Then I am an exception as repair about of the transaxles that have problems but most the require replacement don't get except on the higher end mowers.

And there is a point where repair costs out strip the equipment value. I do repairs when the repair cost more than 50% of the replacement cost; unless, the customer insists. Now I do a Z925A in the shop that is getting a new engine. Unit has over 4000 hrs on it yet it has been well maintained and is worth putting the money as it is used commercially. The same customer came by Saturday with his Z930M that JD wanted a $1000 to replace the wiring harness and it was only 4 F56 terminals that were bad at the PTO switch so got it out for under a $100. But now got to order some more F56 terminals as I am down to my last 20.

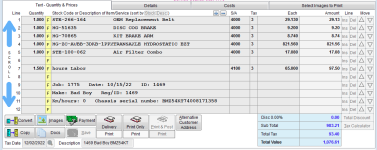

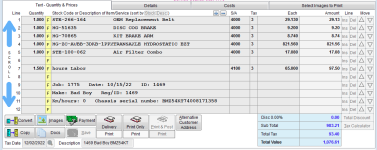

But the last transaxle I replaced was a over 2-1/2 years ago which was billed about $1100. And I currently have the rebuild parts for the unit but I just have gotten around to doing yet due to the current work load and hot steamy weather. The parts were about half the cost of a new unit but with labor is over 80% the cost of a new unit and the new unit came with a six month warranty from HG.

Can't record hours when the hour meter is broken.

Now that customer has since had to repair the Kohler engine short block. I did agree to only 50% of the chipping charge. And this was cause by him doing an oil change and leaving the most important part of an oil change. The oil.

And the replacement outstrips the repair costs when average this over the life of the mower.