You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yardvacuum Impeller Removal

- Thread starter l008com

- Start date

More options

Export threadI think coarse thread. There’s more metal left to shear if it strips. I’d also soak it with penetrating oil; I’d put a bunch of heat on one side then cool it off; and then do it to the other side. If there’s corrosion, you’re trying to break it loose. When I get ready to tighten the bolt, I’d smack it around the outside with a rubber mallet downward as the direction of the shaft. You’re trying to shock it enough to break loose the corrosion but not enough to bend the shaft or impeller. Keep tightening the bolt little by little. Hopefully it’ll pop off. A heat gun will put a lot of heat into the impeller hopefully without warping it.Fine thread, same as gear pullers etc

l008com

Well-Known Member

- Joined

- May 25, 2015

- Threads

- 47

- Messages

- 268

I thought about penatrating oil, but I don't think theres any way to actually get it near the contact zone the way this thing is assembled. You'd have to spray it on the shaft, above the impeller blade. Basically you'll have to remove it to be able to access it to spray oil on it, so that you can remove it

Regarding fine vs coarse, I guess we'll take a vote, 1 vs 1 so far. I can see both benefits and negatives of both options so I'm not sure which would be best.

Regarding fine vs coarse, I guess we'll take a vote, 1 vs 1 so far. I can see both benefits and negatives of both options so I'm not sure which would be best.

The finer thread has an advantage to give more pull/push. However thats not your issue. You sheared the metal, so you pushed too hard. A coarse thread doesn’t remove as much metal so you have more left to resist shear.I thought about penatrating oil, but I don't think theres any way to actually get it near the contact zone the way this thing is assembled. You'd have to spray it on the shaft, above the impeller blade. Basically you'll have to remove it to be able to access it to spray oil on it, so that you can remove it

Regarding fine vs coarse, I guess we'll take a vote, 1 vs 1 so far. I can see both benefits and negatives of both options so I'm not sure which would be best.

Question. Is the impeller made of aluminum.

It’s a mechanical advantage. Think of it as an incline slope. A finer thread is a more gentle slope and a coarse thread is a steep slope. It’s easier to push something up the gentle slope/more distance with lessor effort. However, more threads, less metal left. Weaker to resist shear.Coarse thread will give me bigger threads to push wish, BUT fine threads will give me MORE threads to push with.

And yes I believe it is aluminum.

I’m thinking heat is the only solution. You probably have some corrosion that has the impeller locked to the shaft. Your savior is that aluminum expans at twice the rate as steel. Also putting the heat on the impeller is only going to expan the shaft by transfer of heat from the impeller, so at a lessor rate. I think you have to get the impeller hot enough to sizzle water, like 250 F. I would shoot in a bunch of blaster and put the jack bolt in tight before heating. It should push the blaster around the shaft. If you can get it tight enough, it might build pressure to help push the impeller offAnd note you are dealing a tapered crankshaft.

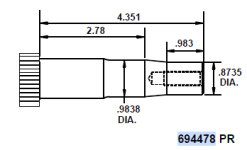

View attachment 70339

The taper section is 1.571" so penetrating oil just don't work as this is a fiction fit.

Gear pullers have fine threads because they allow for a more precise and gradual application of force when pulling parts, ensuring a controlled extraction without damaging the component or the surrounding area, thanks to the smaller pitch of the threads which enables finer adjustments during tightening.

an old rule of thumb is to have a thickness equal to the bolt diameter for threads in steel. The same rule for aluminum is 3 times the bolt diameter. The metal available for threads in the aluminum hub is limited. The torque isn’t an issue. He has already shown that fine threads have sheared; 7/16-20. If he uses a coarse thread, he has more metal to resist shear. Seems a pretty simple decision to me.