Here is the procedure I use and have posted many times. Each tech on this site has their own so you might have to pick the one which works best for you. Simplicity model is on the frame, under the foot rest.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

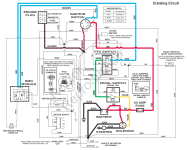

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

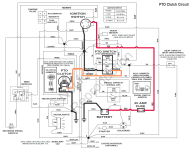

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words.