Been trying to remove the steering wheel but having no luck. Mine has a pin thru the side of the shaft but no matter from which side or how hard i hit it it will not come out in fact tbe end sticking out has split. Any suggestions oh i tried drilling it but not enough room for the drill

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steering wheel removal

- Thread starter Ryanjohn

- Start date

More options

Export threadThose pins should come out in either direction. Here is a trick which may help it you have an assistant. Drill a 1/2 hole in the end grain of a 2 X 4 2” deep. It should be long enough by your assistant to hold tightly against the shaft. Position the hole so you can drive the pin into the hole. While your assistant is holding it firmly in place use a drift punch, not tapered punch, to drive the pin out. If you have enough room carefully heat the shaft before starting with a propane torch to slightly expand the metal.

I'll give it a try over the weekend. Unfortunately no room to heat as the wheel boss gors all the way downThose pins should come out in either direction. Here is a trick which may help it you have an assistant. Drill a 1/2 hole in the end grain of a 2 X 4 2” deep. It should be long enough by your assistant to hold tightly against the shaft. Position the hole so you can drive the pin into the hole. While your assistant is holding it firmly in place use a drift punch, not tapered punch, to drive the pin out. If you have enough room carefully heat the shaft before starting with a propane torch to slightly expand the metal.

bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

They are called roll pins and are a flat spring rolled into a tube so when hammered in they compress & lock in place.

You can get roll pin punched that have a shoulder machined onto the end to hold them in position when you hit the pin.

Use a big heavy hammer and swing it slowly so you can make sure you get a square hit.

The other thing that works is a G clap with a hole in the base and an appropriate sizes push pin.

I use motorcycle chain pins

Because of the split and by virtue of being a spring they can not be drilled out but can be ground out with a Dremel tool & the right cutters but it takes a long time and a steady hand.

You can get roll pin punched that have a shoulder machined onto the end to hold them in position when you hit the pin.

Use a big heavy hammer and swing it slowly so you can make sure you get a square hit.

The other thing that works is a G clap with a hole in the base and an appropriate sizes push pin.

I use motorcycle chain pins

Because of the split and by virtue of being a spring they can not be drilled out but can be ground out with a Dremel tool & the right cutters but it takes a long time and a steady hand.

That would explain why it damaged my drill bitThey are called roll pins and are a flat spring rolled into a tube so when hammered in they compress & lock in place.

You can get roll pin punched that have a shoulder machined onto the end to hold them in position when you hit the pin.

Use a big heavy hammer and swing it slowly so you can make sure you get a square hit.

The other thing that works is a G clap with a hole in the base and an appropriate sizes push pin.

I use motorcycle chain pins

Because of the split and by virtue of being a spring they can not be drilled out but can be ground out with a Dremel tool & the right cutters but it takes a long time and a steady hand.

I might have to buy a clamp at tbe weekend

bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

Usually You Tube is responsible for more of problems than it fixes

However search for "removing roll pins" or even "removing stuck roll pins"

then sit down with a coffee and see how 20 different people do it

If you have made a really bad mess of both ends then I have had to resort to an end mill in a Dremel tool to get the end square so the punch can push strait down without splaying the end out which turns the pin into a Rivet .

However search for "removing roll pins" or even "removing stuck roll pins"

then sit down with a coffee and see how 20 different people do it

If you have made a really bad mess of both ends then I have had to resort to an end mill in a Dremel tool to get the end square so the punch can push strait down without splaying the end out which turns the pin into a Rivet .

I definately ruined one end but hopefuy not the other. I'll check youtube now before i go to bed. ThanksUsually You Tube is responsible for more of problems than it fixes

However search for "removing roll pins" or even "removing stuck roll pins"

then sit down with a coffee and see how 20 different people do it

If you have made a really bad mess of both ends then I have had to resort to an end mill in a Dremel tool to get the end square so the punch can push strait down without splaying the end out which turns the pin into a Rivet .

sgkent

Lawn Addict

- Joined

- Sep 27, 2017

- Threads

- 35

- Messages

- 1,983

you need to support the side opposite that you are hitting. As said, you want a punch with a straight side and flat on the end, slightly smaller than the hole the pin is in. Slap a little penetrating oil on it IF it is rusty otherwise it should come out. I have on occasion used a piece of oak with a hole in it the pin can go into as it comes out, and a cut off nail slightly smaller diameter than the pin and about the same length or the end of a stainless or grade 8 bolt cut off slightly smaller diameter than the pin, and a C clamp. Wear safety glasses.

- Joined

- Feb 19, 2020

- Threads

- 121

- Messages

- 12,883

Probably need make sure it has many flukes for a smoother cutting to prevent grabbing the broken ends. Hopefully the area where the pin is in place is metal instead plastic.Usually You Tube is responsible for more of problems than it fixes

However search for "removing roll pins" or even "removing stuck roll pins"

then sit down with a coffee and see how 20 different people do it

If you have made a really bad mess of both ends then I have had to resort to an end mill in a Dremel tool to get the end square so the punch can push strait down without splaying the end out which turns the pin into a Rivet .

I got project now that I am lucky that I can remove the other end. It is JD LX172 steering where the screw is pressed in. Currently it is now rusted in place and the steering itself is plastic where the screw is at.

I got to be careful to drive it out as it is firmly in place so I need make up an avail to fit the steering wheel area at the pin to try to keep from busting the plastic area. Of the screw itself is NLA so I would to replace with a standard screw of the correct diameter.

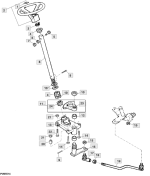

Anyway I will need an assistant on this one as I don't have orangutan arms and legs. LOL. The customer worn the bushing out so much that I having to replace item 13 and the bushings.

Item 13 and 23 have the frame sandwiched between them. And the assembly is timed can't see the other side marks when under the mower putting in the parts.