You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Yardvacuum Impeller Removal

#1

l008com

l008com

So I watched a bunch of youtube videos for removing the impeller off my machine. This is so I can ultimately take the motor off and open it up because I think it overheated and melted it's camshaft. But anyway....

Multiple videos say to use a 7/16" - 20 bolt. So I go pick one up and when I go to thread it in, nada. Totally the wrong threading, although the diameter seems right.

So what's going on here? Did I buy a bolt with the wrong threading? Certainly possible someone could have put it in the wrong spot on the nut and bolt wall at the hardware store. Easy enough to check if someone can tell me what the " - 20" is. Is that like threads per inch or theads per something?

OR does my impeller just need something other than - 20 threading? Unfortunately you need this bolt to remove the impeller so I can't just bring it into the hardware store and try every size until I find one that works - which is what I normally do in a situation like this

BUT I do have a picture, maybe you guys can tell just by looking?

Assuming the "20" is the threads-per-inch, it looks like I have 19 threads per inch here. I assume that missing thread is just the perspective of the camera. So it is a -20 bolt, so I guess I need something else you think?

Oh also here's the model number(s) off the machine itself:

24A-070J799

247.77013.0

And the serial number is:

1H198G70100

Multiple videos say to use a 7/16" - 20 bolt. So I go pick one up and when I go to thread it in, nada. Totally the wrong threading, although the diameter seems right.

So what's going on here? Did I buy a bolt with the wrong threading? Certainly possible someone could have put it in the wrong spot on the nut and bolt wall at the hardware store. Easy enough to check if someone can tell me what the " - 20" is. Is that like threads per inch or theads per something?

OR does my impeller just need something other than - 20 threading? Unfortunately you need this bolt to remove the impeller so I can't just bring it into the hardware store and try every size until I find one that works - which is what I normally do in a situation like this

BUT I do have a picture, maybe you guys can tell just by looking?

Assuming the "20" is the threads-per-inch, it looks like I have 19 threads per inch here. I assume that missing thread is just the perspective of the camera. So it is a -20 bolt, so I guess I need something else you think?

Oh also here's the model number(s) off the machine itself:

24A-070J799

247.77013.0

And the serial number is:

1H198G70100

#3

l008com

l008com

I don't need the whole tool. I just need a simple short bolt to thread i to teh impeller. I can use a piece of rod or something else to be the "insert" it pushes against. Plus the reviews on that thing to not look good. And it looks like there are more than one threading these impellers have so it all leads back to the same question, which size threading am I looking for. I guess I forgot to include my machine model number in the original post.

#4

ILENGINE

ILENGINE

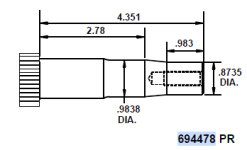

Went and measures the threads on my DR impeller removal tool and they are 20/inch. but it measures .327 in diameter which is smaller than 7/16 but doesn't match up with anything else. From the picture it looks like the threads in your impeller are damaged so they could be flattened causing issues with your bolt.

#5

l008com

l008com

Yeah I don't get it, 7/16-20 is what this bolt is and the threads aren't right at all. YOu have to go through the impeller threads to get to the crankshaft threads so I'm nowhere near those.

#6

StarTech

StarTech

The tool pushes the impeller off so it is design to pass the 3/8-24 threading of crankshaft and bottom out in the blind hole. This prevents the tool from pushing on the end of crankshaft damaging the threads.

Matter of fact any puller that pushes against a shaft should have a sacrificial intermediate block (shaft protectors) as even those pullers can also damage threading without these. They also help prevent the shaft that being press against from flaring.

Here is an example of one in use.

Matter of fact any puller that pushes against a shaft should have a sacrificial intermediate block (shaft protectors) as even those pullers can also damage threading without these. They also help prevent the shaft that being press against from flaring.

Here is an example of one in use.

#7

l008com

l008com

Yeah but what I'm saying is that I can't get this bolt to thread into the initial threads that it is supposed to engage with. Once I can get it to engage, I can throw any old rod in the hole to act as a spacer/pusher so I don't to any damage to the threads on the motor shaft. But I can't do that until I get a bolt that will actually thread in to the impeller, which seems to be my problem. When I started to thread this bolt in, it got a few turns in but it was getting tighter and tighter until it basically stopped. It's gotta be a case of the wrong threading.

#10

StarTech

StarTech

Sounds like it is a M11-1.25 thread very close to 7/16-20 but is tight two ways. 7/16-20 are drilled out at .390 and M11-1.25 is drilled out at .384 and the pitch are slightly different too. Looks the same but are not.

It will nearly impossible to find a M11-1.25 screw.

It will nearly impossible to find a M11-1.25 screw.

#12

Tiger Small Engine

If you can get the engine opened up, can you show us pictures of what a “melted camshaft “ looks like please? Lobes can be compromised, but never heard of a small engine turning 3600 RPMs, melting a cam.

Tiger Small Engine

So I watched a bunch of youtube videos for removing the impeller off my machine. This is so I can ultimately take the motor off and open it up because I think it overheated and melted it's camshaft. But anyway....

Multiple videos say to use a 7/16" - 20 bolt. So I go pick one up and when I go to thread it in, nada. Totally the wrong threading, although the diameter seems right.

So what's going on here? Did I buy a bolt with the wrong threading? Certainly possible someone could have put it in the wrong spot on the nut and bolt wall at the hardware store. Easy enough to check if someone can tell me what the " - 20" is. Is that like threads per inch or theads per something?

OR does my impeller just need something other than - 20 threading? Unfortunately you need this bolt to remove the impeller so I can't just bring it into the hardware store and try every size until I find one that works - which is what I normally do in a situation like this

BUT I do have a picture, maybe you guys can tell just by looking?

View attachment 70231

Assuming the "20" is the threads-per-inch, it looks like I have 19 threads per inch here. I assume that missing thread is just the perspective of the camera. So it is a -20 bolt, so I guess I need something else you think?

View attachment 70232

Oh also here's the model number(s) off the machine itself:

24A-070J799

247.77013.0

And the serial number is:

1H198G70100

If you can get the engine opened up, can you show us pictures of what a “melted camshaft “ looks like please? Lobes can be compromised, but never heard of a small engine turning 3600 RPMs, melting a cam.

#13

l008com

l008com

The whole project will be a youtube video some day. I don't have any idea what the camshaft is going to look like, but what I do know is:

The camshaft is plastic

The engine was running well when I first started it up.

It died and had zero compression when I tried to restart it.

The compression came back but with the valve cover off, the valves were opening and closing at the complete wrong times.

Also I didn't know when I started it up but it had a lot of leaves and similar yard waste packed up under the cover.

So the only thing that makes sense to me is that the came shaft melted to some degree. I'l find out eventually.

The camshaft is plastic

The engine was running well when I first started it up.

It died and had zero compression when I tried to restart it.

The compression came back but with the valve cover off, the valves were opening and closing at the complete wrong times.

Also I didn't know when I started it up but it had a lot of leaves and similar yard waste packed up under the cover.

So the only thing that makes sense to me is that the came shaft melted to some degree. I'l find out eventually.

#14

l008com

l008com

My local hardware store has two big isles of all nuts and bolts. But alas, they only had even numbered mm bolts, no 11mm at all. I grabbed a 10mm just to see but it fit right through the hole without engaging the threads at all.

#15

StarTech

StarTech

I tried to tell you that it is a non standard size. About the only fairly local place that might have an used one is the Toyota Dealer repair shop since it is used as a head bolt.

Now you know why they said to drill for a 7/16-20 tap and tap it for the 7/16-20 bolt.

OR you just buy a set of 8 for around $50+ from the auto part store.

Now you know why they said to drill for a 7/16-20 tap and tap it for the 7/16-20 bolt.

OR you just buy a set of 8 for around $50+ from the auto part store.

#16

l008com

l008com

Hmm I guess I'll have to consider re-tapping the whole, that might be the easiest solution.

#17

L

Laabk2

L

Laabk2

According to the parts diagram it is a 3/8-24 bolt 2.75 inches longSo I watched a bunch of youtube videos for removing the impeller off my machine. This is so I can ultimately take the motor off and open it up because I think it overheated and melted it's camshaft. But anyway....

Multiple videos say to use a 7/16" - 20 bolt. So I go pick one up and when I go to thread it in, nada. Totally the wrong threading, although the diameter seems right.

So what's going on here? Did I buy a bolt with the wrong threading? Certainly possible someone could have put it in the wrong spot on the nut and bolt wall at the hardware store. Easy enough to check if someone can tell me what the " - 20" is. Is that like threads per inch or theads per something?

OR does my impeller just need something other than - 20 threading? Unfortunately you need this bolt to remove the impeller so I can't just bring it into the hardware store and try every size until I find one that works - which is what I normally do in a situation like this

BUT I do have a picture, maybe you guys can tell just by looking?

View attachment 70231

Assuming the "20" is the threads-per-inch, it looks like I have 19 threads per inch here. I assume that missing thread is just the perspective of the camera. So it is a -20 bolt, so I guess I need something else you think?

View attachment 70232

Oh also here's the model number(s) off the machine itself:

24A-070J799

247.77013.0

And the serial number is:

1H198G70100

#18

l008com

l008com

Are you referring to the removal tool or the bolt that holds the impeller on to the motor?

#19

L

Laabk2

L

Laabk2

The bolt that retains the impeller.Are you referring to the removal tool or the bolt that holds the impeller on to the motor?

#20

l008com

l008com

I'm not looking for that, I'm looking for the threading in the impeller itself, that you would use with the removal tool or with the right sized bolt, to remove the impeller.

#23

l008com

l008com

Please see the previous 5 posts.Looks to me like it should be 3/8-24. See the link below (reference 31)

#24

G

Gravelier

G

Gravelier

You said that you encountered resistance after threading in the 7/16-20 bolt a couple turns. Then you were able to force a couple more turns before encountering high resistance. Have you tried running a tap into the hole to see what comes back with the tap? If you are getting 4 turns into the hole, it seems like the bolt and threads are correct and that you have crap in the threads. You can feel the difference when running in the tap if you are cutting metal (cross threading the existing threads) or removing debris. Don’t cut metal with the tap. Another method is make a chaser with the 7/16-20 bolt. I use a 3-corner file to undercut the threads. I tried to upload a picture but I get a msg that it’s too large to upload from my iPad. Good luck

#25

l008com

l008com

I don't own a tap kit, I've been asking around to borrow one but coming up empty so i'll probalby go buy a HF kit after the holidays.

I also had the idea of getting a stick of hot glue or a crayon, an slightly melting it into the threads. The once it cools, popping it off and then comparing the threading of the glue stick to the threading of the bolt itself.

As far as dirt in the threads, it looked clean and it didn't feel like i was binding on dirt, it felt like the threads were wrong. But who knows.

I also had the idea of getting a stick of hot glue or a crayon, an slightly melting it into the threads. The once it cools, popping it off and then comparing the threading of the glue stick to the threading of the bolt itself.

As far as dirt in the threads, it looked clean and it didn't feel like i was binding on dirt, it felt like the threads were wrong. But who knows.

#26

G

Gravelier

G

Gravelier

You said that you encountered resistance after threading in the 7/16-20 bolt a couple turns. Then you were able to force a couple more turns before encountering high resistance. Have you tried running a tap into the hole to see what comes back with the tap? If you are getting 4 turns into the hole, it seems like the bolt and threads are correct and that you have crap in the threads. You can feel the difference when running in the tap if you are cutting metal (cross threading the existing threads) or removing debris. Don’t cut metal with the tap. Another method is make a chaser with the 7/16-20 bolt. I use a 3-corner file to undercut the threads. I tried to upload a picture but I get a msg that it’s too large to upload from my iPad. Good luck

I have several tap and die sets. The one that is from HF I only use to chase or clean up threads. I don’t feel it’s strong enough to cut new threads. If I need to cut new threads (tap or die) I use my old craftsman set. Best of luck.I don't own a tap kit, I've been asking around to borrow one but coming up empty so i'll probalby go buy a HF kit after the holidays.

I also had the idea of getting a stick of hot glue or a crayon, an slightly melting it into the threads. The once it cools, popping it off and then comparing the threading of the glue stick to the threading of the bolt itself.

As far as dirt in the threads, it looked clean and it didn't feel like i was binding on dirt, it felt like the threads were wrong. But who knows.

#27

l008com

l008com

Hmm well maybe I'll try my crayon thing and see if the threads are close, or way off, and go from there.

#28

M

Markdd60

M

Markdd60

There's a reason some have stated using 7/16-20, the M11-1.25 only exist for special applications..... go figure. 7/16-20 = 11.1125 (slightly larger than M11). M11 general tap drill size = 9.75mm / 7/16-20 general tap drill = 9.9218mm (close enough for sure). You already have the existing threaded hole, pick up a 7/16-20 plug tap... local auto or hardware. Those impellers are like cast aluminum it seems, pretty easy to cut new threads.... use a few drops of oil. Be gone silly M11-1.25!

#29

l008com

l008com

Yeah thats what I'm thinking at this point. I don't do thread tapping very often so I'm trying to decide how much of an investment in taps to make. I can just get an individual tap or I can get a whole SAE set or I can get a whole combo SAE & metric set. Decisions decisions. Next weekend I should have time to figure this out.

#30

StarTech

StarTech

I would not waste my money on the HF taps and dies. I brought two set and both were junk and had to return them then I got a couple Vermont American set. NOw of course that was 15 yrs ago and have only replace one tap so far.I don't own a tap kit, I've been asking around to borrow one but coming up empty so i'll probalby go buy a HF kit after the holidays.

I also had the idea of getting a stick of hot glue or a crayon, an slightly melting it into the threads. The once it cools, popping it off and then comparing the threading of the glue stick to the threading of the bolt itself.

As far as dirt in the threads, it looked clean and it didn't feel like i was binding on dirt, it felt like the threads were wrong. But who knows.

#32

l008com

l008com

Tonight I took an imprint of the threads in the hole with some hot glue, and when I held it up to the bolt (7/16-20) I was very surprised that it lined up perfectly! It looks like its a little off on the left edge but thats just an optical illusion due to camera angle. It really was a perfectly alignment all the way across the contact area.

This makes me wonder if I can/should just put the bolt back and force it.

I guess in the end this doesn't really change my plan, I should just get a 7/16-20 tap and it will either slightly expand the diameter or clean the threads or whatever the problem is, it should fix it.

This makes me wonder if I can/should just put the bolt back and force it.

I guess in the end this doesn't really change my plan, I should just get a 7/16-20 tap and it will either slightly expand the diameter or clean the threads or whatever the problem is, it should fix it.

#34

Tool_Maker_Tim

Tool_Maker_Tim

Go to Ace Hardware and see if they stock the tap you require. I am a toolmaker with over forty years of experience in this business. Though I possess nearly every tap and die known to man, occasionally I have to make a trip to the local ace hardware store myself. if it is a one-off use on aluminum or mild steel, don't fret about purchasing a tap or die made of hardened tool steel, but if you plan on using it in more of a production role, then go with a ground high-speed steel version. A good source for higher quality tools is MSC Industrial Supply. They have been my "Go-to" resource for many years. good luck and should you require any technical advice, do not hesitate to contact me. My name is Tim, and I will give you any help that I can.Tonight I took an imprint of the threads in the hole with some hot glue, and when I held it up to the bolt (7/16-20) I was very surprised that it lined up perfectly! It looks like its a little off on the left edge but thats just an optical illusion due to camera angle. It really was a perfectly alignment all the way across the contact area.

View attachment 70272

This makes me wonder if I can/should just put the bolt back and force it.

I guess in the end this doesn't really change my plan, I should just get a 7/16-20 tap and it will either slightly expand the diameter or clean the threads or whatever the problem is, it should fix it.

#35

StarTech

StarTech

You not going the M11-1.25 at MSC or McMaster. Now there are some on Amazon. This is a very odd size and most places will not have it.

Now most places will have the 7/16-20 tap as it is a common size.

Now most places will have the 7/16-20 tap as it is a common size.

#36

l008com

l008com

NAPA had the tap for $4.50 and I am now the proud owner of it.

However if I start messing with this now, its going to turn into a whole huge thing, so I'm going to wait until the end of the week.

I did VERY briefly play around with hand threading it in, and strangely the bolt goes in a lot further than the tap, even though you can line them up and clearly see that they are a perfect match. Very odd. Whatever the issue is, I'll force it through next weekend and hopefully it all works out.

However if I start messing with this now, its going to turn into a whole huge thing, so I'm going to wait until the end of the week.

I did VERY briefly play around with hand threading it in, and strangely the bolt goes in a lot further than the tap, even though you can line them up and clearly see that they are a perfect match. Very odd. Whatever the issue is, I'll force it through next weekend and hopefully it all works out.

#37

l008com

l008com

WELP, this didn't work out so well. I tapped the hole, then put in my spacer to push against, and then my 7/16" bolt and once it got snug, I started tightening it down and instead of popping the impeller off, it stripped the hole right out!

So yeah at this point, I'm kind of wishing I had just went with the official tool, but that tool won't do me any good now. Plus its possible the proper tool would have stripped too, then I'd be in the same boat I'm in now but with even more money wasted.

I'm in too deep though, I can't turn back now, I must keep going!

So I'm thinking I get a half inch tap, half inch bolt, and dry again?

What size drill bit should I use for a half inch tap?

AND do I want fine threading, so theres more threads to grab, or coarse threading, so the threads are larger and harder to strip? Which is best in a situation like this?

ALSO should I skip 1/2" all together and to right to something even bigger like a 5/8"? That seems excessive, but I gotta get this impeller off somehow.

So yeah at this point, I'm kind of wishing I had just went with the official tool, but that tool won't do me any good now. Plus its possible the proper tool would have stripped too, then I'd be in the same boat I'm in now but with even more money wasted.

I'm in too deep though, I can't turn back now, I must keep going!

So I'm thinking I get a half inch tap, half inch bolt, and dry again?

What size drill bit should I use for a half inch tap?

AND do I want fine threading, so theres more threads to grab, or coarse threading, so the threads are larger and harder to strip? Which is best in a situation like this?

ALSO should I skip 1/2" all together and to right to something even bigger like a 5/8"? That seems excessive, but I gotta get this impeller off somehow.

#38

ILENGINE

ILENGINE

1/2 inch tap uses a 29/64 drill bit. And went back and looked at your original picture in post 1 and still think as I did then that the threads in that impellor looked damaged.

#39

l008com

l008com

We'll never know for sure if the original threads were damaged or ok (they looked good to me in person).

But they're definitely damaged now! as they sit in a pile of dirt on my floor.

But they're definitely damaged now! as they sit in a pile of dirt on my floor.

#40

l008com

l008com

Does anyone have any thoughts on whether I should go with the coarse threading or fine threading on the new 1/2" hole and bolt?

I think the options are 1/2"-13 and 1/2"-20.

I think the options are 1/2"-13 and 1/2"-20.

#42

G

Gravelier

G

Gravelier

I think coarse thread. There’s more metal left to shear if it strips. I’d also soak it with penetrating oil; I’d put a bunch of heat on one side then cool it off; and then do it to the other side. If there’s corrosion, you’re trying to break it loose. When I get ready to tighten the bolt, I’d smack it around the outside with a rubber mallet downward as the direction of the shaft. You’re trying to shock it enough to break loose the corrosion but not enough to bend the shaft or impeller. Keep tightening the bolt little by little. Hopefully it’ll pop off. A heat gun will put a lot of heat into the impeller hopefully without warping it.Fine thread, same as gear pullers etc

#43

l008com

l008com

I thought about penatrating oil, but I don't think theres any way to actually get it near the contact zone the way this thing is assembled. You'd have to spray it on the shaft, above the impeller blade. Basically you'll have to remove it to be able to access it to spray oil on it, so that you can remove it

Regarding fine vs coarse, I guess we'll take a vote, 1 vs 1 so far. I can see both benefits and negatives of both options so I'm not sure which would be best.

Regarding fine vs coarse, I guess we'll take a vote, 1 vs 1 so far. I can see both benefits and negatives of both options so I'm not sure which would be best.

#44

G

Gravelier

Question. Is the impeller made of aluminum.

G

Gravelier

The finer thread has an advantage to give more pull/push. However thats not your issue. You sheared the metal, so you pushed too hard. A coarse thread doesn’t remove as much metal so you have more left to resist shear.I thought about penatrating oil, but I don't think theres any way to actually get it near the contact zone the way this thing is assembled. You'd have to spray it on the shaft, above the impeller blade. Basically you'll have to remove it to be able to access it to spray oil on it, so that you can remove it

Regarding fine vs coarse, I guess we'll take a vote, 1 vs 1 so far. I can see both benefits and negatives of both options so I'm not sure which would be best.

Question. Is the impeller made of aluminum.

#45

l008com

l008com

Coarse thread will give me bigger threads to push wish, BUT fine threads will give me MORE threads to push with.

And yes I believe it is aluminum.

And yes I believe it is aluminum.

#46

G

Gravelier

G

Gravelier

It’s a mechanical advantage. Think of it as an incline slope. A finer thread is a more gentle slope and a coarse thread is a steep slope. It’s easier to push something up the gentle slope/more distance with lessor effort. However, more threads, less metal left. Weaker to resist shear.Coarse thread will give me bigger threads to push wish, BUT fine threads will give me MORE threads to push with.

And yes I believe it is aluminum.

#48

G

Gravelier

G

Gravelier

I’m thinking heat is the only solution. You probably have some corrosion that has the impeller locked to the shaft. Your savior is that aluminum expans at twice the rate as steel. Also putting the heat on the impeller is only going to expan the shaft by transfer of heat from the impeller, so at a lessor rate. I think you have to get the impeller hot enough to sizzle water, like 250 F. I would shoot in a bunch of blaster and put the jack bolt in tight before heating. It should push the blaster around the shaft. If you can get it tight enough, it might build pressure to help push the impeller offAnd note you are dealing a tapered crankshaft.

View attachment 70339

The taper section is 1.571" so penetrating oil just don't work as this is a fiction fit.

#49

S

STEVES

S

STEVES

Gear pullers have fine threads because they allow for a more precise and gradual application of force when pulling parts, ensuring a controlled extraction without damaging the component or the surrounding area, thanks to the smaller pitch of the threads which enables finer adjustments during tightening.

#50

G

Gravelier

G

Gravelier

an old rule of thumb is to have a thickness equal to the bolt diameter for threads in steel. The same rule for aluminum is 3 times the bolt diameter. The metal available for threads in the aluminum hub is limited. The torque isn’t an issue. He has already shown that fine threads have sheared; 7/16-20. If he uses a coarse thread, he has more metal to resist shear. Seems a pretty simple decision to me.

#51

l008com

l008com

I have not had time to work on this again, but I hopefully will soon. I will be tapping half inch and using a bolt. So heres the question.....

Given how the impeller is sort of just stuck on there, does it make sense, instead of just cranking the bolt down and hoping it pops free, does it make sense to crank it a little bit, then say give the aluminum impeller a few light taps with a hammer. Then crank a little more, then a few more taps, and so on? Seems like that could help it break loose before stripping the threads (hopefully)? But I have little experience with this type of thing. Thoughts?

Given how the impeller is sort of just stuck on there, does it make sense, instead of just cranking the bolt down and hoping it pops free, does it make sense to crank it a little bit, then say give the aluminum impeller a few light taps with a hammer. Then crank a little more, then a few more taps, and so on? Seems like that could help it break loose before stripping the threads (hopefully)? But I have little experience with this type of thing. Thoughts?

#52

StarTech

StarTech

Well with flywheels here I tighten the forcing screw down as tight as I can by hand. Then using a 2 lb brass hammer strike the top of the forcing screw and re-tighten as a flywheel slowly pulls off the taper. Sometimes it only once and other times it has been several cycles. Basically you are shocking the item off the taper by using tension and play in the threads of the forcing screw.

So far I only had one flywheel that I couldn't pull in 16 yrs and that one someone had gone hog wild with an impact on install.

So far I only had one flywheel that I couldn't pull in 16 yrs and that one someone had gone hog wild with an impact on install.

#53

l008com

l008com

So I stripped out the 7/16" hole and now I'm about to go buy a 1/2" tap and bolt to try again.

But I just started thinking, is that going to be big enough? Or should I go up to 9/16th to make sure i'm getting full new threads with no sign of the old threads?

But I just started thinking, is that going to be big enough? Or should I go up to 9/16th to make sure i'm getting full new threads with no sign of the old threads?

#54

l008com

l008com

Success! I drilled out the hole with a 29/64" bit. Re-tapped it with a 1/2-20 tap. Then put some grease on the bolt so it would be good and lubricated. Then I got it pretty tight, then gave the impeller a few hard taps. Then tightened the bolt a little more and it popped right off! So that part of the job is mission accomplished! After realizing the belt was still holding the impeller in place, I was able to get it all removed and finally get at the three bolts that let me pop the motor off. Now I can star tearing it apart and fixing what i suspect is a melted camshaft.