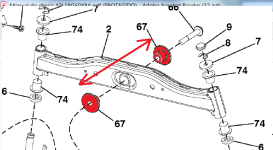

I already did that a few days ago... there was a lot of looseness and I corrected it a little, but I think it's acceptable due to the age of the machine, but now I'm going to remove and analyze the geometry of the tubes... or they welded crooked (not likely) or it was a heavy blow.Pull # 2 out and check the bushes and the hole they run in

One of the two plates that # 2 sits between will have slots for the purpose of adjustment

Usually it is the front one

When you turn there isa very high bending moment at the pivot

Review the ugly weld in post #19... break this rod, just with a very strong blow (my suspicion).