Johner,Johner,

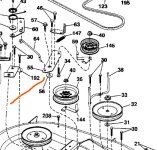

Thanks for the reply I don't know if I still have the old belt because the one that is partially shredded I'm still using and I don't know where the other one went it was from last year. I could tell you according to the product description from when I bought this belt it's 100.25 in by 1/2 in and I bought a belt here locally + 100 in by 5/8 in and it doesn't fit at all and for that one I figured I need 102 in by 5/8 in but I'm going to stick with what I have right now just to see if all the other stuff is working but you make some good points.

Jim

I found the belt and so I cut it and so I used duct tape to tape it basically to a kitchen countertop area and it turns out it's 99 in long it was supposed to be 100.25 in I don't get it. And furthermore it's a little bit too long + that's because of the 1/2-in width where it basically swims inside pulleys and it just sinks down and the 5/8 in belt was too short by about 2 in and it measured stamped right on the belt itself 5/8x100.

And I forgot to mention I just I ran it no more ringing noise when the mower deck is engaged there's a little bit of vibration coming out of the mower deck it might have always been that way but now I'm looking at it more closely it seemed to run pretty good.

Jim

Last edited: