You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Bar and chain selection

#1

PTmowerMech

PTmowerMech

I haven't seen this saw yet.

My brother said he's got a Jonered CS58 (Note. He wasn't at his saw when he gave me the model number. But said he thinks that's the right one).

He was either sold the wrong blade or bar (or both). None the less, he says it won't cut at all. So I'm trying to figure out how to get the right bar & chain for it, as if he just handed me the saw with no bar or chain. Start from scratch, sort of speak.

He says the numbers on the original bar aren't visible.

My brother said he's got a Jonered CS58 (Note. He wasn't at his saw when he gave me the model number. But said he thinks that's the right one).

He was either sold the wrong blade or bar (or both). None the less, he says it won't cut at all. So I'm trying to figure out how to get the right bar & chain for it, as if he just handed me the saw with no bar or chain. Start from scratch, sort of speak.

He says the numbers on the original bar aren't visible.

#2

StarTech

StarTech

Don't forget he may had the chain on sdrawkcab.

I don't anything under PC85. Is there any other numbers on the serial number tag?

I don't anything under PC85. Is there any other numbers on the serial number tag?

#3

PTmowerMech

I just talked to him, CS 2258

PTmowerMech

Don't forget he may had the chain on sdrawkcab.

I don't anything under PC85. Is there any other numbers on the serial number tag?

I just talked to him, CS 2258

#4

StarTech

StarTech

That works. Now does he know if he was running .325 or 3/8 setup. The bar can be anywhere from 13" to 20" in the .325 line or 16" to 24" in the 3/8" pitch and what gauge was the previous setup. can .050 narrow kerf, .050, or .058 on the .325 bar and either .050 or .058 on the 3/8 bar. Which make 24 possible setups.

So you got to put your hand on it and first find out which rim drive clutch setup it has. Then you can start figuring out which BNC setup you need or desire. Personally the 24" 3/8 bar would be a little too much for the saw. I think sticking with 18" would be better.

So you got to put your hand on it and first find out which rim drive clutch setup it has. Then you can start figuring out which BNC setup you need or desire. Personally the 24" 3/8 bar would be a little too much for the saw. I think sticking with 18" would be better.

#5

PTmowerMech

He's almost positive it's a 20" bar. He does have the original bar.

He says he's going to try and drop it off this afternoon.

PTmowerMech

That works. Now does he know if he was running .325 or 3/8 setup. The bar can be anywhere from 13" to 20" in the .325 line or 16" to 24" in the 3/8" pitch and what gauge was the previous setup. can .050 narrow kerf, .050, or .058 on the .325 bar and either .050 or .058 on the 3/8 bar. Which make 24 possible setups.

So you got to put your hand on it and first find out which rim drive clutch setup it has. Then you can start figuring out which BNC setup you need or desire. Personally the 24" 3/8 bar would be a little too much for the saw. I think sticking with 18" would be better.

He's almost positive it's a 20" bar. He does have the original bar.

He says he's going to try and drop it off this afternoon.

#6

StarTech

StarTech

To find the gauge of the BNC without caliper.

Dime = .050

Penny = .058

Quarter = .063 (be a little tight sometimes on new bars)

Just depends which will and which won't. IE penny and dime fits but not the quarter then it is a .058. In this case you it going either the dime or the penny as .063 is not available for this saw in BK095 mount.

It has a modified mount that is not a standard K095 but is a BK095 mount so a K095 bar will not work.

Dime = .050

Penny = .058

Quarter = .063 (be a little tight sometimes on new bars)

Just depends which will and which won't. IE penny and dime fits but not the quarter then it is a .058. In this case you it going either the dime or the penny as .063 is not available for this saw in BK095 mount.

It has a modified mount that is not a standard K095 but is a BK095 mount so a K095 bar will not work.

#7

Hammermechanicman

Hammermechanicman

Get you a couple of these. If you are going to work on saws you need this tool. You can tell bar gauge and chain pitch and guage easily.

#8

StarTech

StarTech

But half the time I can't the find them quickly. I usually have the coins in my pocket.

It like a dime placed across three rivets is a .325 pitch chain and nickle covering three rivets is a .375 pitch chain. These are the most common handheld chainsaw pitches.

It like a dime placed across three rivets is a .325 pitch chain and nickle covering three rivets is a .375 pitch chain. These are the most common handheld chainsaw pitches.

#9

Hammermechanicman

Hammermechanicman

I bought a few. Got 1 in my chainsaw box, 1 on the workbench and a couple at the chain grinders.

#10

StarTech

StarTech

Wish I had the room for multiple grinders but one has to it here, I use some of the space for the blade balancer.

#11

PTmowerMech

Thanks. Ordered and on the way.

PTmowerMech

Get you a couple of these. If you are going to work on saws you need this tool. You can tell bar gauge and chain pitch and guage easily.

Thanks. Ordered and on the way.

#13

Hammermechanicman

Hammermechanicman

Tsumura bars are very good bars. If the bar groove is worn you can use a rail closer to fix it.

Chainsaw Guide Bar Rail Closer Full Adjustable To Fit Different Gauge Bars | eBay

Bar Rail Closer - Add life to your bars and save money ! This tool is a favorite for Harvester Bars, milling bars and other long expensive bars. This tool allows you to close the spread on worn bars.

www.ebay.com

#14

StarTech

StarTech

Oregon Vesa-Cut bar 200VXLHK095 would be a good low cost choice for the bar.

Oregon 72LPX072 saw chain.

Both are very good, low cost, and the chain is a safety chain for homeowner use.

Oregon 72LPX072 saw chain.

Both are very good, low cost, and the chain is a safety chain for homeowner use.

#15

PTmowerMech

For some reason, he won't have an Oregon product. Says he wants Jonsered or Husq.

PTmowerMech

Oregon Vesa-Cut bar 200VXLHK095 would be a good low cost choice for the bar.

Oregon 72LPX072 saw chain.

Both are very good, low cost, and the chain is a safety chain for homeowner use.

For some reason, he won't have an Oregon product. Says he wants Jonsered or Husq.

#16

StarTech

StarTech

Well he if get either Husqvarna or Jonsered bar he going to get an Oregon bar as that's who makes the bars for them. He just be paying extra for the name to painted on it.

#17

PTmowerMech

PTmowerMech

I'm getting the picture that it's doesn't matter if it's an 058 or an 050 gauge, as long as the bar and chain match. Is this going to have an effect on the sprocket?

#18

PTmowerMech

According to what I'm seeing, Husq is back to making their own chains.

Does Husqvarna make their own chains?

These cutting-edge chains are built in the place where it all began: Husqvarna headquarters in Huskvarna, Sweden.

PTmowerMech

Well he if get either Husqvarna or Jonsered bar he going to get an Oregon bar as that's who makes the bars for them. He just be paying extra for the name to painted on it.

According to what I'm seeing, Husq is back to making their own chains.

Does Husqvarna make their own chains?

These cutting-edge chains are built in the place where it all began: Husqvarna headquarters in Huskvarna, Sweden.

#19

StarTech

Not that I know of but check the rim sprocket anyways as maybe heavy worn. Or least at the IPL says the saw is setup in a rim drive drum. It just the .058 is a heavier chain and bar will also be heavier and will affect the feel of the saw.

StarTech

I'm getting the picture that it's doesn't matter if it's an 058 or an 050 gauge, as long as the bar and chain match. Is this going to have an effect on the sprocket?

Not that I know of but check the rim sprocket anyways as maybe heavy worn. Or least at the IPL says the saw is setup in a rim drive drum. It just the .058 is a heavier chain and bar will also be heavier and will affect the feel of the saw.

I haven't seen any info on that but could be possible but I kinda doubt it. I just pull a chain guide and they were still referencing the Oregon products.According to what I'm seeing, Husq is back to making their own chains.

Does Husqvarna make their own chains?

These cutting-edge chains are built in the place where it all began: Husqvarna headquarters in Huskvarna, Sweden.

#20

StarTech

StarTech

Anyway if the customer insists on the name brand then let him spend his money and you make the profit. It is like some my customers insists on Craftsman parts I just given the Craftsman price for the Husqvarna and MTD parts.

#21

PTmowerMech

Heavily worn? That's possible. It's looking pretty thin. But It doesn't look like it's in desperate need.

I see. I just did a quick search and found what I posted. Looks like it was from the Husqvarna website.

It's my brother. And he get emotional when someone contradicts what he says. As in when I told him Oregon chains and bars are good.

There's no profit in this. Just trying to save him some money.

I can get this set up from Stens in a Sabre brand. But I can't find any reviews on their chains.

PTmowerMech

Not that I know of but check the rim sprocket anyways as maybe heavy worn. Or least at the IPL says the saw is setup in a rim drive drum. It just the .058 is a heavier chain and bar will also be heavier and will affect the feel of the saw.

Heavily worn? That's possible. It's looking pretty thin. But It doesn't look like it's in desperate need.

I haven't seen any info on that but could be possible but I kinda doubt it. I just pull a chain guide and they were still referencing the Oregon products.

I see. I just did a quick search and found what I posted. Looks like it was from the Husqvarna website.

Anyway if the customer insists on the name brand then let him spend his money and you make the profit. It is like some my customers insists on Craftsman parts I just given the Craftsman price for the Husqvarna and MTD parts.

It's my brother. And he get emotional when someone contradicts what he says. As in when I told him Oregon chains and bars are good.

There's no profit in this. Just trying to save him some money.

I can get this set up from Stens in a Sabre brand. But I can't find any reviews on their chains.

#22

StarTech

StarTech

I think the Sabre chain and bars are Tri Link. I once was a Sunbelt distributor and the Timber Ridge chains and bars were Tri-Link and they held up well.

The Stens Sabre

3/8 .050 72 DL is SKU 075-3366 K095 mount.

3/8 .058 72 DL is SKU 075-3426 K095 mount.

You have to decide if you want semi chisel or chisel cutters. Appears to be no 20" BNC Combo in the K095 mount.

You can also check the Stens Silver Streak line which fairly good bars and chains too. I have sold them for years without problems.

The Stens Sabre

3/8 .050 72 DL is SKU 075-3366 K095 mount.

3/8 .058 72 DL is SKU 075-3426 K095 mount.

You have to decide if you want semi chisel or chisel cutters. Appears to be no 20" BNC Combo in the K095 mount.

You can also check the Stens Silver Streak line which fairly good bars and chains too. I have sold them for years without problems.

#23

PTmowerMech

I think I can convince him to at least try this one out. Even if I have to tell him the Jonsered stuff is on back order.

www.stens.com

www.stens.com

PTmowerMech

I think the Sabre chain and bars are Tri Link. I once was a Sunbelt distributor and the Timber Ridge chains and bars were Tri-Link and they held up well.

The Stens Sabre

3/8 .050 72 DL is SKU 075-3366 K095 mount.

3/8 .058 72 DL is SKU 075-3426 K095 mount.

You have to decide if you want semi chisel or chisel cutters. Appears to be no 20" BNC Combo in the K095 mount.

You can also check the Stens Silver Streak line which fairly good bars and chains too. I have sold them for years without problems.

I think I can convince him to at least try this one out. Even if I have to tell him the Jonsered stuff is on back order.

Shopping

#24

B

bertsmobile1

B

bertsmobile1

FWIW

On my saws I run 5 chains at a time

When all 5 have worn beyond safe use it is new chains & sprockets .

Stihl recommend a new sprocket every third chain

Never come across a chain that "won't cut" except the ones that were put on backwards

Gauge does not affect the ability to cut 3/8 x 050 or 3/8 x 068 same size of cutters and cutting edges .

To the saw the only difference is the chain is physically heavier, but not all that much

On bars that are excessively worn I usually go up one gauge size

When a saw comes in I measure the gauge then try that one & the next size bigger

A bigger gauge tends to make a cleaner cut as the blade does not rock left - right as much .

As for brands, there is not much in it

I used to fit Oregon for the pros because that is what one wholesaler kept

After that there was Carlton which I would call a high end domestic chain

Then there was the suppliers house brands which I would call acceptable for home owners

I am yet to try Stens Sabre brand as I still have 30 rolls of their previous chain that I bought cheap when they were running the old stock out a few years back

Same story with Oregon, when B & S took over the distribution I bought several 100' rolls that were discounted so have enough chains to last for decades and now B & S only bring in loops which are no use for a workshop as you need to keep 300 in sock & will never have the right one

Like everything else now days, most house brands will be made in China

And like everything else, if the chain & the bar has the brand stamped into it then it will be acceptable quality

If it is unbranded then it will be of dubious quality

As for your brother , fit what he wants .

This is the No 1 rule for all repair shops because the customer will never be happy & every problem with HIS saw will the YOUR fault because you fitted this JUNK chain .

There are 2 things you can not overcome

Stupidity & prejudice

If he want to practice both then let him pay 3 times the price because that is what will make him happy

On my saws I run 5 chains at a time

When all 5 have worn beyond safe use it is new chains & sprockets .

Stihl recommend a new sprocket every third chain

Never come across a chain that "won't cut" except the ones that were put on backwards

Gauge does not affect the ability to cut 3/8 x 050 or 3/8 x 068 same size of cutters and cutting edges .

To the saw the only difference is the chain is physically heavier, but not all that much

On bars that are excessively worn I usually go up one gauge size

When a saw comes in I measure the gauge then try that one & the next size bigger

A bigger gauge tends to make a cleaner cut as the blade does not rock left - right as much .

As for brands, there is not much in it

I used to fit Oregon for the pros because that is what one wholesaler kept

After that there was Carlton which I would call a high end domestic chain

Then there was the suppliers house brands which I would call acceptable for home owners

I am yet to try Stens Sabre brand as I still have 30 rolls of their previous chain that I bought cheap when they were running the old stock out a few years back

Same story with Oregon, when B & S took over the distribution I bought several 100' rolls that were discounted so have enough chains to last for decades and now B & S only bring in loops which are no use for a workshop as you need to keep 300 in sock & will never have the right one

Like everything else now days, most house brands will be made in China

And like everything else, if the chain & the bar has the brand stamped into it then it will be acceptable quality

If it is unbranded then it will be of dubious quality

As for your brother , fit what he wants .

This is the No 1 rule for all repair shops because the customer will never be happy & every problem with HIS saw will the YOUR fault because you fitted this JUNK chain .

There are 2 things you can not overcome

Stupidity & prejudice

If he want to practice both then let him pay 3 times the price because that is what will make him happy

#26

PTmowerMech

PTmowerMech

Apparently Arrowhead bought out Trilink in 2021. They're owned by GenStar Capital which is an equity firm.

#27

PTmowerMech

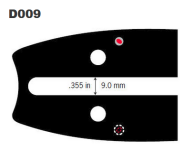

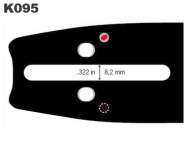

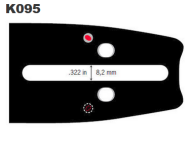

There's nothing about a K095 or a D009 on the Stens page for this bar and chain. And I'm not even sure what those numbers are or mean.

PTmowerMech

Ah crap.Won't work. It is a D009 mount and you want the K095 mount.

View attachment 65641VS

I flip the image so you can compare easier.

View attachment 65643

Oil holes locate on actual K095

View attachment 65642

There's nothing about a K095 or a D009 on the Stens page for this bar and chain. And I'm not even sure what those numbers are or mean.

#28

B

bertsmobile1

By and large private equity firms have 2 modes of operation

1) buy a brand name , downgrade the product to suck the maximun profit out of it then when there is no more big money to be made flog it off then go destroy another business

2) buy a failing brand name ,take it private , cook the books so it looks like they have revived it then relist it sell off 100% and go hide behind their lawyers or senators .

In any case the acquisition officers have 1 and 1 only goal which is to beat what ever share index or government bond rate they link to then pay themselves a hefty percentage of that difference in bonuses

B

bertsmobile1

Which means they are now made in what ever third world country that can supply them the cheapest .Apparently Arrowhead bought out Trilink in 2021. They're owned by GenStar Capital which is an equity firm.

By and large private equity firms have 2 modes of operation

1) buy a brand name , downgrade the product to suck the maximun profit out of it then when there is no more big money to be made flog it off then go destroy another business

2) buy a failing brand name ,take it private , cook the books so it looks like they have revived it then relist it sell off 100% and go hide behind their lawyers or senators .

In any case the acquisition officers have 1 and 1 only goal which is to beat what ever share index or government bond rate they link to then pay themselves a hefty percentage of that difference in bonuses

#29

PTmowerMech

After discussing this a little further, he says it spits out big shavings, but that it cuts crooked. So I advised him that they're not the same thing.

I'm not so sure about the "customer will never be happy" comment. I've had a lot of satisfied customers. Even when things didn't work out exactly right. The only really unsatisfied customer I've ever had was a close friend who's engine blew just after I'd worked on it, while it was still at the shop. A mower I told him to sell the year before because it was old and worn out. The same engine that he'd brought it to me a quart low of oil, twice. But the argument only came when I told him to either leave the mower at the shop, or pay me what I had in it. He wanted the mower, with all the new parts I'd just put on it, and to not pay me because the engine blew while it was with me.

PTmowerMech

FWIW

On my saws I run 5 chains at a time

When all 5 have worn beyond safe use it is new chains & sprockets .

Stihl recommend a new sprocket every third chain

Never come across a chain that "won't cut" except the ones that were put on backwards

Gauge does not affect the ability to cut 3/8 x 050 or 3/8 x 068 same size of cutters and cutting edges .

To the saw the only difference is the chain is physically heavier, but not all that much

On bars that are excessively worn I usually go up one gauge size

When a saw comes in I measure the gauge then try that one & the next size bigger

A bigger gauge tends to make a cleaner cut as the blade does not rock left - right as much .

As for brands, there is not much in it

I used to fit Oregon for the pros because that is what one wholesaler kept

After that there was Carlton which I would call a high end domestic chain

Then there was the suppliers house brands which I would call acceptable for home owners

I am yet to try Stens Sabre brand as I still have 30 rolls of their previous chain that I bought cheap when they were running the old stock out a few years back

Same story with Oregon, when B & S took over the distribution I bought several 100' rolls that were discounted so have enough chains to last for decades and now B & S only bring in loops which are no use for a workshop as you need to keep 300 in sock & will never have the right one

Like everything else now days, most house brands will be made in China

And like everything else, if the chain & the bar has the brand stamped into it then it will be acceptable quality

If it is unbranded then it will be of dubious quality

As for your brother , fit what he wants .

This is the No 1 rule for all repair shops because the customer will never be happy & every problem with HIS saw will the YOUR fault because you fitted this JUNK chain .

There are 2 things you can not overcome

Stupidity & prejudice

If he want to practice both then let him pay 3 times the price because that is what will make him happy

After discussing this a little further, he says it spits out big shavings, but that it cuts crooked. So I advised him that they're not the same thing.

I'm not so sure about the "customer will never be happy" comment. I've had a lot of satisfied customers. Even when things didn't work out exactly right. The only really unsatisfied customer I've ever had was a close friend who's engine blew just after I'd worked on it, while it was still at the shop. A mower I told him to sell the year before because it was old and worn out. The same engine that he'd brought it to me a quart low of oil, twice. But the argument only came when I told him to either leave the mower at the shop, or pay me what I had in it. He wanted the mower, with all the new parts I'd just put on it, and to not pay me because the engine blew while it was with me.

#30

StarTech

StarTech

Don't you have the printed catalog? in the 2022 catalog page 1399 clearly shows the Oregon bar number, The four chars is the mount.

And the 2023 Oregon catalog page For 43 the CS2258 is shown with K095 mounts.

Cutting in a curve is either a improperly sharpen chain or worn bar rails. Probably need to look at the chain and bar yourself. Probably just need the cutters resharpen and depth gauges set at the proper height.

Per Oregon the chain would sharpen at 30 degrees with 10 degree down tilt. Depth gauge are filed to .025". Personally I just forget the 10 degree down angle. 3/16 file if hand filing but I use a grinder myself nowadays. But these grinders take patience to learn how not the burn the cutters. A lot easier to get all the cutter the same with the grinder.

And the 2023 Oregon catalog page For 43 the CS2258 is shown with K095 mounts.

Cutting in a curve is either a improperly sharpen chain or worn bar rails. Probably need to look at the chain and bar yourself. Probably just need the cutters resharpen and depth gauges set at the proper height.

Per Oregon the chain would sharpen at 30 degrees with 10 degree down tilt. Depth gauge are filed to .025". Personally I just forget the 10 degree down angle. 3/16 file if hand filing but I use a grinder myself nowadays. But these grinders take patience to learn how not the burn the cutters. A lot easier to get all the cutter the same with the grinder.

#31

PTmowerMech

Yes sir. Been there, done that. The trucking company I started with was sold to an equity company. We were still hauling the loads, everyone was still doing their jobs. But one day, after about a year, some employee's showed up at the office with chains on the gates and the doors.

Drivers were told to make their deliveries and get back to a terminal within 2 days, because the fuel cards were going to shut off.

PTmowerMech

Which means they are now made in what ever third world country that can supply them the cheapest .

By and large private equity firms have 2 modes of operation

1) buy a brand name , downgrade the product to suck the maximun profit out of it then when there is no more big money to be made flog it off then go destroy another business

2) buy a failing brand name ,take it private , cook the books so it looks like they have revived it then relist it sell off 100% and go hide behind their lawyers or senators .

In any case the acquisition officers have 1 and 1 only goal which is to beat what ever share index or government bond rate they link to then pay themselves a hefty percentage of that difference in bonuses

Yes sir. Been there, done that. The trucking company I started with was sold to an equity company. We were still hauling the loads, everyone was still doing their jobs. But one day, after about a year, some employee's showed up at the office with chains on the gates and the doors.

Drivers were told to make their deliveries and get back to a terminal within 2 days, because the fuel cards were going to shut off.

#32

B

bertsmobile1

B

bertsmobile1

Big shavings & crocked cut = rakers ( bumpers to some ) have been cur too low so the teeth are cutting too deep

This rips the hell out of the bar on semi chisel chains as each link tries to twist under the load .

Also happens when running the saw too slow .

OR misuse like tip cutting .

This rips the hell out of the bar on semi chisel chains as each link tries to twist under the load .

Also happens when running the saw too slow .

OR misuse like tip cutting .

#33

M

MParr

M

MParr

Rotary carries bars and chains for the CS2258. They are probably made by Oregon. He wouldn’t know if you didn’t tell him.

#34

PTmowerMech

I don't have an account with Rotary. But I can probably find it on the inner screen.

What's messed up, is everything I've looked at says all I need is the DL, pitch & gauge. I get all that, order a bar and chain that fits that description, and then @StarTech comes up with some numbers that no one else is talking about and isn't listed on anything i've seen or heard today. Apparently it's important information, otherwise he wouldn't have posted it.

But the order is made & paid for. There's no one at Stens today to cancel or replace the order.

PTmowerMech

Rotary carries bars and chains for the CS2258. They are probably made by Oregon. He wouldn’t know if you didn’t tell him.

I don't have an account with Rotary. But I can probably find it on the inner screen.

What's messed up, is everything I've looked at says all I need is the DL, pitch & gauge. I get all that, order a bar and chain that fits that description, and then @StarTech comes up with some numbers that no one else is talking about and isn't listed on anything i've seen or heard today. Apparently it's important information, otherwise he wouldn't have posted it.

But the order is made & paid for. There's no one at Stens today to cancel or replace the order.

#35

Hammermechanicman

Hammermechanicman

Different saws have different bar mounts. Brand A saw may use a 3/8 .050 72DL chain and brand B saw may take the same chain but the bar mount is different.

Brand of saw determines the bar.

Clutch rim or spur sprocket determines pitch.

Bar determines gauge and number of drive links.

Brand of saw determines the bar.

Clutch rim or spur sprocket determines pitch.

Bar determines gauge and number of drive links.

#36

B

bertsmobile1

B

bertsmobile1

This is where having a paper catalogue is worth it's weight in gold because they all have a shadow board listing of bar mounts so you can place any unknown bar on the pages and find out what bar type is it

oregon bar end mounts

And when you are viewing these dozen or so pages while having a cuppa note that the same brand of saw can have a lot of different bar ends so a single Stihl 22" bar will not fit every Stihl saw

Again I get a lot of customers who come in with a junk bar & lade combo wanting to swap it because they searched they searched Stihl XY" bar then bought the cheapest one that of course did not mount onto their saw .And no they do not get a swap .

oregon bar end mounts

And when you are viewing these dozen or so pages while having a cuppa note that the same brand of saw can have a lot of different bar ends so a single Stihl 22" bar will not fit every Stihl saw

Again I get a lot of customers who come in with a junk bar & lade combo wanting to swap it because they searched they searched Stihl XY" bar then bought the cheapest one that of course did not mount onto their saw .And no they do not get a swap .

#37

PTmowerMech

I had a catalog around here somewhere. I just can't locate the darn thing.

PTmowerMech

This is where having a paper catalogue is worth it's weight in gold because they all have a shadow board listing of bar mounts so you can place any unknown bar on the pages and find out what bar type is it

oregon bar end mounts

And when you are viewing these dozen or so pages while having a cuppa note that the same brand of saw can have a lot of different bar ends so a single Stihl 22" bar will not fit every Stihl saw

Again I get a lot of customers who come in with a junk bar & lade combo wanting to swap it because they searched they searched Stihl XY" bar then bought the cheapest one that of course did not mount onto their saw .And no they do not get a swap .

I had a catalog around here somewhere. I just can't locate the darn thing.

#38

StarTech

StarTech

When you get time sit and do a lot research. There is all kind of designs out there. Really you got to know what you working with and what the customer is trying to do. Enough make your head spin at first but with experience you will know what you are looking for. Most times I am dealing home owners so it is a lot simpler than when a pro comes in.

As for the Rotary bar numbers they are

9532520 20" 3/8" .050 72dl

9533520 20" 3/8" .058 72dl

And I highly recommend using a safety chain as the non safety are dangerous in the hands of non professional.

Both are Pro Sprocket versions with replaceable sprocket tips. Although I yet to replace one as most time the rest of the bar is shot too.

And it comes to chains it is the same thing about styles. You got safety and non safety, different types of bumper links; standard, semi skip, and full skip cutter sequence; semi chisel, chisel, and square face cutters; single and dual rakers. And even got a choice between cross cut and rip cut versions. Head spinning yet?

Most chains you will come across will be cross cut (25-35 degree cutters). Stihl chains are usually file at 25 degrees and most others either 25 or 30 degrees. Rip cut (10 degree cutters) are mostly for milling operation where you are making planks (lumber). This is where you want to break up the shavings more as they are very long otherwise and clog the clutch housings.

I even have a few rare 3/8lp full skip chains here that one particular insists on buying. Oregon has quit making them so when what I got is gone he will have take a standard chain or move up to a larger saw that skip chains are still available for. Normally you will not find skip in a 3/8lp chain.

And just found out a week ago the Rotary has the style of 3/8lp chain I have been looking for my customers that do plunge cuts. I got a 100' roll on the wish list Rotary PO. The particular bumper link style makes it where the bar tip is a lot easier to cut with. I personally do plunge cuts to install wedges for splitting on wood that wedges just don't want to get started. Most chains the bar tip can have a lot of kickback, even the safety ones; although, safety one has less of a kickback.

As Bert said paper catalogs have a lot more info in them than the online stuff. And most of your vendors sales reps have even less knowledge about these specs.

I am old hand filer that finally gave in and brought me a good chain grinder. I actually tried the HF piece of junk grinder. It became so sloppy after a few chains that I disassemble it and threw it in the recycle bin. Kinda had to after a batch of eight chains took over 6 files to sharpen and I had blisters for over a week. Still trying to figure out who made those chains as the customer doesn't remember where he got them.

Last week I got a customer that says he has lots of chains that he needs sharpen so it looks I be sharping a few chains in the near future. He just didn't know I had the equipment to do them or knew more about saw chain than he does.

As for the Rotary bar numbers they are

9532520 20" 3/8" .050 72dl

9533520 20" 3/8" .058 72dl

And I highly recommend using a safety chain as the non safety are dangerous in the hands of non professional.

Both are Pro Sprocket versions with replaceable sprocket tips. Although I yet to replace one as most time the rest of the bar is shot too.

And it comes to chains it is the same thing about styles. You got safety and non safety, different types of bumper links; standard, semi skip, and full skip cutter sequence; semi chisel, chisel, and square face cutters; single and dual rakers. And even got a choice between cross cut and rip cut versions. Head spinning yet?

Most chains you will come across will be cross cut (25-35 degree cutters). Stihl chains are usually file at 25 degrees and most others either 25 or 30 degrees. Rip cut (10 degree cutters) are mostly for milling operation where you are making planks (lumber). This is where you want to break up the shavings more as they are very long otherwise and clog the clutch housings.

I even have a few rare 3/8lp full skip chains here that one particular insists on buying. Oregon has quit making them so when what I got is gone he will have take a standard chain or move up to a larger saw that skip chains are still available for. Normally you will not find skip in a 3/8lp chain.

And just found out a week ago the Rotary has the style of 3/8lp chain I have been looking for my customers that do plunge cuts. I got a 100' roll on the wish list Rotary PO. The particular bumper link style makes it where the bar tip is a lot easier to cut with. I personally do plunge cuts to install wedges for splitting on wood that wedges just don't want to get started. Most chains the bar tip can have a lot of kickback, even the safety ones; although, safety one has less of a kickback.

As Bert said paper catalogs have a lot more info in them than the online stuff. And most of your vendors sales reps have even less knowledge about these specs.

I am old hand filer that finally gave in and brought me a good chain grinder. I actually tried the HF piece of junk grinder. It became so sloppy after a few chains that I disassemble it and threw it in the recycle bin. Kinda had to after a batch of eight chains took over 6 files to sharpen and I had blisters for over a week. Still trying to figure out who made those chains as the customer doesn't remember where he got them.

Last week I got a customer that says he has lots of chains that he needs sharpen so it looks I be sharping a few chains in the near future. He just didn't know I had the equipment to do them or knew more about saw chain than he does.

#39

Hammermechanicman

Hammermechanicman

Good info from star. Probably 90% of what you will see from non pro users be semi chisel safety chain. I personally dislike most safety, anti kickback, green, bumper or whatever else folks call it. On my saws I run full chisel non safety chains. Trying to adjust the depth gauges on some safety chains is just a pain. There is some i call "shark fin" chain that i won't sharpen.

Some of the new electric saws appear to use some non standard micro chain that needs some really thin wheel of file to sharpen I don't have.

Some of the new electric saws appear to use some non standard micro chain that needs some really thin wheel of file to sharpen I don't have.

#40

PTmowerMech

Yes sir, you got my head spinning. Just a few days ago, I thought it was just a matter of matching the gauge, pitch and DL. Now there's 10+ other things to consider.

My brother cuts about 4 chords per year. So he's not the typical homeowner type user. But I'm 100% sure he doesn't care to know about all those different types of chains and bars. He just wants the saw to run and cut when he needs it. He's good at sharpening and using a saw. But doesn't know about what "dirty wood" is. Most of the oak he cuts is dirty. It's been sitting in the woods for at least a year or two. I could advise him to get a semi chiseled chain, but it wouldn't cut as fast as his full chiseled chain, and would (as Bert said) blame me. He doesn't mind sharpening. But if I got a lower grade of chain, he'd have to sharpen it more often. And I'd get blamed for that too.

Learning all this saw stuff is like learning about rebuilding carburetors. So many different things to know about, so many different types.

BTW, thanks for all the info. It's been a huge help (at confusing me lmao )

)

PTmowerMech

When you get time sit and do a lot research. There is all kind of designs out there. Really you got to know what you working with and what the customer is trying to do. Enough make your head spin at first but with experience you will know what you are looking for. Most times I am dealing home owners so it is a lot simpler than when a pro comes in.

As for the Rotary bar numbers they are

9532520 20" 3/8" .050 72dl

9533520 20" 3/8" .058 72dl

And I highly recommend using a safety chain as the non safety are dangerous in the hands of non professional.

Both are Pro Sprocket versions with replaceable sprocket tips. Although I yet to replace one as most time the rest of the bar is shot too.

And it comes to chains it is the same thing about styles. You got safety and non safety, different types of bumper links; standard, semi skip, and full skip cutter sequence; semi chisel, chisel, and square face cutters; single and dual rakers. And even got a choice between cross cut and rip cut versions. Head spinning yet?

Most chains you will come across will be cross cut (25-35 degree cutters). Stihl chains are usually file at 25 degrees and most others either 25 or 30 degrees. Rip cut (10 degree cutters) are mostly for milling operation where you are making planks (lumber). This is where you want to break up the shavings more as they are very long otherwise and clog the clutch housings.

I even have a few rare 3/8lp full skip chains here that one particular insists on buying. Oregon has quit making them so when what I got is gone he will have take a standard chain or move up to a larger saw that skip chains are still available for. Normally you will not find skip in a 3/8lp chain.

And just found out a week ago the Rotary has the style of 3/8lp chain I have been looking for my customers that do plunge cuts. I got a 100' roll on the wish list Rotary PO. The particular bumper link style makes it where the bar tip is a lot easier to cut with. I personally do plunge cuts to install wedges for splitting on wood that wedges just don't want to get started. Most chains the bar tip can have a lot of kickback, even the safety ones; although, safety one has less of a kickback.

As Bert said paper catalogs have a lot more info in them than the online stuff. And most of your vendors sales reps have even less knowledge about these specs.

I am old hand filer that finally gave in and brought me a good chain grinder. I actually tried the HF piece of junk grinder. It became so sloppy after a few chains that I disassemble it and threw it in the recycle bin. Kinda had to after a batch of eight chains took over 6 files to sharpen and I had blisters for over a week. Still trying to figure out who made those chains as the customer doesn't remember where he got them.

Last week I got a customer that says he has lots of chains that he needs sharpen so it looks I be sharping a few chains in the near future. He just didn't know I had the equipment to do them or knew more about saw chain than he does.

Yes sir, you got my head spinning. Just a few days ago, I thought it was just a matter of matching the gauge, pitch and DL. Now there's 10+ other things to consider.

My brother cuts about 4 chords per year. So he's not the typical homeowner type user. But I'm 100% sure he doesn't care to know about all those different types of chains and bars. He just wants the saw to run and cut when he needs it. He's good at sharpening and using a saw. But doesn't know about what "dirty wood" is. Most of the oak he cuts is dirty. It's been sitting in the woods for at least a year or two. I could advise him to get a semi chiseled chain, but it wouldn't cut as fast as his full chiseled chain, and would (as Bert said) blame me. He doesn't mind sharpening. But if I got a lower grade of chain, he'd have to sharpen it more often. And I'd get blamed for that too.

Learning all this saw stuff is like learning about rebuilding carburetors. So many different things to know about, so many different types.

BTW, thanks for all the info. It's been a huge help (at confusing me lmao

#41

StarTech

StarTech

Sounds 1/4 pitch chain and the 1/8" stone should work.

Depth gauges setting haven't been a problem here yet. But some looks like I would need the 5/16" stone ground for dong depth gauges, Currently I use 1/4" stone.

As for type you run is more of the users preference. For me most any chain works well as long it is properly sharpen. Even that square ground carbide chain that I manage to dull work well until I dulled it.

Depth gauges setting haven't been a problem here yet. But some looks like I would need the 5/16" stone ground for dong depth gauges, Currently I use 1/4" stone.

As for type you run is more of the users preference. For me most any chain works well as long it is properly sharpen. Even that square ground carbide chain that I manage to dull work well until I dulled it.

#42

Hammermechanicman

Hammermechanicman

I have 1/8" wheels. Some of the new electric saws have teeth so small the 1/8" won't fit between the tooth and raker. Smaller than the stihl micro chisel.

Most of the cutting I do is cutting down and bucking big dead ash, hackberry and oaks for farmers around me. My brother in law heats with wood and his MS290 struggles in big wood. I have a hot rodded 660 clone and I drop and and buck it for him. Most stuff 24 to 36 inch diameter. Semi chisel is way slower than full chisel with a 25" bar buried in an old oak.

Most of the cutting I do is cutting down and bucking big dead ash, hackberry and oaks for farmers around me. My brother in law heats with wood and his MS290 struggles in big wood. I have a hot rodded 660 clone and I drop and and buck it for him. Most stuff 24 to 36 inch diameter. Semi chisel is way slower than full chisel with a 25" bar buried in an old oak.

#43

PTmowerMech

OK, I found my catalog, and I'm not seeing much more info than what's on their webpage. I do see the D009 number. That's just an Oregon part number.

I just spent 20 minutes on the phone with a Stens rep. He and I are on about the same knowledge level when I comes to bars and chains. Except for a couple of things I knew and he didn't. (pat myself on the back with just 2 fingers). Like me, he only knows pitch, gauge and driver count.

So, since the order has been filled and ready to ship, I may end up eating this bar & chain. But I'll be able to see with my own eyes, how it's not going to work. 076-2036 isn't going to work.

PTmowerMech

Don't you have the printed catalog? in the 2022 catalog page 1399 clearly shows the Oregon bar number, The four chars is the mount.

And the 2023 Oregon catalog page For 43 the CS2258 is shown with K095 mounts.

Cutting in a curve is either a improperly sharpen chain or worn bar rails. Probably need to look at the chain and bar yourself. Probably just need the cutters resharpen and depth gauges set at the proper height.

Per Oregon the chain would sharpen at 30 degrees with 10 degree down tilt. Depth gauge are filed to .025". Personally I just forget the 10 degree down angle. 3/16 file if hand filing but I use a grinder myself nowadays. But these grinders take patience to learn how not the burn the cutters. A lot easier to get all the cutter the same with the grinder.

OK, I found my catalog, and I'm not seeing much more info than what's on their webpage. I do see the D009 number. That's just an Oregon part number.

I just spent 20 minutes on the phone with a Stens rep. He and I are on about the same knowledge level when I comes to bars and chains. Except for a couple of things I knew and he didn't. (pat myself on the back with just 2 fingers). Like me, he only knows pitch, gauge and driver count.

So, since the order has been filled and ready to ship, I may end up eating this bar & chain. But I'll be able to see with my own eyes, how it's not going to work. 076-2036 isn't going to work.

#44

ILENGINE

ILENGINE

The D009 is basically the bar mount for the Dolmar/Makita 6400 series and larger and the Husqvarna saws above 60cc. And if anybody has heard of Solo saws then the 662-667-680-690-694 are D009 K095 is the 42-50cc saws in the Makita/Dolmar, Husqvarna, Poulan,Jonsered. and Solo saws. And the A041 is the 32-40 cc saw sizes.OK, I found my catalog, and I'm not seeing much more info than what's on their webpage. I do see the D009 number. That's just an Oregon part number.

I just spent 20 minutes on the phone with a Stens rep. He and I are on about the same knowledge level when I comes to bars and chains. Except for a couple of things I knew and he didn't. (pat myself on the back with just 2 fingers). Like me, he only knows pitch, gauge and driver count.

So, since the order has been filled and ready to ship, I may end up eating this bar & chain. But I'll be able to see with my own eyes, how it's not going to work. 076-2036 isn't going to work.

#45

B

bertsmobile1

B

bertsmobile1

Because Oregon supplies a lot of OEM bas and because Oregon also supplies aftermarket bars for almost every saw ever made, it's bar end code has become sort of the universal default.

IF you looked at the Oregon catelogue page I dug out & sent a link to you would have seen that each Oregon bar had an equivalent Windsor & Carlton number listed as well.

As for your rep, not surprised most reps only know how to use the current catelogue better than you and of course have access to previous ones .

So most would have no idea about the difference between a 123-123 bar & a 123-456 bar other than the first fits these saws and the latter fits those saws.

My old rep had been in the industry for 50 years and knew everything , including all the mowers that were not listed in the catelogue .

His replacement is a very nice bloke, he came from the automotive industry o knows way less than I do about older mowers

IF you looked at the Oregon catelogue page I dug out & sent a link to you would have seen that each Oregon bar had an equivalent Windsor & Carlton number listed as well.

As for your rep, not surprised most reps only know how to use the current catelogue better than you and of course have access to previous ones .

So most would have no idea about the difference between a 123-123 bar & a 123-456 bar other than the first fits these saws and the latter fits those saws.

My old rep had been in the industry for 50 years and knew everything , including all the mowers that were not listed in the catelogue .

His replacement is a very nice bloke, he came from the automotive industry o knows way less than I do about older mowers

#46

M

MParr

M

MParr

@PTmowerMech , will this help?

Jonsered Chainsaw Bar and Chain Quick Reference Chart | Lawnmower Pros

Jonsered Chainsaw Bar and Chain Quick Reference Chart available online and ready to ship direct to your door. Free tech support. 365 day returns. Worldwide shipping.

www.lawnmowerpros.com

#47

ILENGINE

ILENGINE

And Windsor and Carlton are both owned by Oregon.Because Oregon supplies a lot of OEM bas and because Oregon also supplies aftermarket bars for almost every saw ever made, it's bar end code has become sort of the universal default.

IF you looked at the Oregon catelogue page I dug out & sent a link to you would have seen that each Oregon bar had an equivalent Windsor & Carlton number listed as well.

#48

B

bertsmobile1

So that would make Oregon the only maker of chain saw bars in the USA now

B

bertsmobile1

Didn't know thatAnd Windsor and Carlton are both owned by Oregon.

So that would make Oregon the only maker of chain saw bars in the USA now

#50

PTmowerMech

You're a genius. Thanks

So checking what's on the original bar, it says 050. Not 058. You're chain/bar matching page states that it's 058 gauge.

PTmowerMech

@PTmowerMech , will this help?

Jonsered Chainsaw Bar and Chain Quick Reference Chart | Lawnmower Pros

Jonsered Chainsaw Bar and Chain Quick Reference Chart available online and ready to ship direct to your door. Free tech support. 365 day returns. Worldwide shipping.www.lawnmowerpros.com

You're a genius. Thanks

So checking what's on the original bar, it says 050. Not 058. You're chain/bar matching page states that it's 058 gauge.

#51

B

bertsmobile1

B

bertsmobile1

So you are assuming that the bar is in fact the original one and even then that the bar supplied with the saw is the one it was supposed to have

That is a very big ask

When we bought our chainsaw I got them to fit a smaller & lighter bar so SWMBO could use it

An 050 bar is a lot lighter than an 058 bar

I do not know what chains you have there but the 050 chain & the 058 chain is identical in every dimension apart from the thickness of the drive links.

That is a very big ask

When we bought our chainsaw I got them to fit a smaller & lighter bar so SWMBO could use it

An 050 bar is a lot lighter than an 058 bar

I do not know what chains you have there but the 050 chain & the 058 chain is identical in every dimension apart from the thickness of the drive links.

#52

StarTech

Once you know the needed specs then finding a replacement BNC is easy. Lots of option including lightweight bars for standard chains and even the Pixel (Pica) is option when you them in the correct mount.

StarTech

That what I tried to get thru to PT. You never assume the customer has a matching setup. In this case there is a possibility that either it came setup with .325 or 3/8 pitch. Some aftermarket manuals don't cover both options especially the online ones.So you are assuming that the bar is in fact the original one and even then that the bar supplied with the saw is the one it was supposed to have

That is a very big ask

When we bought our chainsaw I got them to fit a smaller & lighter bar so SWMBO could use it

An 050 bar is a lot lighter than an 058 bar

I do not know what chains you have there but the 050 chain & the 058 chain is identical in every dimension apart from the thickness of the drive links.

Once you know the needed specs then finding a replacement BNC is easy. Lots of option including lightweight bars for standard chains and even the Pixel (Pica) is option when you them in the correct mount.

#53

StarTech

StarTech

Sounds like the manufactures need to come up with a new stone for us to use. Something like a 3/32 or 1/16 it going to be fragile however. I am always breaking the die grinder 1/16 disks.I have 1/8" wheels. Some of the new electric saws have teeth so small the 1/8" won't fit between the tooth and raker. Smaller than the stihl micro chisel.

Most of the cutting I do is cutting down and bucking big dead ash, hackberry and oaks for farmers around me. My brother in law heats with wood and his MS290 struggles in big wood. I have a hot rodded 660 clone and I drop and and buck it for him. Most stuff 24 to 36 inch diameter. Semi chisel is way slower than full chisel with a 25" bar buried in an old oak.

#54

Hammermechanicman

Hammermechanicman

I am about to the point where I just tell customers I don't work on electric stuff. They are dead simple to work on and diagnose but parts are a nightmare. Even when I find parts lists the parts are not available or they cost more than the tool cost new. On the bright side. The battery will die before the saw will need a new chain so one is all it will need.

Does PT know what pitch the drive sprocket is? I see lots of folks putting putting a 3/8 on a .325 or vice versa.

Does PT know what pitch the drive sprocket is? I see lots of folks putting putting a 3/8 on a .325 or vice versa.

#55

StarTech

StarTech

From what I have gather from PT is the operator is just have a cutting problem with it cutting in a curve which is a sharpening problem normally but can be a bar issue too. His client may not even need a replacement BNC; although, depending the chain condition might need a new chain and rim provided the IPL is correct about it having a rim drive system.

#56

Hammermechanicman

Hammermechanicman

I find most saws that cut crooked either have a chain poorly hand filed or the bar groove it worn out. Just about every saw that comes in the shop needs the bar dressed and the groove cleaned because the oil hole it blocked and the bar edges are blue.

#57

B

bertsmobile1

"Sorry I am a mechanic not an electrician so I am not insured for repairing electric gear so I can not work on them "

B

bertsmobile1

Found a simple solution to that oneI am about to the point where I just tell customers I don't work on electric stuff. They are dead simple to work on and diagnose but parts are a nightmare. Even when I find parts lists the parts are not available or they cost more than the tool cost new. On the bright side. The battery will die before the saw will need a new chain so one is all it will need.

Does PT know what pitch the drive sprocket is? I see lots of folks putting putting a 3/8 on a .325 or vice versa.

"Sorry I am a mechanic not an electrician so I am not insured for repairing electric gear so I can not work on them "

#58

StarTech

StarTech

Now Bert you know that you get curly hair with you stick your finger in the light sockets.

Here we got lawnmower mechanics that are totally lost when comes to the electric wiring. I one shop just last week to tell he needed a complete wiring because of a bad fuse holder that costs was 3.65 for the customer. I think my cost on that Pack-con III fuse holder and terminals is under $1.60.

Here we got lawnmower mechanics that are totally lost when comes to the electric wiring. I one shop just last week to tell he needed a complete wiring because of a bad fuse holder that costs was 3.65 for the customer. I think my cost on that Pack-con III fuse holder and terminals is under $1.60.

#59

B

bertsmobile1

They are all made in some 3rd world hovel and parts will not be available even if they are repairable

Then we get to battery stuff and the thread a few days back about charging fires

I do not want to be sued because I fixed some junk pile then it blew up & burned down the idiots house

Every one understands the lack of insurance angle so it does not sound like I am fobbing them off.

Same story with generators I will fix a motor so it is running at the correct speeds .

If it don't make any zappies, take it to an electrician

While I can do it I don't want to

Seen way too many idiots running them in the rain on the back of an aluminium tray with no ground spikes

Then there is the problem of finding obsolete parts .

Got 5 of them here , all came in for a " up tune "

all got fresh oil, filters , plugs & valve lash adjusted.

All ran perfectly not a single one generated & all 5 owners said it was working perfectly when they brought them in

When th 3 years is up they go in the scrap bin after a little visit from mr BFH

B

bertsmobile1

I just do not want to work on themNow Bert you know that you get curly hair with you stick your finger in the light sockets.

Here we got lawnmower mechanics that are totally lost when comes to the electric wiring. I one shop just last week to tell he needed a complete wiring because of a bad fuse holder that costs was 3.65 for the customer. I think my cost on that Pack-con III fuse holder and terminals is under $1.60.

They are all made in some 3rd world hovel and parts will not be available even if they are repairable

Then we get to battery stuff and the thread a few days back about charging fires

I do not want to be sued because I fixed some junk pile then it blew up & burned down the idiots house

Every one understands the lack of insurance angle so it does not sound like I am fobbing them off.

Same story with generators I will fix a motor so it is running at the correct speeds .

If it don't make any zappies, take it to an electrician

While I can do it I don't want to

Seen way too many idiots running them in the rain on the back of an aluminium tray with no ground spikes

Then there is the problem of finding obsolete parts .

Got 5 of them here , all came in for a " up tune "

all got fresh oil, filters , plugs & valve lash adjusted.

All ran perfectly not a single one generated & all 5 owners said it was working perfectly when they brought them in

When th 3 years is up they go in the scrap bin after a little visit from mr BFH

#60

PTmowerMech

My brother bought it new. And has done nothing but brag about it's performance. I remember seeing the saw a couple of years ago when you could still make out the Jonesered on the bar. So I have no doubt it's all original.

PTmowerMech

So you are assuming that the bar is in fact the original one and even then that the bar supplied with the saw is the one it was supposed to have

That is a very big ask

When we bought our chainsaw I got them to fit a smaller & lighter bar so SWMBO could use it

An 050 bar is a lot lighter than an 058 bar

I do not know what chains you have there but the 050 chain & the 058 chain is identical in every dimension apart from the thickness of the drive links.

My brother bought it new. And has done nothing but brag about it's performance. I remember seeing the saw a couple of years ago when you could still make out the Jonesered on the bar. So I have no doubt it's all original.

#61

PTmowerMech

The bar is worn out. The chain has way too much wiggle. It's stamped on the bar 050. And a quarter will slide into it a tiny bit. Plus there's a tiny notch on most of the chain tips (one side only).

PTmowerMech

From what I have gather from PT is the operator is just have a cutting problem with it cutting in a curve which is a sharpening problem normally but can be a bar issue too. His client may not even need a replacement BNC; although, depending the chain condition might need a new chain and rim provided the IPL is correct about it having a rim drive system.

The bar is worn out. The chain has way too much wiggle. It's stamped on the bar 050. And a quarter will slide into it a tiny bit. Plus there's a tiny notch on most of the chain tips (one side only).

#62

M

MParr

M

MParr

Yep, new bar and chain is in order. Has your brother changed his mind on the brand of bar?The bar is worn out. The chain has way too much wiggle. It's stamped on the bar 050. And a quarter will slide into it a tiny bit. Plus there's a tiny notch on most of the chain tips (one side only).

#63

B

bertsmobile1

B

bertsmobile1

IT can be a johnsored bar, but still not be the bar it should have been supplied with

Our saw was a Stihl with a genuine Stihl bar, jus t 2" shorter and one gauge side smaller than the book says should be on there

Our saw was a Stihl with a genuine Stihl bar, jus t 2" shorter and one gauge side smaller than the book says should be on there

#64

StarTech

StarTech

And you actually measure the Stihl bar it is actually short that what they claim or at that is how it is here. EX 18" Bar may only be 17".

#65

S

sessman55

S

sessman55

The chain is on backwardsI haven't seen this saw yet.

My brother said he's got a Jonered CS58 (Note. He wasn't at his saw when he gave me the model number. But said he thinks that's the right one).

He was either sold the wrong blade or bar (or both). None the less, he says it won't cut at all. So I'm trying to figure out how to get the right bar & chain for it, as if he just handed me the saw with no bar or chain. Start from scratch, sort of speak.

He says the numbers on the original bar aren't visible.

#67

M

MParr

Dealer? Jonsered was gobbled up by Husqvarna.

There are at least two very knowledgeable people that have provided the correct bar and chain combination for the saw.

M

MParr

Why?Take it to a dealer.

Dealer? Jonsered was gobbled up by Husqvarna.

There are at least two very knowledgeable people that have provided the correct bar and chain combination for the saw.

#68

StarTech

StarTech

One final comment...

PT sit down and do you research...Otherwords you got some self training to do to educate yourself on bars and chains. It not something you can do overnight either it will take time absorb the info. But you probably have a few cobwebs of the mind to clear out to make room for the info too. There is times here that I got to fight my own cobwebs to retrieve things I got stored away from 20+ yrs ago.

There is times here that I got to fight my own cobwebs to retrieve things I got stored away from 20+ yrs ago.

The Oregon catalog is a good source of info; although it is limited too as you must combine your resources. I had to learn about these on the fly myself as I repaired chainsaws but now it is easy to get the right setup quickly. Of the three catalogs I got here Oregon, Rotary, and Stens; the Oregon catalog is the best when it comes to chainsaw bars and chains.

As the old saying "Knowledge is Power" is true as long as you got good knowledge and not a lot misinformation. And the internet is full of misinformation. Got to stick with the trusted sources and take everything else with a grain of salt.

PT sit down and do you research...Otherwords you got some self training to do to educate yourself on bars and chains. It not something you can do overnight either it will take time absorb the info. But you probably have a few cobwebs of the mind to clear out to make room for the info too.

The Oregon catalog is a good source of info; although it is limited too as you must combine your resources. I had to learn about these on the fly myself as I repaired chainsaws but now it is easy to get the right setup quickly. Of the three catalogs I got here Oregon, Rotary, and Stens; the Oregon catalog is the best when it comes to chainsaw bars and chains.

As the old saying "Knowledge is Power" is true as long as you got good knowledge and not a lot misinformation. And the internet is full of misinformation. Got to stick with the trusted sources and take everything else with a grain of salt.

#69

G

g-man57

G

g-man57

Yup - my first thought too - chain on backward.

I've had a 2258 for nearly 10 years. My old saw was stolen from me. After a man's dog, his chainsaw is the worst thing in the world to steal.

Jonsered (now Husqvarna) made really good saws. I've owned three - that I remember. We used them at work - along with Stihl. 90cc saws. Heavy cutting and lots of it. I've run hundreds, probably over a thousand, of gallons of gas thru chainsaws. The Jonsereds seemed to have fewer issues than the Stihls. Don't get me wrong, Stihl makes a great saw - same with Husqvarna. I always bought Jonsered for ergonomic reasons. They just felt better in my hands. I'm too old now to be buying new saws - but if I did it would be a Hunsky. Probably in the 55cc range.

I do miss the old 'chipper' chains. I was never a fan of 'chisel' chains - they seemed to not keep an edge as long as the chippers. Chisels cut very well - but I like the smooth, vibration free, feel of chippers. I really don't like the anti-kickback chains. They're a pain in the butt to sharpen.

I've had a 2258 for nearly 10 years. My old saw was stolen from me. After a man's dog, his chainsaw is the worst thing in the world to steal.

Jonsered (now Husqvarna) made really good saws. I've owned three - that I remember. We used them at work - along with Stihl. 90cc saws. Heavy cutting and lots of it. I've run hundreds, probably over a thousand, of gallons of gas thru chainsaws. The Jonsereds seemed to have fewer issues than the Stihls. Don't get me wrong, Stihl makes a great saw - same with Husqvarna. I always bought Jonsered for ergonomic reasons. They just felt better in my hands. I'm too old now to be buying new saws - but if I did it would be a Hunsky. Probably in the 55cc range.

I do miss the old 'chipper' chains. I was never a fan of 'chisel' chains - they seemed to not keep an edge as long as the chippers. Chisels cut very well - but I like the smooth, vibration free, feel of chippers. I really don't like the anti-kickback chains. They're a pain in the butt to sharpen.

#70

PTmowerMech

And I've got them written down. Had them written down the moment I seen the post. Just waiting until the one I ordered comes in to see how it's wrong? The numbers on the bar & chain I ordered matched the numbers on the bar. Up til this thread, I was just doing what I've seen online, and what people like Steve Small Engine Saloon stated. Match the DL, gauge and pitch. 99% of everything, other than this thread, says that's all you need to get the right parts.

I'd already ordered the bar & chain before Star and others advised me I'd gotten the wrong stuff. Since the saw has been cutting great, up until recently, I seen no need to believe the numbers on the bar was wrong.

PTmowerMech

Why?

Dealer? Jonsered was gobbled up by Husqvarna.

There are at least two very knowledgeable people that have provided the correct bar and chain combination for the saw.

And I've got them written down. Had them written down the moment I seen the post. Just waiting until the one I ordered comes in to see how it's wrong? The numbers on the bar & chain I ordered matched the numbers on the bar. Up til this thread, I was just doing what I've seen online, and what people like Steve Small Engine Saloon stated. Match the DL, gauge and pitch. 99% of everything, other than this thread, says that's all you need to get the right parts.

I'd already ordered the bar & chain before Star and others advised me I'd gotten the wrong stuff. Since the saw has been cutting great, up until recently, I seen no need to believe the numbers on the bar was wrong.

#71

Hammermechanicman

Once you get the bar and chain stuff figured out it is pretty easy. If you plan to sharpen chains that is another whole thing to learn.

Hammermechanicman

Good info from star. Don't know if you use a chainsaw but if you do here is a link to a series of vids about proper and safe use of chainsaws. May help keep you off the Darwin awards. I work with lots of farmers clearing dead trees out of fence rows and creek banks. Most of them scare the sh!t out of me! No PPE and just doing stupid stuff.One final comment...

PT sit down and do you research...Otherwords you got some self training to do to educate yourself on bars and chains. It not something you can do overnight either it will take time absorb the info. But you probably have a few cobwebs of the mind to clear out to make room for the info too.There is times here that I got to fight my own cobwebs to retrieve things I got stored away from 20+ yrs ago.

The Oregon catalog is a good source of info; although it is limited too as you must combine your resources. I had to learn about these on the fly myself as I repaired chainsaws but now it is easy to get the right setup quickly. Of the three catalogs I got here Oregon, Rotary, and Stens; the Oregon catalog is the best when it comes to chainsaw bars and chains.

As the old saying "Knowledge is Power" is true as long as you got good knowledge and not a lot misinformation. And the internet is full of misinformation. Got to stick with the trusted sources and take everything else with a grain of salt.

Once you get the bar and chain stuff figured out it is pretty easy. If you plan to sharpen chains that is another whole thing to learn.

#72

L

LMPPLUS

L

LMPPLUS

I haven't seen this saw yet.

My brother said he's got a Jonered CS58 (Note. He wasn't at his saw when he gave me the model number. But said he thinks that's the right one).

He was either sold the wrong blade or bar (or both). None the less, he says it won't cut at all. So I'm trying to figure out how to get the right bar & chain for it, as if he just handed me the saw with no bar or chain. Start from scratch, sort of speak.

He says the numbers on the original bar aren't visible.

#73

PTmowerMech

I don't want to sound like I'm arguing with anyone, just trying to figure this bar & chain thing out. Every legit place I've looked at, says the same thing. Match the DL, gauge & pitch. That's what I did. Since this bar has been working great, up until it finally wore out (it's the original one). If it was wrong, as Bert suggested, seems it would've been worn out in the first year. The numbers you gave me, didn't jive with the numbers on the bar. 058 is what you posted, when the bar says 050.

Ok, so let's say the bar that came with it from the store was the wrong one. I'm not sure how wrong it could be if it's worked so well for so long. Seems the sprocket on either end would've given out by now.

PTmowerMech

One final comment...

PT sit down and do you research...Otherwords you got some self training to do to educate yourself on bars and chains. It not something you can do overnight either it will take time absorb the info. But you probably have a few cobwebs of the mind to clear out to make room for the info too.There is times here that I got to fight my own cobwebs to retrieve things I got stored away from 20+ yrs ago.

The Oregon catalog is a good source of info; although it is limited too as you must combine your resources. I had to learn about these on the fly myself as I repaired chainsaws but now it is easy to get the right setup quickly. Of the three catalogs I got here Oregon, Rotary, and Stens; the Oregon catalog is the best when it comes to chainsaw bars and chains.

As the old saying "Knowledge is Power" is true as long as you got good knowledge and not a lot misinformation. And the internet is full of misinformation. Got to stick with the trusted sources and take everything else with a grain of salt.

I don't want to sound like I'm arguing with anyone, just trying to figure this bar & chain thing out. Every legit place I've looked at, says the same thing. Match the DL, gauge & pitch. That's what I did. Since this bar has been working great, up until it finally wore out (it's the original one). If it was wrong, as Bert suggested, seems it would've been worn out in the first year. The numbers you gave me, didn't jive with the numbers on the bar. 058 is what you posted, when the bar says 050.

Ok, so let's say the bar that came with it from the store was the wrong one. I'm not sure how wrong it could be if it's worked so well for so long. Seems the sprocket on either end would've given out by now.

#74

PTmowerMech

PTmowerMech

@LMPPLUS, this post (the OP you quoted) was what I was posting prior to actually seeing it the saw. Once he got here, we worked out some details on a few things. Like the bar. I thought he'd bought a new bar & chain. When in fact it was only the chain he bought. It was fairly new, but was cutting crooked.

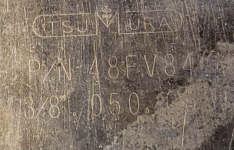

The numbers on the bar weren't visible. I had to use my magnifying glass to see them. (even with my spectacles on). But my phones camera made it easy to take a pic.

Getting the saw in hand, I was able to figure out why it was cutting at an angle The bar was worn out, and the new chains tip on one side, had some damage to the point. (full chisel).

The rest has been trying to figure out why using the DL, gauge and pitch isn't the only info needed when ordering a new bar.

The numbers on the bar weren't visible. I had to use my magnifying glass to see them. (even with my spectacles on). But my phones camera made it easy to take a pic.

Getting the saw in hand, I was able to figure out why it was cutting at an angle The bar was worn out, and the new chains tip on one side, had some damage to the point. (full chisel).

The rest has been trying to figure out why using the DL, gauge and pitch isn't the only info needed when ordering a new bar.

#75

MarineBob

MarineBob

I didn't read all the comments so my apologies if this has been noted. Is the chain on backwards? Many moons ago I bought a clearance McCholough (sp??) saw that was on display in a shop. Took it home and the sucker would not cut. Scratched my head for a long while then realized the chain was on backwards.......duh... I guess who ever took it out of the box in the shop just put the chain on never thinking about the orientation.

#76

PTmowerMech

Yeah, it's on right. Has always been on right. My brother has been cutting wood for a long time. Back in the day, my dad owned a tree service business down in Dallas. He worked with my dad a lot. Prior to that, dad used to cut and haul pulp wood. He and my other brother had to work with him. So he's not a novice when it comes to chainsaws. Just doesn't know the technical details like some of the techs here.

I was young at the time and lived with mom when the pulp wood and the tree service was going on.

PTmowerMech

I didn't read all the comments so my apologies if this has been noted. Is the chain on backwards? Many moons ago I bought a clearance McCholough (sp??) saw that was on display in a shop. Took it home and the sucker would not cut. Scratched my head for a long while then realized the chain was on backwards.......duh... I guess who ever took it out of the box in the shop just put the chain on never thinking about the orientation.

Yeah, it's on right. Has always been on right. My brother has been cutting wood for a long time. Back in the day, my dad owned a tree service business down in Dallas. He worked with my dad a lot. Prior to that, dad used to cut and haul pulp wood. He and my other brother had to work with him. So he's not a novice when it comes to chainsaws. Just doesn't know the technical details like some of the techs here.

I was young at the time and lived with mom when the pulp wood and the tree service was going on.

#77

StarTech

StarTech

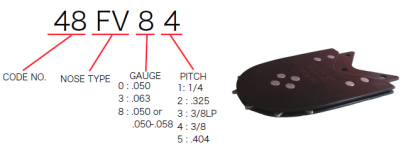

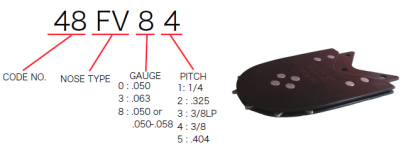

But they leave one important thing out and that is the bar mount. The gauge is important to a point otherwords it must make the bar gauge. And what appears to have happen over time is someone replaced the Jonsered bar with Tsumura bar. The Tsumura PN 48FV84 in your image is just the replaceable bar tip which is actually a .050 / .058 tip.

And the Tsumura Bar mount that matches the K095 is their A012. Which only came in a .058 gauge. Its PN is 381FV4.

Reference Material

Tsumura Catalog

And there appears a typo in the catalog as the 20" 3/8" .058" should be PN (T)381FV4 in the A012 (K095) mount and not 381PV4

And be careful as some site imaging a carving bar and not the standard shape bar.

And the Tsumura Bar mount that matches the K095 is their A012. Which only came in a .058 gauge. Its PN is 381FV4.

Reference Material

Tsumura Catalog

And there appears a typo in the catalog as the 20" 3/8" .058" should be PN (T)381FV4 in the A012 (K095) mount and not 381PV4

And be careful as some site imaging a carving bar and not the standard shape bar.

#78

B

bertsmobile1

B

bertsmobile1

An 058 chain will run fine in an 050 bar, it just puts more load on the saw because there is not the right clearance

In a short time the wider chain will wear the sides on the bar groove

In a short time the wider chain will wear the sides on the bar groove

#79

StarTech

Just recently had a customer with a new BNC correctly matched to the saw that return because the chain quit moving. He forget that the BNC needs oil. I barely got the chain un welded from the bar groove.