tape or heat shrink but wrapping them together can cause some bulk but normally that's not a concern on a mower.

Notice I said it's one of the best connections. I didn't say it was the best fix because I have never soldered a single wire on a lawn mower and I've been doing this for decades!

I don't have the time for all that!

Sure, he can come back and tell us how simple it is because he has a propane a small hand torch for one of those newfangled harbor freight instant pot instant cold $12.99 soldering tools but I don't play that game.

I have a set of crimpers some quick connects some cramp connectors some wire nuts some good 3M brand electrical tape and heat shrink.

Far faster for me too stretch, pope, twist.. or actually separate, cut, strip, insert and squeeze than it is to solder but again personal preference.

I don't have any problem with people with differences of opinion but we don't need to be jerks to each other..

My way is the best for me and your way is the best for you and his way is the best for him. Works out just fine. Lol

#33

M

Mrjeff62

M

Mrjeff62

I have had the same issue with mine. First issue was the seat safety switch... I'm barely heavy enough to compress the seat springs to activate the safety relay. So I bypassed it. Second issue was netwrap got wound around the blades, which prevented them from turning, thus killing the engine when engaged. I had to take the blades off to completely clear the mess. Third, the switch itself seem to be going out, I imagine from age and wear and tear. I currently have a bungie cord hooked to the left side of the steering column running across to the red engage button with just enough tension to keep slight side pressure on the button. This seems to be working so far.new here, so have a craftsman 917272011 mower. runs like a champ. when running, i pull the knob for the blades to engage and it kills the motor. There is a wire set up that goes down to the bottom of the mower for i am assuming the clutch set up that makes the belt go around and shows continuity when the knob is pulled on. Not sure what else to do or look for. Any and all help is much appreciated. Thank you

#34

B

bigunn

B

bigunn

Had this problem on one of my craftsman it would run with the clutch depressed if I sat on the seat and either I pulled the blade switch it would kill the engine if I let the clutch it would kill the engine so was looking at the wiring and found a relay behind the battery I had a bunch of relays found a match and it solved the problem.

#35

StarTech

Then a darn Briggs pressure washer comes in a leaking pump. Briggs has NLA the pump seals. Briggs is getting to where everything I order is NLA. Then I get snapped at here for offering a different way of doing the job as I solder will stiffen the wires. On top of that I had warm up my fingers in my coffee because they were hurting so bad from the cold. Adding the guy to my ignore list just means I not wasting my time reading his posts; unless, I want to.

And I have used about every method of soldering over the years. Some works better than others. But just haven't much experience with the hot air method for doing surface mounts yet. I started using the splices as I had make up several Briggs kill harnesses over the winter. And I had been looking for them for years to install thermal fuses and make other repairs where solder just will not hold or work. One place is portable heater elements. They perform just just as well as other solderless terminals such the F56 (GM, Aptriv) terminals that use open barrel crimps. You can also add an extra wire (tap) without cutting the first wire in two, just remove enough insulation to make the connection and reseal the insulation with heat shrink, liquid tape, or whatever you normally use; just not scotch tape or paper tape.

StarTech

I not completely gone just went to lurking mode. Yesterday was a bad day in the shop here. Everything went wrong. ATV that came in for u joints needs a new drive shaft instead because the idiot drove until u-joint ears are ready to break. I wasted my time buying the u-joints. What worst is that if install a new half shaft it is $400 vs $75 it was for the u-joints. I did manage to find an used half section but probably will need to change out the u-joint. But $50 is a lot easier on the customer's wallet.No reason to leave and no reason to ignore anybody. You do it your way and he will do it his. I'll probably do it a third different way and we'll probably all three get the same end result that fixes the problem and that's really all that matters.

What matters to us individually it takes or how hard or easy it is to do it. I'm going to have to agree with him that a solder connection is one of the best out there especially if you wrap the wires first and then solder and then tape or heat shrink but wrapping them together can cause some bulk but normally that's not a concern on a mower.

Notice I said it's one of the best connections. I didn't say it was the best fix because I have never soldered a single wire on a lawn mower and I've been doing this for decades!

I don't have the time for all that!

Sure, he can come back and tell us how simple it is because he has a propane a small hand torch for one of those newfangled harbor freight instant pot instant cold $12.99 soldering tools but I don't play that game.

I have a set of crimpers some quick connects some cramp connectors some wire nuts some good 3M brand electrical tape and heat shrink.

Far faster for me too stretch, pope, twist.. or actually separate, cut, strip, insert and squeeze than it is to solder but again personal preference.

I don't have any problem with people with differences of opinion but we don't need to be jerks to each other..

My way is the best for me and your way is the best for you and his way is the best for him. Works out just fine. Lol

Then a darn Briggs pressure washer comes in a leaking pump. Briggs has NLA the pump seals. Briggs is getting to where everything I order is NLA. Then I get snapped at here for offering a different way of doing the job as I solder will stiffen the wires. On top of that I had warm up my fingers in my coffee because they were hurting so bad from the cold. Adding the guy to my ignore list just means I not wasting my time reading his posts; unless, I want to.

And I have used about every method of soldering over the years. Some works better than others. But just haven't much experience with the hot air method for doing surface mounts yet. I started using the splices as I had make up several Briggs kill harnesses over the winter. And I had been looking for them for years to install thermal fuses and make other repairs where solder just will not hold or work. One place is portable heater elements. They perform just just as well as other solderless terminals such the F56 (GM, Aptriv) terminals that use open barrel crimps. You can also add an extra wire (tap) without cutting the first wire in two, just remove enough insulation to make the connection and reseal the insulation with heat shrink, liquid tape, or whatever you normally use; just not scotch tape or paper tape.

#36

shadetree#1

You previously said the seat switch is disconnected.

Have you ever operated this mower with the seat switch disconnected?

The reason I ask is because if a seat switch is disconnected, unplugged or bad when the electric PTO is en-gauged the engine will immediately die.

My point being you need to investigate/test the seat switch electrical connections and the switch with a electrical tester.

shadetree#1

Back to your post #11. (last time we heard from you)No sorry, when the motor running, and wether the clutch is in or out and then I pull engage knob out the motor dies.

And this is also with the deck belt disconnected

You previously said the seat switch is disconnected.

Have you ever operated this mower with the seat switch disconnected?

The reason I ask is because if a seat switch is disconnected, unplugged or bad when the electric PTO is en-gauged the engine will immediately die.

My point being you need to investigate/test the seat switch electrical connections and the switch with a electrical tester.

#37

C

CaptFerd

C

CaptFerd

Welcome back everyone. The guy with the problem went awol last Tuesday. Just may be that he was wanting to know what magic wire he could twist together with another to get it going again. If the sell all cars guy comes back my advice would be to study and understand the atomic bomb schematic StarTech dropped on page one. The magic wire looms through many switches and connectors to keep the mower from becoming a death trap. My crystal ball is broken so I cant tell you where the open in the circuit is. But the answers to your problem are most likely already posted in this thread.

#38

T

Thom75

I had a similar issue, After much testing,I replaced the ignition switch and fixed the problem.

T

Thom75

new here, so have a craftsman 917272011 mower. runs like a champ. when running, i pull the knob for the blades to engage and it kills the motor. There is a wire set up that goes down to the bottom of the mower for i am assuming the clutch set up that makes the belt go around and shows continuity when the knob is pulled on. Not sure what else to do or look for. Any and all help is much appreciated. Thank you

I had a similar issue, After much testing,I replaced the ignition switch and fixed the problem.

#39

T

TobyU

I streamlined the type of equipment I work on so now I turn down more than I actually take or about 50/50.

For those pressure washers, I've been telling people for years that I only work on the engine running part because in my climate, 95% of the calls I get are ones that worked fine last time they use them but they simply won't start now.

I tell them I can fix that and make them run properly but if they hook water to it and it leaks or doesn't pump I don't do those repairs and they're out of luck.

Three or four years ago maybe five or six it certainly was not cost-effective to fix them because the cheapest pump you could get even on eBay was $132. Then the pumps bottomed out to 62 to 68 dollars and I did manage to fix a small handful for people that were really nice or long-term repeat customers because it was an economical cost effective repair.

Now those pumps have gotten back up to about 80 minimum so it's borderline.

I've told a lot of them where to order and how easy it is to install the pump so they can do it themselves because frankly, I don't have the time.

I could fix 20 mowers a day and still have a backlog.

I know some of the older and more commercial grade pumps do have parts available and you can get the seal kits and files etc but most of the consumer grade ones now aren't available like that and it's an entire pump replacement.

If you haven't already, take the part number from one of them and put it into an eBay search box and you should find a price that makes it worth swapping off the pumps instead of trying to put seals and stuff like that internally.

There was a time about 9 years ago that certain parts were actually cheaper on Amazon but hasn't been the case for five or six years now. If you scroll down eBay you will be able to find better pricing on almost everything outdoor power equipment related.

T

TobyU

I feel you. Starting last year I lowered my stress level a lot with my shop I no longer taking everything that everyone wants to bring me.I not completely gone just went to lurking mode. Yesterday was a bad day in the shop here. Everything went wrong. ATV that came in for u joints needs a new drive shaft instead because the idiot drove until u-joint ears are ready to break. I wasted my time buying the u-joints. What worst is that if install a new half shaft it is $400 vs $75 it was for the u-joints. I did manage to find an used half section but probably will need to change out the u-joint. But $50 is a lot easier on the customer's wallet.

Then a darn Briggs pressure washer comes in a leaking pump. Briggs has NLA the pump seals. Briggs is getting to where everything I order is NLA. Then I get snapped at here for offering a different way of doing the job as I solder will stiffen the wires. On top of that I had warm up my fingers in my coffee because they were hurting so bad from the cold. Adding the guy to my ignore list just means I not wasting my time reading his posts; unless, I want to.

And I have used about every method of soldering over the years. Some works better than others. But just haven't much experience with the hot air method for doing surface mounts yet. I started using the splices as I had make up several Briggs kill harnesses over the winter. And I had been looking for them for years to install thermal fuses and make other repairs where solder just will not hold or work. One place is portable heater elements. They perform just just as well as other solderless terminals such the F56 (GM, Aptriv) terminals that use open barrel crimps. You can also add an extra wire (tap) without cutting the first wire in two, just remove enough insulation to make the connection and reseal the insulation with heat shrink, liquid tape, or whatever you normally use; just not scotch tape or paper tape.

I streamlined the type of equipment I work on so now I turn down more than I actually take or about 50/50.

For those pressure washers, I've been telling people for years that I only work on the engine running part because in my climate, 95% of the calls I get are ones that worked fine last time they use them but they simply won't start now.

I tell them I can fix that and make them run properly but if they hook water to it and it leaks or doesn't pump I don't do those repairs and they're out of luck.

Three or four years ago maybe five or six it certainly was not cost-effective to fix them because the cheapest pump you could get even on eBay was $132. Then the pumps bottomed out to 62 to 68 dollars and I did manage to fix a small handful for people that were really nice or long-term repeat customers because it was an economical cost effective repair.

Now those pumps have gotten back up to about 80 minimum so it's borderline.

I've told a lot of them where to order and how easy it is to install the pump so they can do it themselves because frankly, I don't have the time.

I could fix 20 mowers a day and still have a backlog.

I know some of the older and more commercial grade pumps do have parts available and you can get the seal kits and files etc but most of the consumer grade ones now aren't available like that and it's an entire pump replacement.

If you haven't already, take the part number from one of them and put it into an eBay search box and you should find a price that makes it worth swapping off the pumps instead of trying to put seals and stuff like that internally.

There was a time about 9 years ago that certain parts were actually cheaper on Amazon but hasn't been the case for five or six years now. If you scroll down eBay you will be able to find better pricing on almost everything outdoor power equipment related.

#40

StarTech

StarTech

Oh on the pressure washer Brigg only wants $375 for the pump which more than the whole pressure cost the customer. I seeing if he will go for a $150 repair with an after market Himore or FAIP pump. I believe from the images the Briggs pump is the FAIP pump just rebranded.

And yes I can still get a $85 pump for the unit if we want go el cheapo route. I might even just suggest he order the pump and install it himself.

And yes I can still get a $85 pump for the unit if we want go el cheapo route. I might even just suggest he order the pump and install it himself.

#41

T

TobyU

As far as El cheapo, I don't know what model pump you're dealing with or unit but pretty much all of the ones or at least 98% of the ones I see and have seen for 10 years and 100% all of the ones that have the vertical crankshaft engine on top of the cart frame with the pump mounted underneath are ALL El cheapos! Even the people who would buy a replacement for a Troy-Bilt from troy-bilt.. it's still just a generic one manufacturer by some Chinese company so I don't think it matters what brand you buy or where you get it from.

Now the more commercial grade ones will have that larger rectangular pump often with a sight glass for the oil or at least a dipstick and a drain plug because the owner's manual actually tells you to change the crankcase oil at a certain number of hours consistently.

Now, these are still probably made in Japan at least most of them but it's a more robust design and those pumps do cost a little more.

The problem is some of these companies are still ridiculously capitalizing on their markup.

If you buy a carburetor for a generac generator from generac you can pay over $100 for it!

It's a Chinese carburetor probably not even Huayi which I find are actually very good. They are kind of like the high-end brand name of Chinese carbs.

But you can get this car or one just like it from eBay or Amazon for under $15 shipped to your door!

Troy-Bilt (MTD) does the same thing.

I understand using quality Parts when you know their quality and they stay quality and there's an obvious known difference between those and cheap ones but today the differences are few and far between.

Every local shop in a 50 mi radius of me still does everything the old fashioned way.

They order everything for the local distributors paying good money for it and they only mark it up a slight little amount. No shop is making a killing on their parts!

When they need that Troy-Bilt snowblower carburetor they end up with one from a Troy-Bilt box and it cost them between 45 and 60 bucks so they add another 8 or $12 on it when they sell it to the customer.

I guess in some ways this is good because if Troy-Bilt wasn't making such a killing on Parts they would have to raise the price of their new machines but I just can't do this.

Eventually these shops are going to have to start sourcing better prices for their parts. Hopefully.

T

TobyU

Like I said, that's what I've done a lot because I just don't want to take the time to mess with them and I really don't like to hose people on the labor for just an install but you know time is time.Oh on the pressure washer Brigg only wants $375 for the pump which more than the whole pressure cost the customer. I seeing if he will go for a $150 repair with an after market Himore or FAIP pump. I believe from the images the Briggs pump is the FAIP pump just rebranded.

And yes I can still get a $85 pump for the unit if we want go el cheapo route. I might even just suggest he order the pump and install it himself.

As far as El cheapo, I don't know what model pump you're dealing with or unit but pretty much all of the ones or at least 98% of the ones I see and have seen for 10 years and 100% all of the ones that have the vertical crankshaft engine on top of the cart frame with the pump mounted underneath are ALL El cheapos! Even the people who would buy a replacement for a Troy-Bilt from troy-bilt.. it's still just a generic one manufacturer by some Chinese company so I don't think it matters what brand you buy or where you get it from.

Now the more commercial grade ones will have that larger rectangular pump often with a sight glass for the oil or at least a dipstick and a drain plug because the owner's manual actually tells you to change the crankcase oil at a certain number of hours consistently.

Now, these are still probably made in Japan at least most of them but it's a more robust design and those pumps do cost a little more.

The problem is some of these companies are still ridiculously capitalizing on their markup.

If you buy a carburetor for a generac generator from generac you can pay over $100 for it!

It's a Chinese carburetor probably not even Huayi which I find are actually very good. They are kind of like the high-end brand name of Chinese carbs.

But you can get this car or one just like it from eBay or Amazon for under $15 shipped to your door!

Troy-Bilt (MTD) does the same thing.

I understand using quality Parts when you know their quality and they stay quality and there's an obvious known difference between those and cheap ones but today the differences are few and far between.

Every local shop in a 50 mi radius of me still does everything the old fashioned way.

They order everything for the local distributors paying good money for it and they only mark it up a slight little amount. No shop is making a killing on their parts!

When they need that Troy-Bilt snowblower carburetor they end up with one from a Troy-Bilt box and it cost them between 45 and 60 bucks so they add another 8 or $12 on it when they sell it to the customer.

I guess in some ways this is good because if Troy-Bilt wasn't making such a killing on Parts they would have to raise the price of their new machines but I just can't do this.

Eventually these shops are going to have to start sourcing better prices for their parts. Hopefully.