Jeff Klink

Forum Newbie

- Joined

- Jul 24, 2024

- Threads

- 1

- Messages

- 5

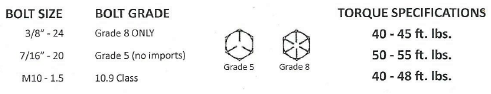

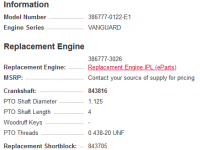

Oil accumulating in mower belt pulley above the clutch. Need to try to replace oil seal above the clutch but so far have been unable to loosen the bolt on the shaft beneath the clutch. Dumb question: does this bolt loosen in the universal direction -- counter-clockwise and, as I suspect, does it take an impact wrench to loosen it? Once the clutch is removed, what else, if anything, needs to be removed in order to access the old oil seal (Part No. 805049S)?