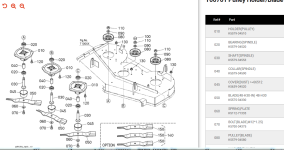

Has anyone have this happen? Cutting my grass and heard a loud bang. Thought I might have hit a sprinkler head. Nope, the bolt snapped and the blade,,,luckily drove into the ground.

Not sure on how to fix. Try to drill out the bolt or replace the Final drive. In either case how do I prevent the final drive from spinning while I am trying to remove?

Thanks, any suggestions would be very welcome. Tom

Not sure on how to fix. Try to drill out the bolt or replace the Final drive. In either case how do I prevent the final drive from spinning while I am trying to remove?

Thanks, any suggestions would be very welcome. Tom