You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Stihl Backpack Blower BR420 Magnum

#1

A

AlabamaDan

A

AlabamaDan

Hi! I hate to just jump in and my first post is a plea for help. Please forgive me. I have a Stihl 420 Magnum Backpack Blower and I'm trying to get it running again, my son's no longer around to rake. It will turn over and tries to run, but it doesn't quite get there.

Today I removed the carb and soaked it for two hours in Berryman's Dip, you know the 1 gallon can. The air filter looked new and the spark plug looked pretty close to new.

The fuel lines are still flexible and don't appear to be damaged. If there is a little fuel filter in the tank, I didn't check it...

I did put fresh gas/oil mixture in it.

I set the kill switch to the up position (I).

If I set the throttle to wide open and fiddle around with the choke it will crank and run for a second and then die.

Ideas?

Thanks for the help ahead of time.

Today I removed the carb and soaked it for two hours in Berryman's Dip, you know the 1 gallon can. The air filter looked new and the spark plug looked pretty close to new.

The fuel lines are still flexible and don't appear to be damaged. If there is a little fuel filter in the tank, I didn't check it...

I did put fresh gas/oil mixture in it.

I set the kill switch to the up position (I).

If I set the throttle to wide open and fiddle around with the choke it will crank and run for a second and then die.

Ideas?

Thanks for the help ahead of time.

#2

D

Darryl G

D

Darryl G

Hi from Connecticut and welcome to the forum. I'm a landscaper who obviously has heavy reliance on blowers. So I'm not one of the experts here but I've picked up a thing or two about getting and keeping small engines running.

Soaking the carb may not be enough. Sounds like you may have a plugged jet. You can strip a twist-tie and use the wire to carefully ream it out. Do you have ethanol in your gasoline there? I've had equipment accumulate an ethanol/water emulsion in the bottom of the tank during storage that fouled the fuel filter. And yes it should have one inside the tank. I hook the inlet line with a bent wire. I'd certainly replace it. I always replace the plug too for any starting/running issue rather than clean them. The first thing I do is dump fuel and replace with fresh, clean/replace air filter, replace spark plugs, clean the carbon from the muffler screen (I hold with pliers and torch with a lighter then brush off) and replace fuel filter. It's all about eliminating potential causes.

The mechanics here can offer a lot more detailed diagnostic info to help you get your blower running. Several make their daily rounds here.

Soaking the carb may not be enough. Sounds like you may have a plugged jet. You can strip a twist-tie and use the wire to carefully ream it out. Do you have ethanol in your gasoline there? I've had equipment accumulate an ethanol/water emulsion in the bottom of the tank during storage that fouled the fuel filter. And yes it should have one inside the tank. I hook the inlet line with a bent wire. I'd certainly replace it. I always replace the plug too for any starting/running issue rather than clean them. The first thing I do is dump fuel and replace with fresh, clean/replace air filter, replace spark plugs, clean the carbon from the muffler screen (I hold with pliers and torch with a lighter then brush off) and replace fuel filter. It's all about eliminating potential causes.

The mechanics here can offer a lot more detailed diagnostic info to help you get your blower running. Several make their daily rounds here.

#3

Boudreaux In Eunice La.

Boudreaux In Eunice La.

Hey Dan.......... What you gonna do besides Hey I'm from LA and I have a blower that runs good, but I'll be back in a week or so if it goes out ... LOL Are you from LA ????

I am but not Los Angry and Lower Alabama, but Louisiana......... I have spent some money in Bayou La Batre though,,, I had a bar room there ....

You have 2 adjustments on your carb if i'm right .......... L and H jet's ..... When you soaked the carb was your metering diaphragm still really soft or was it stiff ???? That makes a world of difference .... Also the pump side diaphragm should be in order....

Go ahead and see if you can locate the fuel filter in the take and check it.. Those should be changed once a year....

Does it run on choke pretty good ??? Or half choke ???

Let us know Mon Ami ~!~!

I am but not Los Angry and Lower Alabama, but Louisiana......... I have spent some money in Bayou La Batre though,,, I had a bar room there ....

You have 2 adjustments on your carb if i'm right .......... L and H jet's ..... When you soaked the carb was your metering diaphragm still really soft or was it stiff ???? That makes a world of difference .... Also the pump side diaphragm should be in order....

Go ahead and see if you can locate the fuel filter in the take and check it.. Those should be changed once a year....

Does it run on choke pretty good ??? Or half choke ???

Let us know Mon Ami ~!~!

#4

A

AlabamaDan

Hi! I'm very familiar with Mobile in LA, but from UA. Louisiana is one of my favorite states. Thanks for the reply. I didn't disassemble the carb, but soaked it whole. That has worked for me on several other machines. I try not to disassemble carbs if I can get away with it. They tend not to run well after "I" do that. It's a last resort for me.

It doesn't seem to run no matter what position the choke is in. However, I have read that this model, while highly regarded as a great engine, tends to flood easily and should only be closed barely and rarely. Sounds like I may need to pull the plug and check for fuel in the cylinder.

A

AlabamaDan

Hey Dan.......... What you gonna do besides Hey I'm from LA and I have a blower that runs good, but I'll be back in a week or so if it goes out ... LOL Are you from LA ????

I am but not Los Angry and Lower Alabama, but Louisiana......... I have spent some money in Bayou La Batre though,,, I had a bar room there ....

You have 2 adjustments on your carb if i'm right .......... L and H jet's ..... When you soaked the carb was your metering diaphragm still really soft or was it stiff ???? That makes a world of difference .... Also the pump side diaphragm should be in order....

Go ahead and see if you can locate the fuel filter in the take and check it.. Those should be changed once a year....

Does it run on choke pretty good ??? Or half choke ???

Let us know Mon Ami ~!~!

Hi! I'm very familiar with Mobile in LA, but from UA. Louisiana is one of my favorite states. Thanks for the reply. I didn't disassemble the carb, but soaked it whole. That has worked for me on several other machines. I try not to disassemble carbs if I can get away with it. They tend not to run well after "I" do that. It's a last resort for me.

It doesn't seem to run no matter what position the choke is in. However, I have read that this model, while highly regarded as a great engine, tends to flood easily and should only be closed barely and rarely. Sounds like I may need to pull the plug and check for fuel in the cylinder.

#5

A

AlabamaDan

Thanks for the replay. Connecticut is a beautiful state. I drove through there a couple years ago and it is really pretty country up there. Back to my problems. I plan to fish the filter out of the tank today and clean the muffler screen. I don't have a filter, but I could go with out a filter for testing couldn't it?

It's been sitting for a 3-4 years - with an empty tank. I seem to recall that it I took it to the mechanic and they tuned it up (lazy) because it wasn't running well. I couldn't get it to run then and just bought an electric one at a yard sale. That is now dead so I'm back to this old Stihl. Back then I did run regular ethanol gas, but I've since switched to 100% gas for my small engines. That tune up is the reason I didn't replace the spark plug. I figure if the filter still looks brand new and was replaced at the same time as the spark plug then it should be good too.

I'll try the screen (which I knew nothing about,) the in-tank filter, and pulling the plug to check and see if I flooded it today. Thanks for the advice guys.

A

AlabamaDan

Hi from Connecticut and welcome to the forum. I'm a landscaper who obviously has heavy reliance on blowers. So I'm not one of the experts here but I've picked up a thing or two about getting and keeping small engines running.

Soaking the carb may not be enough. Sounds like you may have a plugged jet. You can strip a twist-tie and use the wire to carefully ream it out. Do you have ethanol in your gasoline there? I've had equipment accumulate an ethanol/water emulsion in the bottom of the tank during storage that fouled the fuel filter. And yes it should have one inside the tank. I hook the inlet line with a bent wire. I'd certainly replace it. I always replace the plug too for any starting/running issue rather than clean them. The first thing I do is dump fuel and replace with fresh, clean/replace air filter, replace spark plugs, clean the carbon from the muffler screen (I hold with pliers and torch with a lighter then brush off) and replace fuel filter. It's all about eliminating potential causes.

The mechanics here can offer a lot more detailed diagnostic info to help you get your blower running. Several make their daily rounds here.

Thanks for the replay. Connecticut is a beautiful state. I drove through there a couple years ago and it is really pretty country up there. Back to my problems. I plan to fish the filter out of the tank today and clean the muffler screen. I don't have a filter, but I could go with out a filter for testing couldn't it?

It's been sitting for a 3-4 years - with an empty tank. I seem to recall that it I took it to the mechanic and they tuned it up (lazy) because it wasn't running well. I couldn't get it to run then and just bought an electric one at a yard sale. That is now dead so I'm back to this old Stihl. Back then I did run regular ethanol gas, but I've since switched to 100% gas for my small engines. That tune up is the reason I didn't replace the spark plug. I figure if the filter still looks brand new and was replaced at the same time as the spark plug then it should be good too.

I'll try the screen (which I knew nothing about,) the in-tank filter, and pulling the plug to check and see if I flooded it today. Thanks for the advice guys.

#6

ILENGINE

ILENGINE

Since Darryl brought up the muffler screen. If you have one with the round exhaust hole, make sure it hasn't been filled with mud from the dirt dauber. also there is an internal screen inside the carb that can get plugged preventing fuel flow Normally will present itself with primer type carbs when you push the primer bulb down and it either is slow to come back up or doesn't come back up at all.

#7

Boobala

Boobala

According to my files, your blower uses a Walbro model # HD-28A .. or a HD-29 carburetor, I believe they are close enough to use either, but I could NOT find much for an HD-29, only a HD 29-1

https://www.ereplacementparts.com/walbro-hd28a-carburetor-parts-c-139716_142749_139838.html

https://sleequipment.com/walbro-gen...etor-assy.html#product_tabs_additional_tabbed

https://www.m-jardin.fr/wp-content/...tent/documentation/stihl/souffleurs/br340.pdf

https://www.ereplacementparts.com/walbro-hd28a-carburetor-parts-c-139716_142749_139838.html

https://sleequipment.com/walbro-gen...etor-assy.html#product_tabs_additional_tabbed

https://www.m-jardin.fr/wp-content/...tent/documentation/stihl/souffleurs/br340.pdf

#9

Boobala

Boobala

#11

B

bertsmobile1

B

bertsmobile1

Go to the Walbro web page.

Hidden in the bottom right corner on the cube carb page is a link to their service manuals and even a couple of videos.

Nothing hard about them except they need to be clean and when you work on them you need to be clean and the area needs to be clean enough to conduct open heart surgery in.

I do it in the workshop bathroom.

Get a diaphragm kit for you carb , should be around $ 10 (US).

Despite all of the fertilizer you see on U-Tube always replace the diaphragm & gaskets, they are very cheap and telling the difference between a good one and a not quite so good one is a difficult job.

Your problem sounds like either a clogged exhaust or clogged high speed jet.

Inside the carb is a little screen which gets bocked.

When left unused for long times fuel can leave gum inside the tiny holes.

However before you start, loosen or remove the muffler and try again.

If it runs then your muffler is blocked.

On the fuel tank there are 2 fuel lines.

One is the outlet & the other the return.

Pull then off at the carb, after tanking photos or lableing them then blow gently down the filler cap.

Fuel should flow out of one of them .

Put the cap back on. Pinch off the one that did not flow fuel and leave the tank in the sun.

Fuel should start flowing out of the outlet tube as the tank gets hot if the filter is clean enough to be used.

If the muffler and the fuel tank check out OK then time to pull the carb down.

And don't forget the most important tool in the box, your camera use it every time you remove any part.

Hidden in the bottom right corner on the cube carb page is a link to their service manuals and even a couple of videos.

Nothing hard about them except they need to be clean and when you work on them you need to be clean and the area needs to be clean enough to conduct open heart surgery in.

I do it in the workshop bathroom.

Get a diaphragm kit for you carb , should be around $ 10 (US).

Despite all of the fertilizer you see on U-Tube always replace the diaphragm & gaskets, they are very cheap and telling the difference between a good one and a not quite so good one is a difficult job.

Your problem sounds like either a clogged exhaust or clogged high speed jet.

Inside the carb is a little screen which gets bocked.

When left unused for long times fuel can leave gum inside the tiny holes.

However before you start, loosen or remove the muffler and try again.

If it runs then your muffler is blocked.

On the fuel tank there are 2 fuel lines.

One is the outlet & the other the return.

Pull then off at the carb, after tanking photos or lableing them then blow gently down the filler cap.

Fuel should flow out of one of them .

Put the cap back on. Pinch off the one that did not flow fuel and leave the tank in the sun.

Fuel should start flowing out of the outlet tube as the tank gets hot if the filter is clean enough to be used.

If the muffler and the fuel tank check out OK then time to pull the carb down.

And don't forget the most important tool in the box, your camera use it every time you remove any part.

#12

D

Darryl G

It seems that those screens frequently get dropped and "accidentally" stepped on before getting tossed in the trash. :laughing:

And you can run without the filter with a clean tank and fuel for diagnostic purposes but it may want to float.

D

Darryl G

Part #28. I may not have it anymore. PO may have taken in out already.

It seems that those screens frequently get dropped and "accidentally" stepped on before getting tossed in the trash. :laughing:

And you can run without the filter with a clean tank and fuel for diagnostic purposes but it may want to float.

#13

A

AlabamaDan

A

AlabamaDan

So, I disassembled the blower again. I found little puddles of liquid around on top of the gas tank and cover. This is a little disturbing for me

These muffler bolts were ridiculously tight... way beyond what seems appropriate to me.

It was very odd. The muffler had some liquid in it? There was about an ounce of liquid inside the muffler. AND the muffler weighs about 5 lbs. Is that normal?

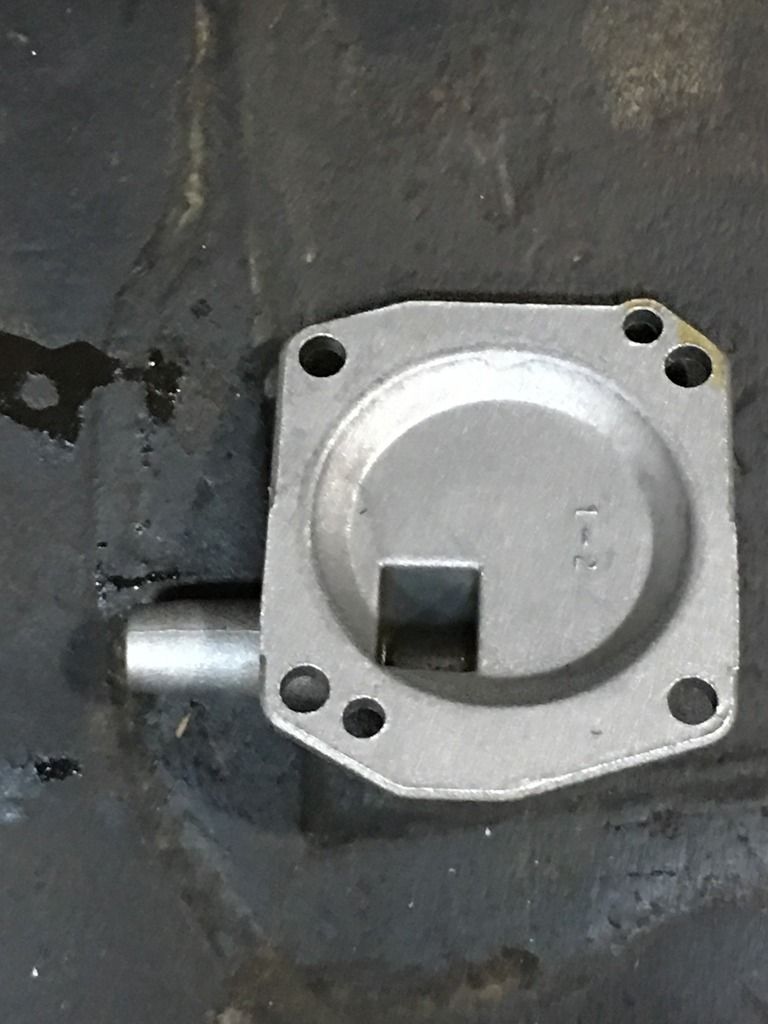

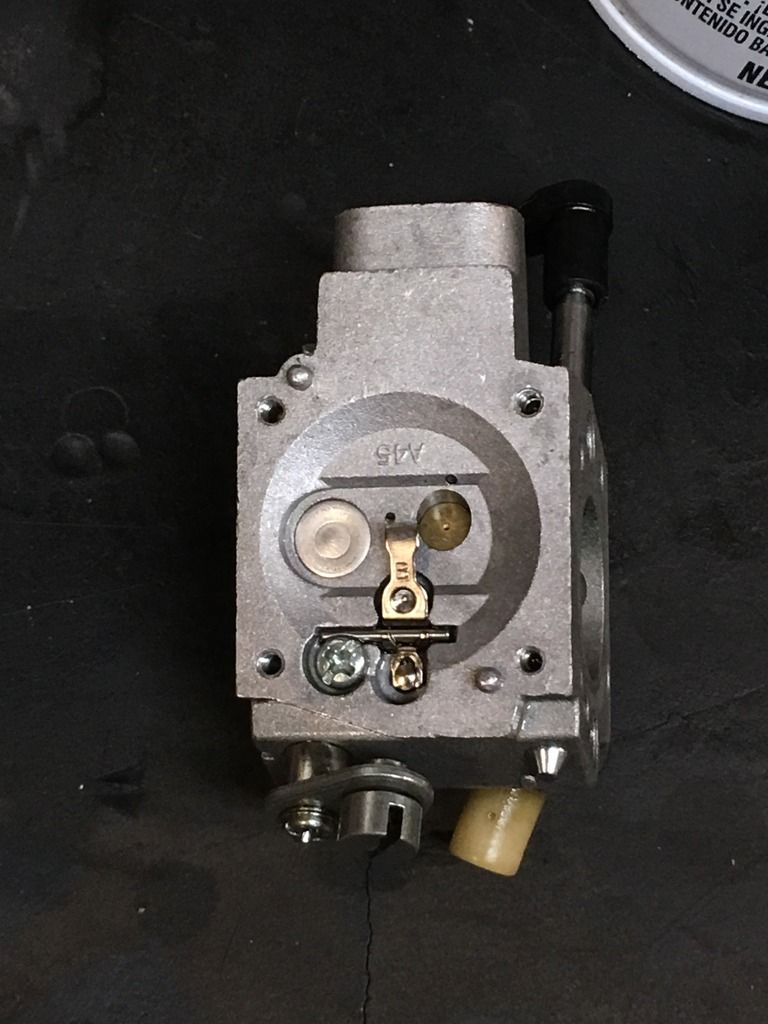

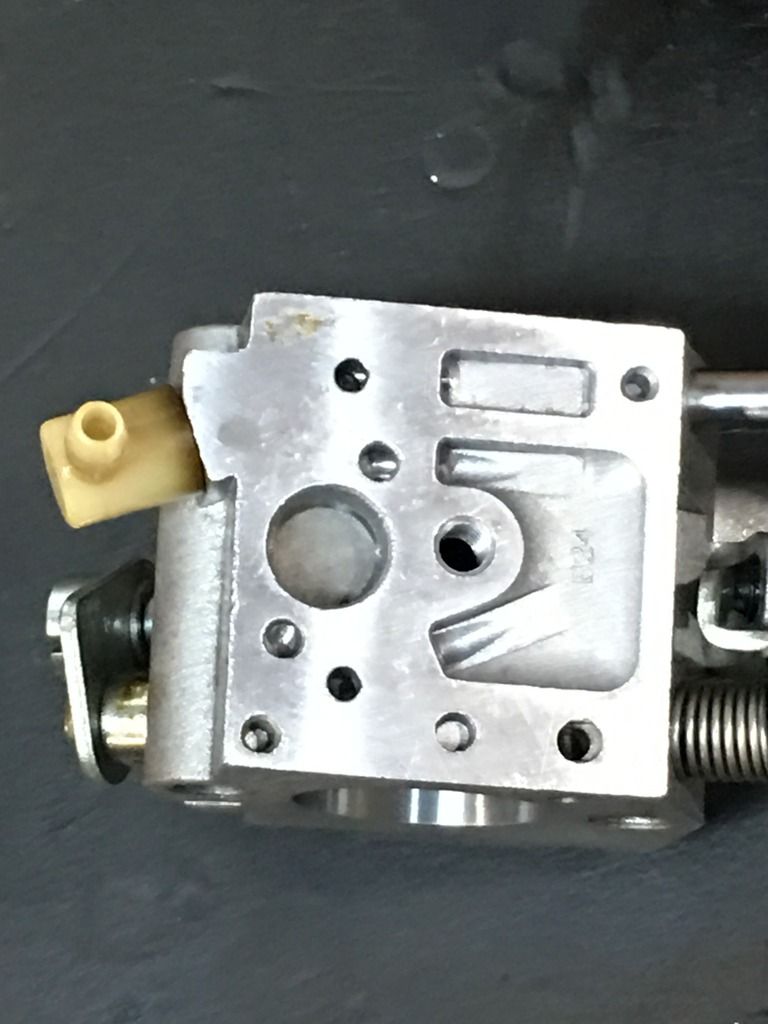

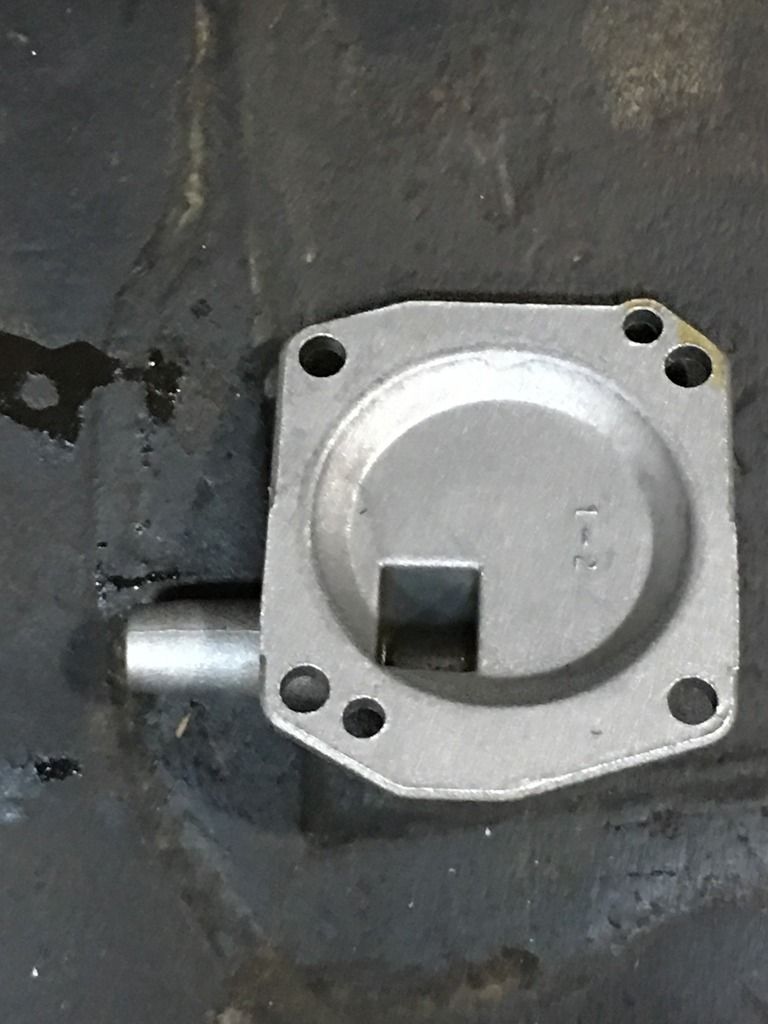

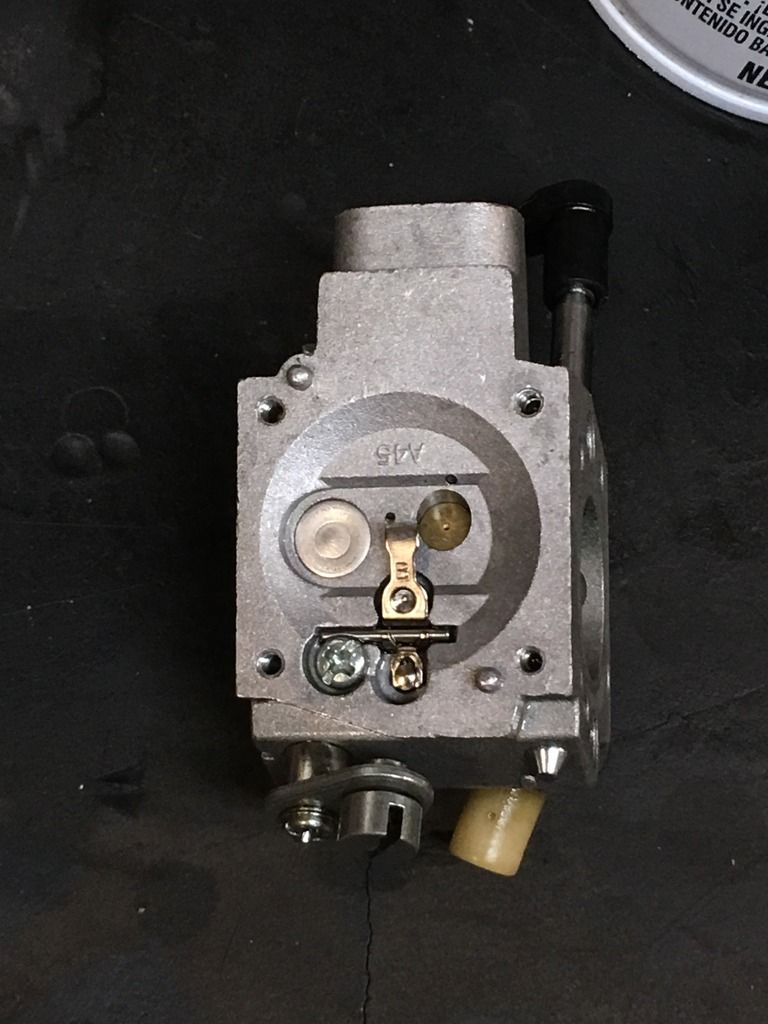

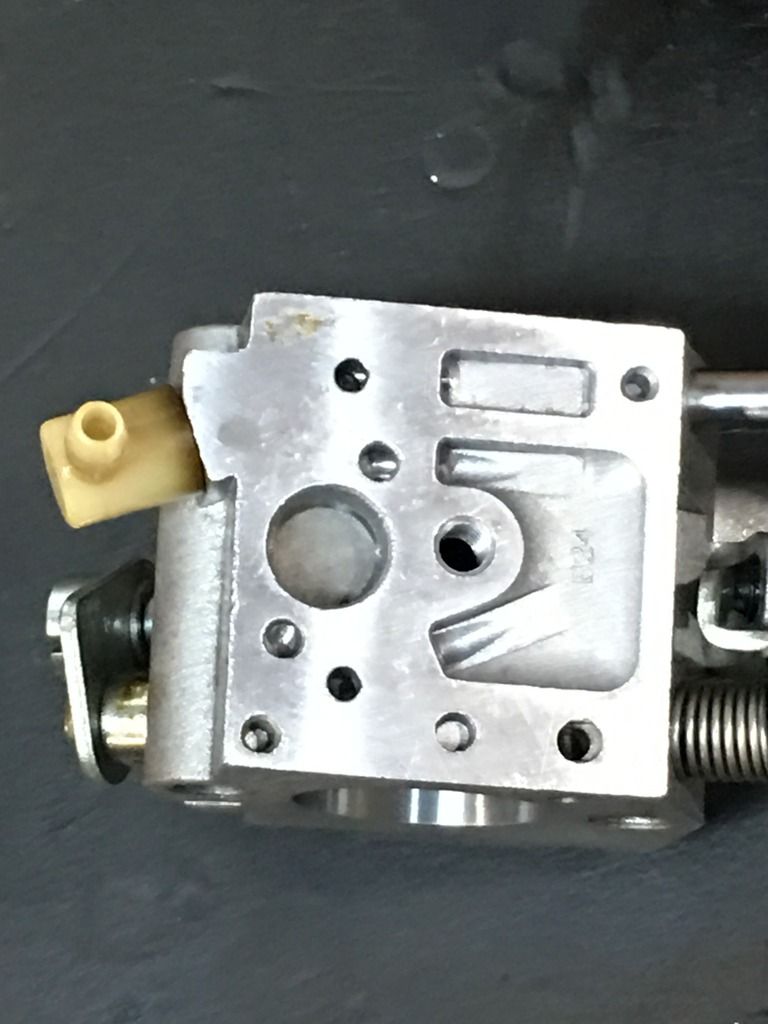

I took a little of the carb apart and it looks pretty good to me. This is exactly how it looked. I didn't do any additional cleaning.

These muffler bolts were ridiculously tight... way beyond what seems appropriate to me.

It was very odd. The muffler had some liquid in it? There was about an ounce of liquid inside the muffler. AND the muffler weighs about 5 lbs. Is that normal?

I took a little of the carb apart and it looks pretty good to me. This is exactly how it looked. I didn't do any additional cleaning.

#14

Boudreaux In Eunice La.

Boudreaux In Eunice La.

Hey Dan..... La. here again......... This is a buddy of mine in this video.... He is a Stihl dealer and Authorized service center for Stihl........ BTW your metering diaphragm looks hard to me, that's the one that looks like a wagon wheel..........It's not doing it's job and causing the flooding from the carb that you see...... This vid will put you at ease ............

Enjoy Mon Ami ,,,, https://youtu.be/7-VpdJEJRRw

Enjoy Mon Ami ,,,, https://youtu.be/7-VpdJEJRRw

#15

A

AlabamaDan

That wagon wheel thing is supposed to be flexible? I don't recall if it was or not. I'll double check it. and I'll watch the vid...

A

AlabamaDan

Hey Dan..... La. here again......... This is a buddy of mine in this video.... He is a Stihl dealer and Authorized service center for Stihl........ BTW your metering diaphragm looks hard to me, that's the one that looks like a wagon wheel..........It's not doing it's job and causing the flooding from the carb that you see...... This vid will put you at ease ............

Enjoy Mon Ami ,,,, https://youtu.be/7-VpdJEJRRw

That wagon wheel thing is supposed to be flexible? I don't recall if it was or not. I'll double check it. and I'll watch the vid...

#16

Boudreaux In Eunice La.

Boudreaux In Eunice La.

Yep soft as silk.... If you can play a tune with it like clicker it's junk........ All that time setting up makes em hard.......

#17

A

AlabamaDan

A

AlabamaDan

That's a great video. Thanks. Not only was it informative, but any beer will do... :lol

#18

B

bertsmobile1

B

bertsmobile1

Dan,

what you have done is fallen for the newbie mistake of ripping everything apart before you took the time to actually work out what was wrong.

Thus you have the original problem to contend with plus any / all of the problems introduced by yourself in ripping things apart.

Back in my original response I suggested that you try running it without the muffler .

So your only problem could have been whatever is inside that 1 lb muffler that is making it weight 5 lbs.

Next you have fuel pooling on top of the tank,

So you now have a fuel leak that you did not have before you started to fix the blower.

The fuel tank & carb are a low pressure, pressure vessel and run at around 5 to 10 psi.

If a fuel line has a leak in it or the grommets in the fuel tank do not seal or the carb is not airtight or the vent is not working or the fuel cap is not working, then the blower will start but not run for long.

There is a logical proceedure for these thongs and that is to start from the beginning, the fuel tank.

If it holds pressure and can also suck in air then chances are it is ok.

The next thing you do is block off the return line dip the carb in a jar of water and pump the inlet line.

You can just blow into it.

If all is working OK there will be no bubbles.

If you have a pressure tester with a gauge, the carb must hold 10 psi.

You will read all sorts of trash about "pop off pressure , ignore it. Forcing the fuel needle to lift off it's seat by applying too much pressure to the fuel intake tells you nothing other than you have been led down the garden path by a shaved monkey with less idea about what he is doing than you had before you started.

Now that the carb is apart, clean it and DO NOT BLAST HIGH PRESSURE AIR THROUGH ANY PASSAGE. All that does is jamb debris so hard into tiny holes it can never been dislodged.

Skip the beer.

Anyone who touches an engine after drinking either has a bad booze problem or is an idiot.

Sorry Bou, I know Steve is a friend of yours and I know he knows a lot by what he says, but beers are what you have when you have successfully fixed your equipment and kocking off a few tinnies while you are working will not help the outcome one tiny little bit.

what you have done is fallen for the newbie mistake of ripping everything apart before you took the time to actually work out what was wrong.

Thus you have the original problem to contend with plus any / all of the problems introduced by yourself in ripping things apart.

Back in my original response I suggested that you try running it without the muffler .

So your only problem could have been whatever is inside that 1 lb muffler that is making it weight 5 lbs.

Next you have fuel pooling on top of the tank,

So you now have a fuel leak that you did not have before you started to fix the blower.

The fuel tank & carb are a low pressure, pressure vessel and run at around 5 to 10 psi.

If a fuel line has a leak in it or the grommets in the fuel tank do not seal or the carb is not airtight or the vent is not working or the fuel cap is not working, then the blower will start but not run for long.

There is a logical proceedure for these thongs and that is to start from the beginning, the fuel tank.

If it holds pressure and can also suck in air then chances are it is ok.

The next thing you do is block off the return line dip the carb in a jar of water and pump the inlet line.

You can just blow into it.

If all is working OK there will be no bubbles.

If you have a pressure tester with a gauge, the carb must hold 10 psi.

You will read all sorts of trash about "pop off pressure , ignore it. Forcing the fuel needle to lift off it's seat by applying too much pressure to the fuel intake tells you nothing other than you have been led down the garden path by a shaved monkey with less idea about what he is doing than you had before you started.

Now that the carb is apart, clean it and DO NOT BLAST HIGH PRESSURE AIR THROUGH ANY PASSAGE. All that does is jamb debris so hard into tiny holes it can never been dislodged.

Skip the beer.

Anyone who touches an engine after drinking either has a bad booze problem or is an idiot.

Sorry Bou, I know Steve is a friend of yours and I know he knows a lot by what he says, but beers are what you have when you have successfully fixed your equipment and kocking off a few tinnies while you are working will not help the outcome one tiny little bit.

#19

Boudreaux In Eunice La.

Boudreaux In Eunice La.

Bert ........... You and I have always helped people on here and agreed on a lot of stuff........ First of all Dan said in post 4 he is scared to even take a carb apart , that's why he soaked the whole carb in Chen Dip for 2 hours, THE whole carb still assembled ........New to me on that one.....

Post 11 you did say say to run without the muffler... I agree all the way ... IL Engine told him to take the arrestor screen out... Dan said none in there and the muffler had some fluid and weighed 4 pounds ...... I doubt he weighed it though .... and it might have have some issues..... If he tried to run it without the muffler off we don't know and it hasen't ran in a couple years anyway.... So i don't think it would run anyway......

In my first post I told him that his diaphragm might be bad ..... Then he showed a pic of it and it sure looks that way to me ........ That is sure sign of flooding the carb and leaking on top of the tank......Plus soaking the whole carb in chem dip..... Every bit of trash is still in the carb..... Do you agree ??

Post 11 you said a high speed jet might be clogged and the screen inside clogged also..... You gotta tear a carb apart to get to that screen ...... So he didn't tear the carb apart prematurely When I saw that I opted to show him a good video to put him at ease to show him how easy it is do that, since he is not tech inclined like he said he was .....

Steve's Small Engine Saloon is just a name for his channel..... It's a name only and while he is running his business he don't drink........He announces a different beer in each video .....Also he has sponsors from companies and that's why he doesn't have ads / commercials on his channel..........He doesn't get drunk and act like a idiot on his videos.....

Now let's please see what he does tomorrow and help him out further along in his issue >>>>>>>

Plus Tard Mon Ami ~!~!

Post 11 you did say say to run without the muffler... I agree all the way ... IL Engine told him to take the arrestor screen out... Dan said none in there and the muffler had some fluid and weighed 4 pounds ...... I doubt he weighed it though .... and it might have have some issues..... If he tried to run it without the muffler off we don't know and it hasen't ran in a couple years anyway.... So i don't think it would run anyway......

In my first post I told him that his diaphragm might be bad ..... Then he showed a pic of it and it sure looks that way to me ........ That is sure sign of flooding the carb and leaking on top of the tank......Plus soaking the whole carb in chem dip..... Every bit of trash is still in the carb..... Do you agree ??

Post 11 you said a high speed jet might be clogged and the screen inside clogged also..... You gotta tear a carb apart to get to that screen ...... So he didn't tear the carb apart prematurely When I saw that I opted to show him a good video to put him at ease to show him how easy it is do that, since he is not tech inclined like he said he was .....

Steve's Small Engine Saloon is just a name for his channel..... It's a name only and while he is running his business he don't drink........He announces a different beer in each video .....Also he has sponsors from companies and that's why he doesn't have ads / commercials on his channel..........He doesn't get drunk and act like a idiot on his videos.....

Now let's please see what he does tomorrow and help him out further along in his issue >>>>>>>

Plus Tard Mon Ami ~!~!

#20

A

AlabamaDan

It may be a newbie mistake, but diagnosing things is something that's a little difficult for me. Once I find the issue, I can fix just about anything I just have to find out what to fix.

I feel like I was taking it piece by piece. I started by removing the carb and soaking it whole. I've had a lot of success with this, for better or worse it has been a reliable go to on fixing my small engines the last year or so. Best results actually. Unfortunately that didn't work. So now I've dove a little deeper in the carb and while I was at it I took the muffler off.

My inspection of the fuel lines look good.

Judging by the nastiness of the motor and everything behind that cover as it was originally, I'd say it's been leaking or spewing or flooding or whatever for quite some time. I don't think that's a new thing.

I like the advice of running it without the muffler to see what happens. I'll reassemble, although it probably needs a new diaphragm, and try to run it without choking it. I'll also pull out the in tank filter and replace it.

I am apprehensive about buying some china made carb. I thought I'd try this walbro first.

I'm not 100% sure I understand your tests for the carb, but I'll read it again just to make sure.

No high pressure air - got it. Haven't done it yet so I should be good. Glad you told me.

As for the beer, that's just a joke.

A

AlabamaDan

Dan,

what you have done is fallen for the newbie mistake of ripping everything apart before you took the time to actually work out what was wrong.

Thus you have the original problem to contend with plus any / all of the problems introduced by yourself in ripping things apart.

Back in my original response I suggested that you try running it without the muffler .

So your only problem could have been whatever is inside that 1 lb muffler that is making it weight 5 lbs.

Next you have fuel pooling on top of the tank,

So you now have a fuel leak that you did not have before you started to fix the blower.

The fuel tank & carb are a low pressure, pressure vessel and run at around 5 to 10 psi.

If a fuel line has a leak in it or the grommets in the fuel tank do not seal or the carb is not airtight or the vent is not working or the fuel cap is not working, then the blower will start but not run for long.

There is a logical proceedure for these thongs and that is to start from the beginning, the fuel tank.

If it holds pressure and can also suck in air then chances are it is ok.

The next thing you do is block off the return line dip the carb in a jar of water and pump the inlet line.

You can just blow into it.

If all is working OK there will be no bubbles.

If you have a pressure tester with a gauge, the carb must hold 10 psi.

You will read all sorts of trash about "pop off pressure , ignore it. Forcing the fuel needle to lift off it's seat by applying too much pressure to the fuel intake tells you nothing other than you have been led down the garden path by a shaved monkey with less idea about what he is doing than you had before you started.

Now that the carb is apart, clean it and DO NOT BLAST HIGH PRESSURE AIR THROUGH ANY PASSAGE. All that does is jamb debris so hard into tiny holes it can never been dislodged.

Skip the beer.

Anyone who touches an engine after drinking either has a bad booze problem or is an idiot.

Sorry Bou, I know Steve is a friend of yours and I know he knows a lot by what he says, but beers are what you have when you have successfully fixed your equipment and kocking off a few tinnies while you are working will not help the outcome one tiny little bit.

It may be a newbie mistake, but diagnosing things is something that's a little difficult for me. Once I find the issue, I can fix just about anything I just have to find out what to fix.

I feel like I was taking it piece by piece. I started by removing the carb and soaking it whole. I've had a lot of success with this, for better or worse it has been a reliable go to on fixing my small engines the last year or so. Best results actually. Unfortunately that didn't work. So now I've dove a little deeper in the carb and while I was at it I took the muffler off.

My inspection of the fuel lines look good.

Judging by the nastiness of the motor and everything behind that cover as it was originally, I'd say it's been leaking or spewing or flooding or whatever for quite some time. I don't think that's a new thing.

I like the advice of running it without the muffler to see what happens. I'll reassemble, although it probably needs a new diaphragm, and try to run it without choking it. I'll also pull out the in tank filter and replace it.

I am apprehensive about buying some china made carb. I thought I'd try this walbro first.

I'm not 100% sure I understand your tests for the carb, but I'll read it again just to make sure.

No high pressure air - got it. Haven't done it yet so I should be good. Glad you told me.

As for the beer, that's just a joke.

#21

A

AlabamaDan

A

AlabamaDan

I couldn't sleep so I went out to the shop. I cleaned the frame underneath the motor and tank and down the exhaust side of the motor. What a mess.

I checked the diaphragm again. That little disc is metal so it should be rigid, however it all is and shouldn't be. All the black rubber should be as soft as silk from what I've researched. That's definitely an issue.

I emptied the tank and checked it out. I appears good and clean and doesn't appear to be leaking.

I reassembled the air filter housing, carb, pull starter etc. Basically everything except the muffler and plastic cover.

I pulled the plug and I checked the compression on the cylinder three times: 75, 80, 80. I would think that's good compression. Before checking the compression I laid it down and pulled it a bunch and no gas or anything came out any holes. If it was overly flooded, it's good now.

When it warms up I'll put some fresh gas in and try to crank it (no choke) without the muffler and see what happens.

I checked the diaphragm again. That little disc is metal so it should be rigid, however it all is and shouldn't be. All the black rubber should be as soft as silk from what I've researched. That's definitely an issue.

I emptied the tank and checked it out. I appears good and clean and doesn't appear to be leaking.

I reassembled the air filter housing, carb, pull starter etc. Basically everything except the muffler and plastic cover.

I pulled the plug and I checked the compression on the cylinder three times: 75, 80, 80. I would think that's good compression. Before checking the compression I laid it down and pulled it a bunch and no gas or anything came out any holes. If it was overly flooded, it's good now.

When it warms up I'll put some fresh gas in and try to crank it (no choke) without the muffler and see what happens.

#22

Boudreaux In Eunice La.

Boudreaux In Eunice La.

Hey Dan......... Yep it's cold here too......... Need to do some outside work myself........ I don't like the highs in the upper 40's and the 50's ...............

So your your metering diaphragm is hard like I thought it would be........ It might run and it might not....... You can use the choke to try and start it... 2 or 3 pulls then back off of the choke.... Did you see the model number on the carb ???

It should be one of the ones that Boo Boo said it was....... I looked it up a while back and think I seen the same number..... I can look the kit number up for you IF you have the carb we talked about .......

Like Bert said earlier about 12 to 15 bux in your area .......... Check to see if your fuel lines are loose where they go into the tank.... Just pull or push them to check.........

Let us know Mon Ami ~!~!

So your your metering diaphragm is hard like I thought it would be........ It might run and it might not....... You can use the choke to try and start it... 2 or 3 pulls then back off of the choke.... Did you see the model number on the carb ???

It should be one of the ones that Boo Boo said it was....... I looked it up a while back and think I seen the same number..... I can look the kit number up for you IF you have the carb we talked about .......

Like Bert said earlier about 12 to 15 bux in your area .......... Check to see if your fuel lines are loose where they go into the tank.... Just pull or push them to check.........

Let us know Mon Ami ~!~!

#23

A

(Account Closed)

A

(Account Closed)

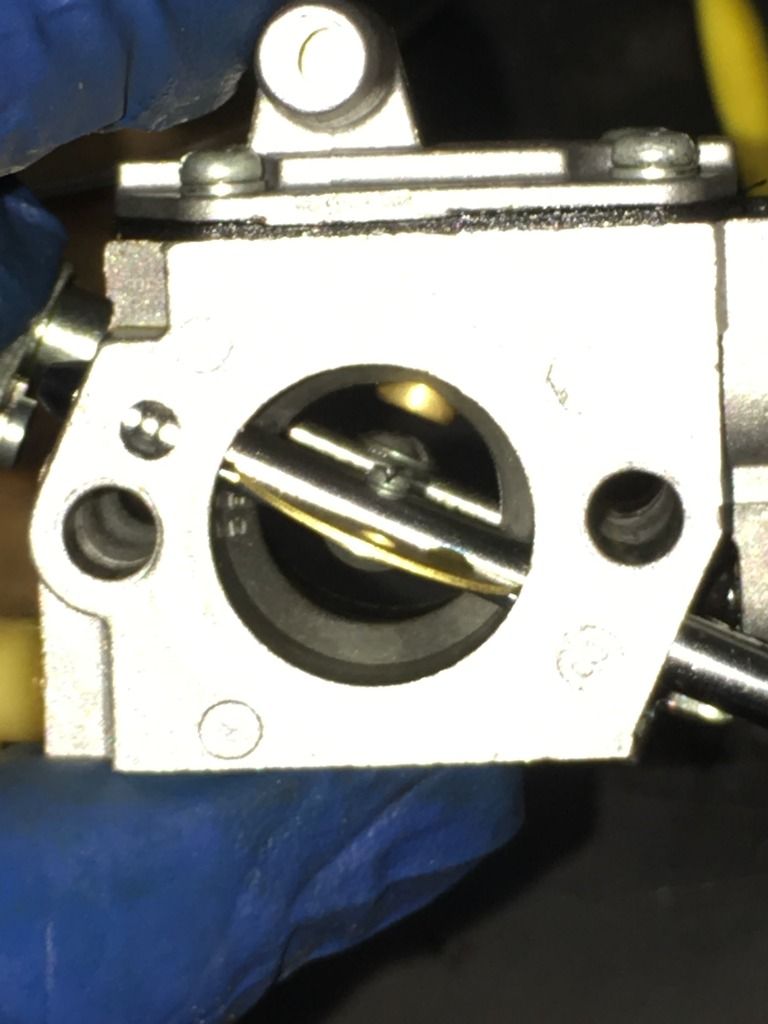

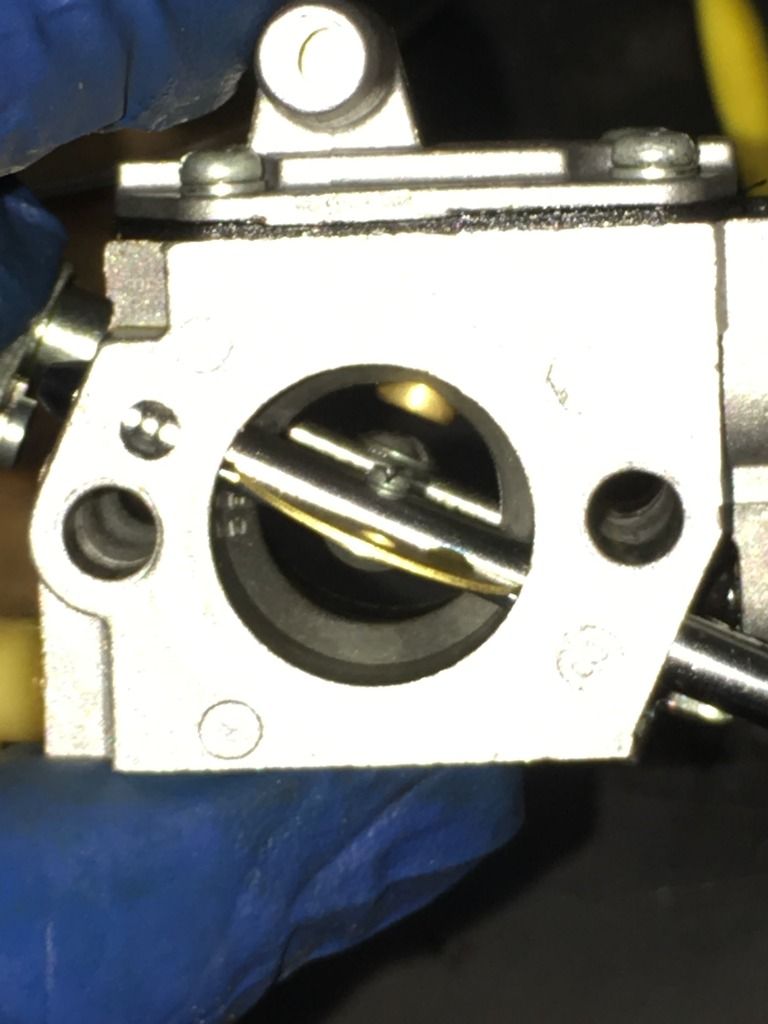

Here's a pic from a customers machine showing the carb INTERNAL FILTER. Pictured is EXACTLY how I found it.

It'll take you longer to remove it than to tear it down. If you access to a Ultra Sonic Cleaner, that is your best bet if it's seriously clogged (I use as a last resort).

Make sure you remove that filter for cleaning as well as the needle. Once I found a piece of crap in between the two which drove me crazy..

I would NOT use carb cleaner on any rubber parts, but brake cleaner. It's not nearly as aggressive. Blowing out the metal body orifices, it's fine...

If you can remove the setting screws (L & H), gently screw them in taking note of the settings. Remove for cleaning and later reinstall to where you removed them.. Stihls aren't bad, but once it starts, slowly start adjusting the "H" (high) screw CC, richening up the mix. Someone may have dinked with it and once running, should help..

But you definitly have a carb issue with flooding and leaning out....

It'll take you longer to remove it than to tear it down. If you access to a Ultra Sonic Cleaner, that is your best bet if it's seriously clogged (I use as a last resort).

Make sure you remove that filter for cleaning as well as the needle. Once I found a piece of crap in between the two which drove me crazy..

I would NOT use carb cleaner on any rubber parts, but brake cleaner. It's not nearly as aggressive. Blowing out the metal body orifices, it's fine...

If you can remove the setting screws (L & H), gently screw them in taking note of the settings. Remove for cleaning and later reinstall to where you removed them.. Stihls aren't bad, but once it starts, slowly start adjusting the "H" (high) screw CC, richening up the mix. Someone may have dinked with it and once running, should help..

But you definitly have a carb issue with flooding and leaning out....